Carbon pen and manufacturing method thereof

A technology for carbon pens and pen holders, which is applied in the direction of non-mechanical pencils, printing, writing utensils, etc. It can solve problems such as difficult curling, achieve the effects of reducing binding force, improving product quality, and avoiding broken cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

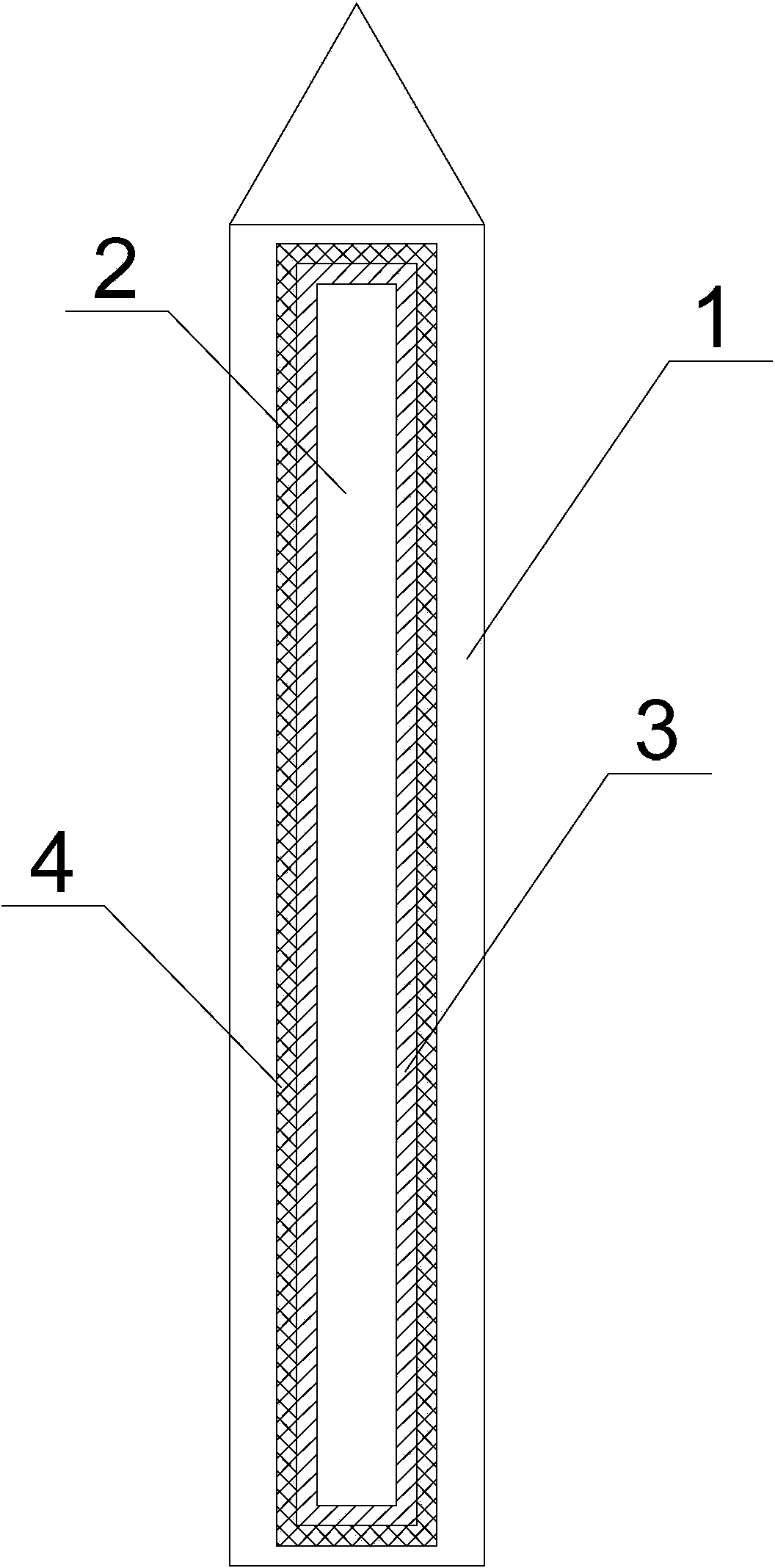

[0026] see figure 1 , the carbon pen of the present invention comprises a wood penholder 1 and a carbon pen core 2 arranged in the wood penholder 1, a glue layer 4 is arranged between the wood penholder 1 and the carbon pen core 2, and the outer surface of the carbon pen core 2 A resin protection layer 3 is provided between the surface and the glue layer 4, the resin protection layer 3 is formed by mixing acrylic resin and anhydrous acetone at a weight ratio of 1:9, and the glue layer 4 is made of PVAC glue.

[0027] The preparation method of a kind of carbon pen of the present invention comprises groove step, rubber core step, beam clip step and planer bar step, specifically as follows:

[0028] Grooving step: dig out grooves on the wooden board;

[0029] Rubber core step: Spray glue in the slot and put in carbon refill;

[0030] Clamping step: Glue two wooden boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com