Fuel injection valve for combustion engine

A technology for fuel injection valves and combustion engines, which is applied in the direction of fuel injection devices, special fuel injection devices, engine components, etc., and can solve problems such as performance degradation in the combustion process, to avoid coking and deposit formation, reduce pollutant emissions or The effect of particle emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

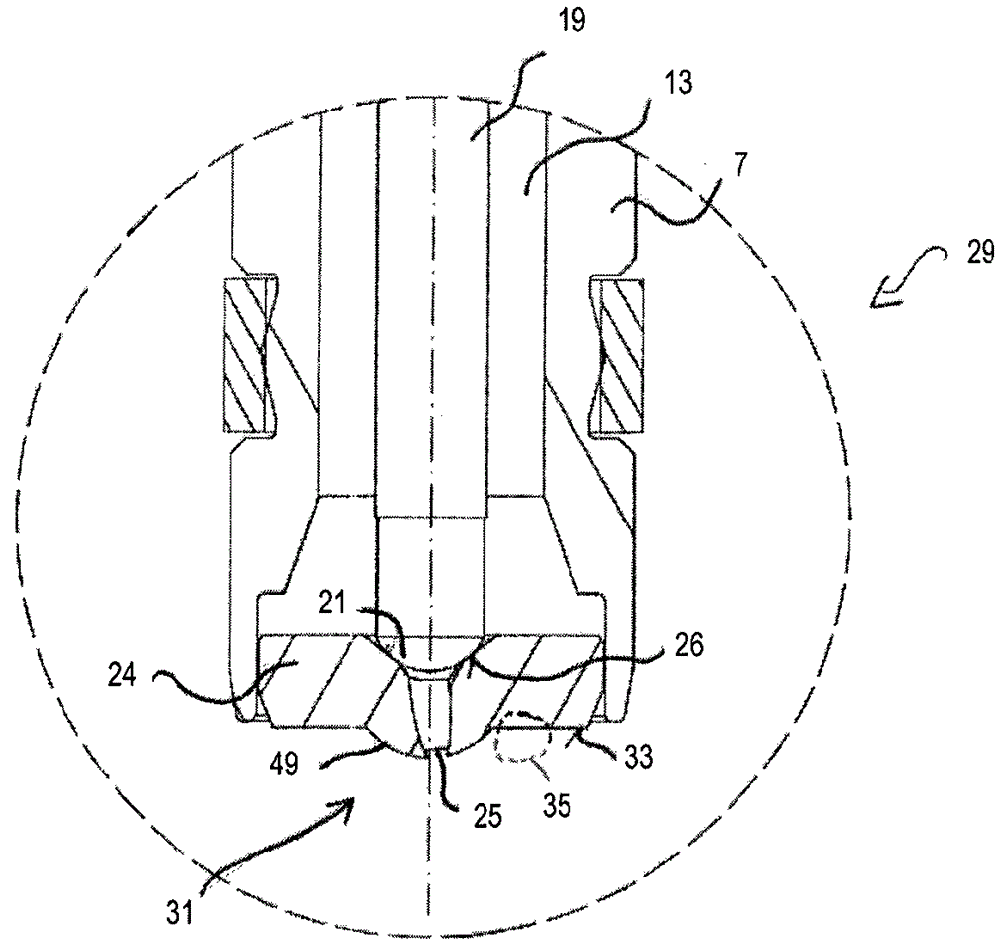

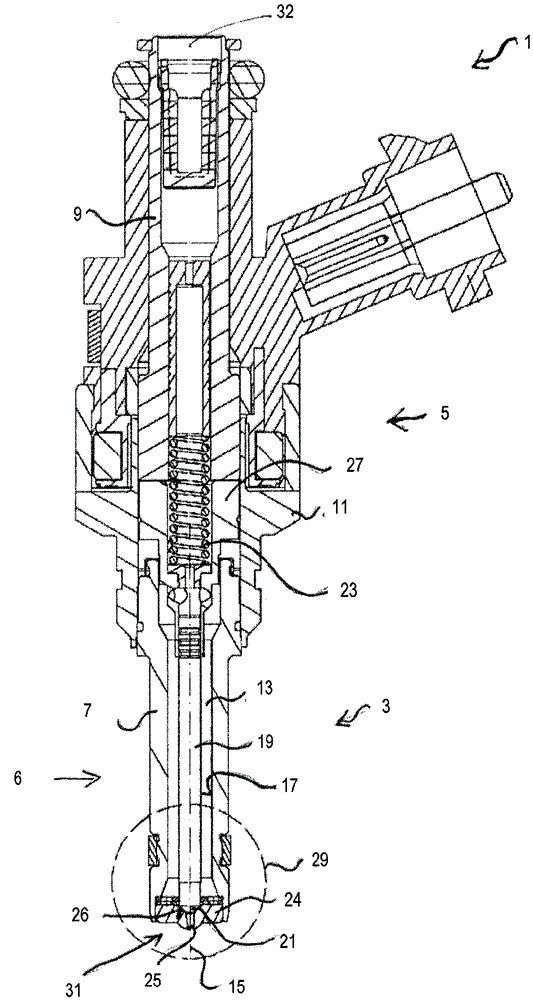

[0040] figure 1 An exemplary embodiment of an injection valve 1 with a nozzle assembly 3 and an actuator 5 is shown. The actuator 5 functionally interacts with the set of nozzle assemblies 3 .

[0041] The nozzle assembly 3 includes a valve body 6 . Injection valve 1 also includes an injector body 9 . The valve body 6 is fixedly connected to the injector body 9 , for example by means of a nozzle cap nut 11 . Other connection means like press-fit and / or welded connections are also conceivable for the fixed connection of the injector body 9 to the valve body 6 . Valve body 6 and injector body 9 form a common housing of injection valve 1 for hydraulically connecting a fuel outlet port 31 of injection valve 1 to a fuel inlet port 32 of injection valve 1 .

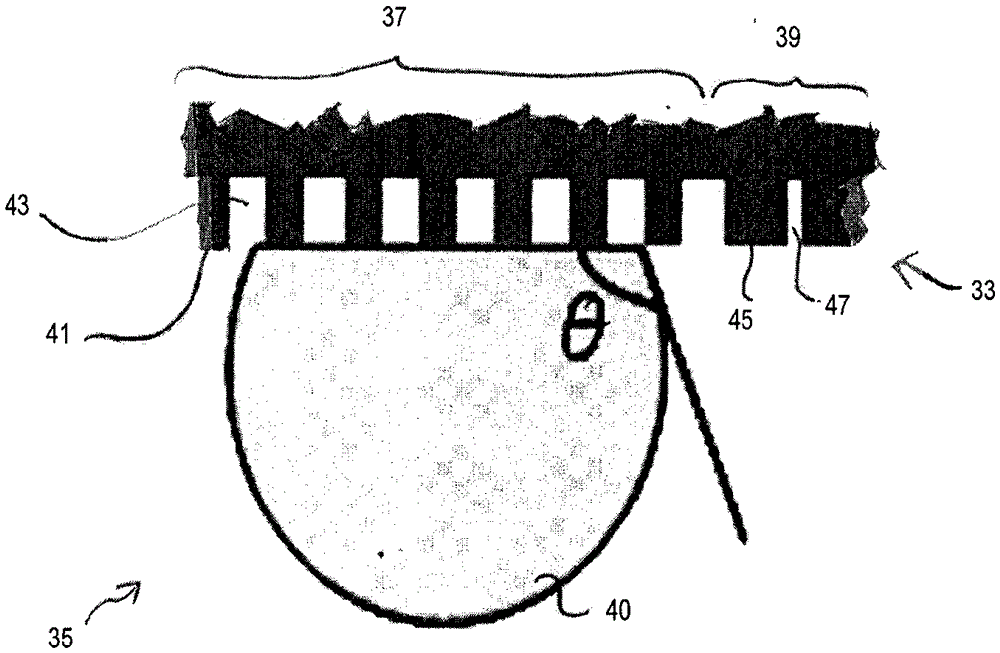

[0042] The valve body 6 has a base body 7 comprising a valve chamber 13 with a central longitudinal axis 15 and a wall 17 . Inside the valve chamber 13 , a valve needle 19 is arranged, which is included in the nozzle assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com