Compounding and cutting machine of hot melt adhesive

A technology of hot melt adhesive and integrated machine, which is applied in the direction of layered products, lamination devices, lamination auxiliary operations, etc., can solve the problems of unguaranteed product quality, low production efficiency, and many manual operations, so as to reduce production costs and The effect of equipment investment, high work efficiency and less human operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

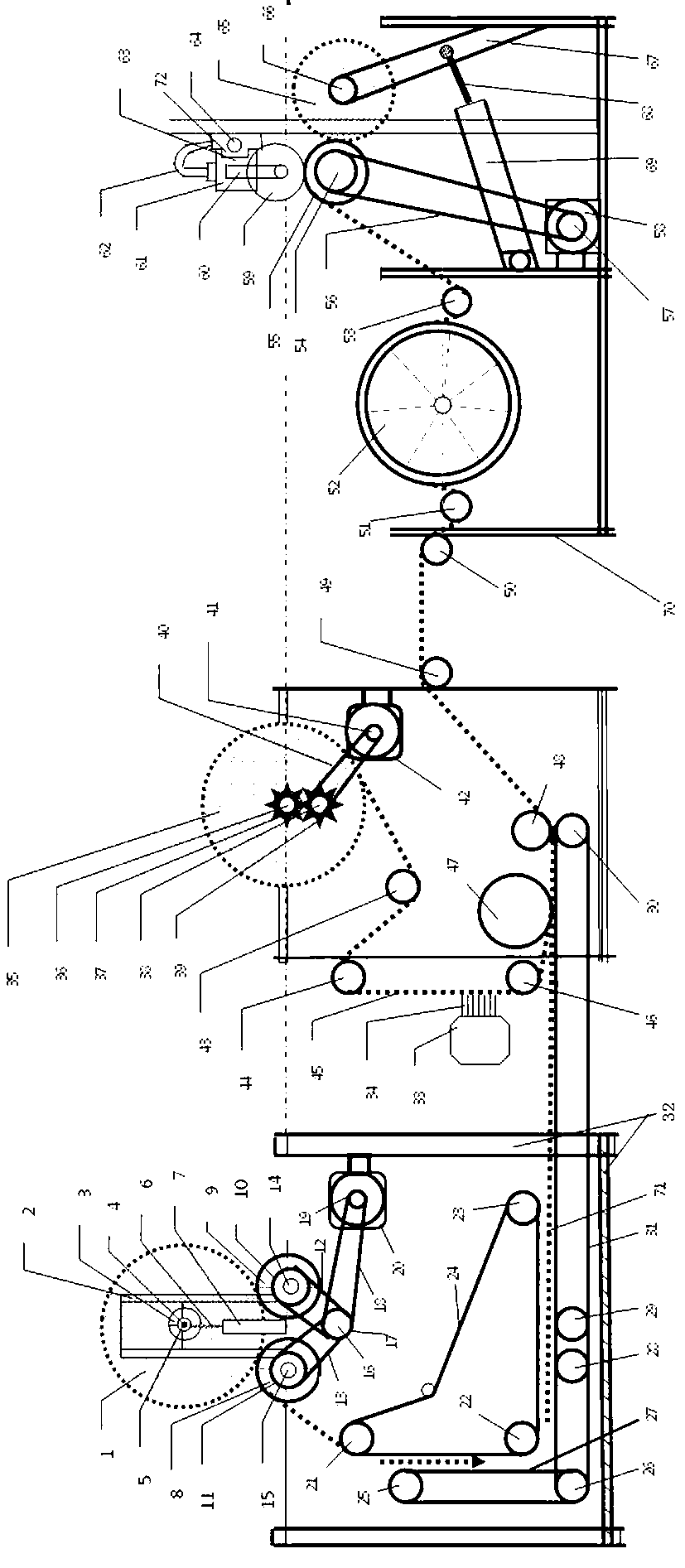

[0022] Refer to attached figure 1 , The hot melt adhesive composite slitting machine includes a frame, an unwinding part, a conveying part, a glue spraying part, a compounding part, a slitting part and a winding part.

[0023]The unwinding part consists of two unwinding mechanisms, one is the unwinding of the bonded material, usually the unwinding of the melt-blown cloth; the other is the unwinding of the adhesive material, usually the unwinding of the spunbonded cloth. The two kinds of unwinding correspond to two kinds of unwinding mechanisms, the meltblown cloth unwinding mechanism and the spunbonded cloth unwinding mechanism. The melt-blown cloth unwinding mechanism includes rotating roller one 8, rotating roller two 9, rotating shaft one 14, rotating shaft two 15, transmission sprocket one 10, transmission sprocket two 11, unwinding roller one 5, clamping Device, support 2, transmission chain one 12, transmission chain two 13, auxiliary shaft 16, transmission sprocket thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com