Servo gluing quantification machine

A technology of gluing and servo electric cylinders, which is applied to coatings and devices for coating liquid on the surface, etc. It can solve the problems of high measurement accuracy of servo push cylinders, long lengths of actuators, and bulky volumes, etc., to improve pressure resistance Stable reliability and service life, long life, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

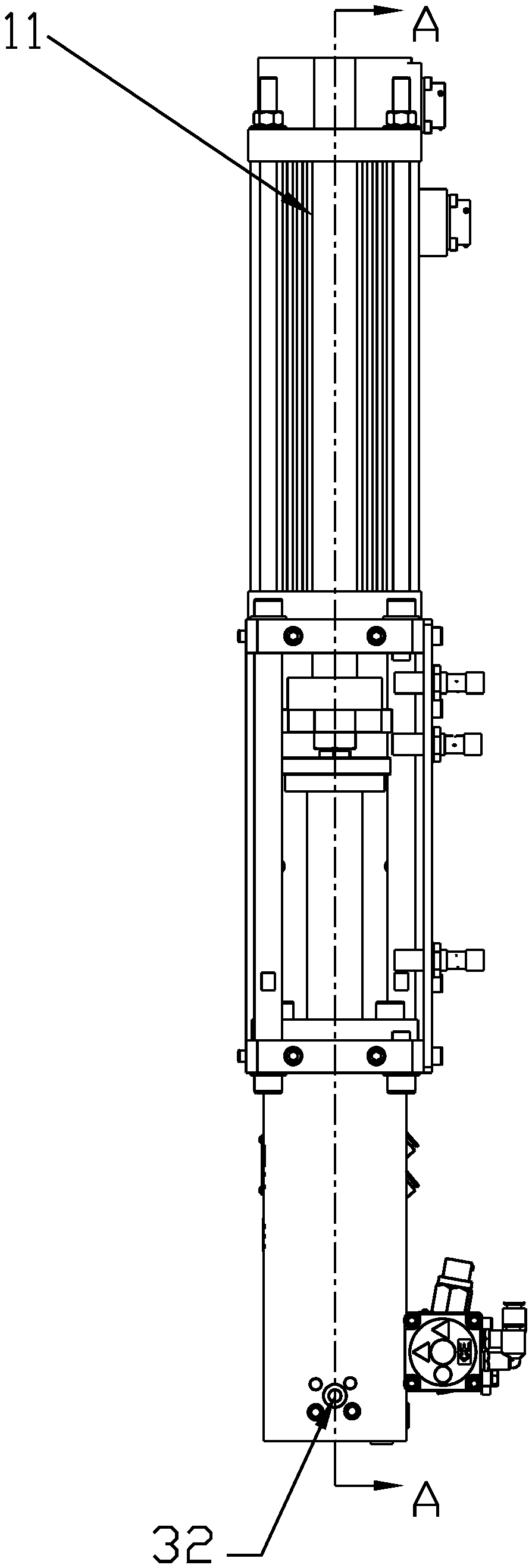

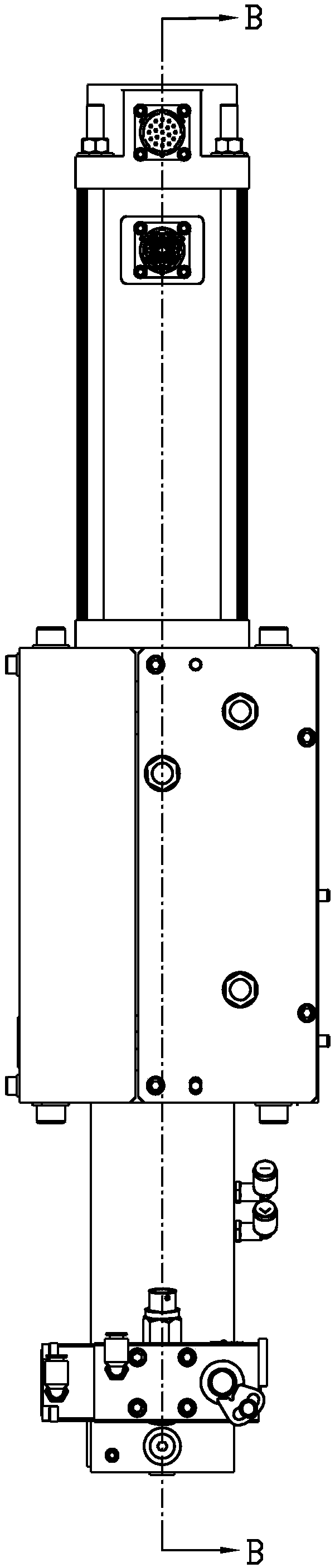

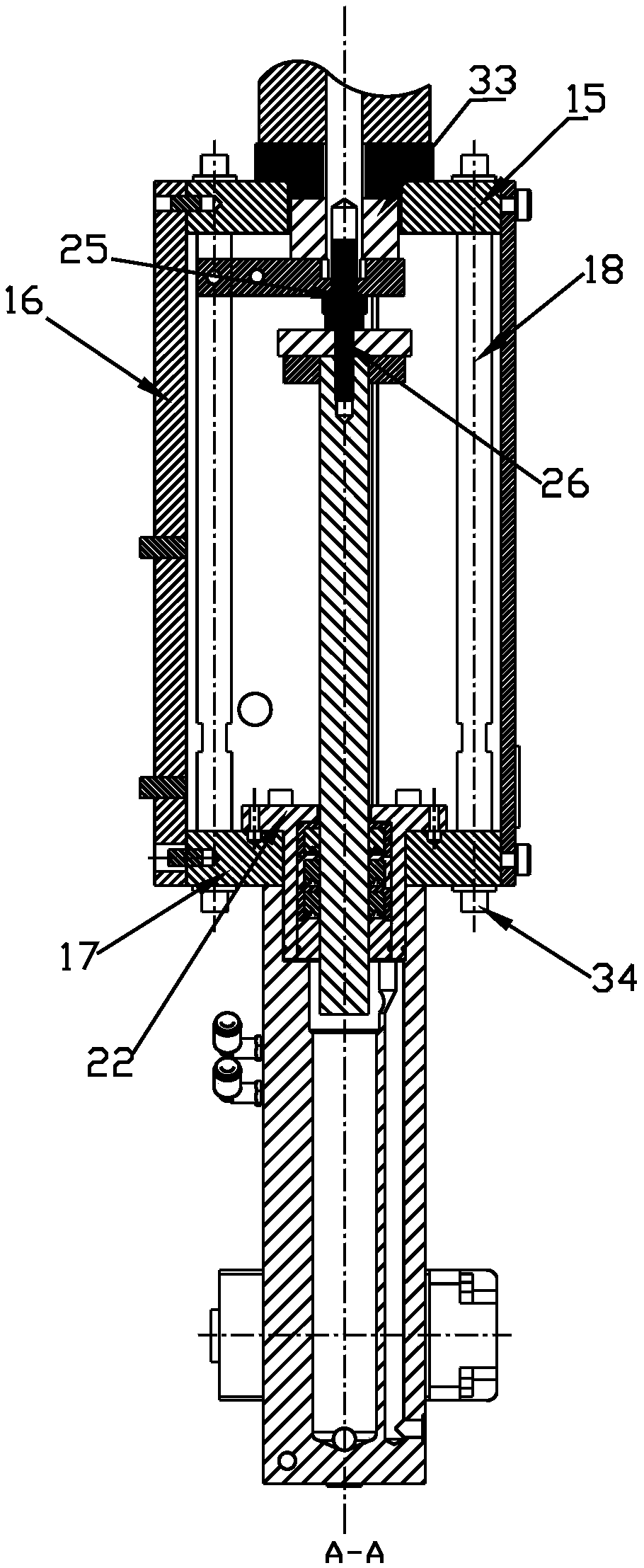

[0022] Such as Figure 1-Figure 4 As shown, a servo glue dosing machine includes a servo electric cylinder 11, a bracket, and a glue cylinder 29. The servo electric cylinder 11 is fixedly connected to the glue cylinder 29 through the bracket. The glue cylinder 29 has a glue inlet chamber with an upper opening. The upper part of the upper seal is equipped with a throat seal metal part 22, the throat seal metal part 22 has a vertical shaft hole, a piston rod 27 is installed in the vertical shaft hole, and a dynamic mechanism for sealing the gap between the piston rod 27 and the vertical shaft hole is installed in the vertical shaft hole. The seal, the diameter of the piston rod 27 is smaller than the inner diameter of the glue inlet chamber, the bottom of the glue cylinder 29 is provided with a glue inlet connected to the glue inlet, and a glue inlet valve 30 is installed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com