Complex salt and method for preparing high-molecular-weight poly-p-phenylenepyridino-bisiminazole (PIPD) from same

A high molecular weight, phenylene pyridine technology, applied in the preparation of carboxylates, organic chemistry, etc., can solve the problems of low polymer molecular weight, low reaction efficiency, easy oxidation of TD salt, etc., and achieve high polymer molecular weight, simple operation, The effect of short reaction times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

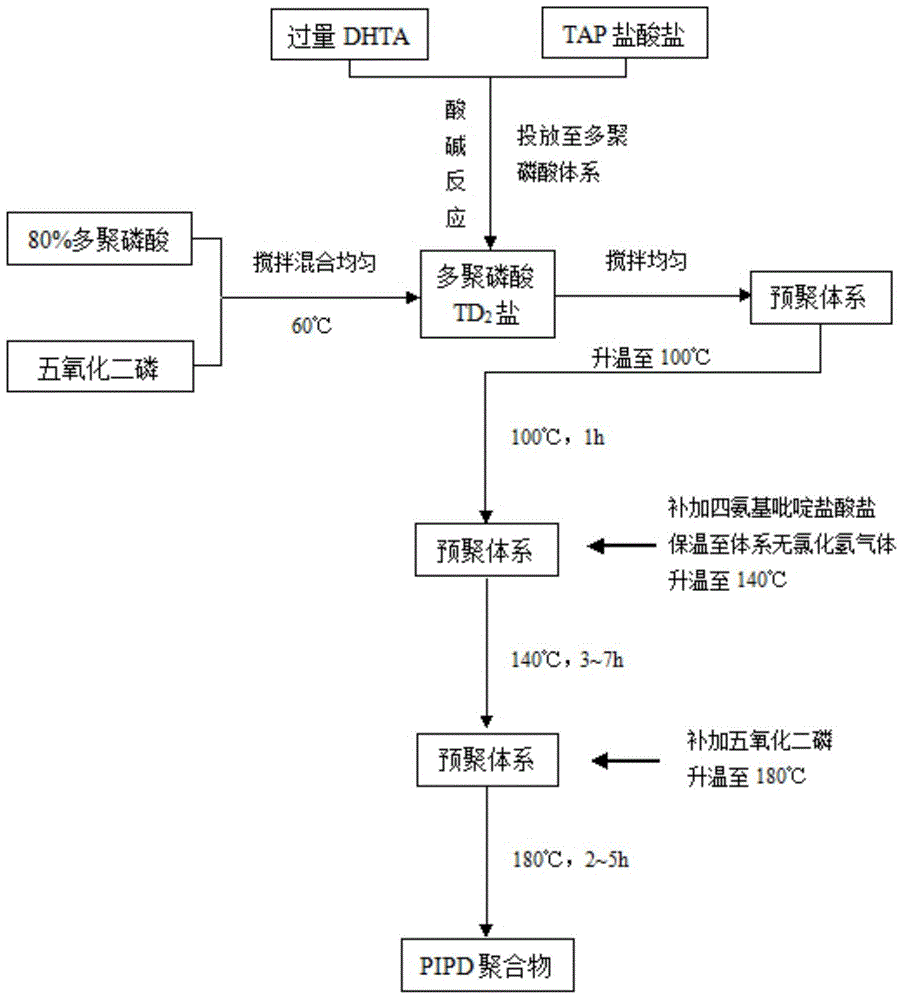

[0037] A kind of preparation method of high molecular weight poly-p-phenylenepyridobisimidazole adopts following steps to prepare:

[0038] 1. Under a nitrogen atmosphere, add 19.8g (0.1mol) of 2,5-dihydroxyterephthalic acid into deoxygenated water and stir evenly, then add 0.3L (0.5mol / L) of sodium hydroxide solution and heat to Stir at 50-90°C to continue the reaction; make 13.325g (0.05mol) of 2,3,5,6-tetraaminopyridine hydrochloride into an aqueous solution, add 0.14g of stannous chloride, pour it into the reactor, and accelerate the stirring. Adjust the pH of the system to neutral, react in an ice bath for 0.5h, precipitate a yellow precipitate, filter the precipitate under a nitrogen atmosphere, wash the filter cake with deoxygenated water, freeze, and then place it in a freeze dryer to dry to obtain TD 2 Salt.

[0039] 2. Under the protection of nitrogen, add 125.2g of polyphosphoric acid with a mass percentage of 80% and 28.3g of phosphorus pentoxide to the reactor, s...

Embodiment 2

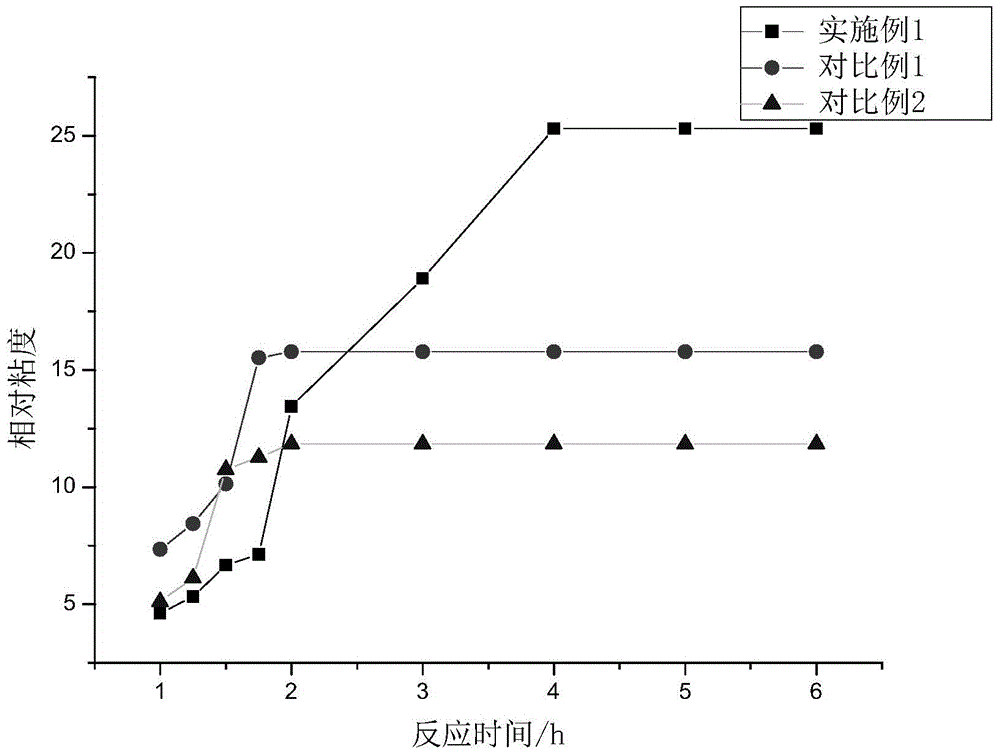

[0043] The specific method is the same as that in Example 1, except that in step 2, the reaction was carried out at 140° C. for 4 hours to obtain a poly-p-phenylenepyridobisimidazole polymer, and the measured relative viscosity was 13.41.

Embodiment 3

[0045] The specific method is the same as that in Example 1, except that in step 2, the reaction is carried out at 140° C. for 5 hours to obtain poly-p-phenylenepyridobisimidazole polymer, and the measured relative viscosity is 14.26.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com