Processing apparatus and processing method for flocking flexible shaft

A technology for flocking flexible shafts and processing equipment, applied in the direction of flexible shafts, mechanical equipment, shafts, etc., can solve the problems of lack of product versatility, thread degumming, low processing efficiency, etc., to avoid residual glue and weak bonding , to avoid thread jumping and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

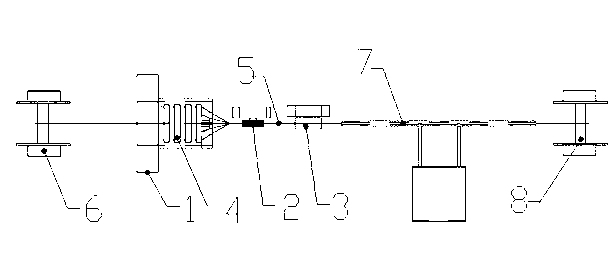

[0020] The processing equipment of a kind of flocking flexible shaft of present embodiment, as figure 1 As shown, it includes a warehouse 1, a heating device 2 and a traction wheel 3; the heating device 2 is a high-frequency coil or a heating wire. A woolen I-shaped wheel 4 coiled with wool is placed in the material warehouse 1; the flexible shaft 5 to be flocked as the core thread is coiled on the flexible shaft I-shaped wheel 6, and one end of the flexible shaft 5 passes through the material warehouse 1 and the The heating device 2 is connected to the traction wheel 3; the wool is wound on the flexible shaft 5. A cooling pipe 7 and a winding wheel 8 are also provided behind the traction wheel 3 , and the flexible shaft 5 passes through the cooling pipe 7 and is coiled on the winding wheel 8 .

[0021] The processing method of the processing equipment of a kind of flocking flexible shaft of application present embodiment, comprises the following steps:

[0022] Step 1: Coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com