Supported olefin polymerization catalyst, preparation method and application thereof

A technology for olefin polymerization and catalysts, which is applied in the field of supported olefin polymerization catalysts and their preparation and application, and can solve problems such as high cost, complicated preparation methods, and difficult catalyst forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

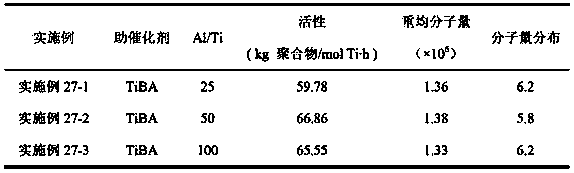

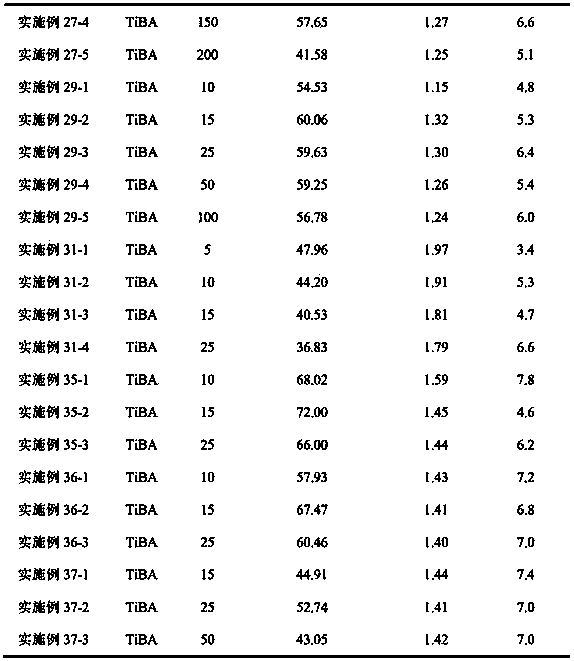

Examples

Embodiment 1

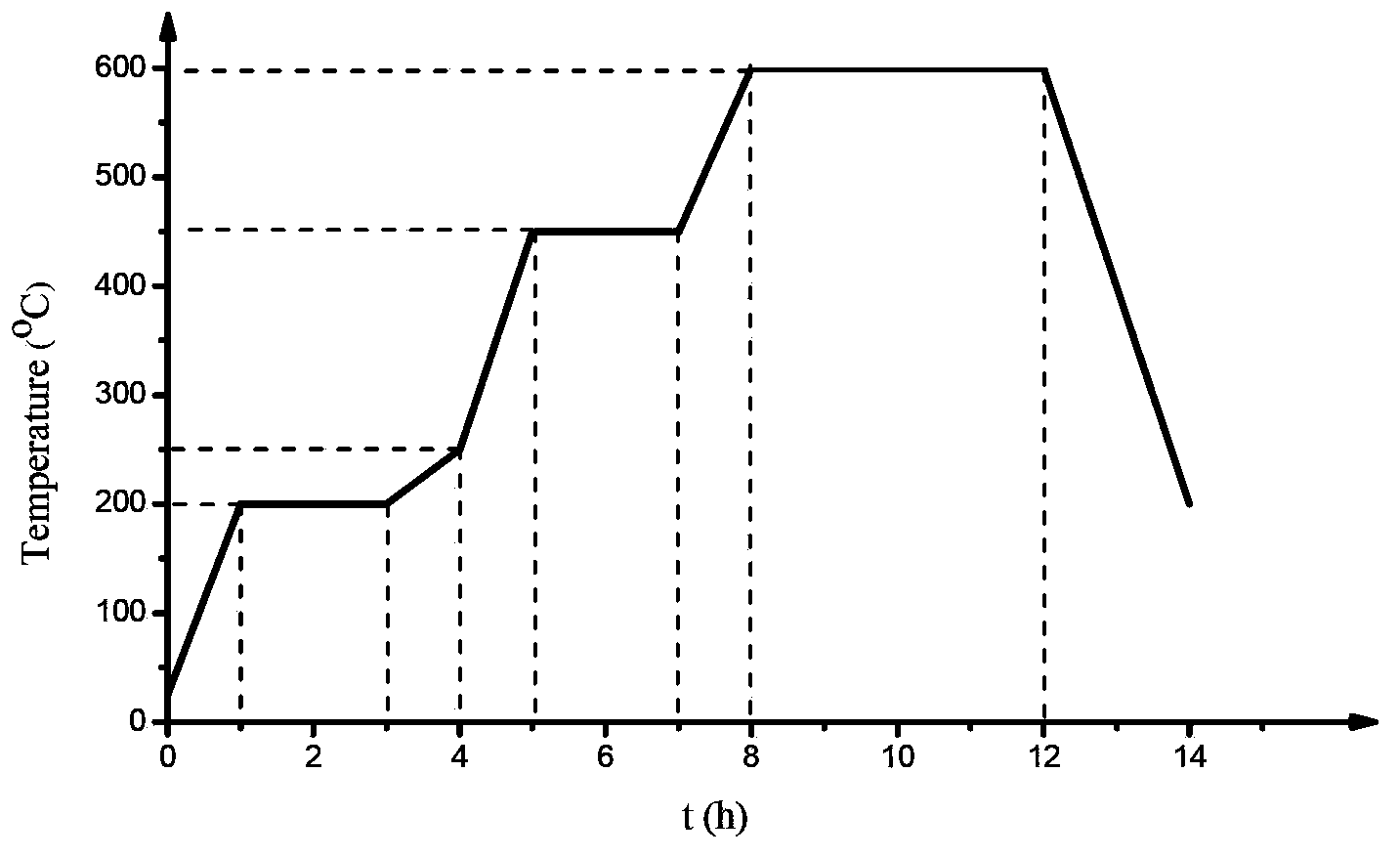

[0184] 10g silica gel (pore volume is 1.5-1.7cm 3 / g, the surface area is 250-300m 2 / g) impregnated in magnesium nitrate aqueous solution (Mg loading is 15wt%), continuously stirred and impregnated at room temperature for 5h, then heated to 120°C for 5h, and then transferred to 120°C oven for 6h; the silica gel carrier impregnated with magnesium nitrate Place it in a quartz fluidized bed for roasting activation, use a nitrogen atmosphere before 300°C, then switch to high-purity air, and keep it at 600°C for 4 hours, then switch to a nitrogen atmosphere after cooling down to 400°C naturally, and protect it in a nitrogen atmosphere Down transfer, the above-mentioned roasting temperature control program is as follows figure 1 shown. Get the catalyst precursor that 2g obtains in 30mlTiCl 4 The solution was reacted at 140° C. for 2 h, washed several times with n-hexane at room temperature, and finally vacuum-dried to obtain a catalyst for storage until use.

Embodiment 2

[0186] 10g silica gel (pore volume is 1.5-1.7cm 3 / g, the surface area is 250-300m 2 / g) impregnated in an aqueous solution of magnesium acetate (Mg loading is 15wt%), impregnated with continuous stirring at room temperature for 5 hours, then heated to 120°C for 5 hours, and then transferred to a 120°C oven for 6 hours; the silica gel carrier impregnated with magnesium acetate Place it in a quartz fluidized bed for roasting activation, use a nitrogen atmosphere before 300°C, then switch to high-purity air, and keep it at 600°C for 4 hours, then switch to a nitrogen atmosphere after cooling down to 400°C naturally, and protect it in a nitrogen atmosphere Down transfer, the above-mentioned roasting temperature control program is as follows figure 1 shown. Get the catalyst precursor that 2g obtains in 30mlTiCl 4The solution was reacted at 140° C. for 2 h, washed several times with n-hexane at room temperature, and finally vacuum-dried to obtain a catalyst for storage until use...

Embodiment 3

[0188] 10g silica gel (pore volume is 1.5-1.7cm 3 / g, the surface area is 250-300m 2 / g) impregnated in an aqueous solution of magnesium acetate (Mg loading is 15wt%), impregnated with continuous stirring at room temperature for 5 hours, then heated to 120°C for 5 hours, and then transferred to a 120°C oven for 6 hours; the silica gel carrier impregnated with magnesium acetate Place it in a quartz fluidized bed for roasting activation, use a nitrogen atmosphere before 300°C, then switch to high-purity air, and keep it at 600°C for 4 hours, then switch to a nitrogen atmosphere after cooling down to 400°C naturally, and protect it in a nitrogen atmosphere Down transfer, the above-mentioned roasting temperature control program is as follows figure 1 shown. Get the catalyst precursor that 2g obtains in 30mlTiCl 4 The solution was reacted at 140°C for 2 hours, washed three times with n-hexane at 70°C, washed several times at room temperature, and finally dried in vacuum to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com