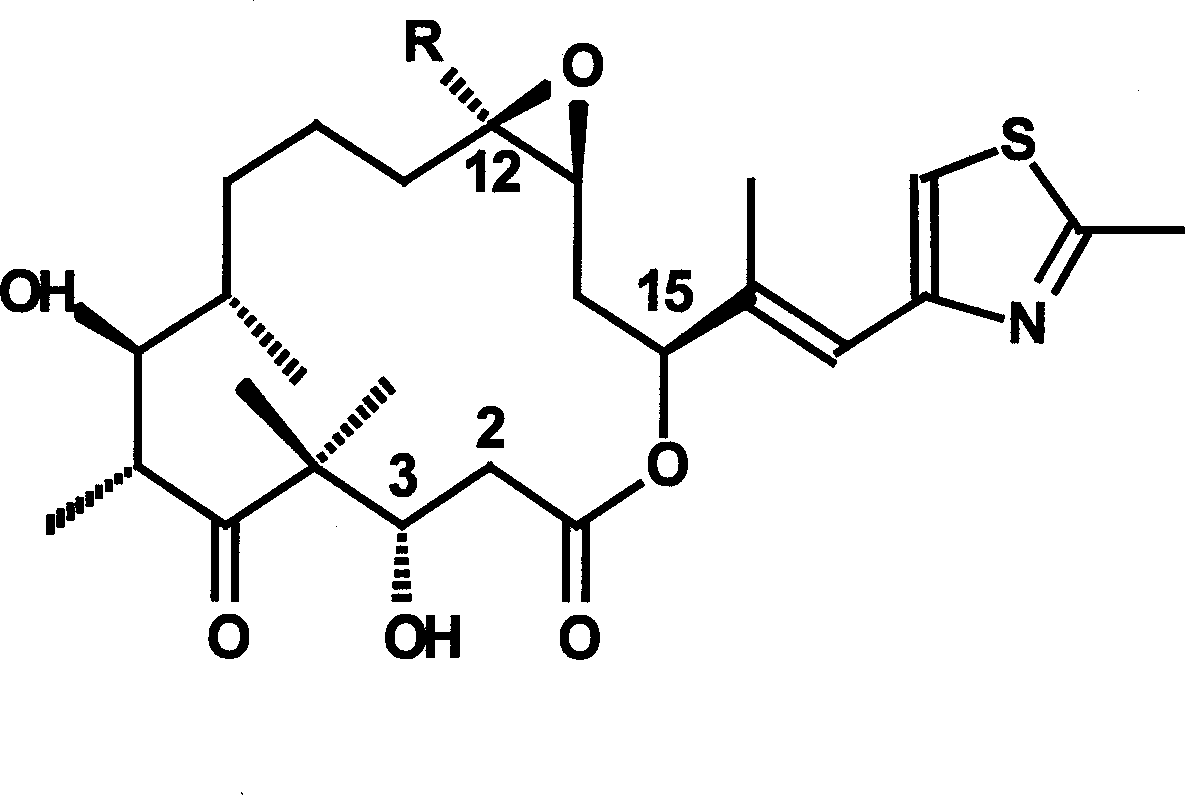

Process for separating and purifying ebormycine from fermented myxobacterium liquid

A technology of epothilone and myxobacteria, which is applied in the field of separation and purification of macrolide compounds, can solve the problems of high process cost, failure to achieve industrial production, and no major progress patents, etc., to improve feasibility and reliability Scalability, good economic benefits and application prospects, efficient and economical separation and purification effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

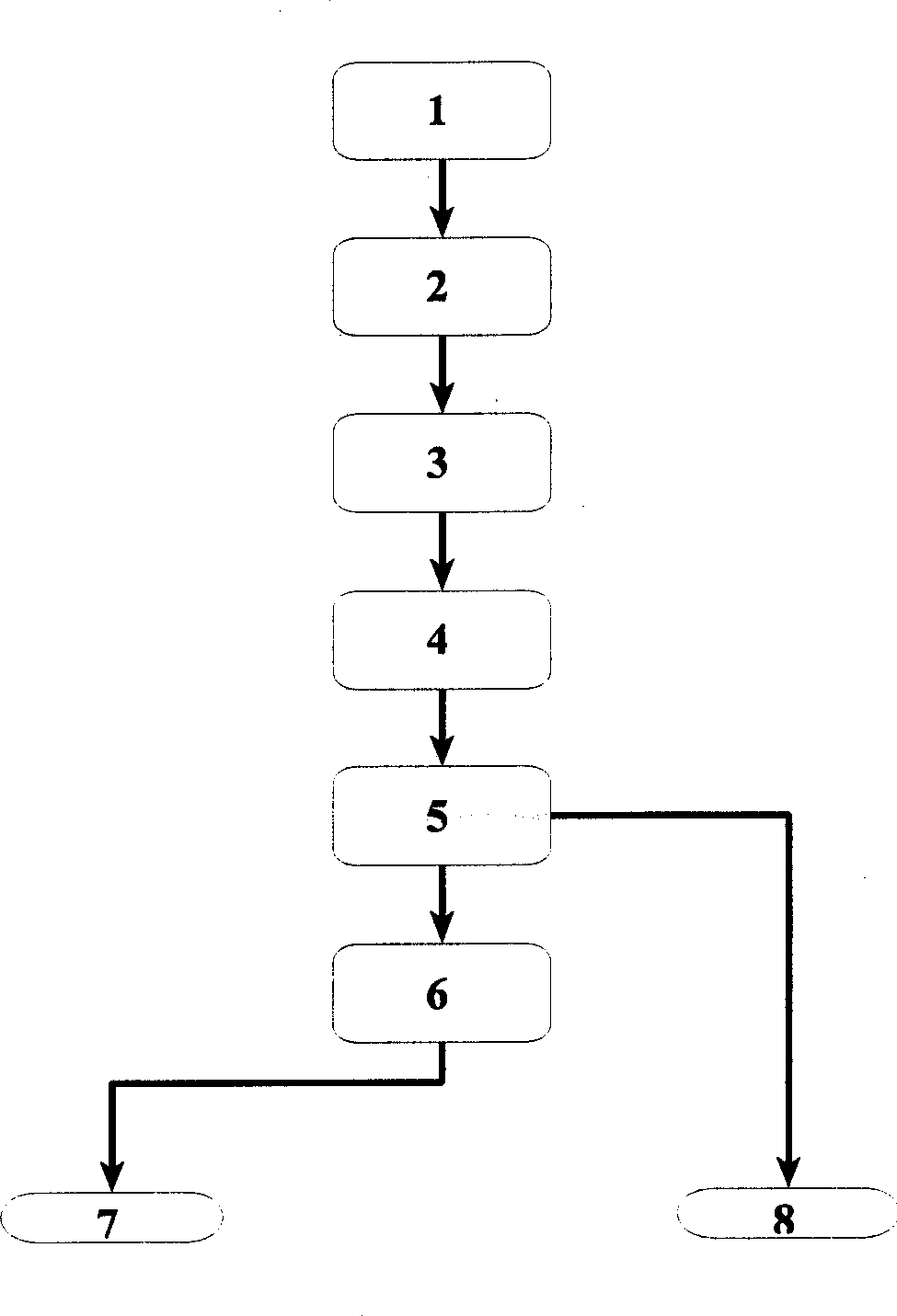

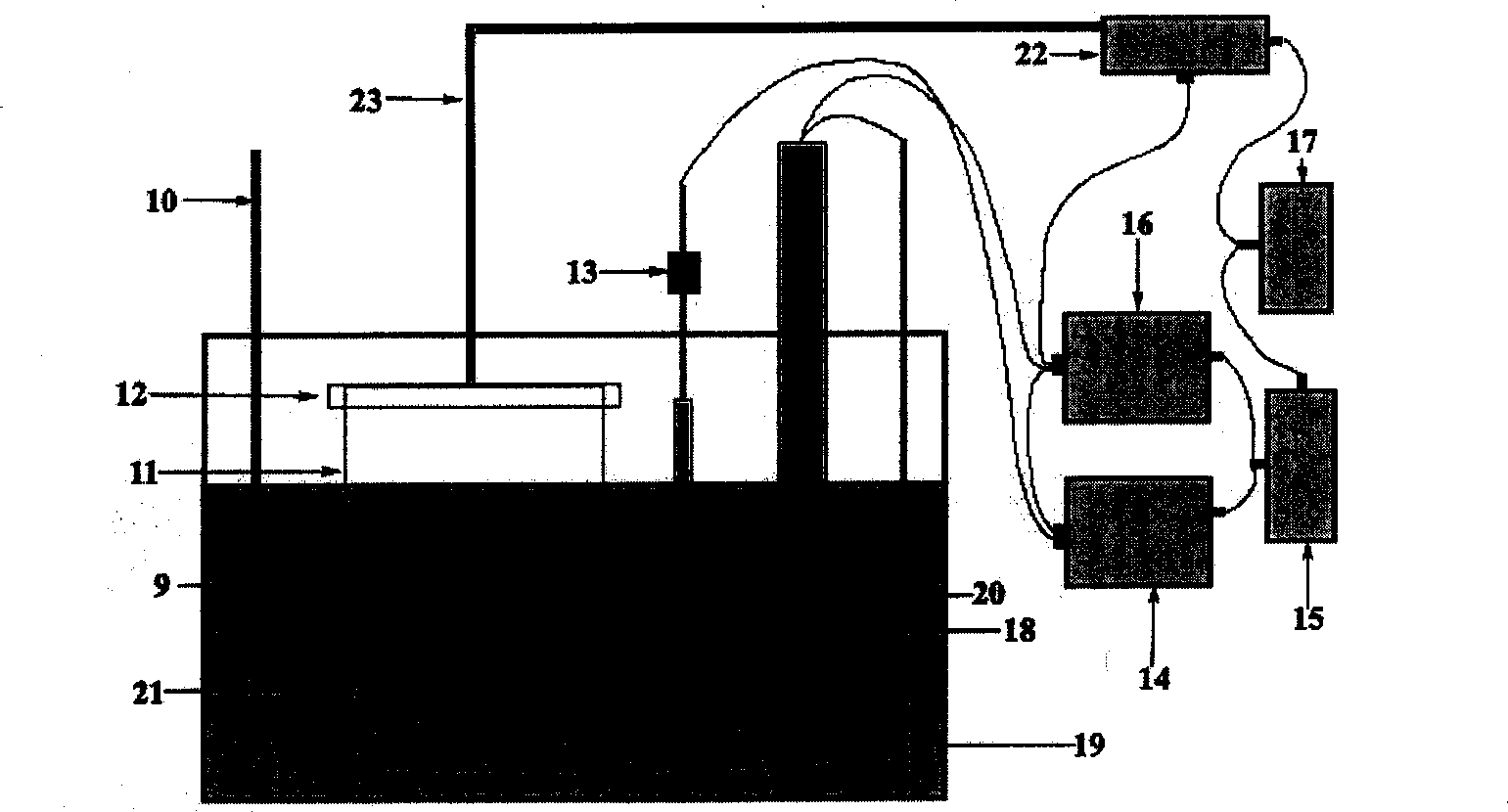

Method used

Image

Examples

Embodiment 2

[0043] In the method of the present invention, the adsorption rate of the mixed resin for epothilones is 100%, and when the crystallization step is completed, the extraction rate of epothilones is 90%, and the purity is 97%. The extraction rate of bleomycin A and B is 89%, and the purity is 99.99%. Embodiment 2: The present invention utilizes technical means such as mixed resin adsorption, solid-liquid fractional extraction, molecular sieve chromatography, crystallization and high-efficiency liquid phase separation, separates and extracts epothilone from a kind of myxobacterium S. cellulosus fermentation broth, Concrete step sequence is as follows: (1) the preparation of mixed resin: CD180, CAD-40, XDA, S-8, NKA-II, AB-8 six kinds of resins are by weight 0.8: 0.8: 1.8: 0.8: 2.8: 1.8 Mix, suspend and dissolve in an equal volume of distilled water to prepare a mixed resin solution. (2) Mixed resin adsorption: when carrying out S. cellulosus fermentation, add 1% (volume / volume) ...

Embodiment 3

[0047] In the method of the present invention, the adsorption rate of the mixed resin for epothilones is 95%, and when the crystallization step is completed, the extraction rate of epothilones is 90%, and the purity is 95%. The extraction rate of bleomycin A and B is 82%, and the purity is 99.91%. Embodiment 3: The present invention utilizes technical means such as mixed resin adsorption, solid-liquid stepwise extraction, molecular sieve chromatography, crystallization and high-efficiency liquid phase separation, separates and extracts epothilone from a kind of myxobacterium S. cellulosus fermentation broth, Concrete step sequence is as follows: (1) the preparation of mixed resin: CD180, CAD-40, XDA, S-8, NKA-II, AB-8 six kinds of resins are by weight 1.2: 1.2: 2.3: 1.2: 3.2: 2.3 Mix, suspend and dissolve in an equal volume of distilled water to prepare a mixed resin solution. (2) Mixed resin adsorption: when carrying out S. cellulosus fermentation, add 1% (volume / volume) mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com