Correlated flux injection section test method and construction technique

A test method and technology related to flow rate, which is applied in the directions of measurement, earthwork drilling and production, wellbore/well components, etc., can solve the problems of application scale limitation, high measurement lower limit, interpretation error, etc., and achieve high accuracy, small area, and flow rate The effect of small state changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to further disclose the technical solution of the present invention, below in conjunction with the accompanying drawings, the following examples are described in detail:

[0046] 1, basic principle of the present invention

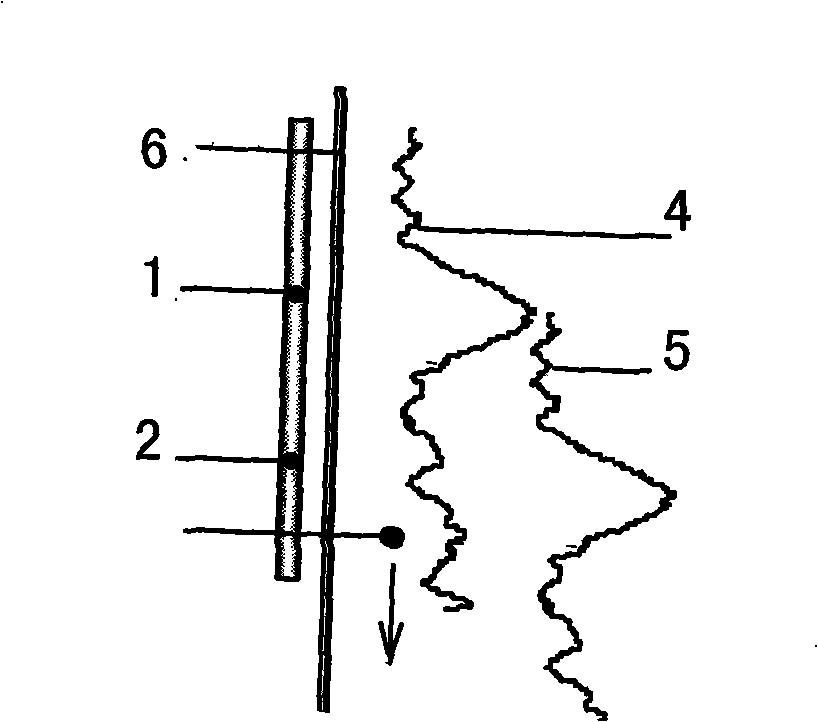

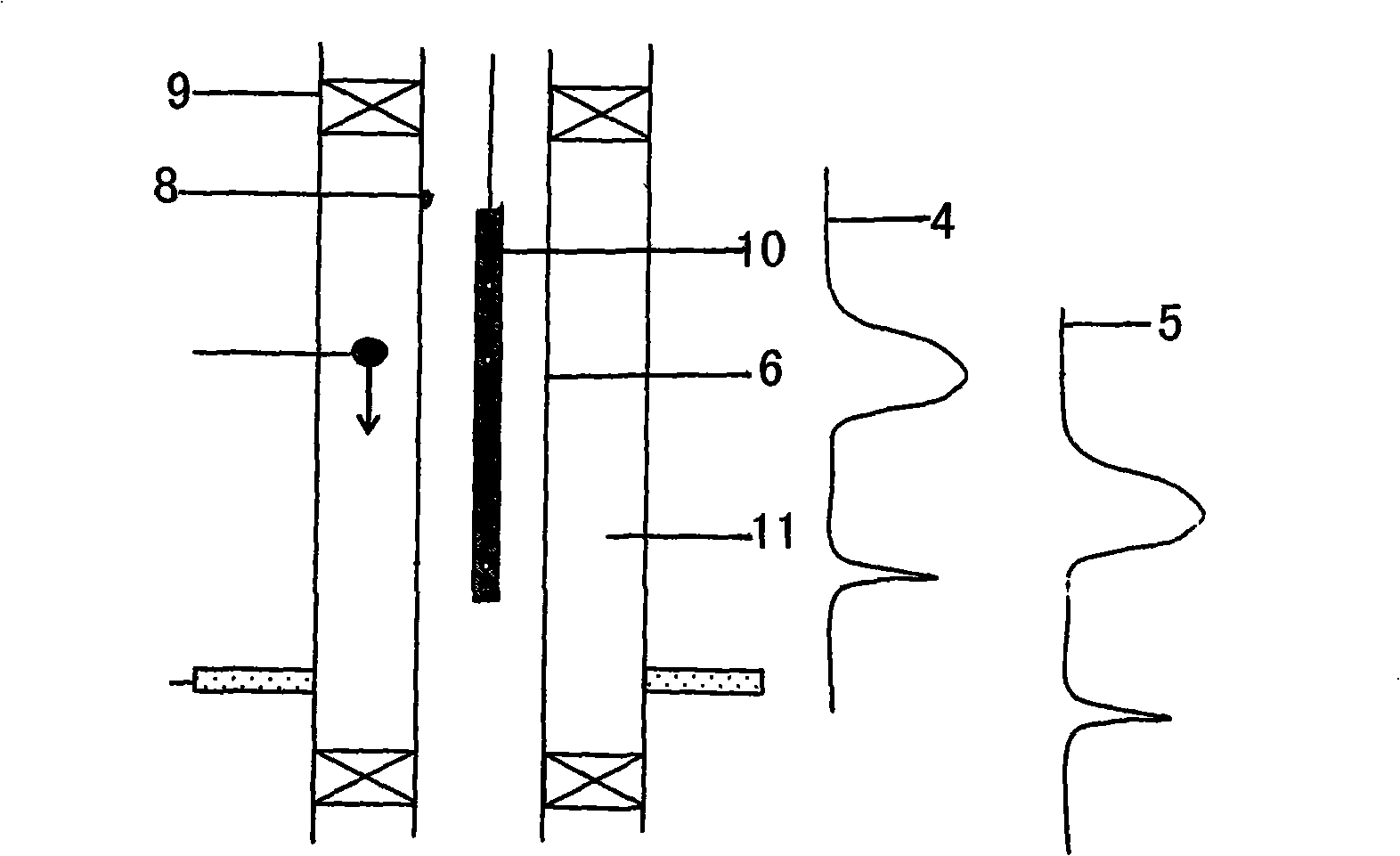

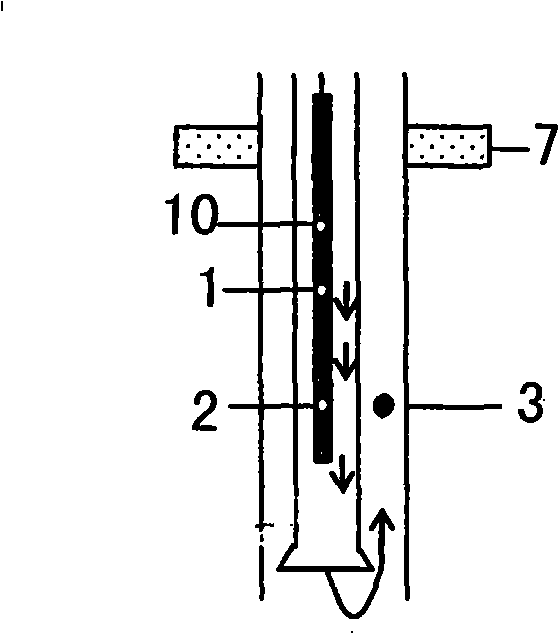

[0047] When the tracer is close to the detector, the detector will generate a corresponding output signal. If the tracer with a certain moving speed passes through two detectors with a certain distance, the two detectors will be in sequence generate respective output signals such as figure 1 shown. Due to the small distance between the two detectors,

[0048] Therefore, the output curves of the two detectors have a good similarity. It is approximately considered that the output signals of the two detectors are the same, but one of the signals is delayed by a certain time compared to the other. This delay time can be calculated by correlation Calculated by the algorithm, since the distance between the two detectors is fixed, it is easy to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com