Production technology and equipment for preparing 4-hydroxybutyl acrylate through extraction separation

A hydroxybutyl acrylate and production process technology, which is applied in the preparation of carboxylate, the preparation of organic compounds, the separation/purification of carboxylate, etc., can solve the problems of deepening product color, difficulty in separation and purification, and easy polymerization. Achieve low production cost, simple process, good activity and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below by specific embodiment the present invention is further described:

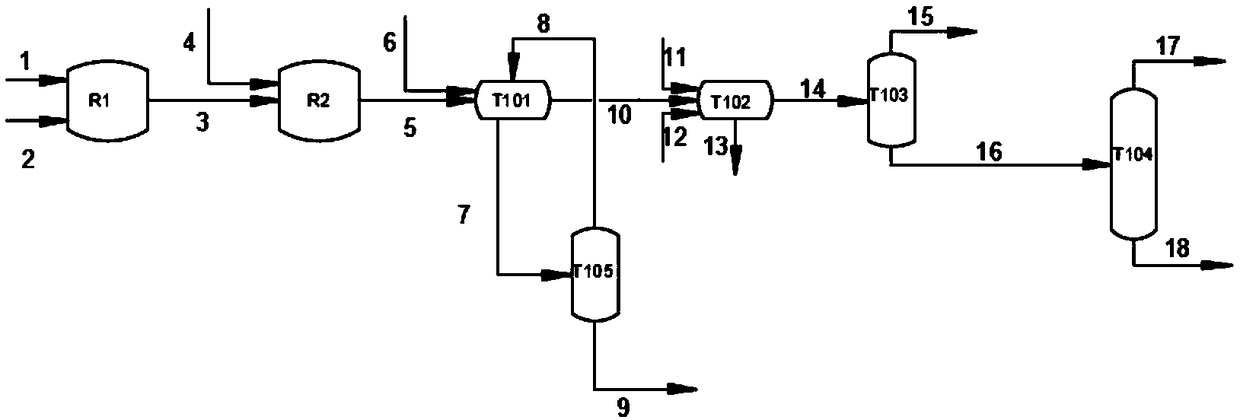

[0027] The main steps of the technical process of producing 4-hydroxybutyl acrylate by the direct esterification method designed by the present invention are as follows:

[0028] Reaction section: 1,4-butanediol with a mass flow rate of 24.75kg / h, p-toluenesulfonic acid with a mass flow rate of 0.3kg / h, acrylic acid with a mass flow rate of 13.15kg / h, and a mass flow rate of The hydroquinone of 0.05kg / h, the p-hydroxyl methyl ether of mass flow rate 0.05kg / h is added in the reactor and reacted, and the reaction product contains 52.5% of 4-hydroxybutyl acrylate, 10.8% of 1,4 - Butanediol diacrylate, 0.19% of acrylic acid, 0.01% of hydroquinone and para-hydroxyanisole, 0.5% of p-toluenesulfonic acid, 27.6% of 1,4-butanediol, 8.5% of water.

[0029] After the reaction finished, stream 3 was rich in 4-hydroxybutyl acrylate, 1,4-butanediol diacrylate, 1,4-butanediol and a small amount of acrylic acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com