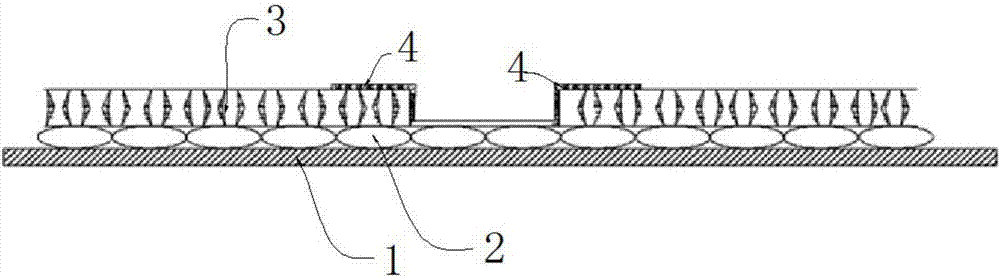

Tail end and hinge structure of PP cellular board and treatment process thereof

A treatment process and technology of honeycomb panels, which are applied to the end of honeycomb panels and hinge structure, the end of PP honeycomb panels and hinge structure and their processing technology fields, can solve the problems of poor peripheral strength, honeycomb leakage, residual glue and other problems, and achieve Save material costs, improve commodity quality, and solve the effect of residual glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

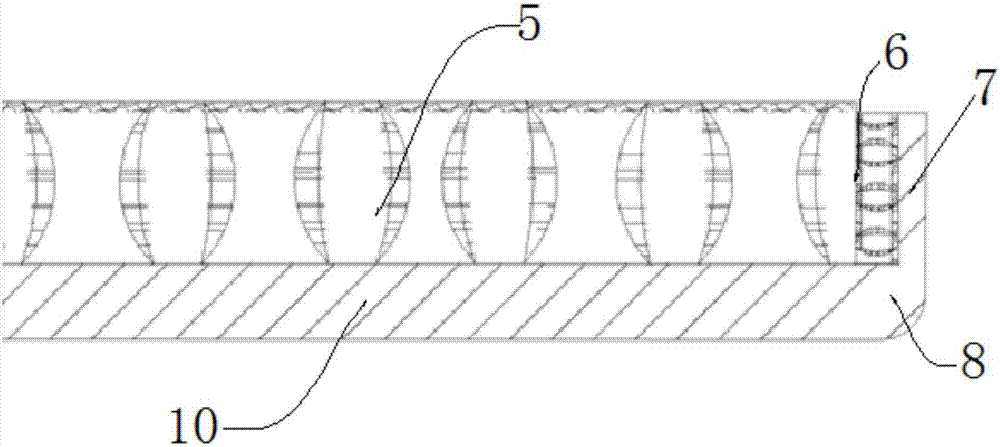

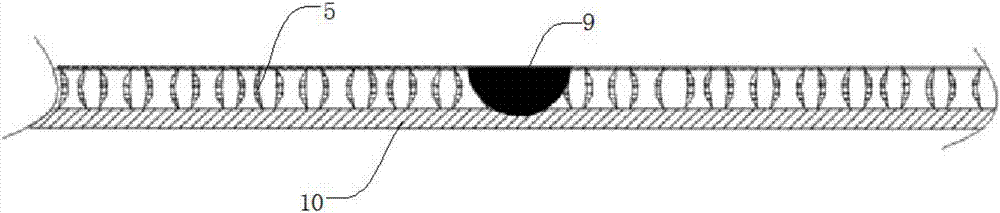

[0042] The first step: PP and PET in the skin layer 10 are mixed according to a certain ratio to form the skin layer 10, so that the composition of the skin layer 10 contains PP, and when the skin layer 10 is melted and compounded with the PP in the barrel, the skin layer 10 will Composite with honeycomb plate layer 5. Since the composition of the skin layer 10 contains PP and the composition of the honeycomb panel layer 5 is PP, it will be bonded in the molten state, thereby eliminating the need for a solvent adhesive layer, reducing the damage of the adhesive to the environment and personnel, and at the same time the product VOC Performance is improved. PP is contained in the skin layer, and the skin layer 10 is bonded to the honeycomb panel layer 5 by utilizing the principle of similar compatibility.

[0043] The second step: put the honeycomb plate layer 5 with the skin layer 10 into the mould, the upper mold body 13 and the lower mold body 14 are closed, and the honeycom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com