Preparation method of adhesive tape

A tape and heat-sensitive adhesive technology, applied in the direction of adhesives, sustainable manufacturing/processing, film/sheet adhesives, etc., can solve the problem of inability to protect the process, low product yield, affecting product appearance and yield, etc. problem, achieve the effect of increasing the package and protection area, avoiding scratches or damage, and reducing the difficulty of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

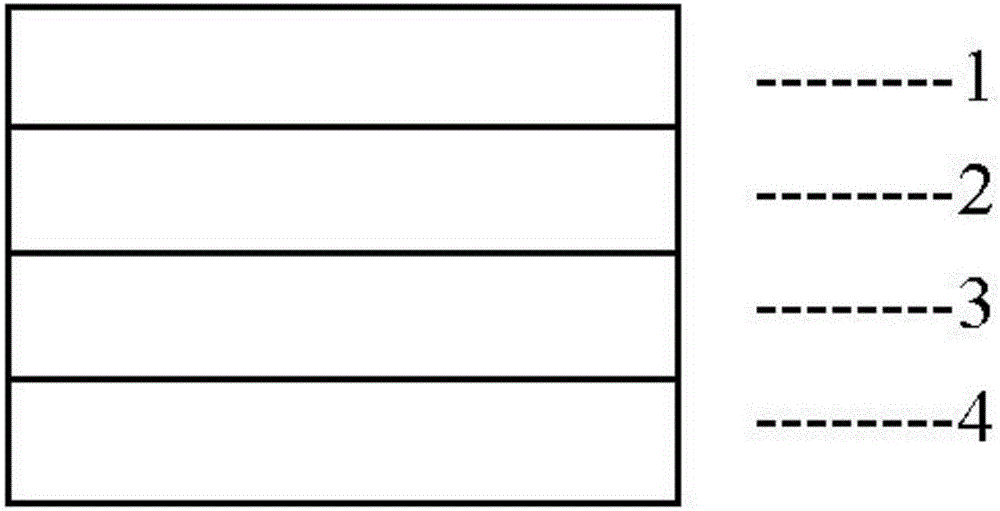

Image

Examples

Embodiment 1

[0028] A kind of preparation method of adhesive tape, carry out according to the following steps:

[0029] 1) Preparation of pressure-sensitive adhesive: 50 parts of alkyl methacrylate, 2 parts of hydroxyl-containing methacrylate copolymer and 30 parts of tackifying resin are used as solvents in toluene and ethyl acetate to react to form a solid The slurry with a content of 45% is added to the stirring device, and then 1.5 parts of isocyanate curing agent is added, dissolved and stirred into a uniform and stable viscous liquid to form an acrylic pressure-sensitive adhesive liquid with a solid content of 45%.

[0030] 2) Preparation of heat-sensitive adhesive: respectively dissolve 45 parts of rubber elastomer and 55 parts of tackifying resin to form a slurry with a solid content of 50%, add it to the stirring device, and then add 2 parts of softener and 5 parts of antioxidant , dissolved and stirred into a uniform and stable viscous liquid. Specifically, the rubber elastomer ...

Embodiment 2

[0034] 1) Preparation of pressure-sensitive adhesive: 75 parts of alkyl methacrylate, 1.2 parts of hydroxyl-containing methacrylate copolymer and 40 parts of tackifying resin are used as solvents in toluene and ethyl acetate to react to form a solid The slurry with a content of 50% is added to the stirring device, and then 2 parts of isocyanate curing agent is added, dissolved and stirred into a uniform and stable viscous liquid to form an acrylic pressure-sensitive adhesive liquid with a solid content of 50%.

[0035] 2) Preparation of heat-sensitive adhesive: respectively dissolve 50 parts of rubber elastomer and 60 parts of tackifying resin to form a slurry with a solid content of 50%, add it to the stirring device, and then add 1 part of softener and 10 parts of antioxidant , dissolved and stirred into a uniform and stable viscous liquid. Specifically, the rubber elastic body is a styrene-butadiene-styrene block copolymer, the tackifying resin is a rosin resin, the softeni...

Embodiment 3

[0039]1) Preparation of pressure-sensitive adhesive: 90 parts of alkyl methacrylate, 0.2 part of hydroxyl-containing methacrylate copolymer and 35 parts of tackifying resin are used as solvents in toluene and ethyl acetate to react to form a solid The slurry with a content of 45% is added to the stirring device, and then 3 parts of isocyanate curing agent is added, dissolved and stirred into a uniform and stable viscous liquid to form an acrylic pressure-sensitive adhesive liquid with a solid content of 45%.

[0040] 2) Preparation of heat-sensitive adhesive: respectively dissolve 40 parts of rubber elastomer and 50 parts of tackifying resin to form a slurry with a solid content of 50%, add it to the stirring device, and then add 5 parts of softener and 1 part of antioxidant , dissolved and stirred into a uniform and stable viscous liquid. Specifically, the rubber elastomer is a styrene-butadiene-styrene block copolymer, the tackifying resin is a terpene resin, the softener is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com