Preparation method of polycarboxylate water reducer containing polyether side chains

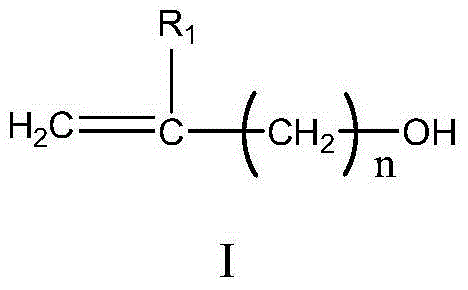

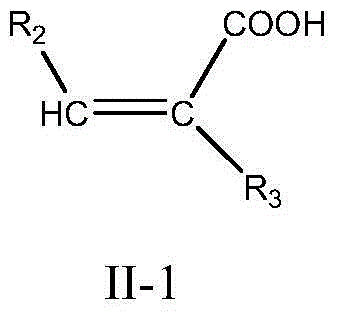

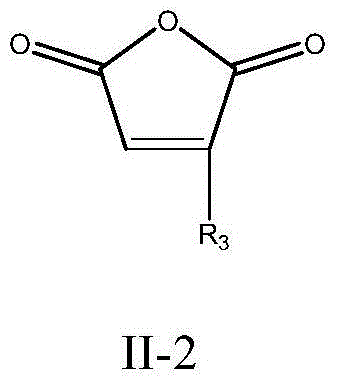

A technology of polyether side chain and polycarboxylic acid, which is applied in the field of preparation of polycarboxylate water reducer, can solve the influence of polycarboxylate water reducer on performance, reduce the molecular weight of polycarboxylate water reducer, and reduce the double bond content To achieve the effect of good concrete application performance, mild conditions and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Add 10.05g of 2-methallyl alcohol, 80g of dimethyl sulfoxide, 1.35g of hydrogen peroxide, 40g of acrylic acid, 1.2g of mercaptoacetic acid and 0.4g of vitamin C into the reaction kettle, at 60±5℃ Under full stirring, reacted for 3.5 hours.

[0042] Add sodium hydride to neutralize the polymer product to pH=6~8. Continue to add 0.2g of sodium hydroxide, and raise the temperature to 120°C, continue to add 325g of ethylene oxide, and keep the reaction temperature between 120 and 180°C. After the reaction is completely stopped, add acetic acid to neutralize the sodium hydroxide.

[0043] The obtained product is spray-dried to obtain a solid powdery polycarboxylate water reducer product.

[0044] The obtained polycarboxylate water reducer product is made into an aqueous solution with a mass concentration of 20%, and the measured viscosity is 11.32mm according to the kinematic viscosity measurement method of GB / T265-88 petroleum products. 2 / s.

Embodiment 2

[0046] Add 8.1g of allyl alcohol, 100g of N,N-dimethylformamide, 1.35g of hydrogen peroxide, 54.4g of maleic anhydride, 1.2g of thioglycolic acid and 0.4g of vitamin C into the reaction kettle together, at 50±5 Under the condition of ℃, fully stir and react for 4 hours.

[0047]Add metal sodium to neutralize the polymer product to pH=6~8. Continue to add 0.2 g of sodium hydroxide, raise the temperature to 120° C., and continuously add 327 g of ethylene oxide. Keep the reaction temperature between 120 and 180°C, and add phosphoric acid to neutralize after the reaction is completely stopped.

[0048] The obtained product is spray-dried to obtain a solid powdery polycarboxylate water reducer product.

[0049] The obtained polycarboxylate water reducer product is made into an aqueous solution with a mass concentration of 20%, and the measured viscosity is 8.12mm according to the kinematic viscosity measurement method of GB / T265-88 petroleum products. 2 / s.

Embodiment 3

[0051] 12g of 3-methyl-3-buten-1-alcohol, 120g dimethyl sulfoxide, 1.35g hydrogen peroxide, 40g acrylic acid, 1.2g thioglycolic acid and 0.4g vitamin C were added to the reactor together, Stir well at 65±5°C and react for 5 hours.

[0052] Add potassium hydride to neutralize the polymer product to pH=6~8. Continue to add 0.2 g of sodium hydroxide, raise the temperature to 120° C., and continuously add 323 g of ethylene oxide. Keep the reaction temperature between 120 and 180°C, and add acetic acid to neutralize after the reaction is completely stopped.

[0053] The obtained product is spray-dried to obtain a solid powdery polycarboxylate water reducer product.

[0054] The obtained polycarboxylate water reducer product is made into an aqueous solution with a mass concentration of 20%, and the measured viscosity is 12.44mm according to the kinematic viscosity measurement method of GB / T265-88 petroleum products 2 / s. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com