CATALYST COMPOSITION FOR PREPARING ELASTIC COPOLYMER, AND METHOD FOR PREPARING ELASTIC COPOLYMER, WHICH COMPRISES ETHYLENE AND alpha-OLEFIN OR ETHYLENE, alpha-OLEFIN AND UNCONJUGATED DIENE, BY USING SAME

A compound and copolymer technology, applied in chemical instruments and methods, organic chemistry, metallocene, etc., can solve problems such as unclear electronic interaction and the effect of increasing activity, achieve excellent thermal stability, maintain catalyst activity, and excellent The effect of reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

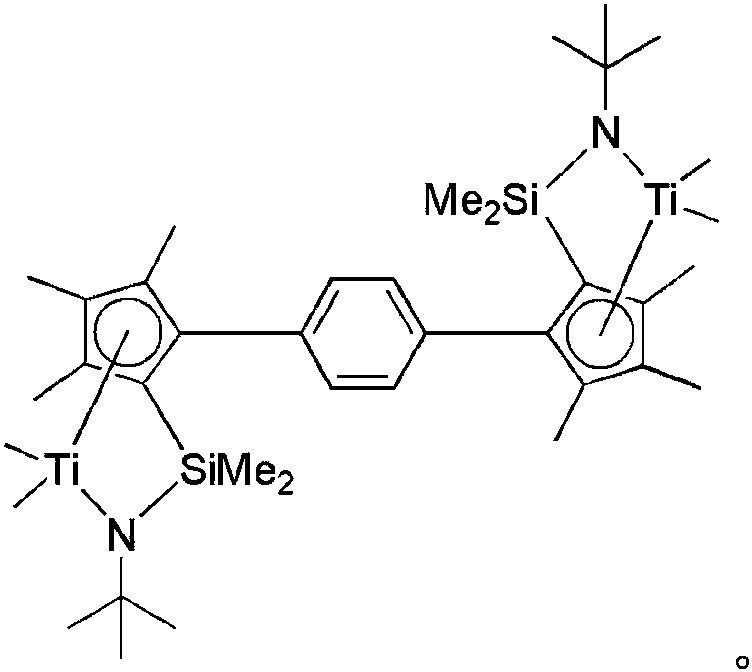

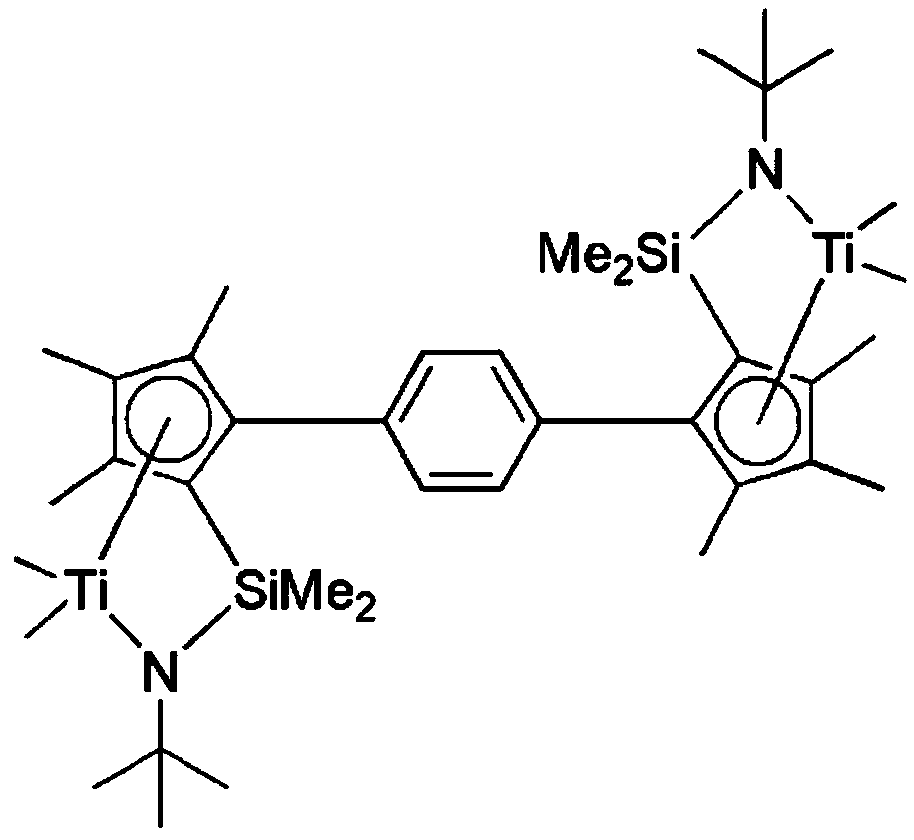

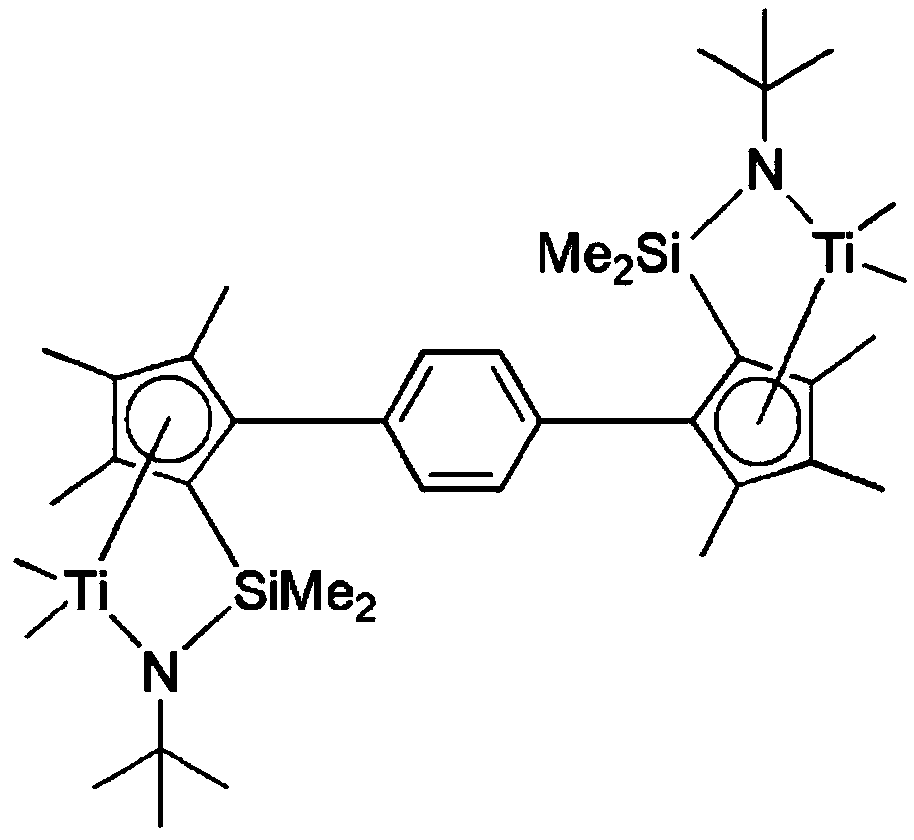

[0028] According to the method for preparing ethylene base elastic copolymer according to one embodiment of the present invention, ethylene, α-olefin and C4-C30 diene polymerization to carry out. The transition metal catalyst composition of the binuclear constrained geometry comprises: a transition metal compound of the binuclear constrained geometry represented by the following formula 1, in its structure, the cyclopentadiene ligands of the catalysts of the two constrained geometry linked via 1,4-phenylene; and one or more cocatalyst compounds selected from the group consisting of organoaluminum compounds, organoaluminoxane compounds, and boron compounds.

[0029] [Formula 1]

[0030]

[0031] Transition metal compounds of binuclear constrained geometry represented by formula 1 can provide a catalyst structure with advantages in terms of catalyst stability and high molecular weight formation compared with conventional transition metal catalysts, which consist of monomol...

preparation Embodiment 1

[0084] [Preparation Example 1] Preparation of Complex 1

[0085]

[0086] Preparation of 1,4-bis(trimethylcyclopentadienyl)benzene (compound 1-a)

[0087]1,4-Dibromobenzene (49 g) and diethyl ether (50 mL) were added to a 250 mL flask, and n-butyllithium (2.5 M in hexane) (83 mL) was slowly added dropwise at 0° C. , and reacted at room temperature for 1 hour. After cooling the flask containing the reaction solution to 0°C again, a mixed solution of 2,3,4-trimethyl-2-cyclopenten-1-one (25.65 g) and diethyl ether (20 mL) was added to the cooled flask , stirred for 10 minutes, and then refluxed. After refluxing for 1 hour, the flask was cooled to 0° C. again, and n-butyllithium (2.5 M in hexane solution) (83 mL) was added thereto, followed by stirring at room temperature for 1 hour. After cooling the flask containing the reactant to 0° C. again, a mixed solution of 2,3,4-trimethylcyclopent-1-one (25.65 g) and diethyl ether (20 mL) was slowly added dropwise thereto. After ...

Embodiment 1

[0102] [Example 1] Prepare EPDM by continuous solution polymerization

[0103] EPDM was prepared by polymerizing ethylene, propylene, and 5-ethylidene-2-norbornene (ENB) by a continuous polymerization apparatus using the compound (1) prepared in Preparation Example 1 as a main catalyst.

[0104] Into a 1L autoclave reactor, add n-hexane (0.5L), triisobutylaluminum (2.3mmol), dimethylanilinium tetrakis(pentafluorophenyl)borate cocatalyst solution (15μmol) and 5 - Ethylidene-2-norbornene (ENB). Propylene was fed into the reactor at room temperature and fully pressurized to 8 bar. The reactor was heated to 80°C, then ethylene was pressurized to 30 bar. Polymerization was carried out by injecting and pressurizing procatalyst compound (1) (1.5 μmol) with 34 bar of ethylene through a measuring cylinder. The heat of reaction generated after initiation of polymerization was adjusted as much as possible by the reactor internal temperature maintaining device, and the highest polymeri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com