Side-coupling grating for laser, method for manufacturing same, and laser comprising same

A technology for coupling gratings and lasers, applied in the field of semiconductor technology and nano-processing, can solve the problems of insufficient exposure and glue stacking, and achieve the effects of reducing costs, reducing time, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

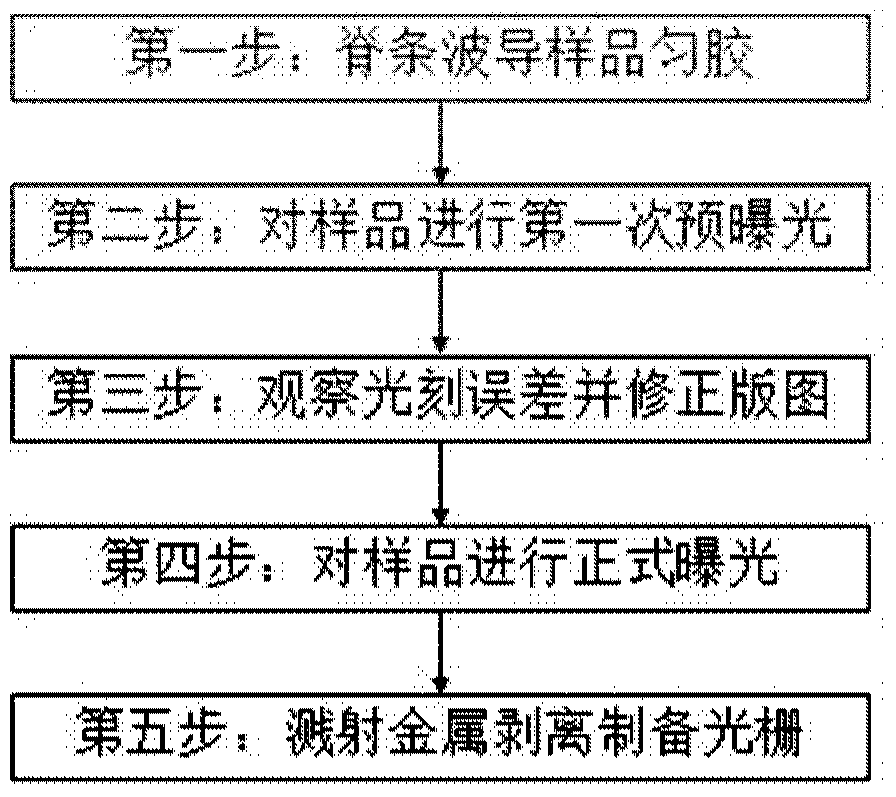

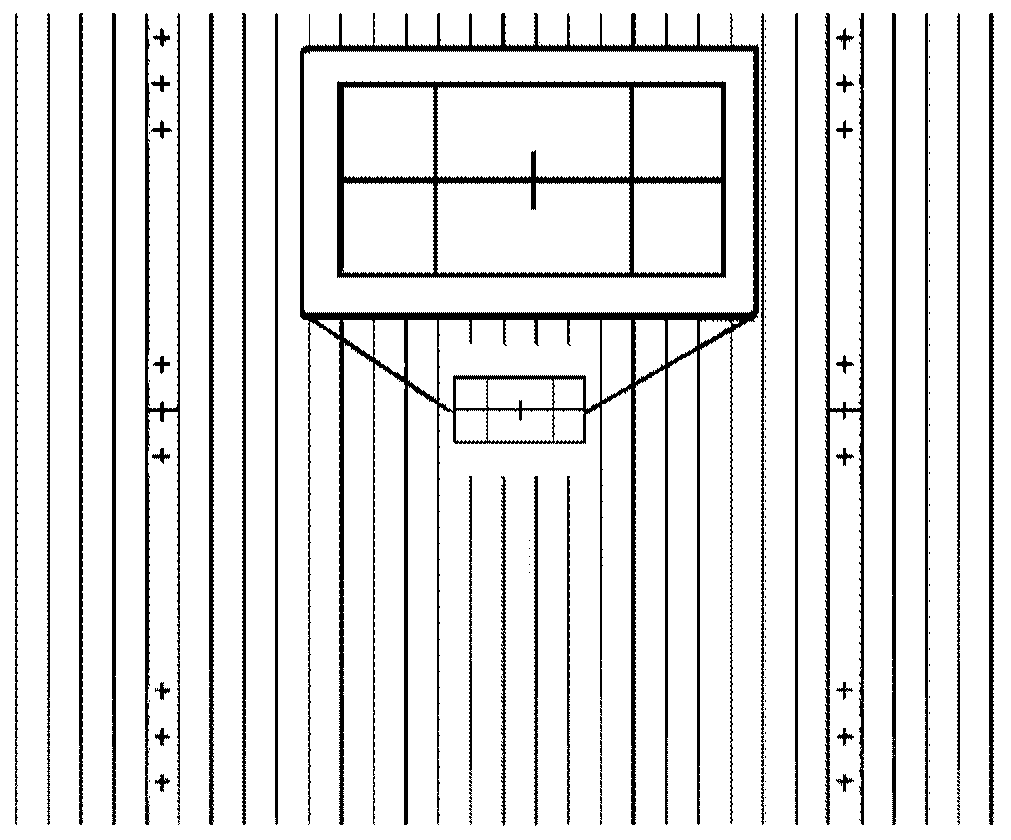

[0035] According to the overall inventive concept of the present invention, there is provided a method for preparing the side-coupling grating of a laser. That is, the first electron beam exposure pre-lithography is performed on the epitaxial wafer with the ridge waveguide, and then the layout and the After the distance error of the ridge waveguide is corrected, the grating layout is corrected, and the formal grating exposure is performed, and then the metal sputtering and stripping are performed to complete the preparation of the metal grating.

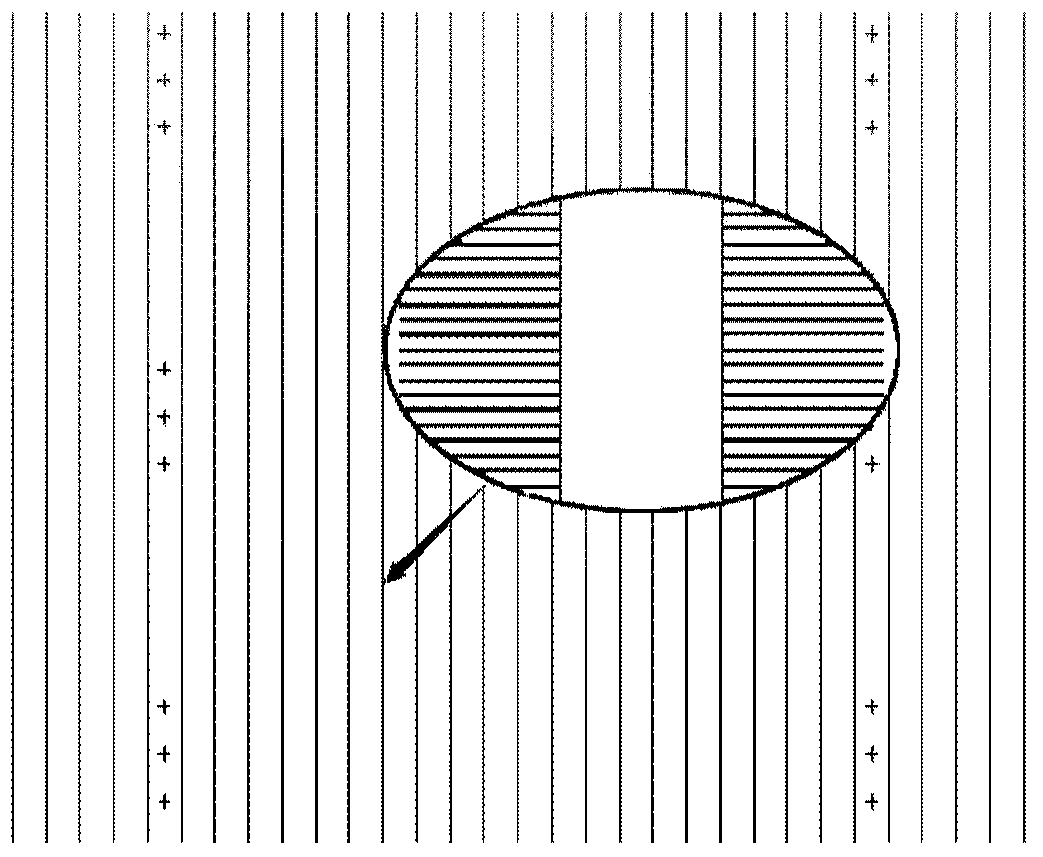

[0036] The laser ridge waveguide is formed by dry etching, preferably using an ICP etching system. Preferably, the width of the ridge waveguide is 3 to 5 μm. For the position of the grating, the effective area of the grating is within a distance of approximately 2 μm on both sides of the ridge waveguide. Therefore, when designing the grating, the overall width is designed to be 2 to 3 μm on both sides of the ridge waveguide.

[0037] Fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com