Biodegradable waterproof polycarbonate composite material and preparation method therefor

A technology for waterproof polycarbonate and composite materials, applied in the field of composite materials, can solve problems such as difficulty in meeting, and achieve the effects of improved impact resistance, simple preparation method and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

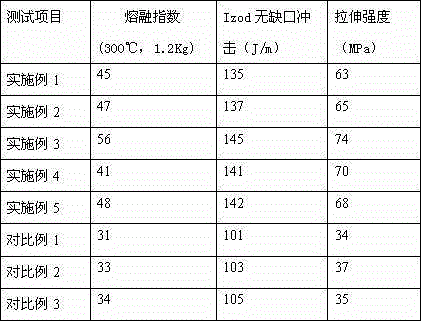

Examples

Embodiment 1

[0030] (1) Weigh 80kg of polycarbonate, 20kg of polyvinyl acetate resin, 8kg of polyvinyl butyral, 3kg of 1,4-butanediol diacrylate, 2kg of ethylene tetrafluoroethylene copolymer, 4,4'-bis (2,2-epoxypropoxy)octafluorobiphenyl 1kg, polybithiazole 0.2kg, polyvinylidene fluoride 2kg, butyl acetate 2kg, mix well;

[0031] (2) Add the above components into a three-blade mixer and mix evenly, add 3kg of ground potassium fluorozirconate, 0.05kg of toner, and 1kg of di-n-butyltin dilaurate, and add them to a twin-screw extruder, Add 11 kg of hydroxypropyl methylcellulose to the side feeding port of the machine, melt, extrude, dry, and pelletize to obtain a biodegradable waterproof polycarbonate composite material.

[0032] The temperature of each section of the twin-screw extruder is as follows: the temperature of the first zone is 160°C, the temperature of the second zone is 190°C, the temperature of the third zone is 210°C, the temperature of the fourth zone is 200°C, and the temper...

Embodiment 2

[0035] (1) Weigh 80kg of polycarbonate, 20kg of polyvinyl acetate resin, 8kg of polyvinyl butyral, 3kg of 1,4-butanediol diacrylate, 2kg of ethylene tetrafluoroethylene copolymer, 4,4'-bis (2,2-epoxypropoxy)octafluorobiphenyl 1kg, polybithiazole 0.2kg, mix well;

[0036] (2) Add the above components into a three-blade mixer and mix evenly, add 3kg of ground potassium fluorozirconate and 1kg of di-n-butyltin dilaurate, add them to the twin-screw extruder, and feed them on the side of the twin-screw extruder Add 11 kg of hydroxypropyl methylcellulose, melt, extrude, dry, and pelletize to obtain a biodegradable waterproof polycarbonate composite material.

[0037] The temperature of each section of the twin-screw extruder is as follows: the temperature of the first zone is 160°C, the temperature of the second zone is 190°C, the temperature of the third zone is 210°C, the temperature of the fourth zone is 200°C, and the temperature of the fifth zone is 170°C.

[0038] The perform...

Embodiment 3

[0040] (1) Weigh 90kg of polycarbonate, 30kg of polyvinyl acetate resin, 15kg of polyvinyl butyral, 6kg of 1,4-butanediol diacrylate, 5kg of ethylene tetrafluoroethylene copolymer, 4,4'-bis (2,2-epoxypropoxy) octafluorobiphenyl 2kg, polybithiazole 1kg, polyvinylidene fluoride 2kg, butyl acetate 2kg, mix well;

[0041] (2) Add the above components into a three-blade mixer and mix evenly, add 7kg of ground potassium fluorozirconate, 0.05kg of toner, and 2kg of di-n-butyltin dilaurate, and add them to a twin-screw extruder, Add 16 kg of hydroxypropyl methylcellulose to the side feeding port of the machine, melt, extrude, dry, and pelletize to obtain a biodegradable waterproof polycarbonate composite material.

[0042] The temperature of each section of the twin-screw extruder is as follows: the temperature of the first zone is 180°C, the temperature of the second zone is 200°C, the temperature of the third zone is 220°C, the temperature of the fourth zone is 210°C, and the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com