Patents

Literature

143results about How to "Prevent offline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

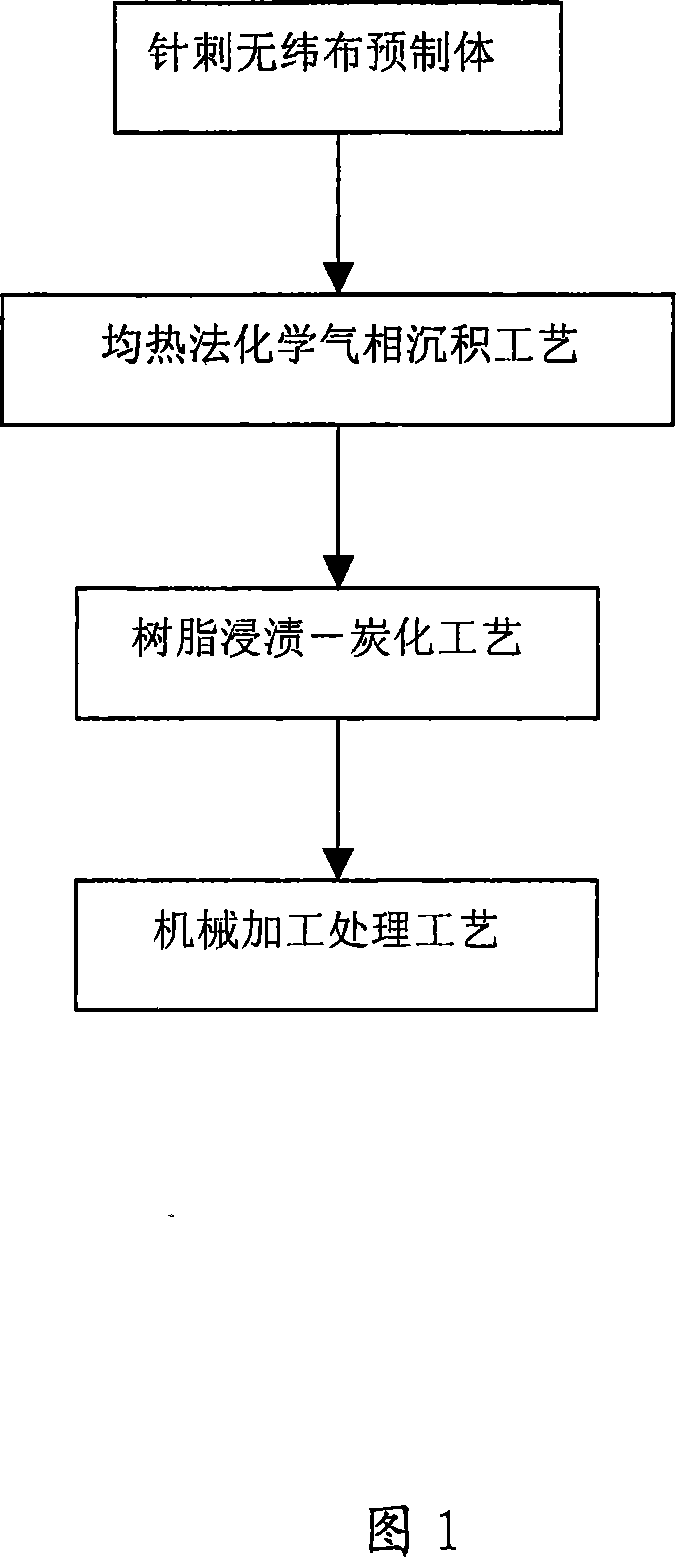

Method for manufacturing charcoal / charcoal pantograph pan in use for electric locomotive

ActiveCN101049803AHigh strengthImprove anti-friction performanceConductive layers on insulating-supportsNon-conductive material with dispersed conductive materialGas phaseEngineering

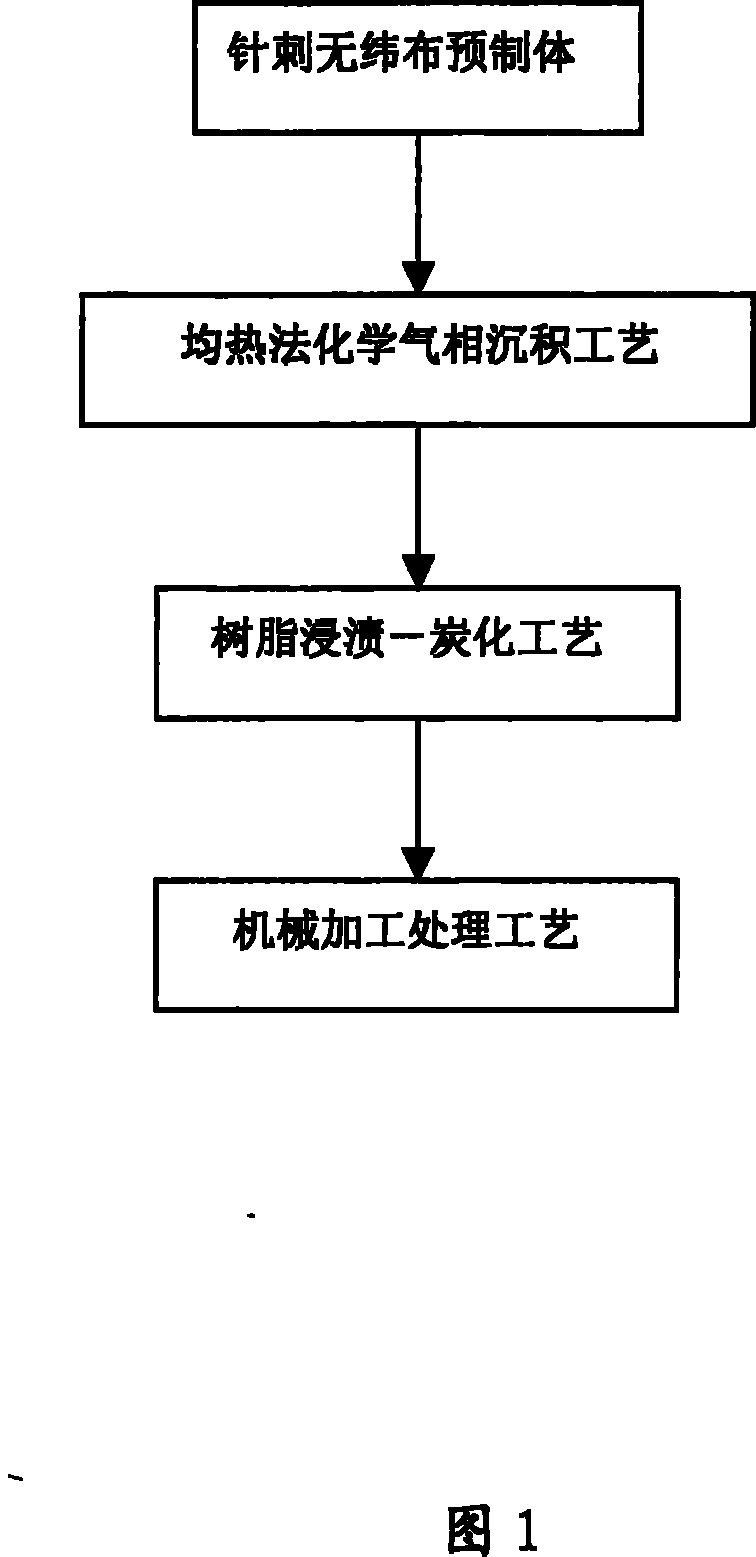

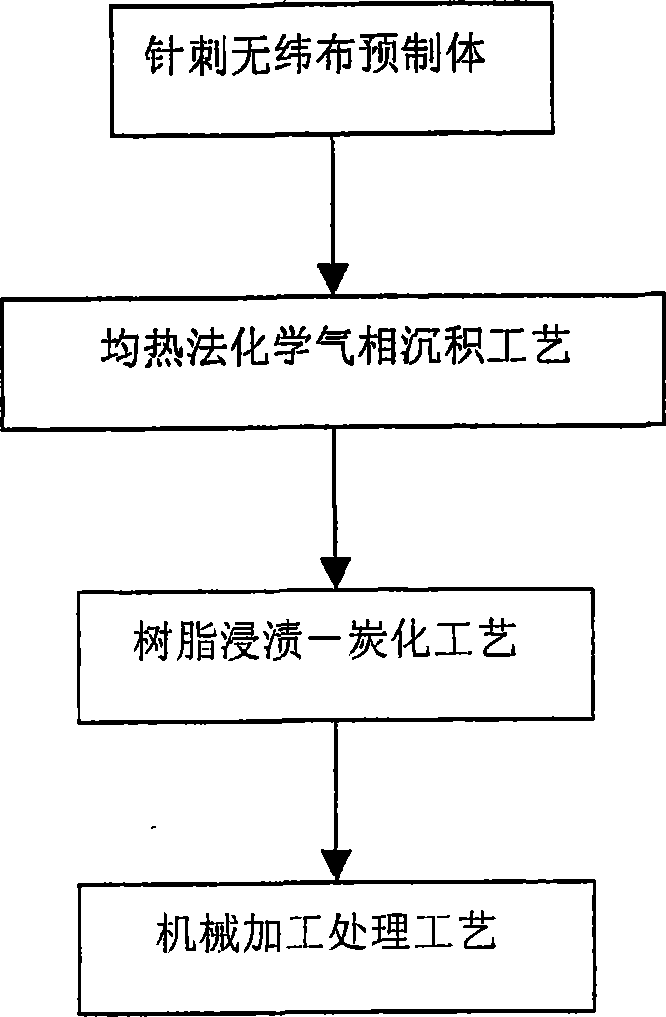

A carbon / carbon slide block of current collector for electric locomotive is prepared through providing prefabricated body made of punched non-weft fabric with tridirectional structure, depositing pyrolytic carbon by CVD, compacting by resin dipping-charring process several times, and machining.

Owner:XIAN CHAOMA SCI TECH

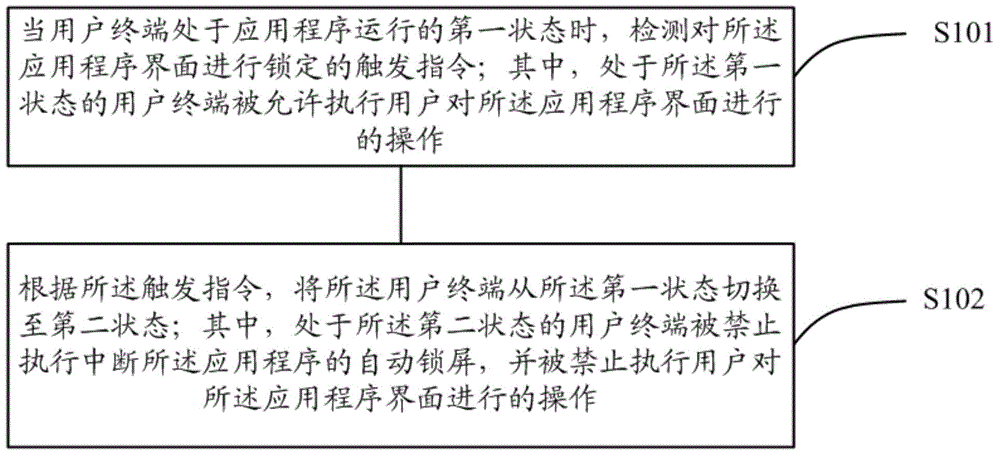

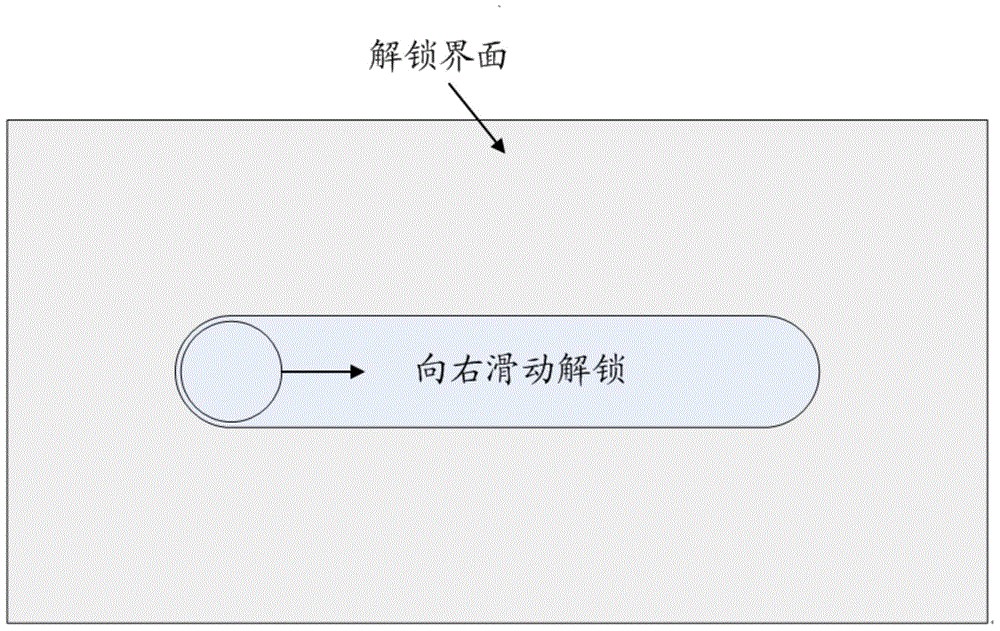

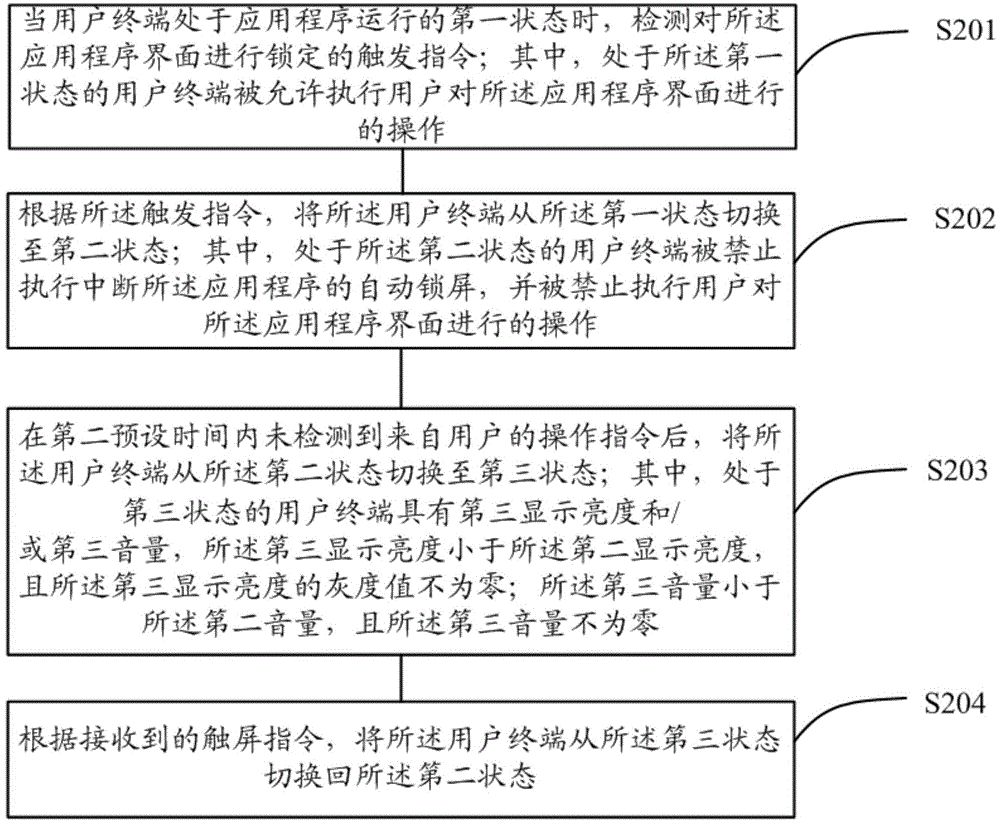

User terminal, status switching method thereof, status switching device, game control method and game control device

InactiveCN104820564AReduce brightnessLower the volumeInput/output processes for data processingComputer terminalApplication software

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

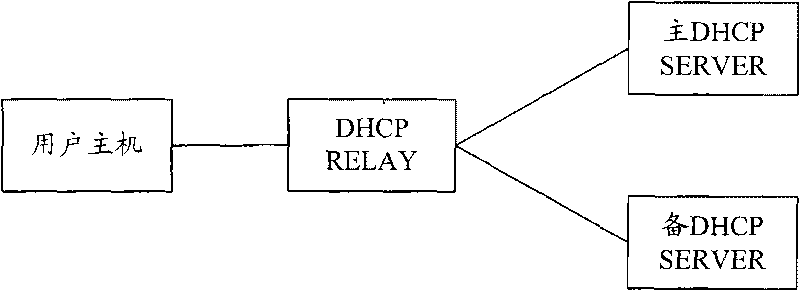

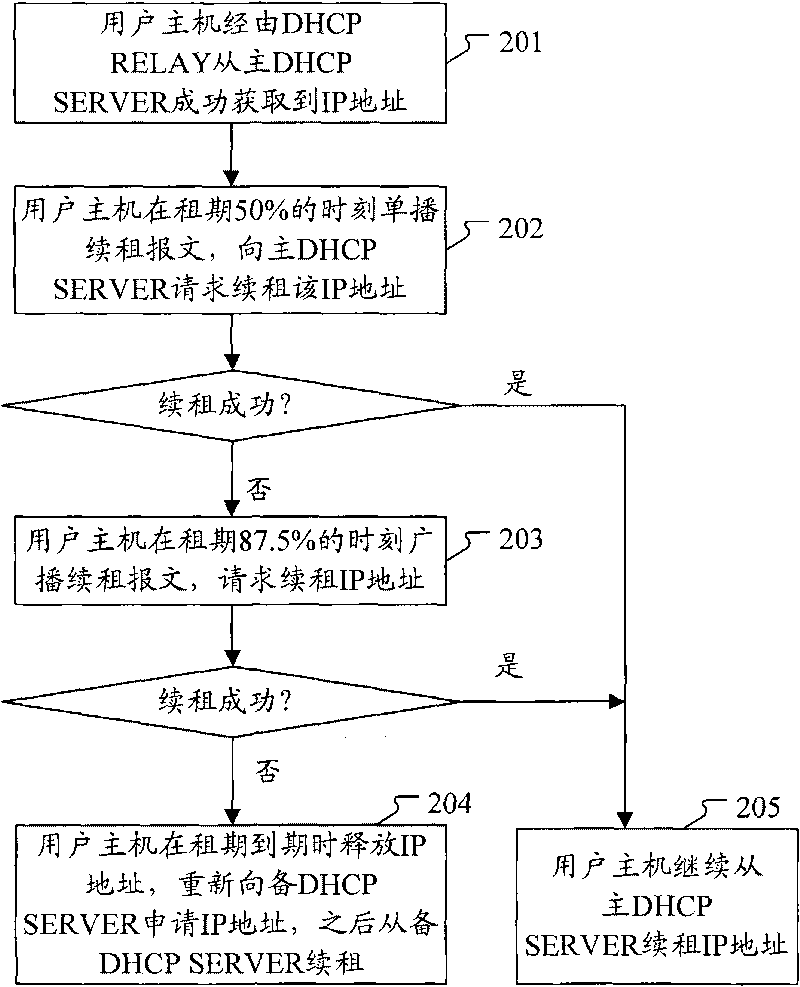

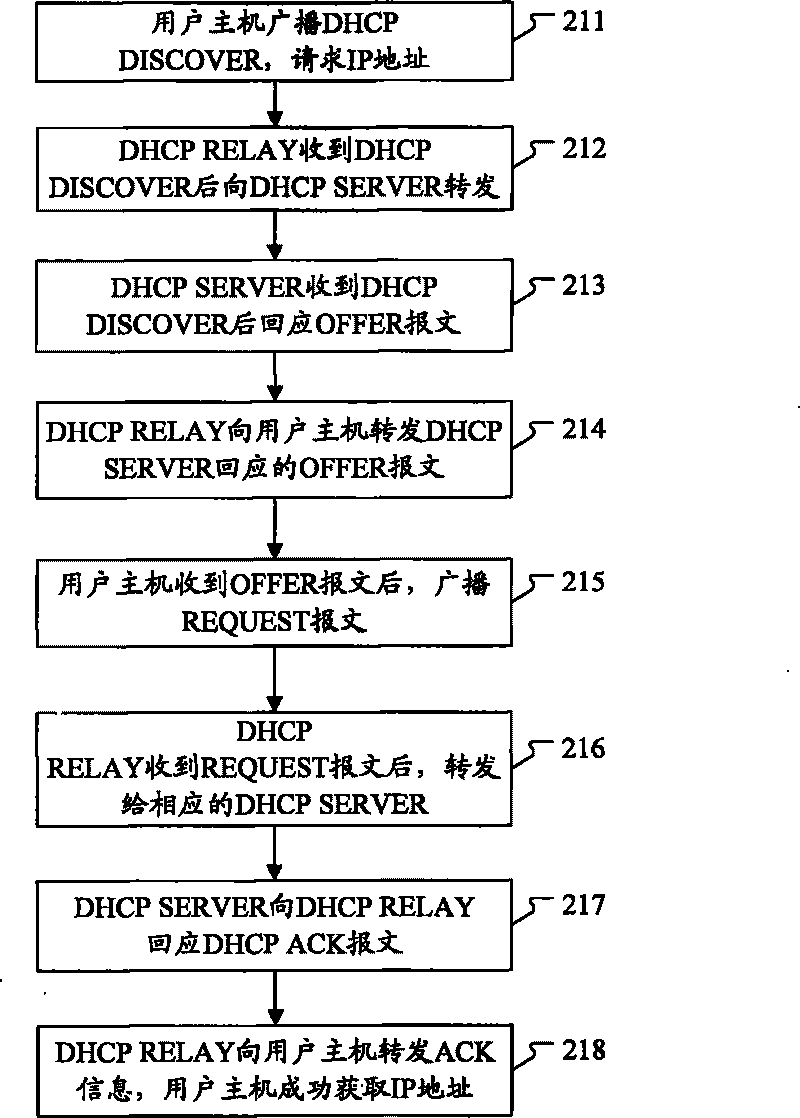

Method and system for realizing backup of DHCP server

ActiveCN101729559AAvoid offlineImprove satisfactionData switching networksUser satisfactionIp address

The invention discloses a method for realizing backup of a dynamic host configuration protocol (DHCP) server, which comprises that: a user host acquires an IP address from a main DHCP SERVER through a DHCP RELAY; the user host requests for reletting and does not receive a response of the main DHCP SERVER, the DHCP RELAY initiates an IP address request to a standby DHCP SERVER; and the DHCP RELAY applies for and acquires the IP address, and sends a compulsory reletting message to the user host. The invention also correspondingly discloses a system for realizing the backup of the DHCP server; and when the main DHCP SERVER is not available, the online user host does not need experiencing processes of releasing the IP address and applying for the IP address once again and can realize the switching of the DHCP SERVER; therefore, the method and the system can avoid off line of users due to the fault of the DHCP SERVER, improve the satisfaction of the users, and relieve the pressure of network equipment due to on line again of the users together.

Owner:ZTE CORP

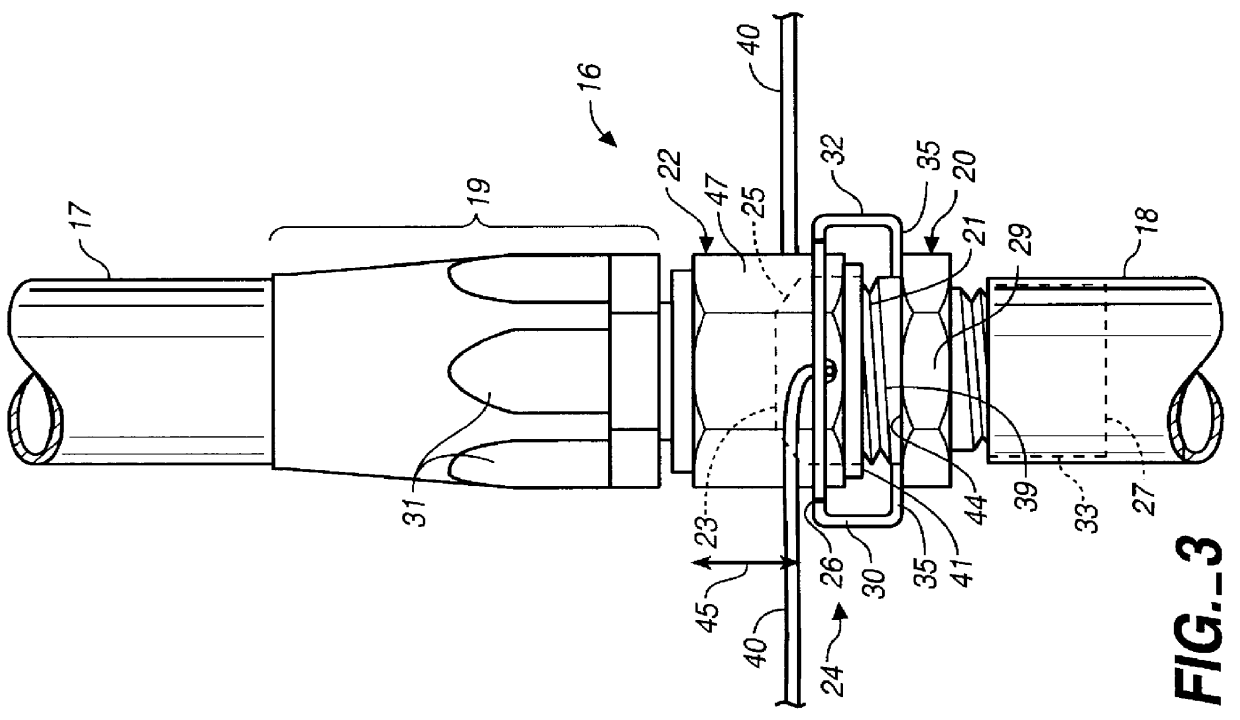

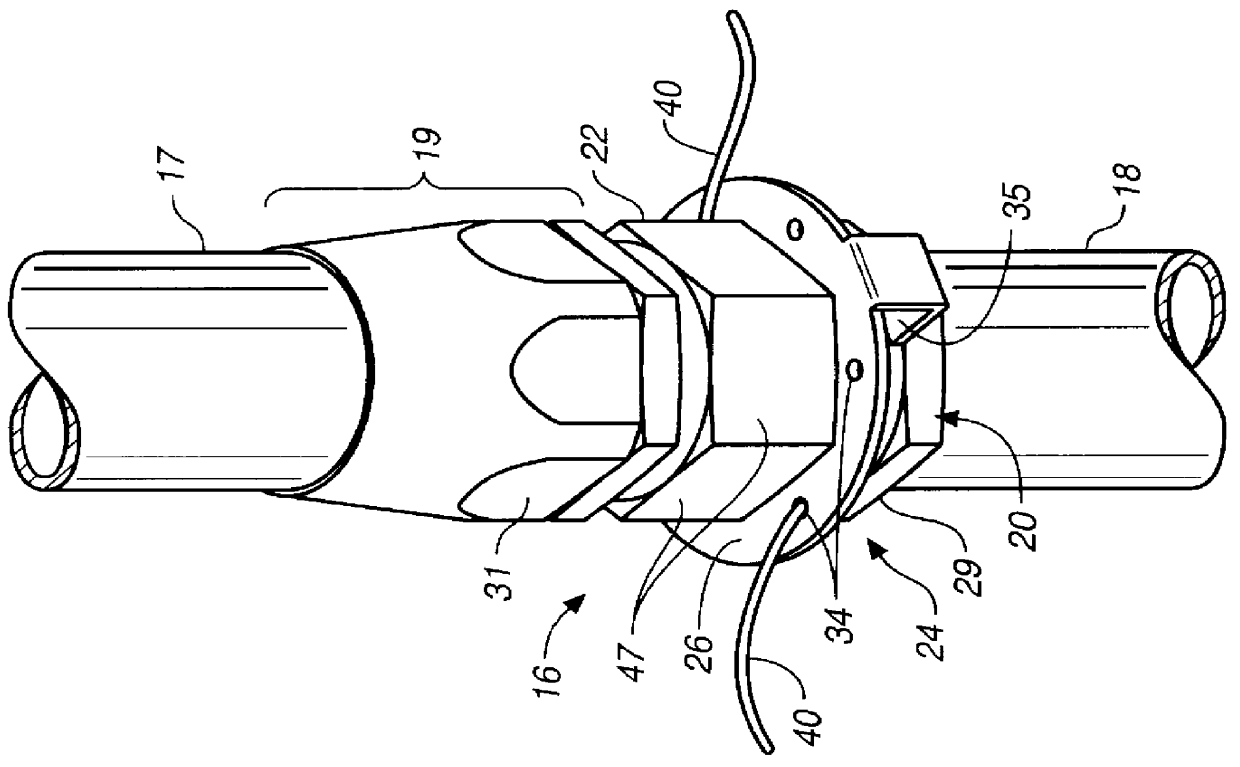

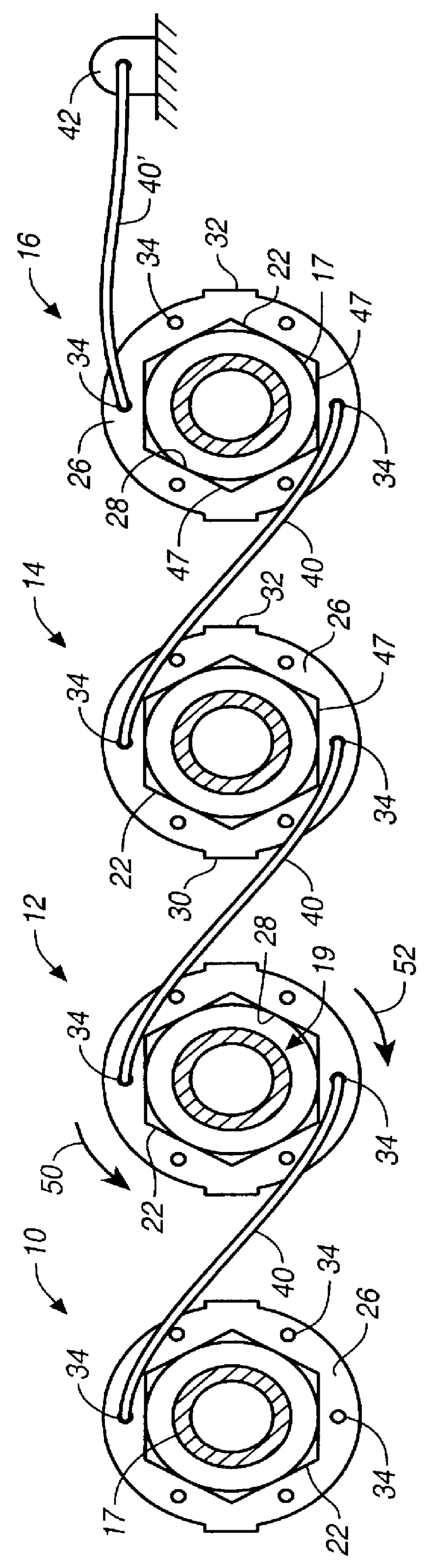

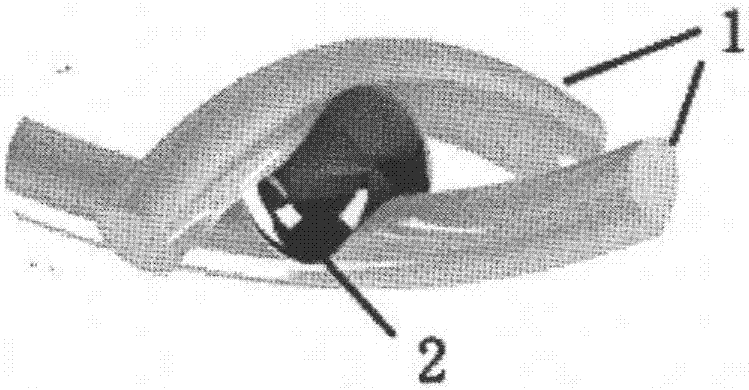

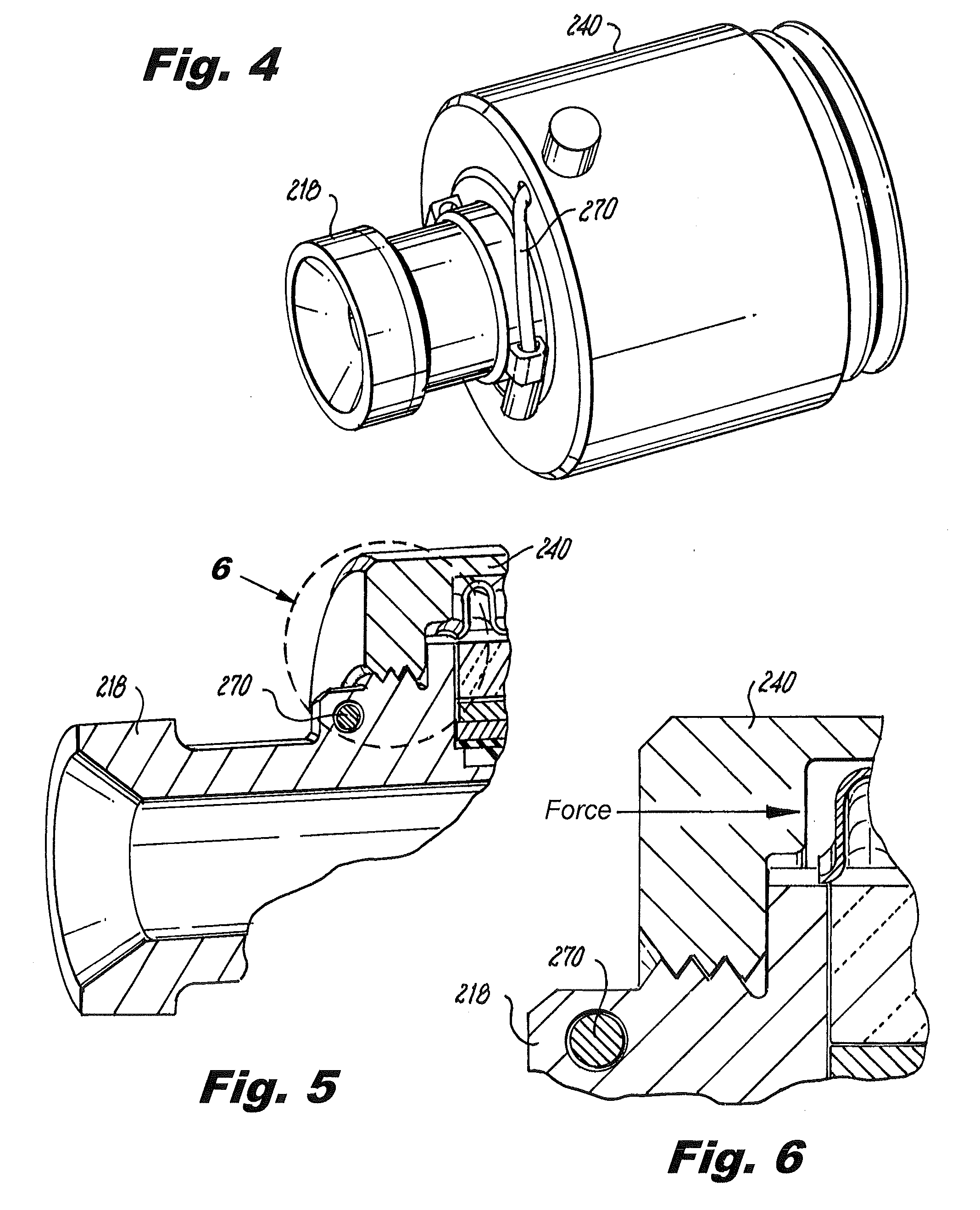

Safety collar and tendon assembly for threaded connections

InactiveUS6135509APrevent relative rotation therebetweenPrevent movementEngine sealsJoints with sealing surfacesRebarEngineering

A safety collar and tendon assembly (24) for joining a female connector (22) and a male connector (20), comprising a collar member (26) having at least one tab (30, 32) with a radially inwardly projecting leg (35) which extends into an annular recess (39) between the male connection (20) and the female connection (22) to prevent axial movement of the collar member (26) along the connection assembly (16) and thereby maintain engagement of collar (26) around a non-circular (hexagonal) surface (47) of the female connector (22). Also part of the safety collar and tendon assembly (24) is a tendon or length of wire (40) which is secured at one end to collar (26) and at its other end is either secured to a similar collar on an adjacent threaded connection or to a fixed structure. Unthreading of the connection assembly (16) is prevented by the tendon (40), which prevents rotation of collar (26).

Owner:BILLINGTON WELDING & MFG

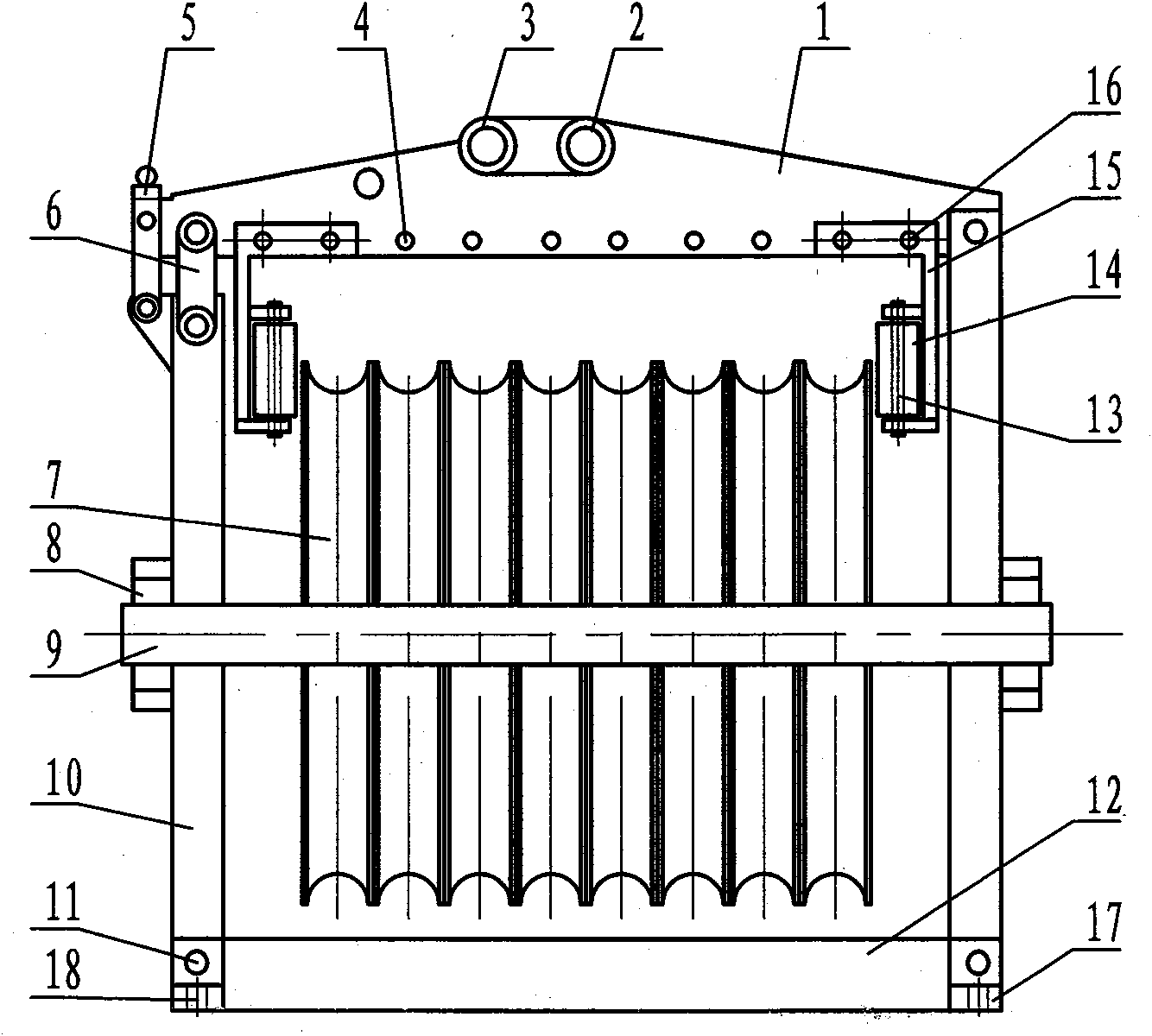

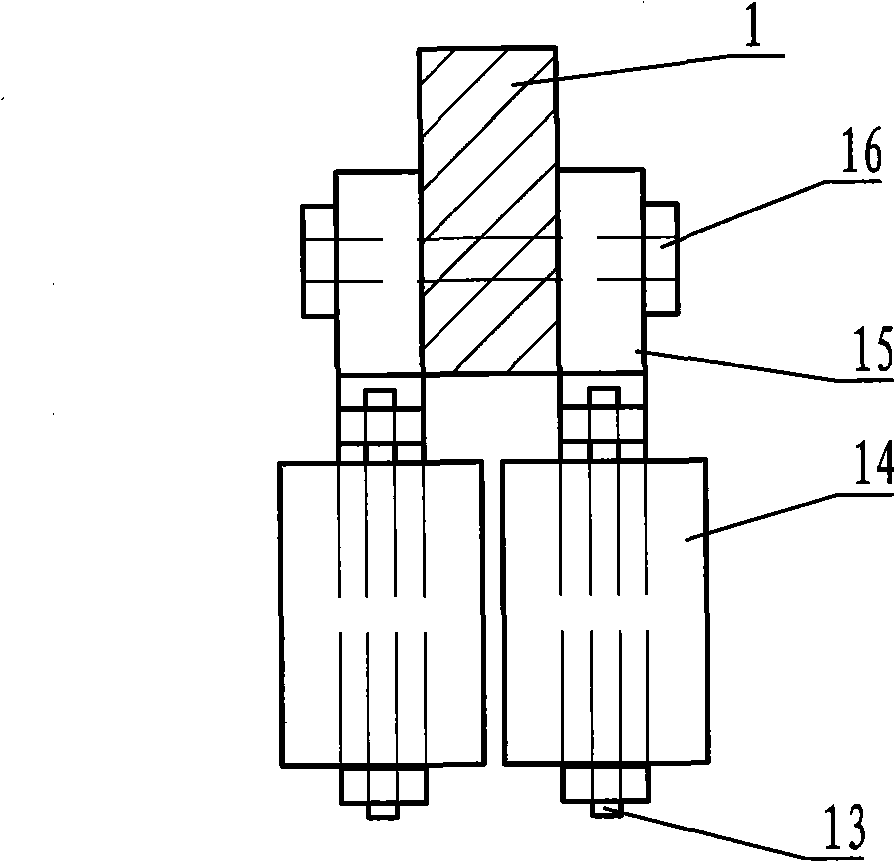

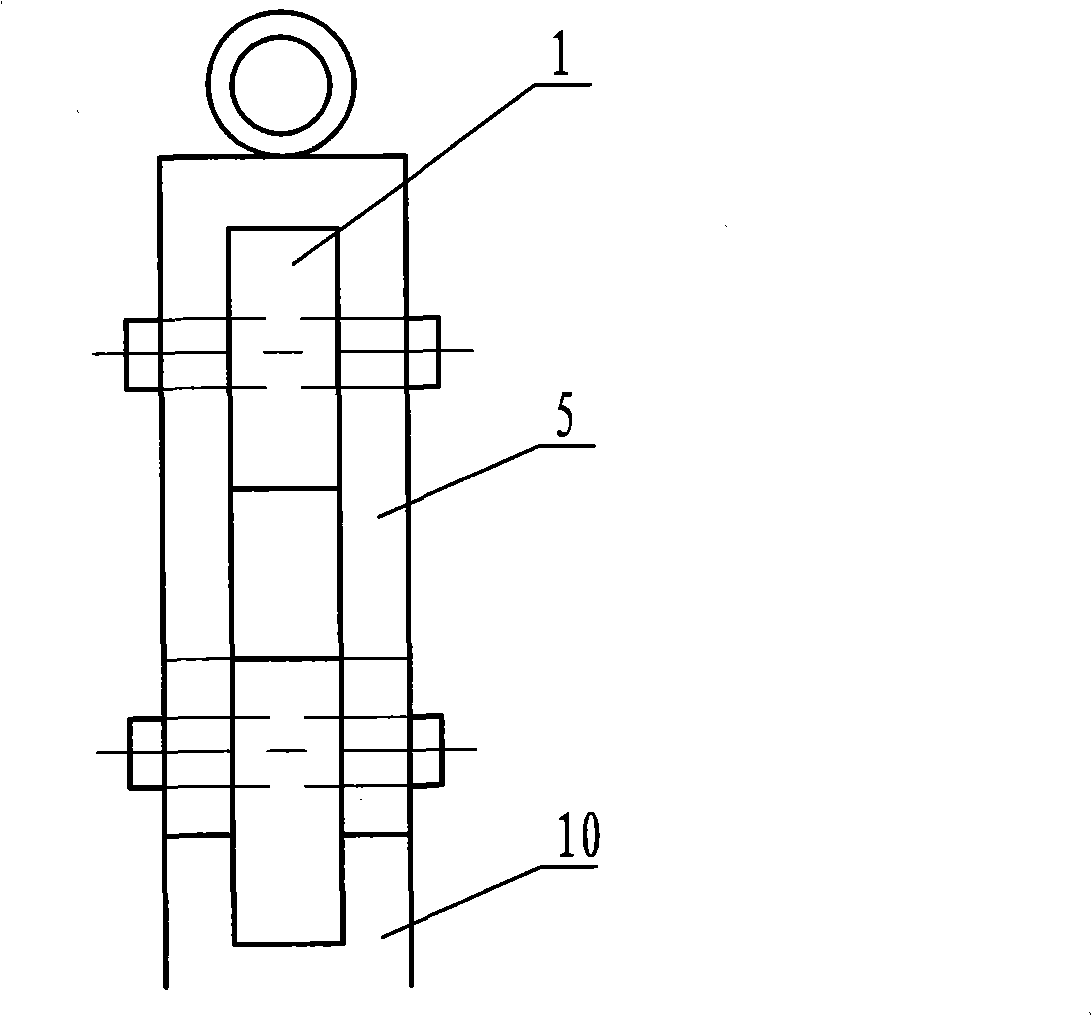

General combined type stringing pulley

ActiveCN102074910APlay a guiding roleConvenient addition and subtractionApparatus for overhead lines/cablesTransmission lineEngineering

The invention discloses a general combined type stringing pulley. The pulley comprises a main hanging board, a bottom board, two side columns and a principal axis, wherein primary and secondary hooks are arranged at the top of the main hanging board; conductor wheels penetrate through the principal axis; the side column at one side is movably connected with the main hanging board via a primary connection board and a secondary connection board; the main hanging board and the bottom board are connected with other connection parts of the side columns with bolts; the principal axis is movably arranged on the two side columns and is fastened by nuts; a row of blocking wheel carrier connecting holes with space equal to the width of the conductor wheels are arranged at the lower end of the main hanging board; blocking wheels corresponding to the upper edges of the conductor wheels are pairwise arranged at the two sides of the conductor wheels respectively; the blocking wheels are fixed belowthe main hanging board with fixed bolts via blocking wheel carriers; and supporting seats with anchor holes are arranged at the two ends of the bottom board. The pulley can be used for stringing various transmission lines and various quantities of split conductors. Stringing of all split quantities of transmission lines can be satisfied as long as the construction unit only manufactures a pulley and then increases the quantity of the conductor wheels according to the quantity of the split conductors.

Owner:STATE GRID CORP OF CHINA +1

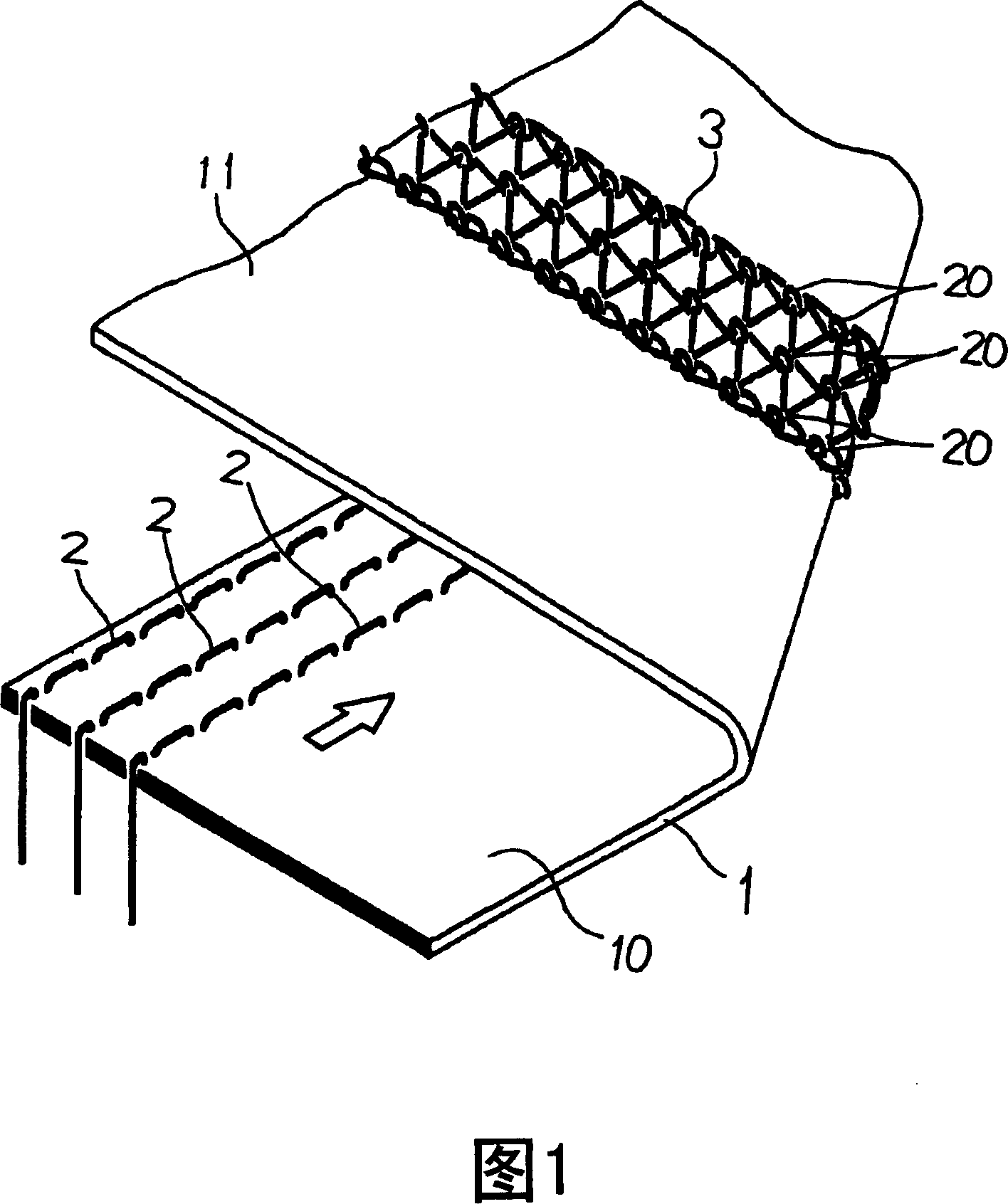

Textile-based enhanced degradable tube cavity support and preparation method and application thereof

The invention provides a textile-based enhanced degradable tube cavity support and a preparation method and application thereof. The textile-based enhanced degradable tube cavity support is characterized by comprising a hollow tubular fabric formed by two-dimensionally and three-directionally knitting degradable macromolecular silk yarns as knitting silk yarns, wherein axial silk yarns are introduced between two groups of knitting silk yarns in the knitting process and are not knitted, the axial silk yarns are molten through a heat treatment process, weaving points of the two groups of degradable macromolecular silk yarns are bonded and fixed through the molten axial silk yarns, and accordingly the textile-based enhanced degradable tube cavity support stable in shape is obtained. The shortcoming that the edge knitted by a machine is easy to loosen and a structure is not easy to fix can be effectively overcome, slippage of the weaving points of the support can be effectively prevented, the number of the weaving points per unit length when the support is radially compressed is increased, and the radial supporting force of the support is increased.

Owner:DONGHUA UNIV

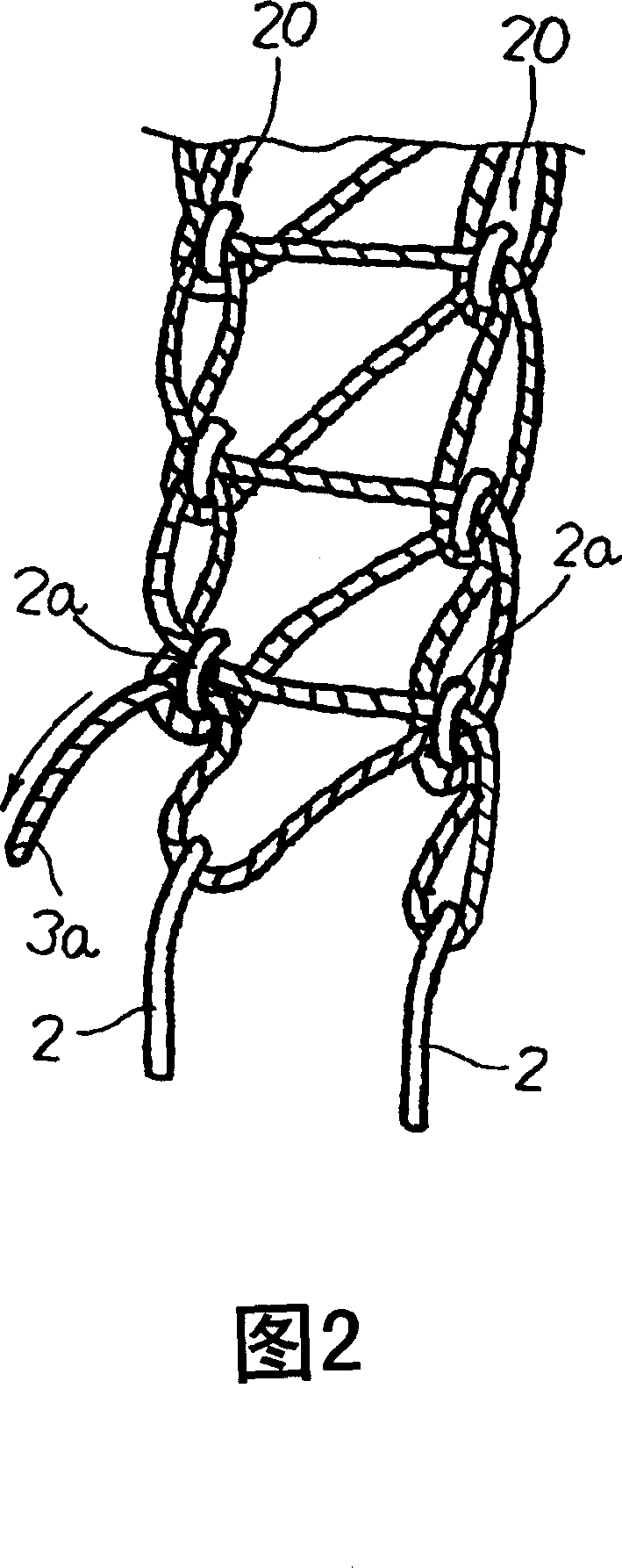

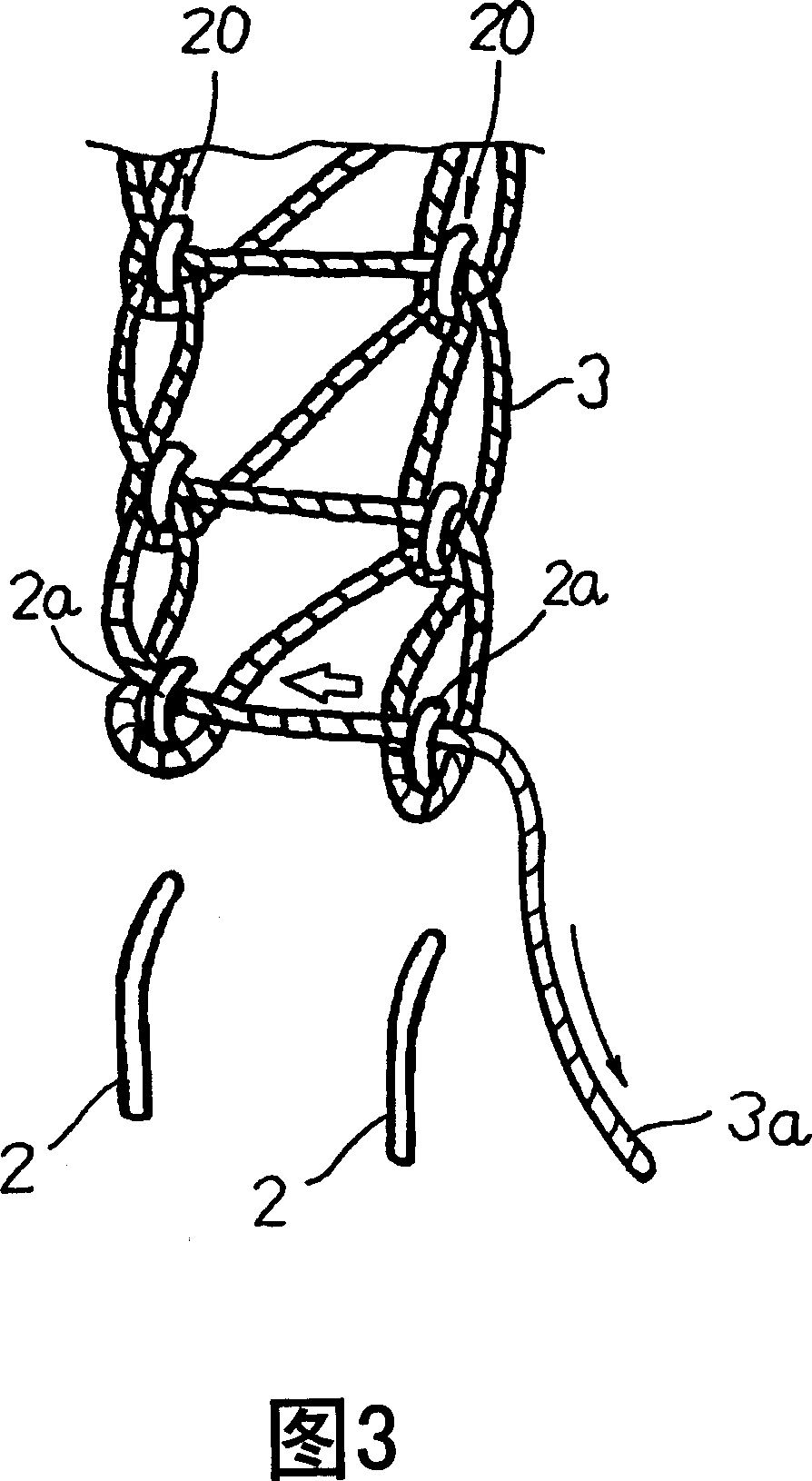

Stitch structure

A stitch structure capable of effectively preventing the occurrence of raveling peculiar to double chain stitches irrespective of sewing conditions is provided by the stitch structure of double chain stitches including a plural number of needle threads forming rows of thread loops at the rear face of a cloth and one looper thread entwined with the rows of thread loops at the rear face of the cloth; wherein the looper thread is cut at one side of the positions at which it is entwined in the mode of interlacing with the preceding loops preceding to the final loops at the respective sewing termination ends of the respective rows of thread loops.

Owner:YAMATO SEWING MASCH MFG CO LTD

Online roller replacing and overhauling technology of fan-shaped segment of continuous casting machine

ActiveCN103121093AReduce labor intensityReduce maintenance personnelMaterials scienceUltimate tensile strength

The invention relates to online roller replacing and overhauling technology of a fan-shaped segment of a continuous casting machine and belongs to the technical field of metallurgy continuous casting technology. The online roller replacing and overhauling technology of the fan-shaped segment of the continuous casting machine is characterized in that the whole fan-shaped segment is sequentially sectioned into 16 sections (from the first section to the sixteenth section). Outer arc rollers of sections from the first section till the seventh section and inner and outer arc rollers of sections from the eighth section to the sixteenth section respectively undergo online replacing and overhauling. The online roller replacing and overhauling technology of the fan-shaped segment of the continuous casting machine has the advantages that a single roller undergoes online replacing and overhauling, the phenomenon that a complete fan-shaped segment is off line due to failure in reaching a period is avoided, labor intensity is reduced, overhauling staff is reduced, maintenance cost is saved and overhauling time and warm shutdown time are reduced.

Owner:WUYANG IRON & STEEL +1

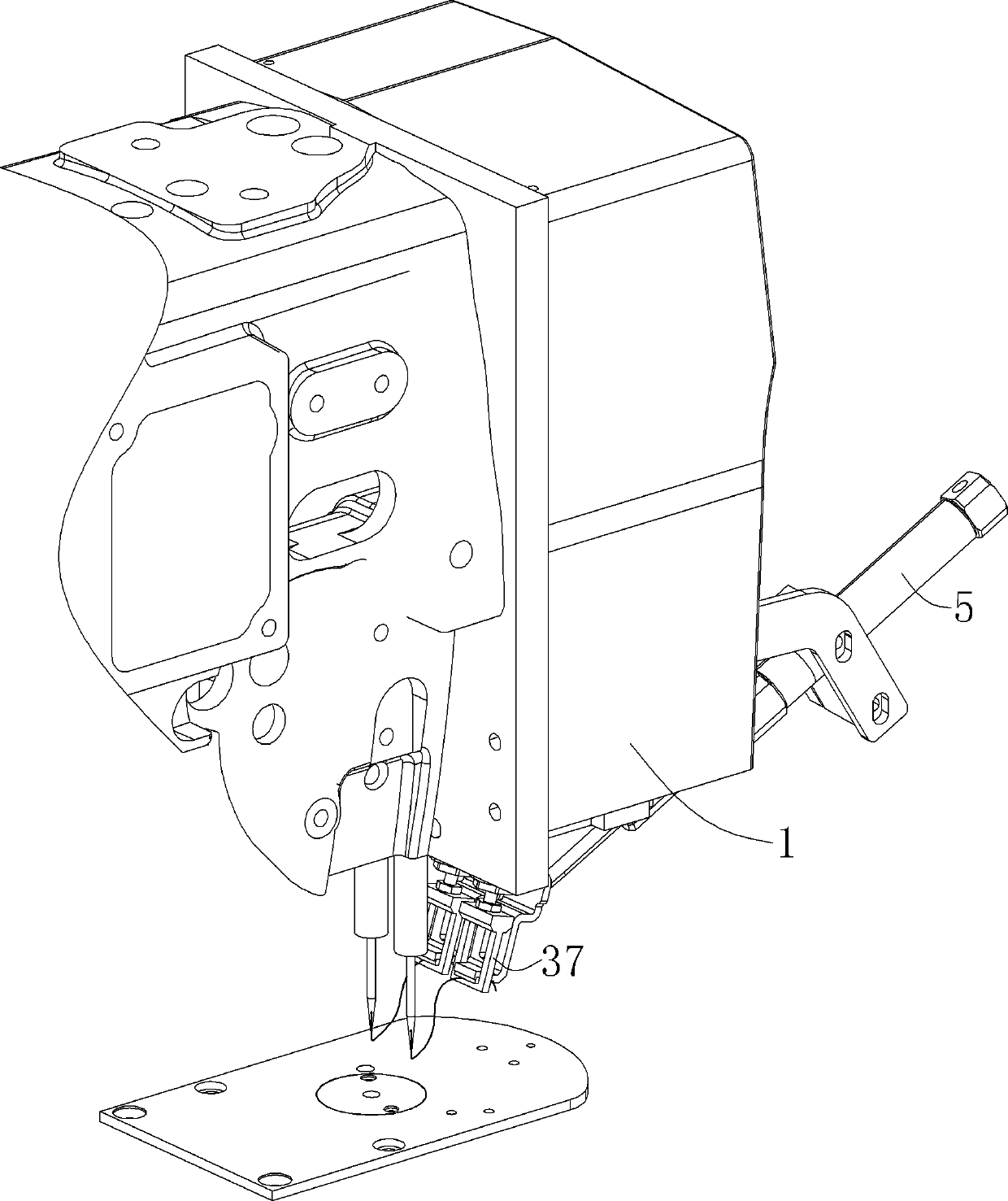

Multi-needle-bar sewing machine

The invention discloses a multi-needle-bar sewing machine. The sewing machine comprises a machine head shell and a sewing control system and is provided with an installing support fixed to the machine head shell, a positioning support, at least one switching air cylinder set fixed to the machine head shell, and a thread pulling air cylinder arranged on the machine head shell, the installing support is horizontally provided with a multi-needle-bar module composed of at least two needle bars in a sliding mode, the positioning support horizontally slides along with the multi-needle-bar module and is provided with at least two thread clamping parts used for clamping upper threads, at least two drivers capable of being independently matched with the corresponding thread clamping parts to clamp the threads are arranged on the positioning support, the switching air cylinder set is composed of at least one air cylinder, drives the multi-needle-bar module and the positioning support to horizontally slide together and makes any needle bar in the multi-needle-bar module, the corresponding thread clamping part and the corresponding driver move to the working position, and the driver in the working position can fix a thread residue to the corresponding thread clamping part after a thread is hooked by the thread pulling air cylinder.

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

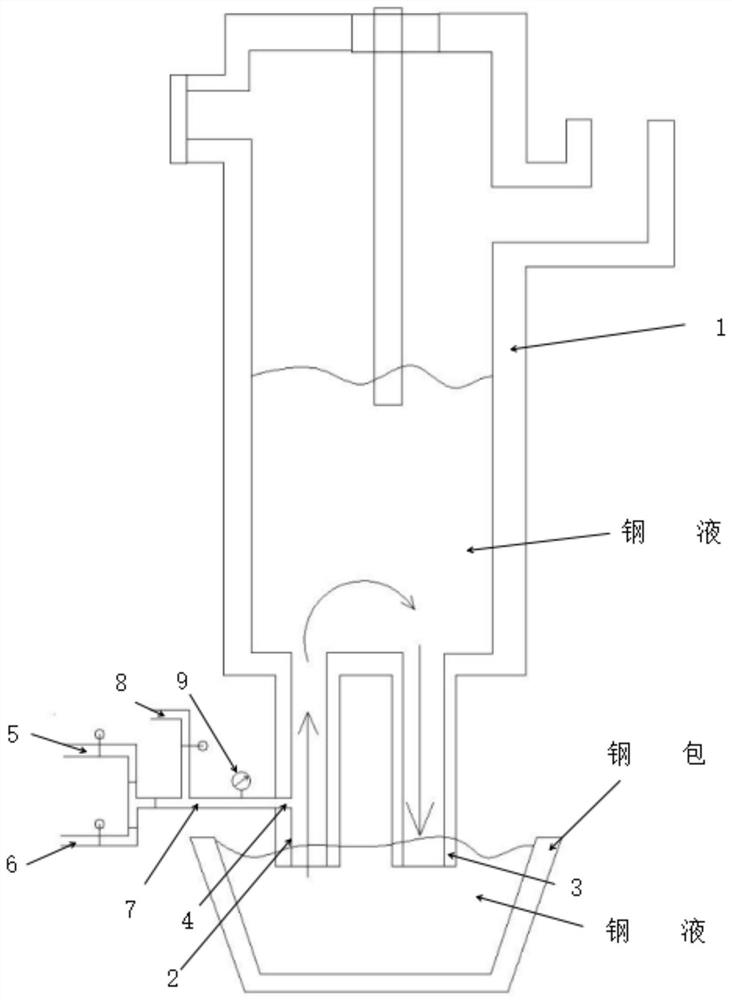

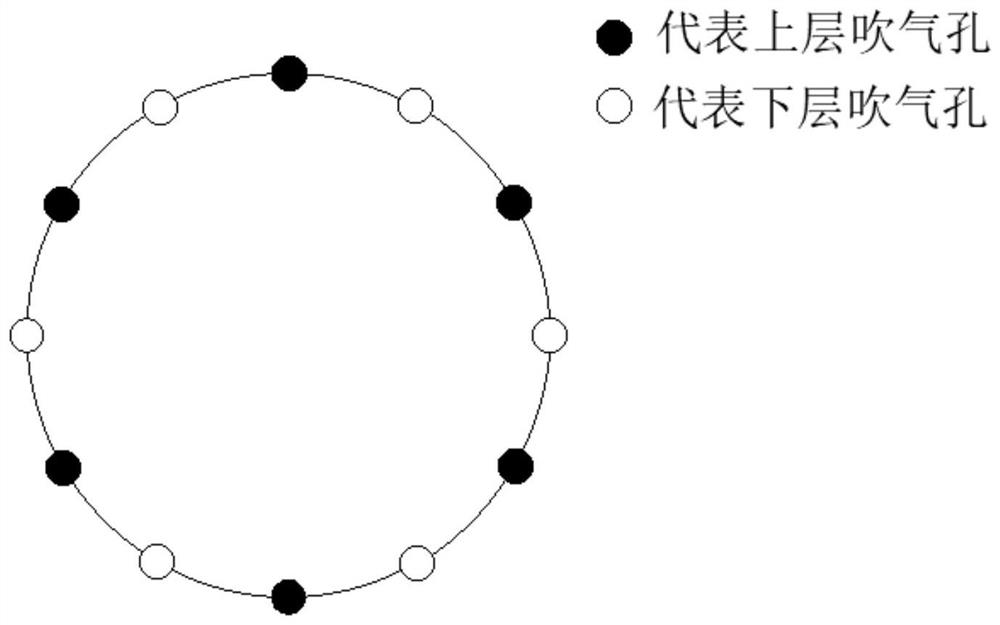

Anti-blocking device for blow hole of dip tube of RH furnace and method for removing steel slag from blow hole

PendingCN112877507AExtended service lifeEnsure circulation efficiencyProcess efficiency improvementFerrous metallurgyEngineering

The invention belongs to the field of ferrous metallurgy steelmaking, and particularly relates to an anti-blocking device for a blow hole of a dip tube of a RH furnace and a method for removing steel slag from the blow hole. By arranging an oxygen branch pipeline and a flow meter on a blow pipeline, when the blow hole in an ascending tube of the dip tube becomes smaller or is completely blocked, oxygen gas is introduced when a vacuum tank is not treated, and oxygen gas and the steel slag in the blow hole of the ascending tube of the dip pipe are subjected to oxidation reaction, so that the blocked steel slat at the blow hole of the ascending tube of the dip tube is melted, and the steel slag or molten steel is blown out of the blow hole by virtue of oxygen gas at a certain flow speed. The cleaning process is safe and efficient, is more efficient than additional reactants, is short in treatment time and lower in cost, and particularly can be used for effectively removing steel slag which is deeply blocked in the blow hole. The anti-blocking device can effectively reduce a condition that flow of the blow hole is reduced or the blow hole is completely blocked, so that the circulation effect in the service life of the dip tube is ensured, and the dip tube is prevented from being off line due to blockage.

Owner:SHANDONG IRON & STEEL CO LTD

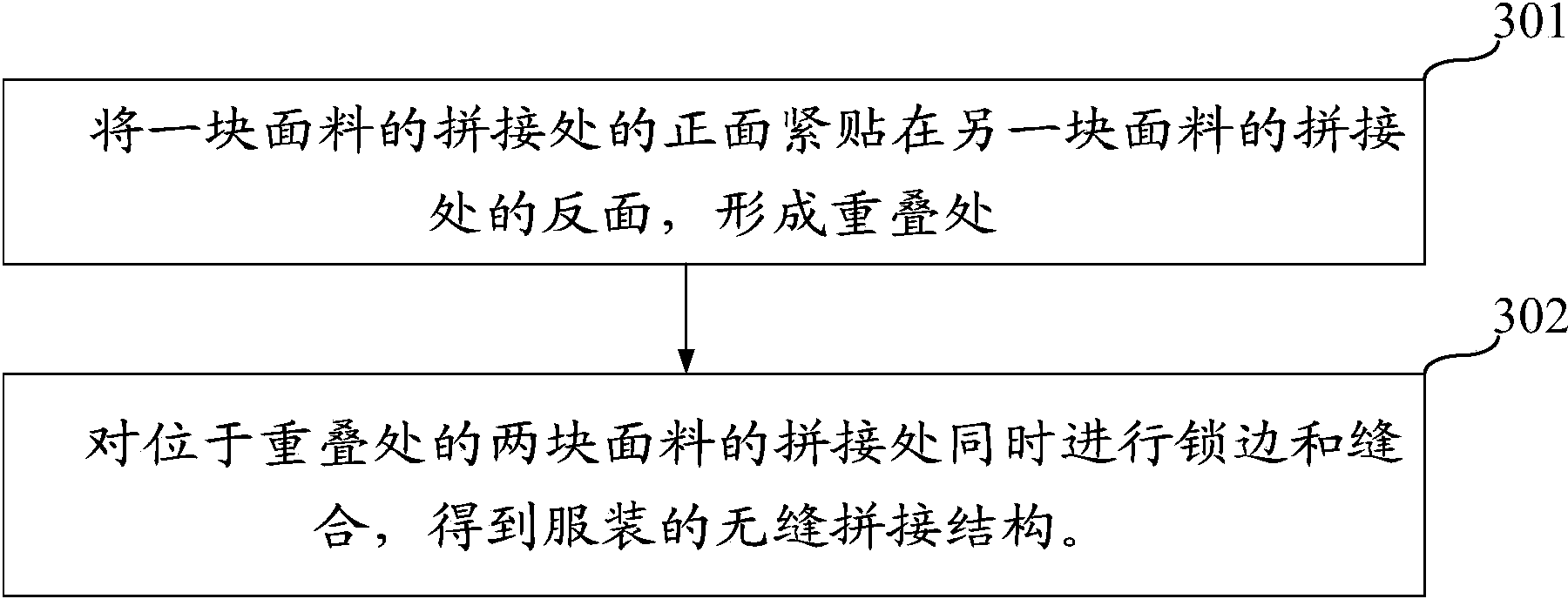

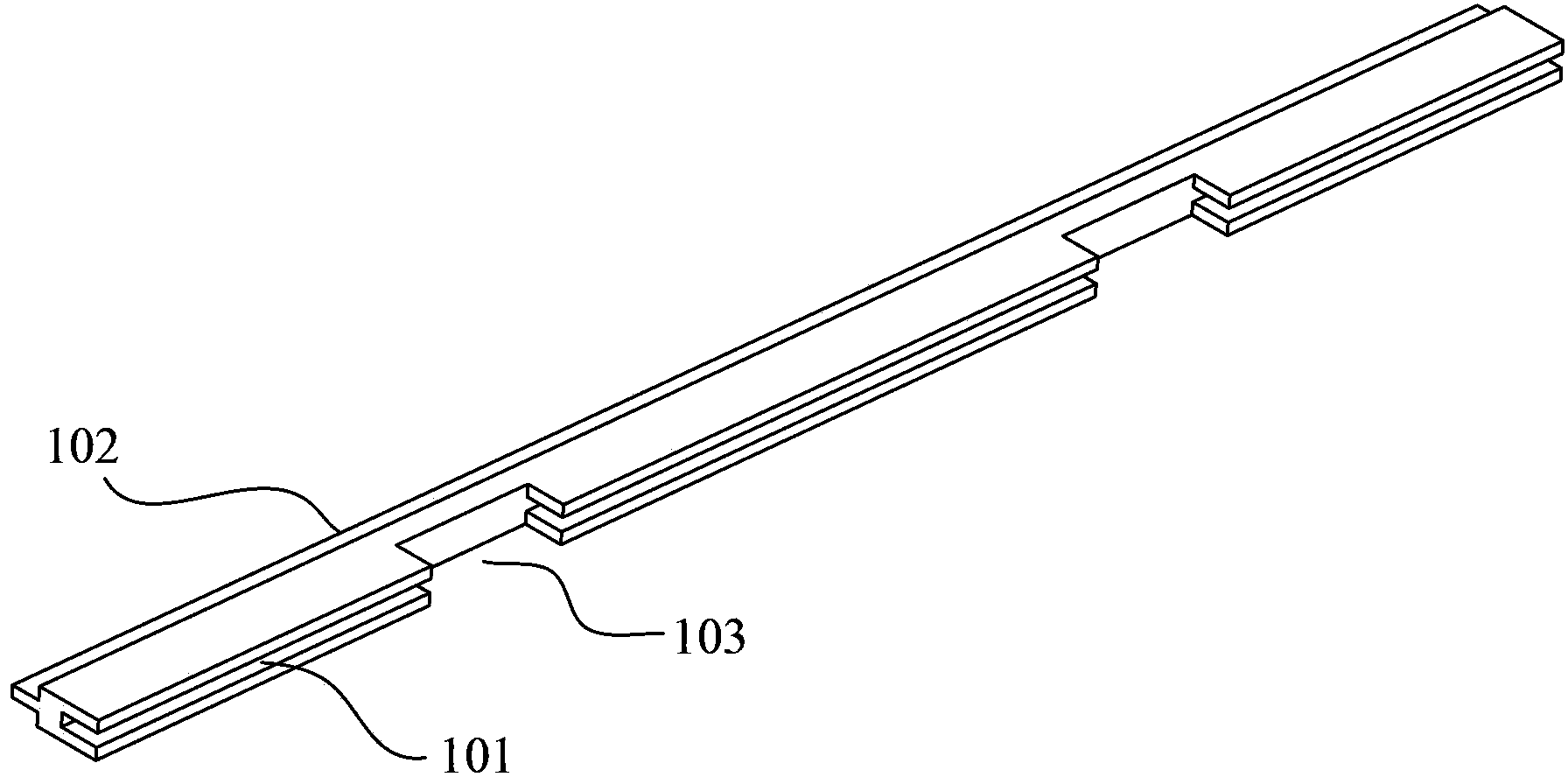

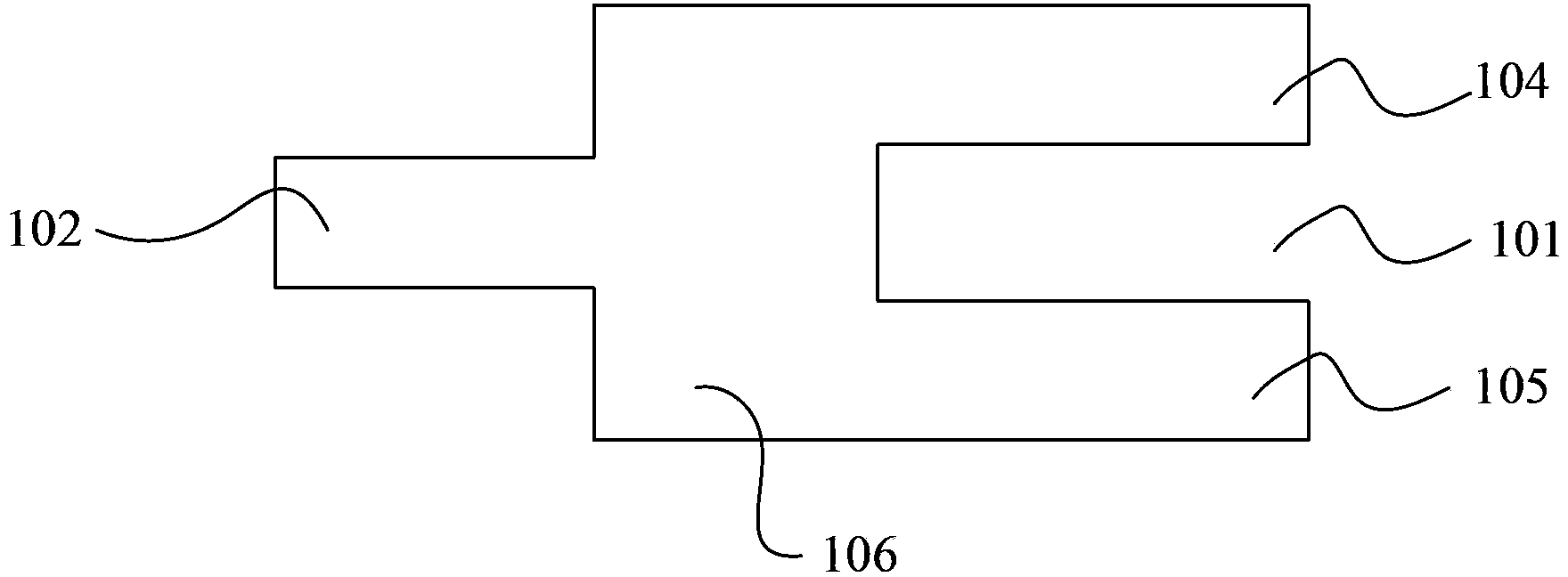

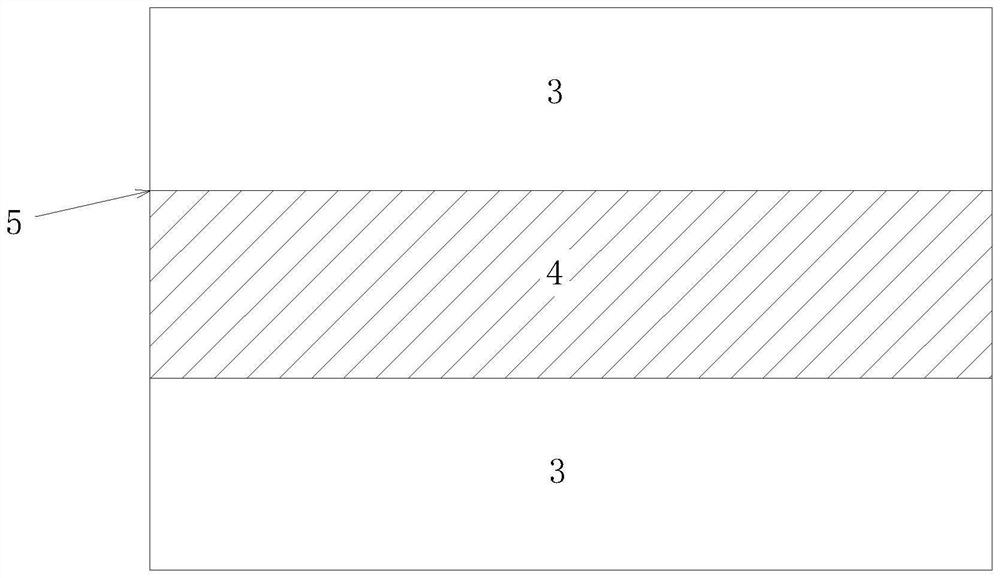

Clothing seamless splicing structure and clothing seamless splicing method

The invention relates to the field of clothing, in particular to a clothing seamless splicing structure and a clothing seamless splicing method. The clothing seamless splicing structure comprises two fabrics to be spliced, the front side of the splicing position of one fabric and the reverse side of the splicing position of the other fabric are overlapped and sewn, and overlock is arranged at the splicing positions of the two fabrics. The splicing principle is that firstly, overlapping is performed in the mode that the front side is tightly attached to the reverse side, so that a protruding overlapping portion formed when the front side is tightly attached to front side is avoided, and therefore the overlapping positions of the two fabrics are made to be smoother; secondly the splicing positions are overlocked and sewn simultaneously so that the two fabrics are connected together, and meanwhile the problem that the edges of the fabrics loose threads is avoided. Therefore, the clothing seamless splicing structure is shaped like a plane, the structure is smoother, and the clothing with the seamless splicing structure is not prone to rubbing skin while being worn next to the skin, is more comfortable to wear, and has the advantages of being firm and not prone to loosing the threads.

Owner:周剑

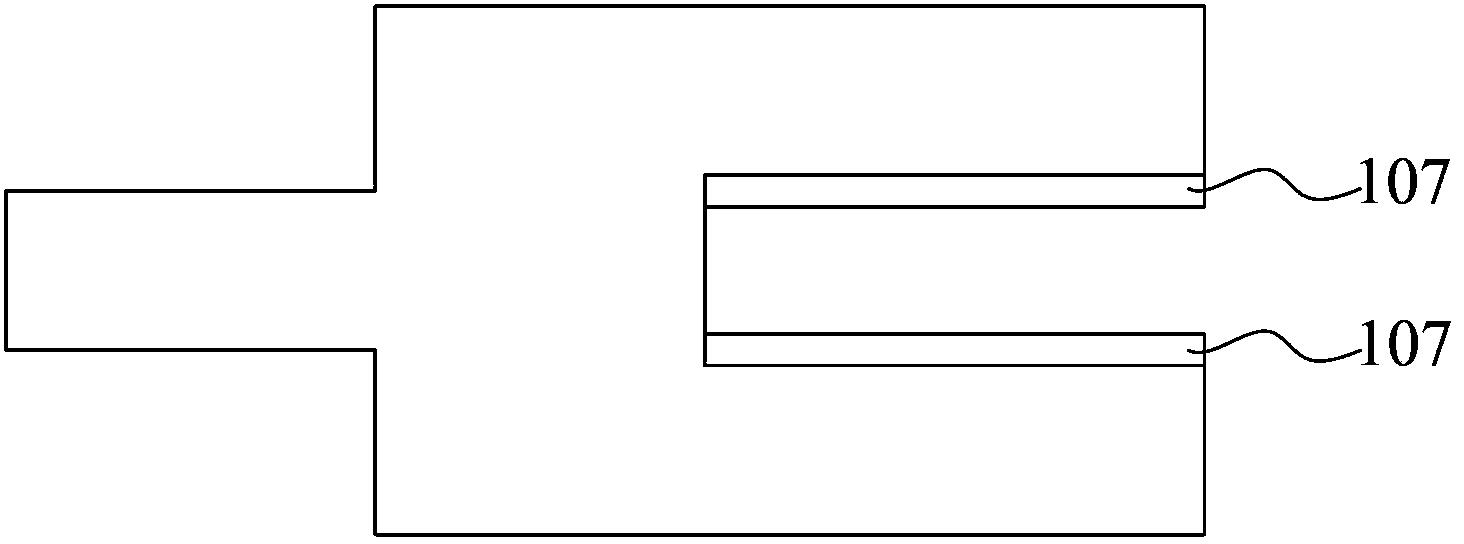

Fixing plugboard for printed circuit board

InactiveCN104349604AReduce distortionAvoid deformationPrinted circuit assemblingSolderingPrinted circuit board

The invention discloses a fixing plugboard for a printed circuit board. The fixing plugboard comprises a plugboard body, the plugboard body is provided with a slot, and the width of the slot is adaptive to the thickness of the printed circuit board. According to the fixing plugboard for the printed circuit board, provided by the invention, the plugboard body is provided with the slot for clamping the printed circuit board, when the printed circuit board passes through a peak furnace, the fixing plugboard is pressed to at least one side of the printed circuit board, the slot of the fixing plugbaord and the edge of the printed circuit board cooperate in a clamping mode so as to be fixed together, thus deformation is reduced. Before furnace operation, the fixing plugboard is pressed to the at least one side of the printed circuit board, the printed circuit board can be fixed, deformation due to heating of the printed circuit board is prevented, the risk of falling off from the conveying track of the peak furnace is avoided, and the risk of fusion soldering tin rushing to the top surface of the printed circuit board is also avoided, such that the problem that a lot of printed circuit boards are took out from a production line is prevented, and the quality of the printed circuit board and the production efficiency are improved.

Owner:GREE ELECTRIC APPLIANCES INC

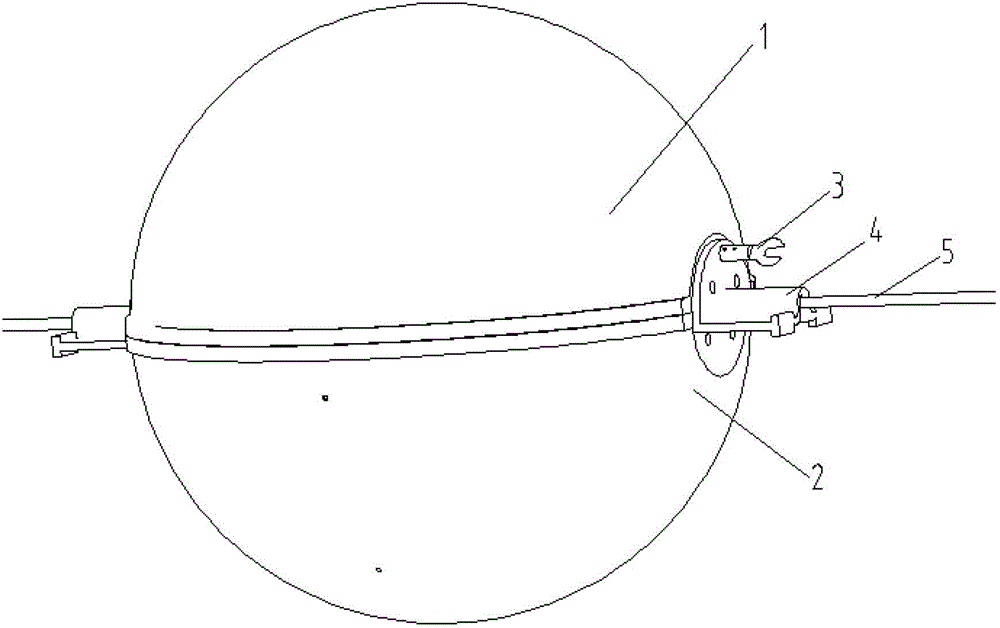

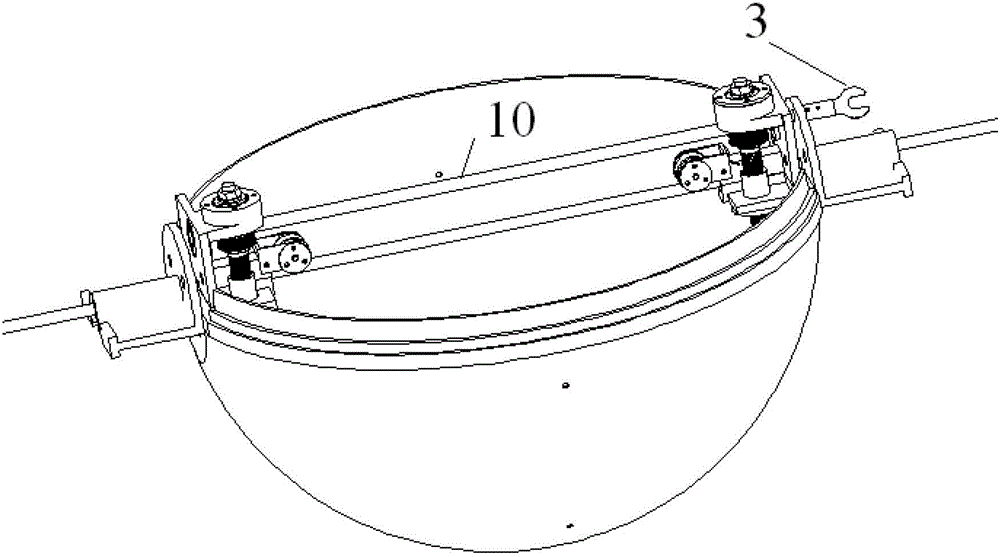

Aeronautical marker sphere

ActiveCN102982631AAvoid the technical difficulty of precise alignmentImplement automatic installationOverhead installationVisible signalling systemsAviationLocking mechanism

The invention discloses an aeronautical marker sphere which comprises a spherical thin-wall housing, two locking mechanisms, travelling wheels, interface racks and a rotating joint, wherein the spherical thin-wall housing is divided into an upper semisphere and a lower semisphere; the interface racks are arranged at the two ends of the spherical thin-wall housing; the two locking mechanisms are arranged on a central axis of the spherical thin-wall housing; the travelling wheels are mounted on the locking mechanisms; the locking mechanisms are connected by a worm shaft; one side of the worm shaft is connected with the rotating joint; and the aeronautical marker sphere locks the sphere on a power transmission cable by rotating the rotating joint. The aeronautical marker sphere has the characteristics that the aeronautical marker sphere is convenient to mount and disassemble, simple in structure, high in automation degree and low in mounting cost.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

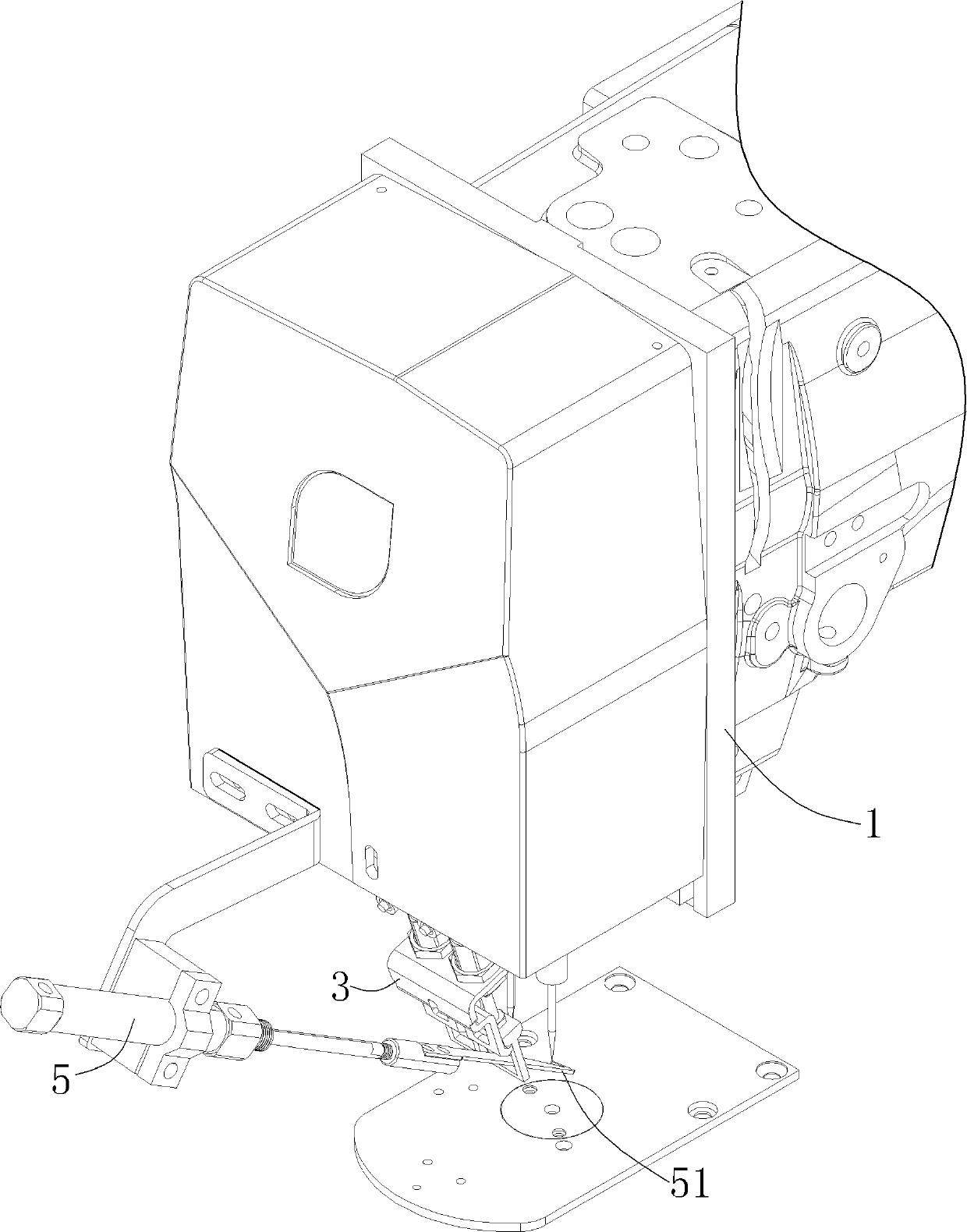

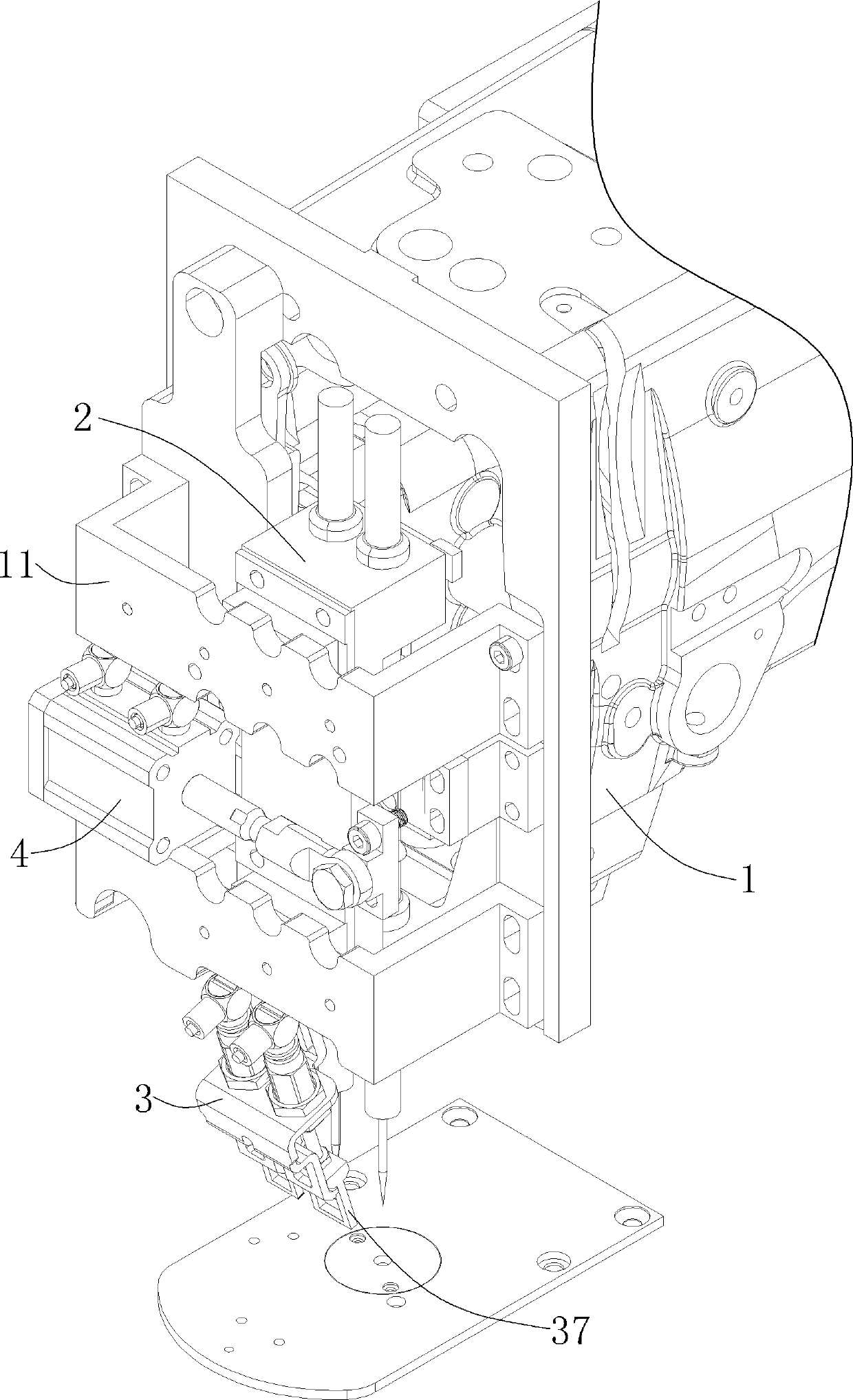

Mechanism for achieving tight stitching and variable needle gauge reinforcement and achievement method thereof

The invention relates to the technical field of stitching, in particular to a mechanism for achieving tight stitching and variable needle gauge reinforcement and an achievement method thereof. According to the method, micro needle gauge reinforcement can be achieved when stitching starts or ends, and it is prevented that a thread residue comes out of a stitching material after trimming, so that amark of reinforced stitching on the stitching material is shortened, a nest on the stitching material is prevented to a certain degree, tight stitching can be achieved, and accordingly convenience ofequipment operation and maintenance is improved. According to the technical scheme, an electromagnetic baffle is provided and connected with an installation supporting frame, a reset spring is arranged on a limiting pin in a sleeving mode, the limiting pin is arranged in a guiding hole of a limiting guiding block, an electromagnet is arranged on the rear end surface of the limiting guiding block,the limiting guiding block is arranged on the installation supporting frame through a side surface installation hole, a limiting sliding block is arranged in a top kidney-shaped hole in a limiting connecting rod, the limiting connecting rod is arranged on a needle gauge base through a top connecting hole, the lower end of the limiting connecting rod is connected with a back stitch connecting rod assembly, and the back stitch connecting rod assembly is connected with a back stitching electromagnet through a connecting hole in the lower end of the back stitch connecting rod assembly.

Owner:XIAN TYPICAL IND

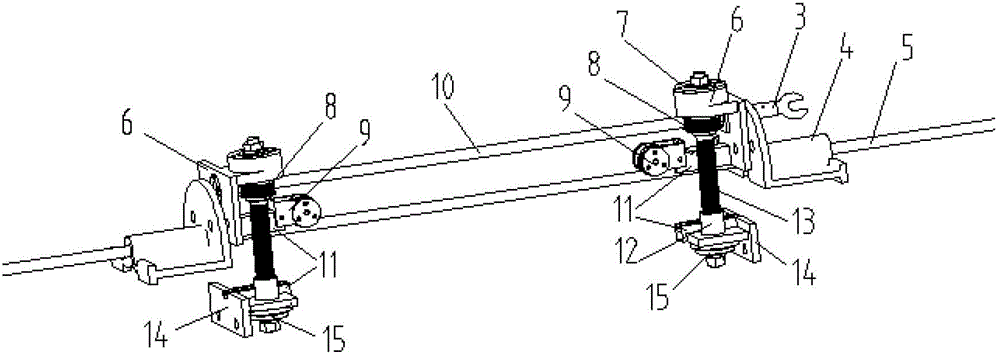

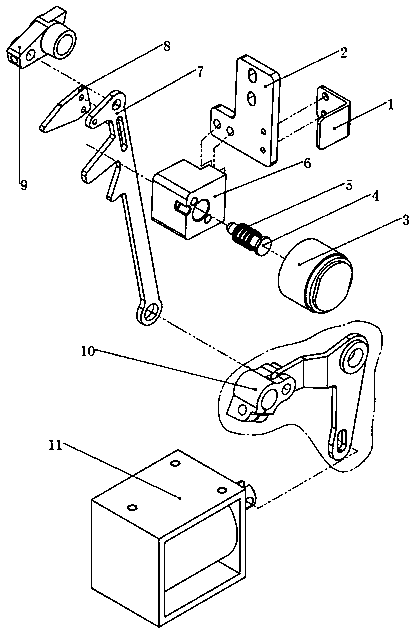

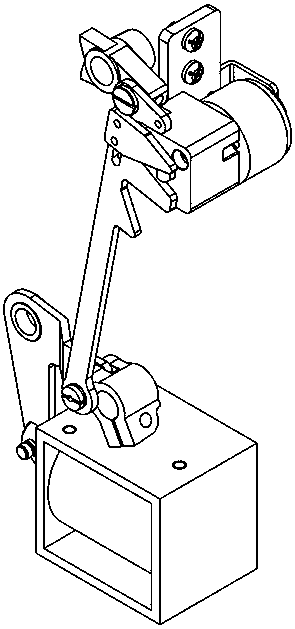

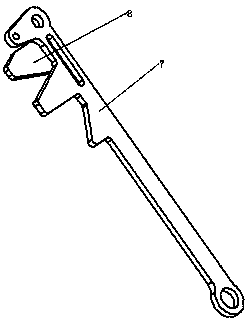

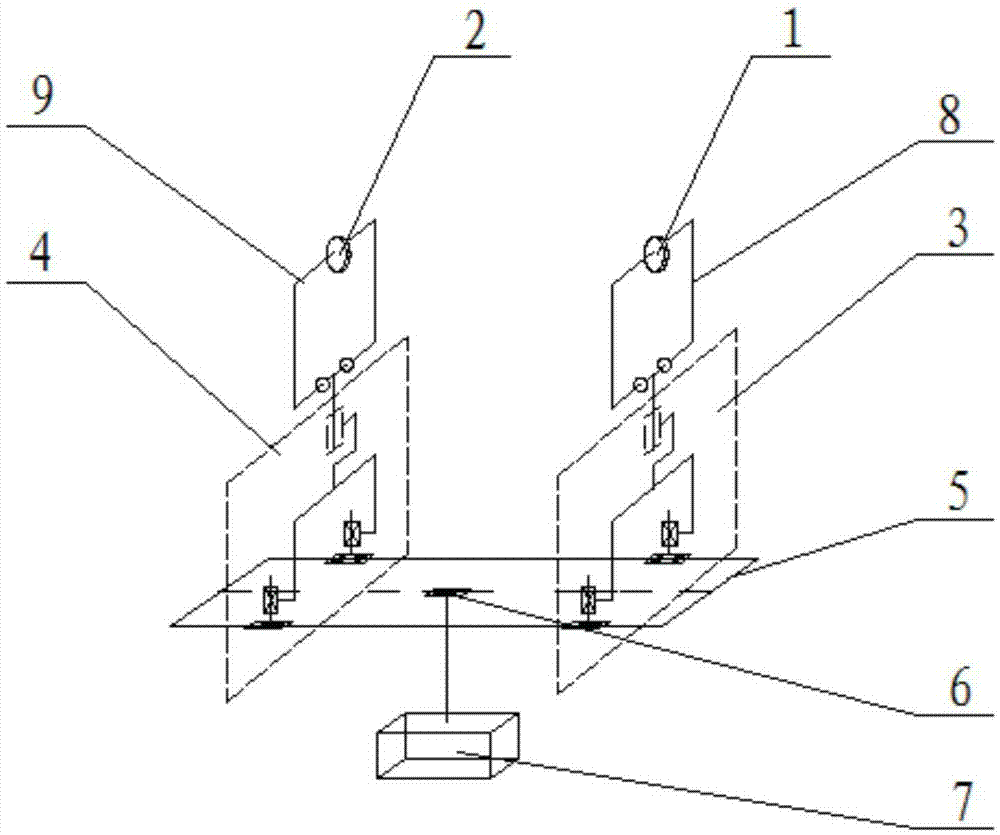

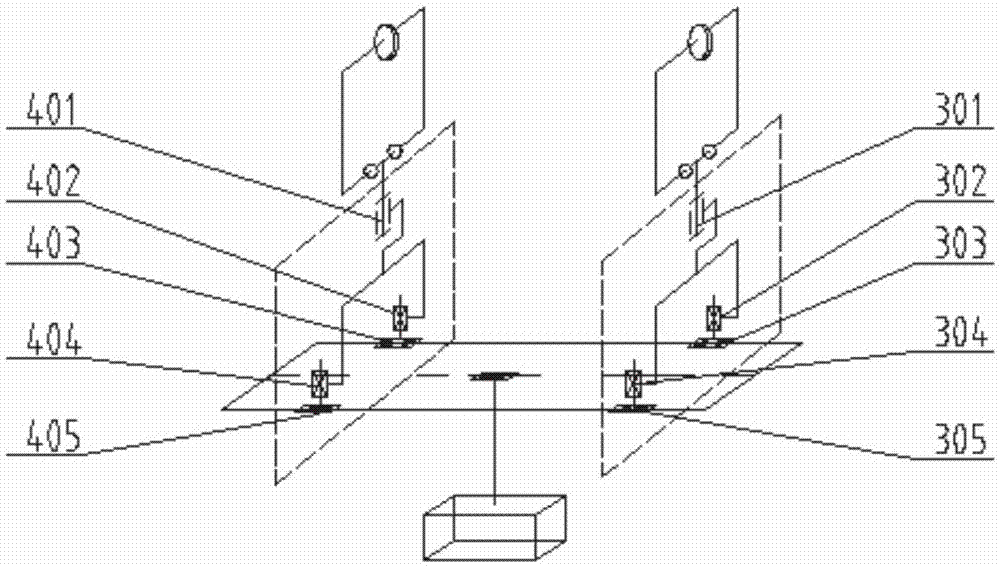

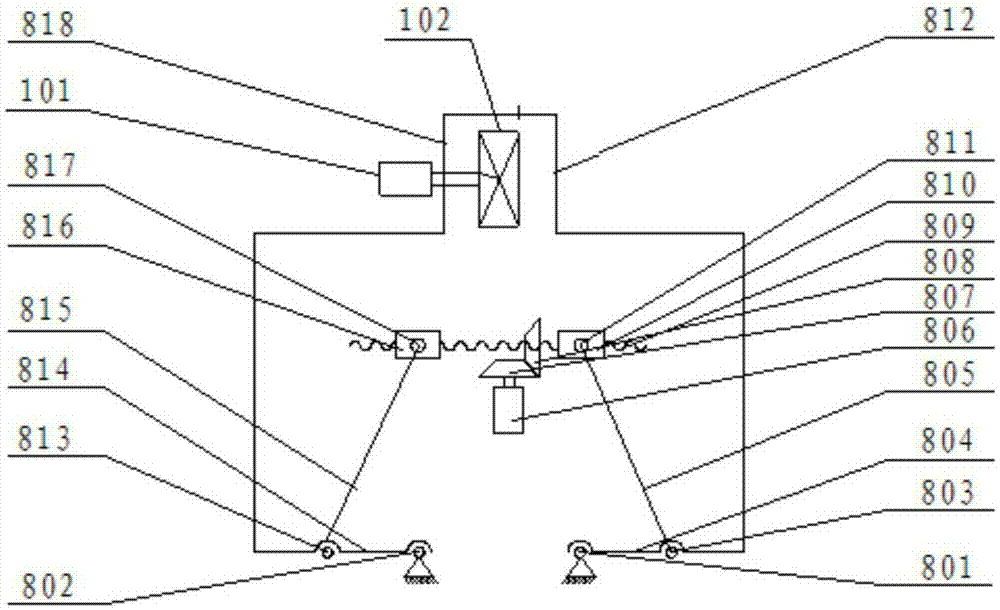

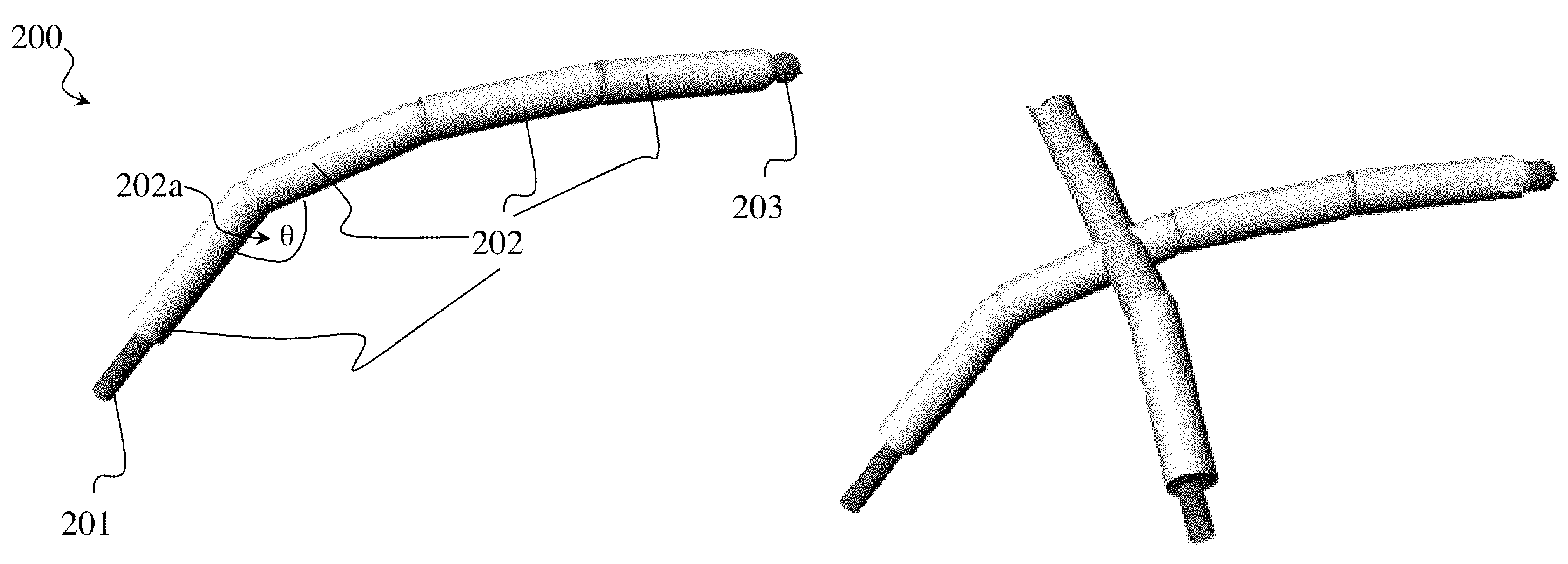

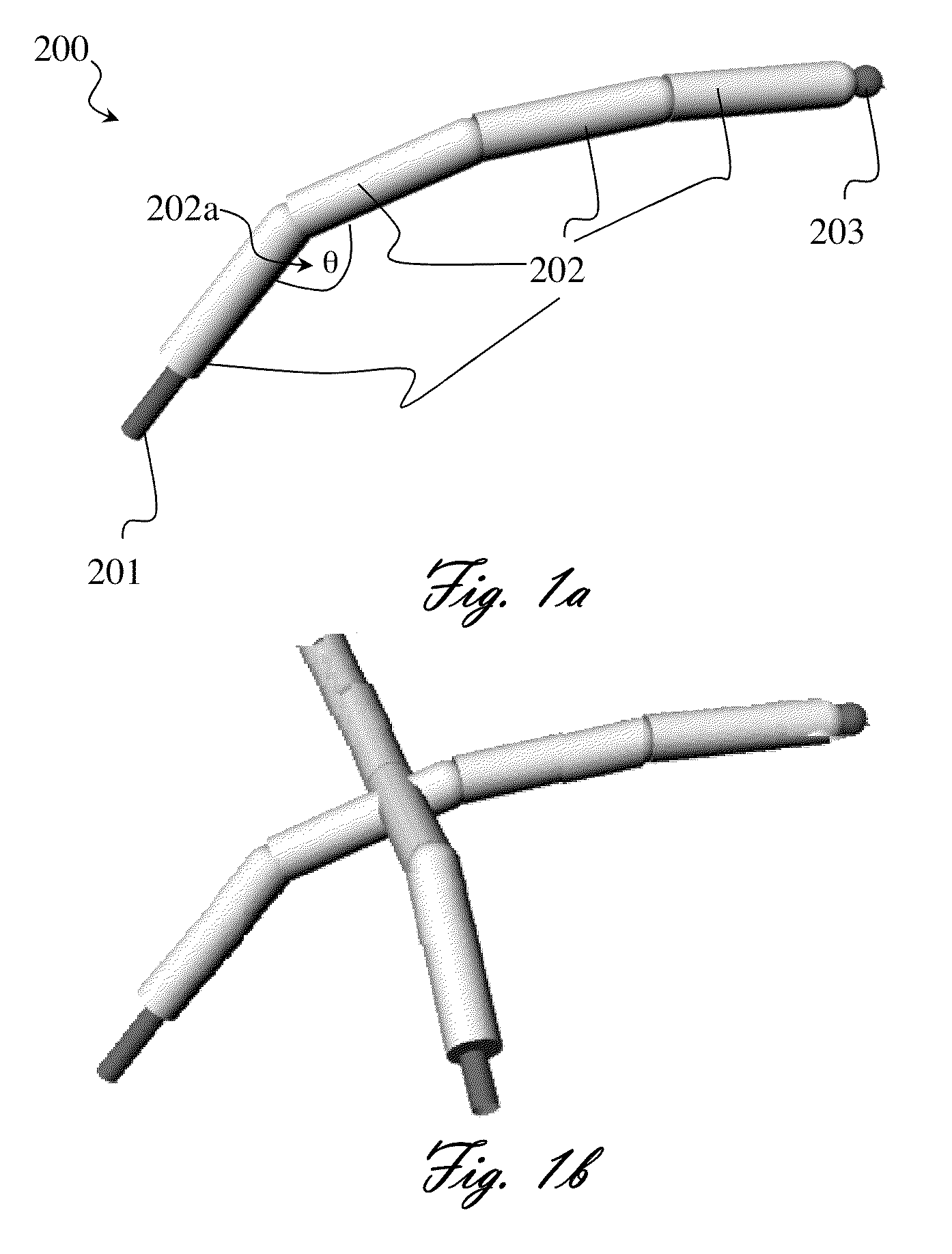

Inspection robot mechanism

ActiveCN106898966AHas the function of walking along the lineCapable of crossing barriersApparatus for overhead lines/cablesMechanical engineeringObstacle crossing

The invention relates to a mobile robot mechanism, and particularly relates to an inspection robot mechanism applicable to narrow inspection operation space. The inspection robot mechanism comprises a front walking mechanism, a rear walking mechanism, a front arm, a rear arm, a front opening and closing mechanism, a rear opening and closing mechanism, a guide rail and a box body, wherein the box body is arranged below the guide rail and is in sliding connection with the guide rail; the front arm and the rear arm are arranged above the guide rail and are in sliding connection with the guide rail; the front opening and closing mechanism and the rear opening and closing mechanism are respectively hinged at the tail ends of the front arm and the rear arm; the front walking mechanism and the rear walking mechanism are respectively arranged on the front opening and closing mechanism and the rear opening and closing mechanism; and the inspection robot mechanism walks on a transmission line through the front walking mechanism and the rear walking mechanism, and inspection operation is carried out. The inspection robot mechanism has the advantages of strong obstacle crossing ability, little operation space and good safety protection.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

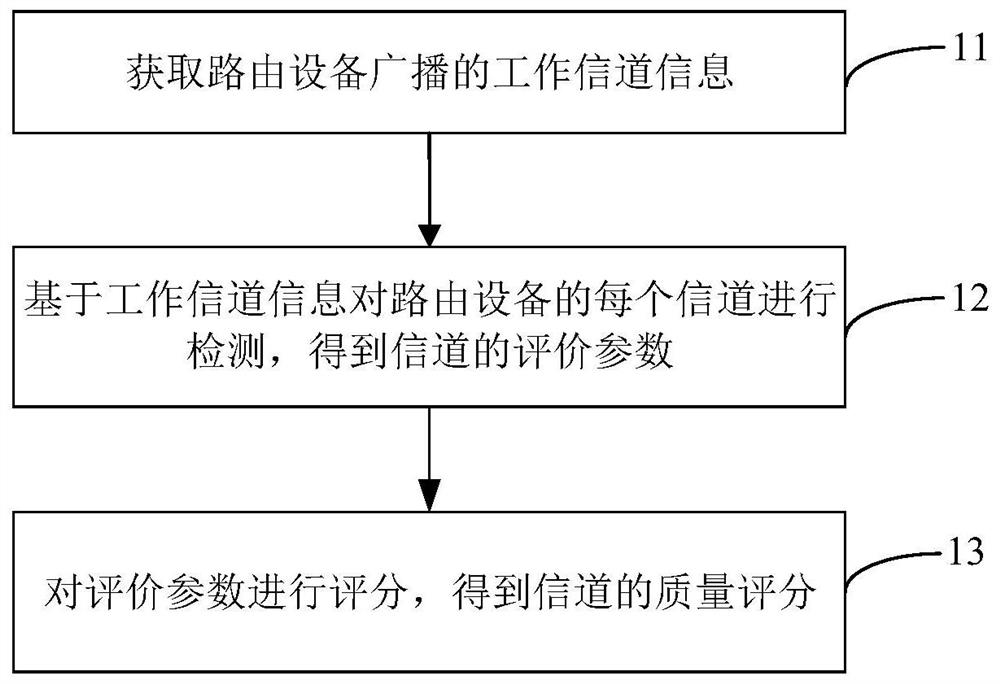

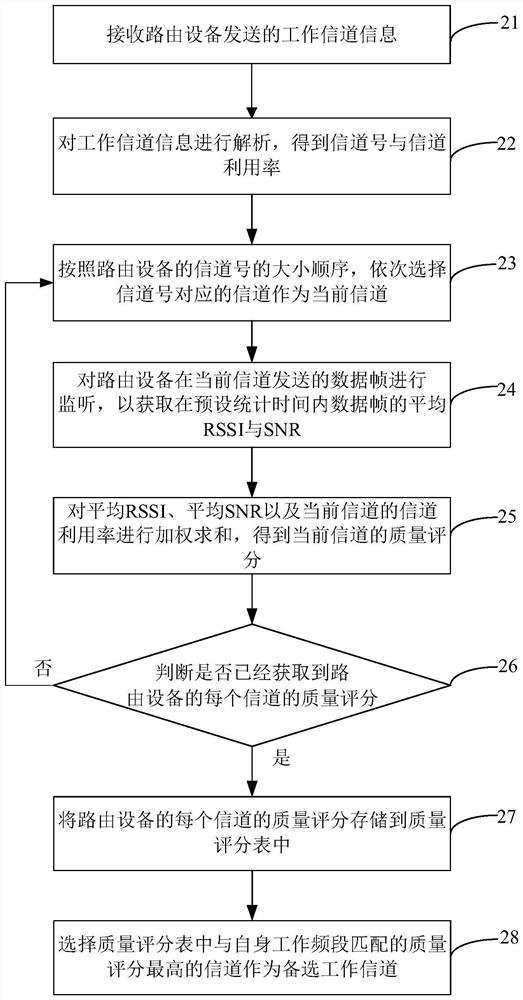

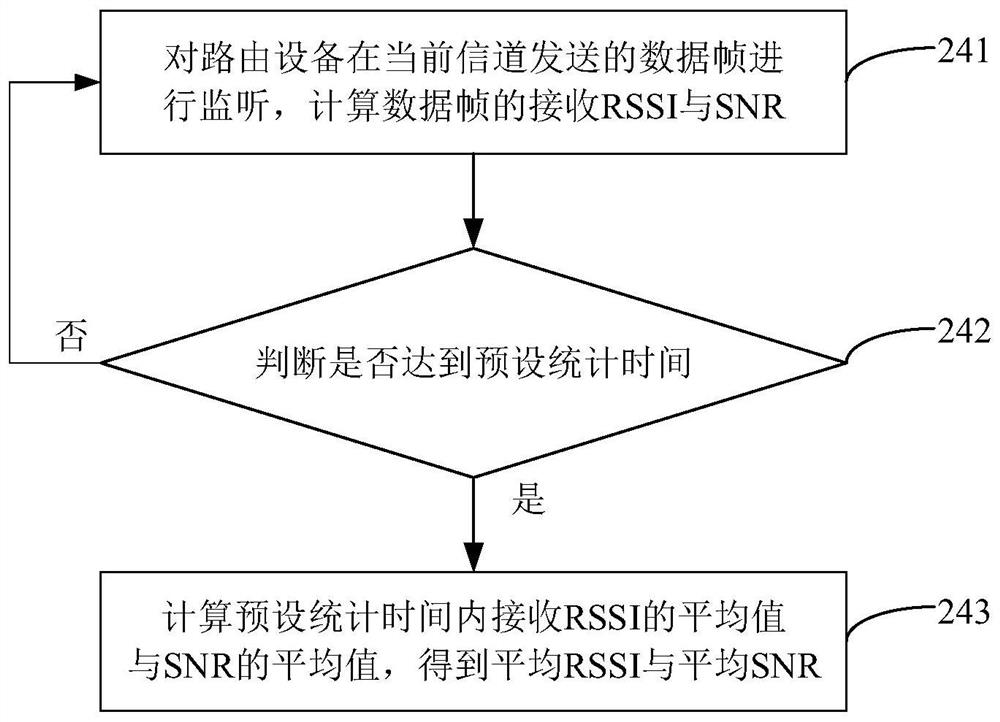

Link quality judgment method, network camera and readable storage medium

ActiveCN113114521ASolve the problem that the quality judgment takes a long timePrevent offlineTransmission monitoringData switching networksEngineeringData mining

The invention discloses a link quality judgment method, a network camera and a computer readable storage medium. The method comprises the following steps: acquiring working channel information broadcasted by routing equipment; detecting each channel of the routing equipment based on the working channel information to obtain evaluation parameters of the channels; and scoring the evaluation parameters to obtain a quality score of the channel. According to the method, the link quality can be quickly and accurately judged.

Owner:ZHEJIANG DAHUA TECH CO LTD

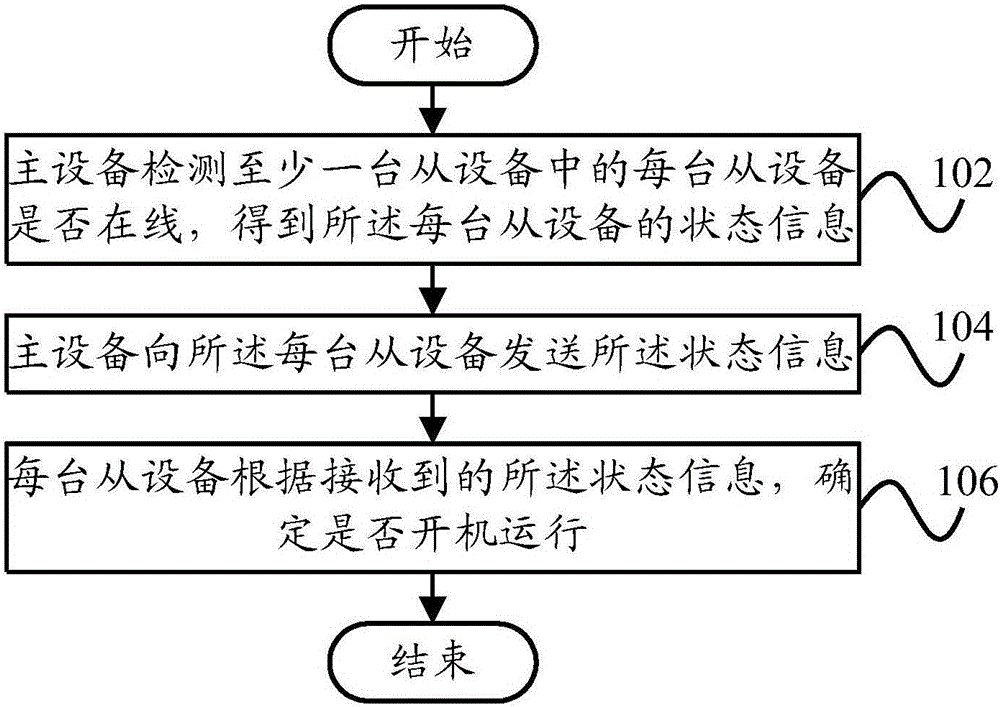

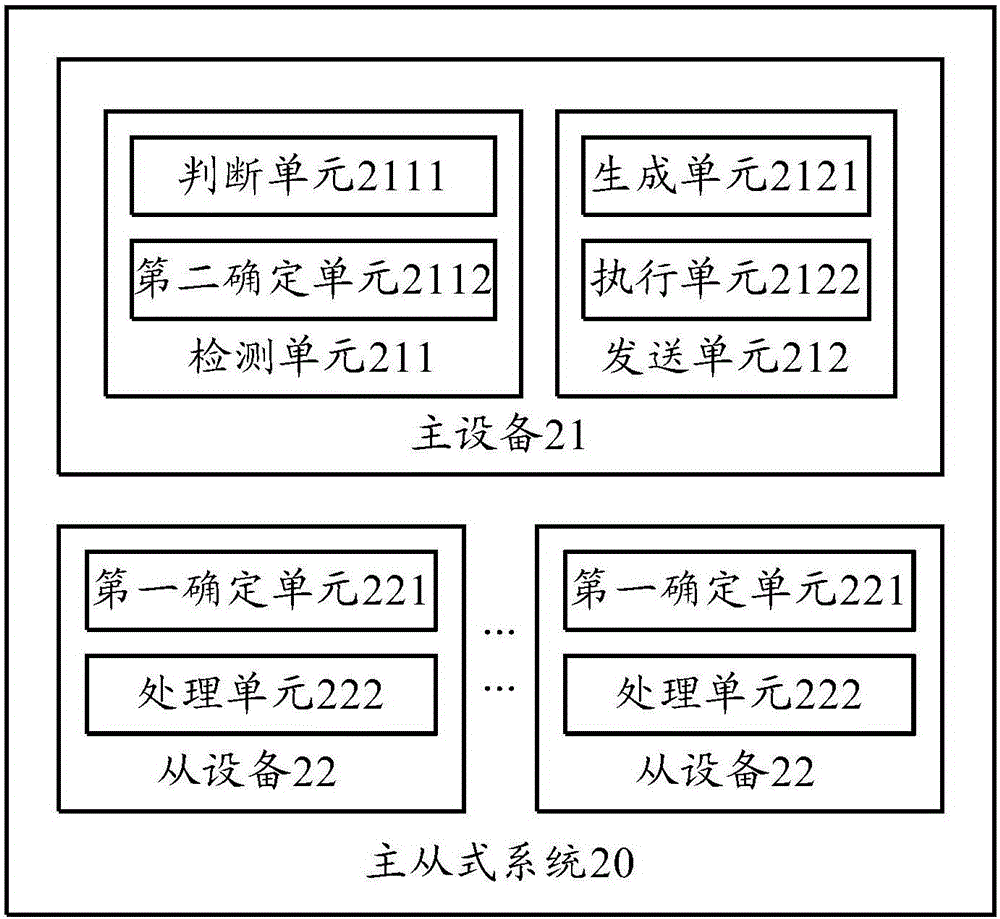

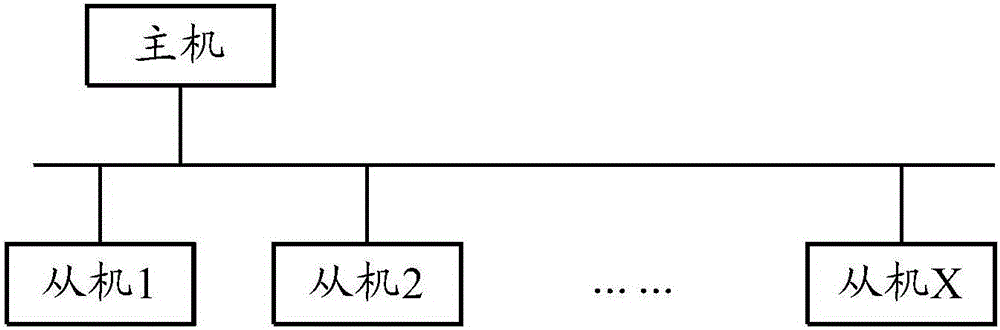

Method for processing communication failures in master-slave system and master-slave system

ActiveCN105721172APrevent offlineGuaranteed to workSubstation remote connection/disconnectionProcess communicationComputer engineering

The invention provides a method for processing communication failures in a master-slave system and the master-slave system. The master-slave system comprises master device and slave device. The method comprises the following steps: detecting, by the master device, whether each slave device is online, so as to obtain state information of each slave device; sending the state information to each slave device by the master device; and determining, by each slave device, whether each slave equipment is started to be operated according to the received state information. According to the technical scheme, the slave device in the master-slave system can take the detection result of the master device as basis to determine whether the slave device is started to be operated, so that when the sending of the slave device is invalid, the slave device cannot be automatically started to be operated and then the normal work of the master-slave system can be ensured.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

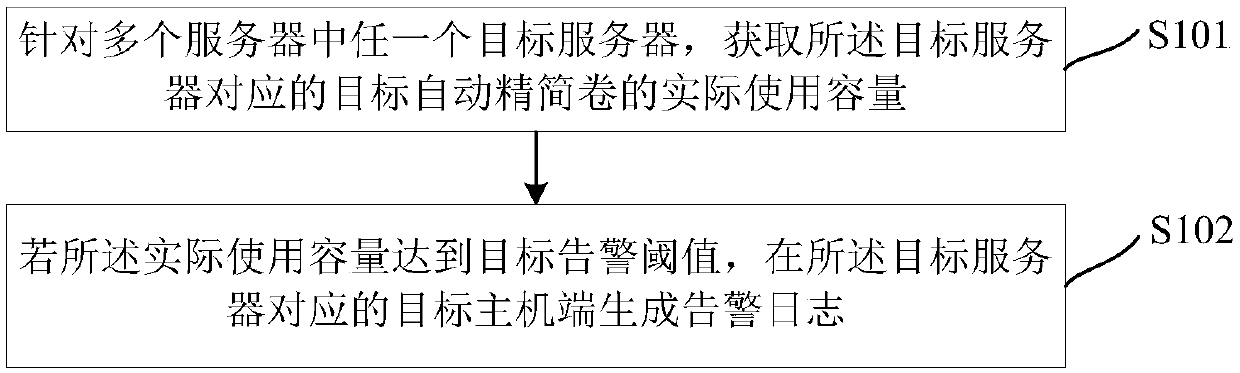

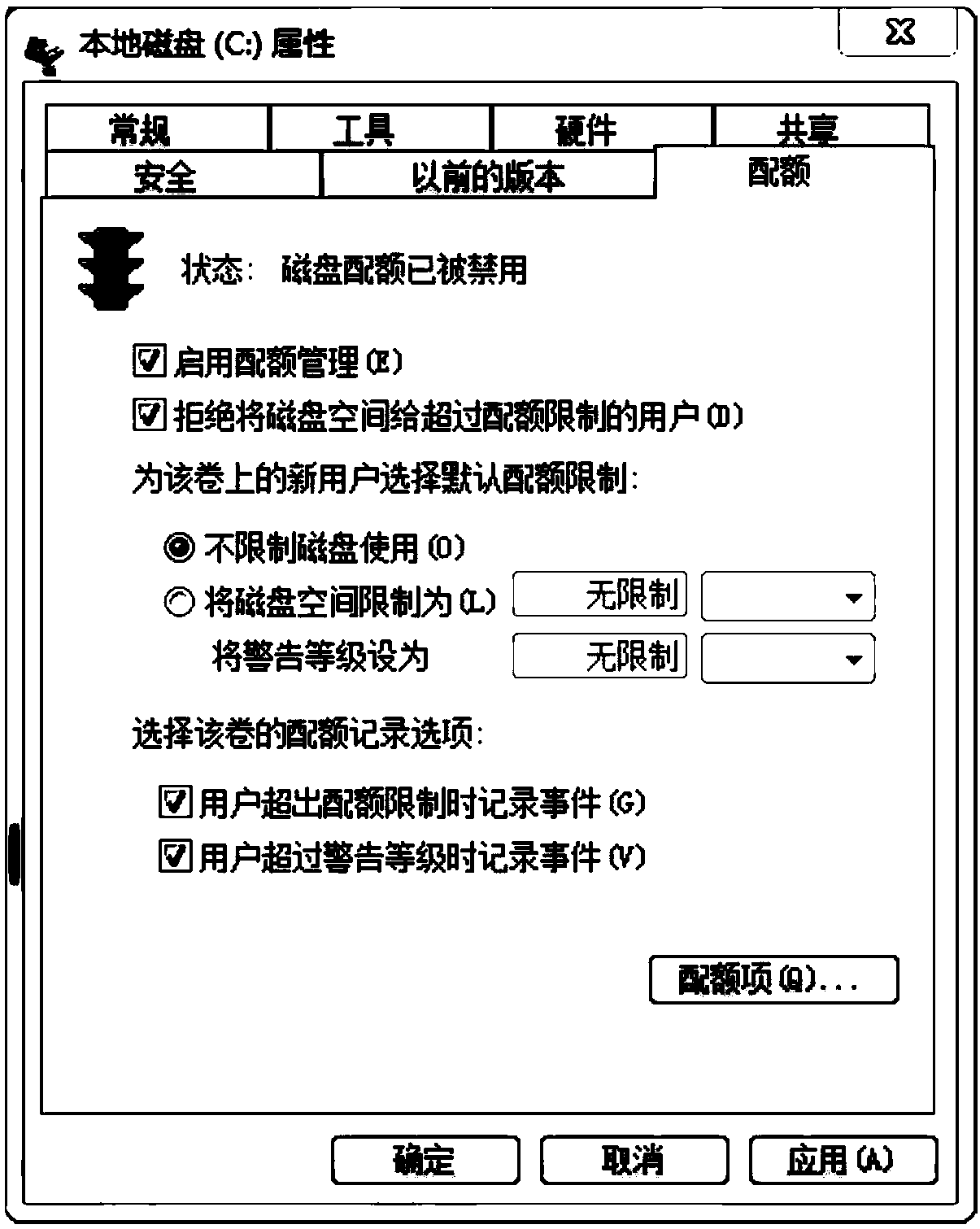

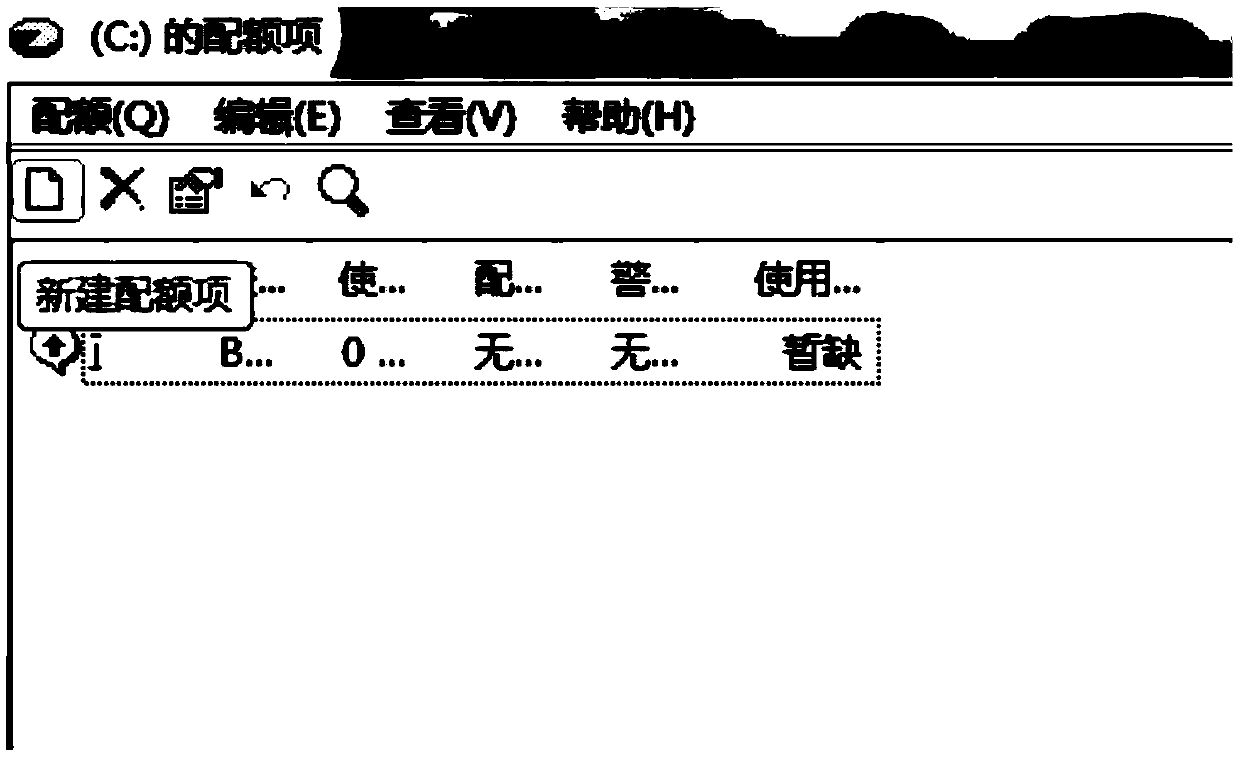

Information prompting method and device

An information prompting method and device are disclosed in embodiments of that present application, the method is applied to a storage system, the storage system is connected with a plurality of servers, Each server has corresponding automatic reduced volume, preset preset capacity of each automatic reduced volume, for any one of a plurality of servers, in the process of using the capacity of theautomatic reduced volume by the target server, obtaining the actual capacity of the target automatic reduced volume corresponding to the target server; If the actual usage capacity reaches the targetalarm threshold, an alarm log is generated at the target host end corresponding to the target server. Because the alarm log is generated on the target host, The target host terminal is user-oriented,and the user will often operate at the target host terminal. Therefore, the user can timely view the alarm log of the target host terminal, so as to promptly remind the user to expand the storage pool, avoid the storage system offline due to the exhaustion of the storage pool capacity, and ensure the business continuity.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

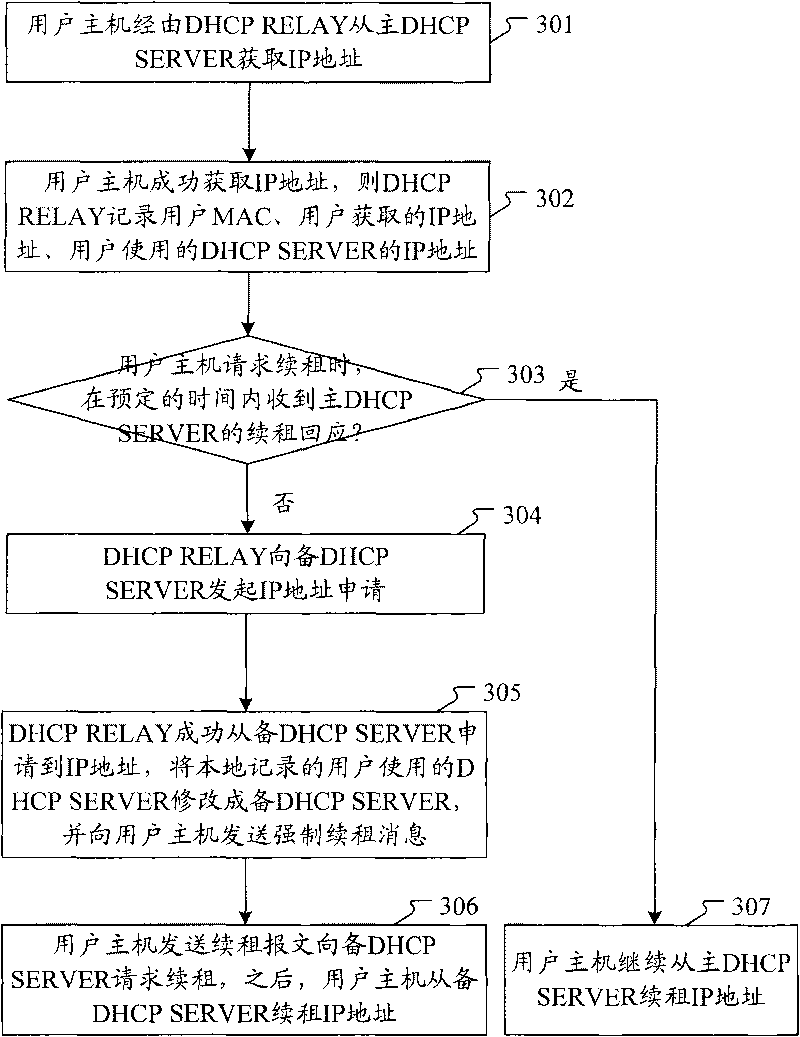

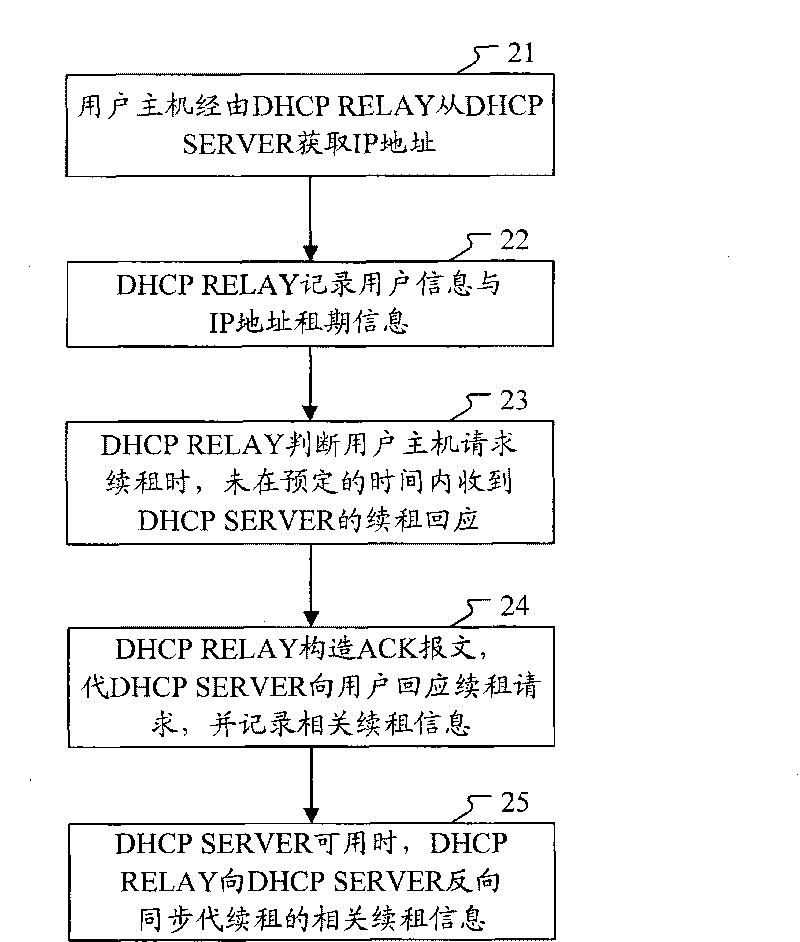

Method and system for backing up DHCP SERVER

InactiveCN101729610AImprove user satisfactionRelieve stressData switching networksUser satisfactionIp address

The invention discloses a method for backing up a dynamic host configuration protocol server (DHCP SERVER), which comprises that: a user host acquires an IP address from the DHCP SERVER through a dynamic host configuration protocol delay (DHCP DELAY); when the user host requests for reletting and does not receive a reletting response of the DHCP SERVER, the DHCP DELAY responds to the reletting request of a user and records related reletting information; and when the DHCP SERVER is available, the DHCP DELAY sends the reletting information to the DHCP SERVER for synchronization. The invention also correspondingly discloses a system for backing up the DHCP SERVER. The user host does not need waiting to apply for the IP address again until the DHCP SERVER is available, and can continue using the previous IP address, so the method and the system can avoid off line of users due to the fault of the DHCP SERVER, improve the satisfaction of the users, and relieve the pressure of network equipment due to on line again of the users together.

Owner:ZTE CORP

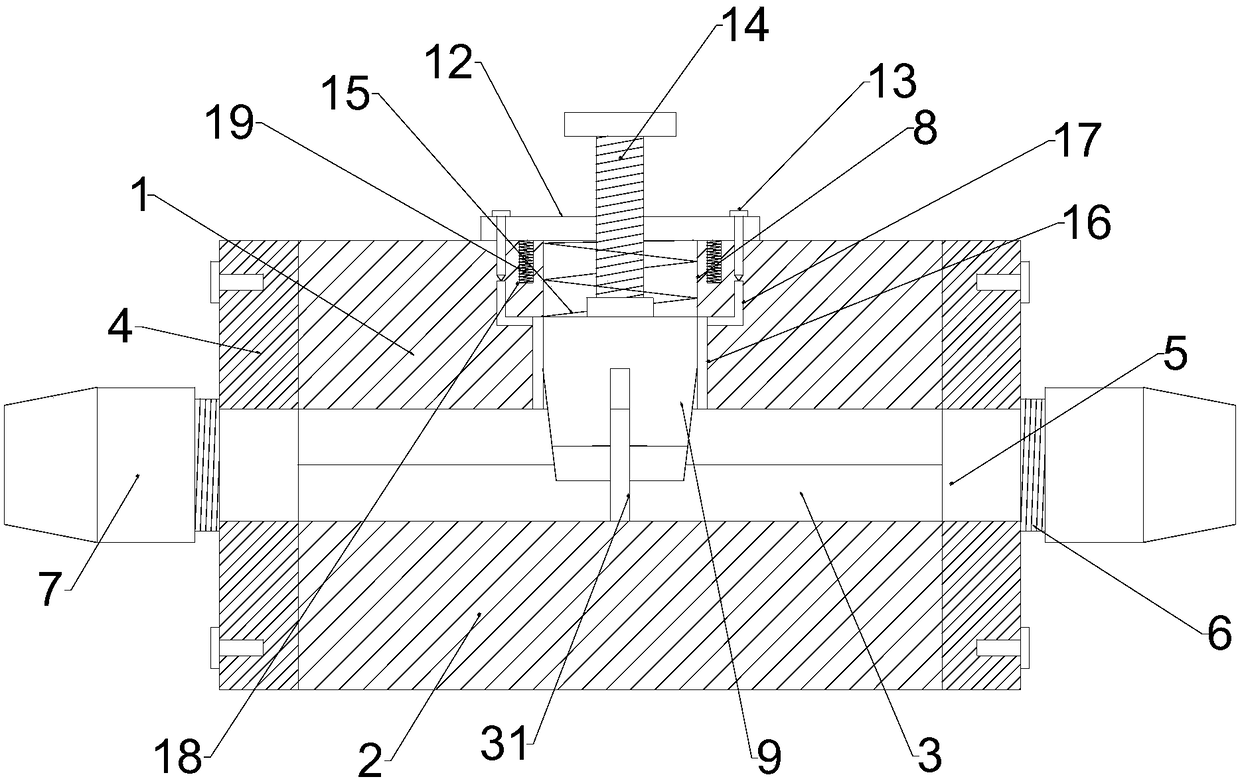

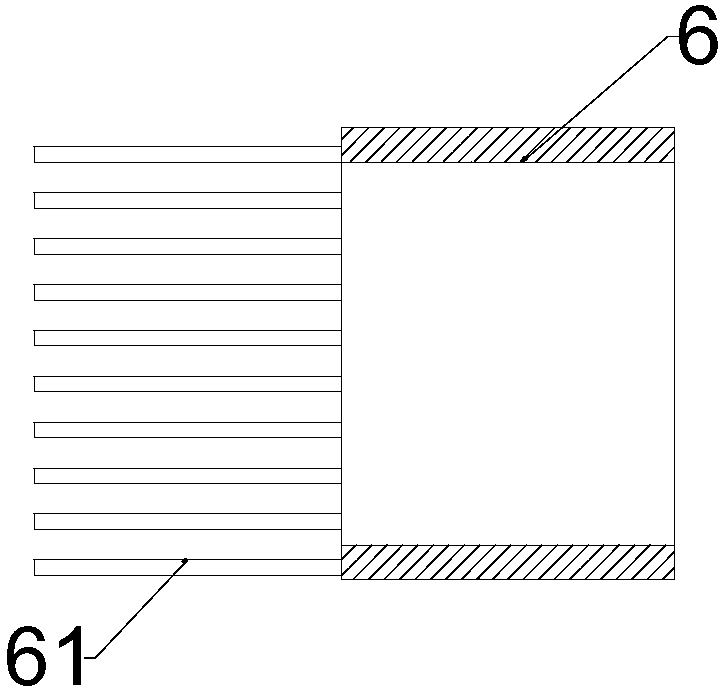

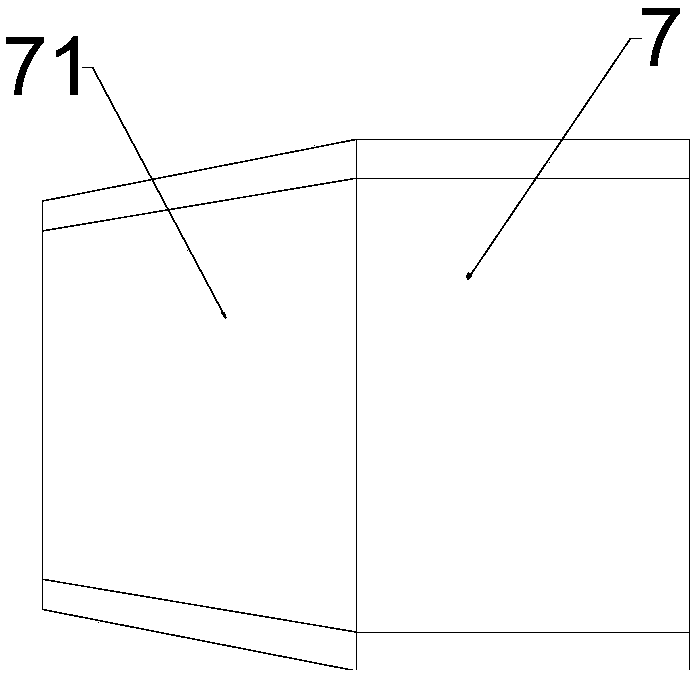

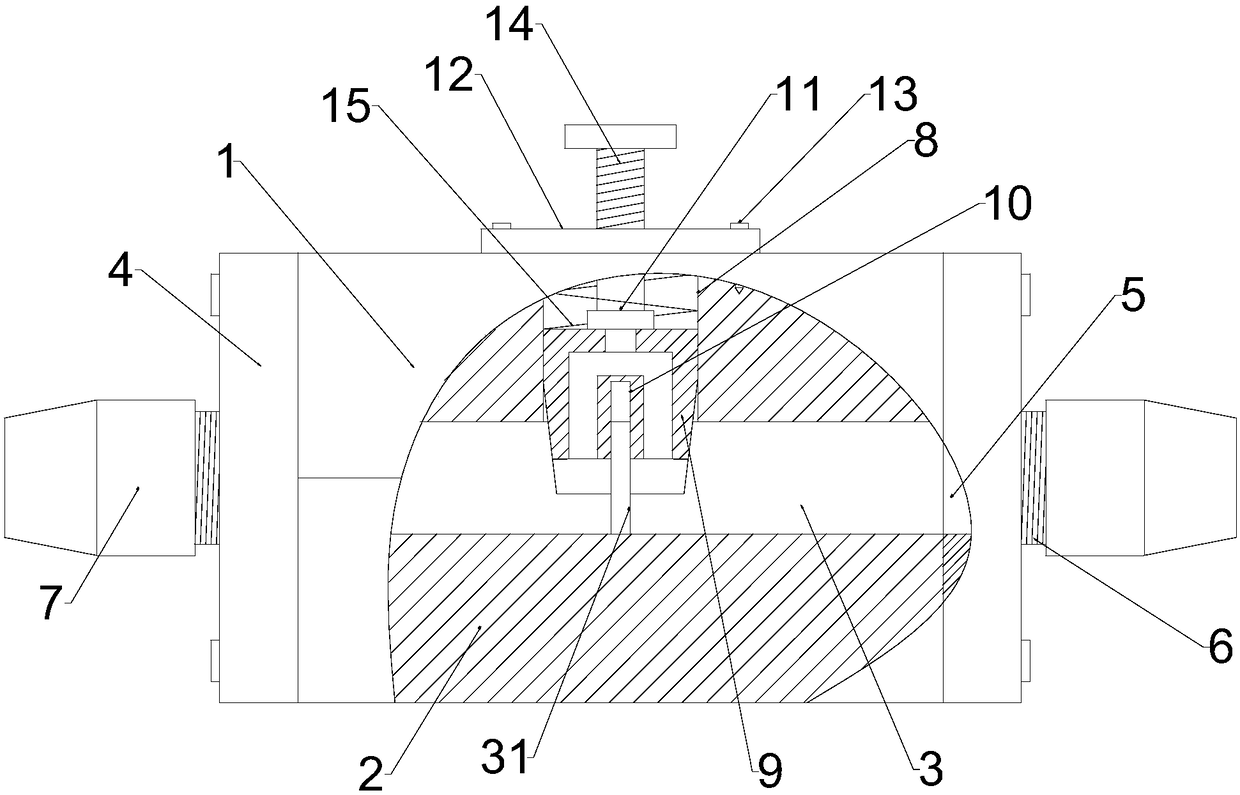

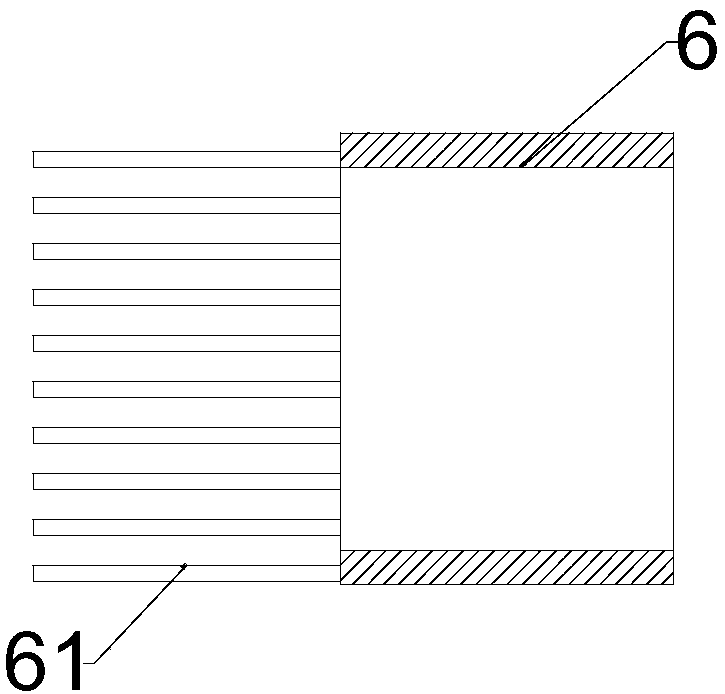

Anti-explosion secure combined type cable adapting device

ActiveCN108110689AFirmly connectedPrevent offlineApparatus for joining/termination cablesAgricultural engineeringComputer terminal

The invention discloses an anti-explosion secure combined type cable adapting device comprising an adapter body which is composed of an upper fixing block and a lower fixing block, wherein an installation through hole is firmed at the middle part of the upper fixing block and the lower fixing block, a conductive baffle plate is arranged at the middle part of the installation through hole, side fixing plates are arranged on two sides of the adapter body, threaded joints are arranged on the outer sides of the side fixing plates, fixing sleeve covers are arranged in the peripheries of the threaded joints, a sliding installation groove is arranged at the upper middle part of the upper fixing block in a perpendicularly penetrating manner, a limiting block is arranged in the sliding installationgroove, a conductive block is arranged on the limiting block, an installation cover plate is arranged on the upper fixing block, a threaded rod is arranged at the middle part of the installation cover plate, a thermal conducting strip is arranged in the sliding installation groove, thermal conducting wires are arranged on two sides of the thermal conducting strips, and a blind hole and a compression spring are arranged on the upper fixing block. The device provided by the invention is movably fit and combined and convenient to disassemble; the cable is tightly pressed and fixed via the limiting block and connected via the conductive block and the conductive baffle plate, when the temperature rises, the installation cover plate drops down and thus the terminal is connected, so as to be safer.

Owner:JILIN JIANYAN SCI & TECH

Method for manufacturing charcoal / charcoal pantograph pan in use for electric locomotive

ActiveCN101049803BHigh strengthImprove anti-friction performanceConductive layers on insulating-supportsNon-conductive material with dispersed conductive materialElectricityGas phase

A carbon / carbon slide block of current collector for electric locomotive is prepared through providing prefabricated body made of punched non-weft fabric with tridirectional structure, depositing pyrolytic carbon by CVD, compacting by resin dipping-charring process several times, and machining.

Owner:XIAN CHAOMA SCI TECH

Combined active power cable connection device

ActiveCN108336516APrevent offlineFirmly connectedElectric connection structural associationsClamped/spring connectionsPower cableEngineering

The invention discloses a combined active power cable connection device. The combined active power cable connection device comprises an adaptor body, wherein the adaptor body comprises an upper fixedblock and a lower fixed block, placement through holes are formed in middle parts of the upper fixed block and the lower fixed block, insulation partition plates are arranged at middle parts of the placement through holes, side fixed plates are symmetrically riveted at two sides of the adaptor body, threaded connectors are arranged at outer sides of the side fixed plates, thin steel sheets are arranged at tail ends of the threaded connectors, fixed sleeve covers are arranged at the peripheries of the threaded connectors, a sliding placement groove is vertically formed in a middle part of the upper fixed block in a penetrating way, a limitation block is movably engaged with the sliding placement groove, a conductive sheet and a wire are arranged on the limitation block, a placement cover plate is arranged on the upper fixed block, and a threaded rod is arranged at a middle part of the placement cover plate. The combined active power cable connection device is movably matched and combined and is convenient to disassemble, a cable is locked and fixed by the fixed sleeve cover, the tail end also can be pressed and fixed by the limitation block and communicates with the wire via the conductive sheet, and the combined active power cable connection device is convenient and flexible to use.

Owner:上海爱谱华顿电子科技(集团)有限公司

Flexible segmented support structure

An elongated segmented binding cord (SBC) for reversibly housing and securing articles of manufacturing. The SBC reversibly houses and secures objects to a specified location while maintaining a predetermined amount of tension applied on the objects. The SBC includes a main longitudinal axis that includes a plurality of interlockable segments and abutments at opposing ends. Each abutment is adapted to at least reversibly attach at the specified location.

Owner:MEDI MAG

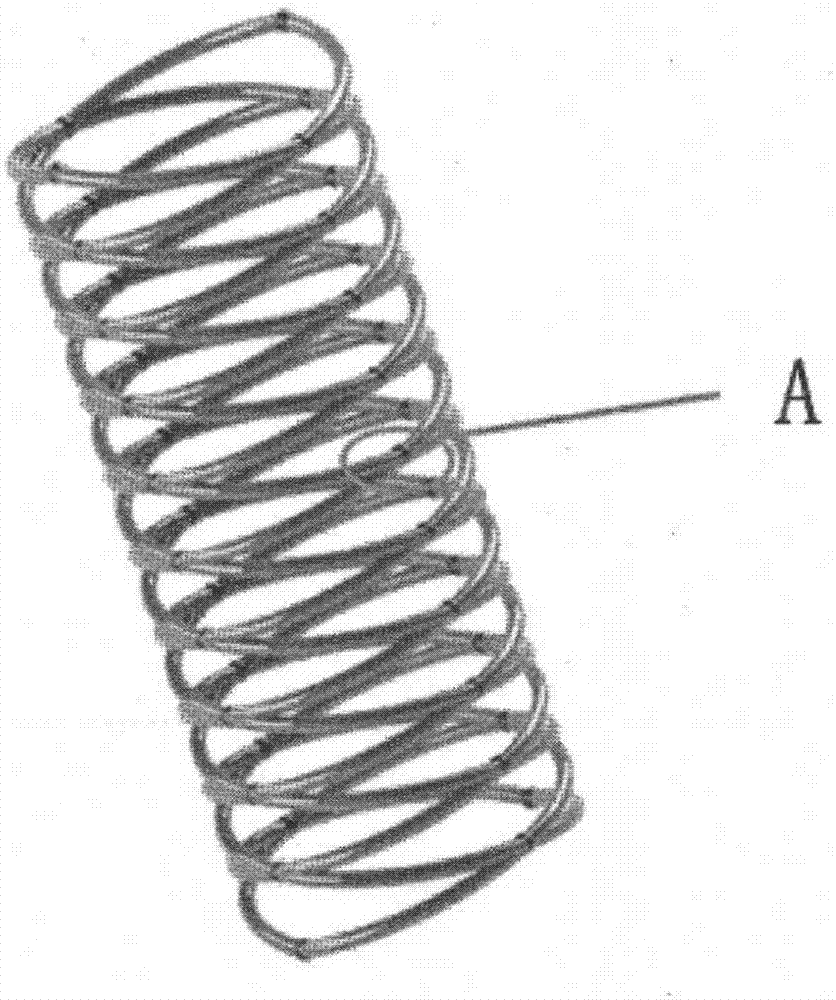

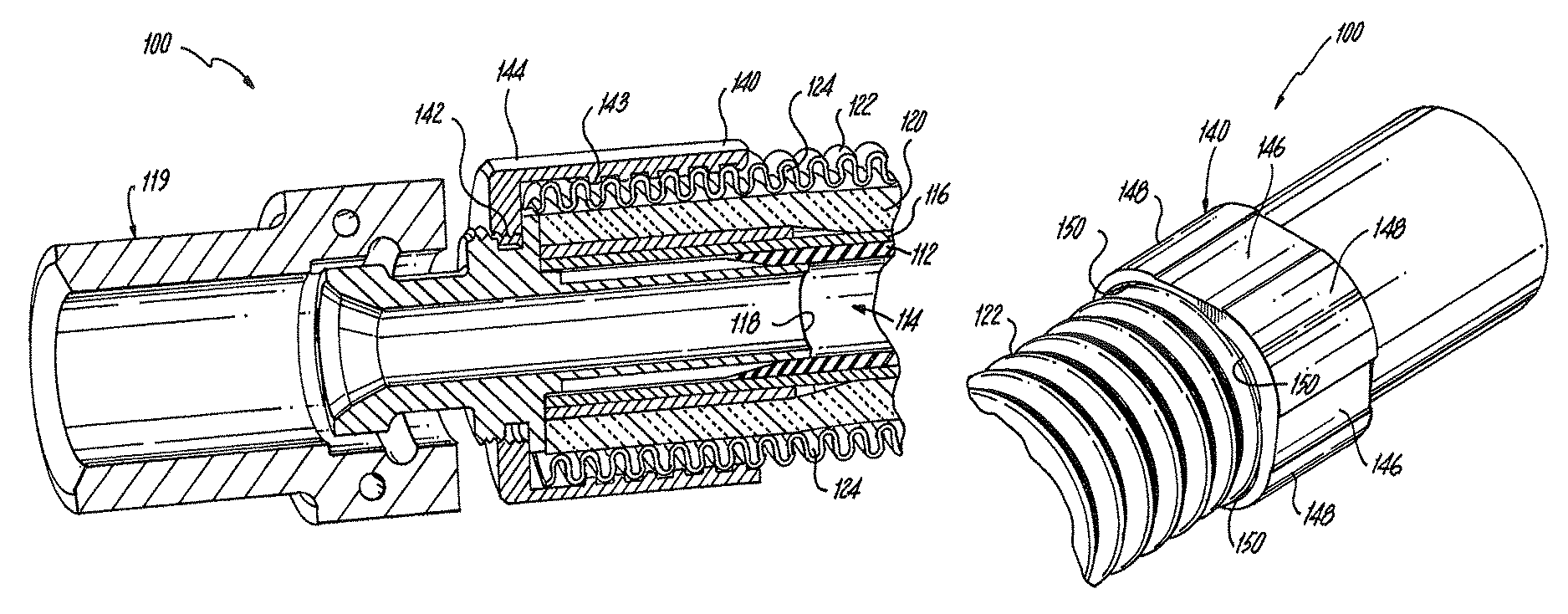

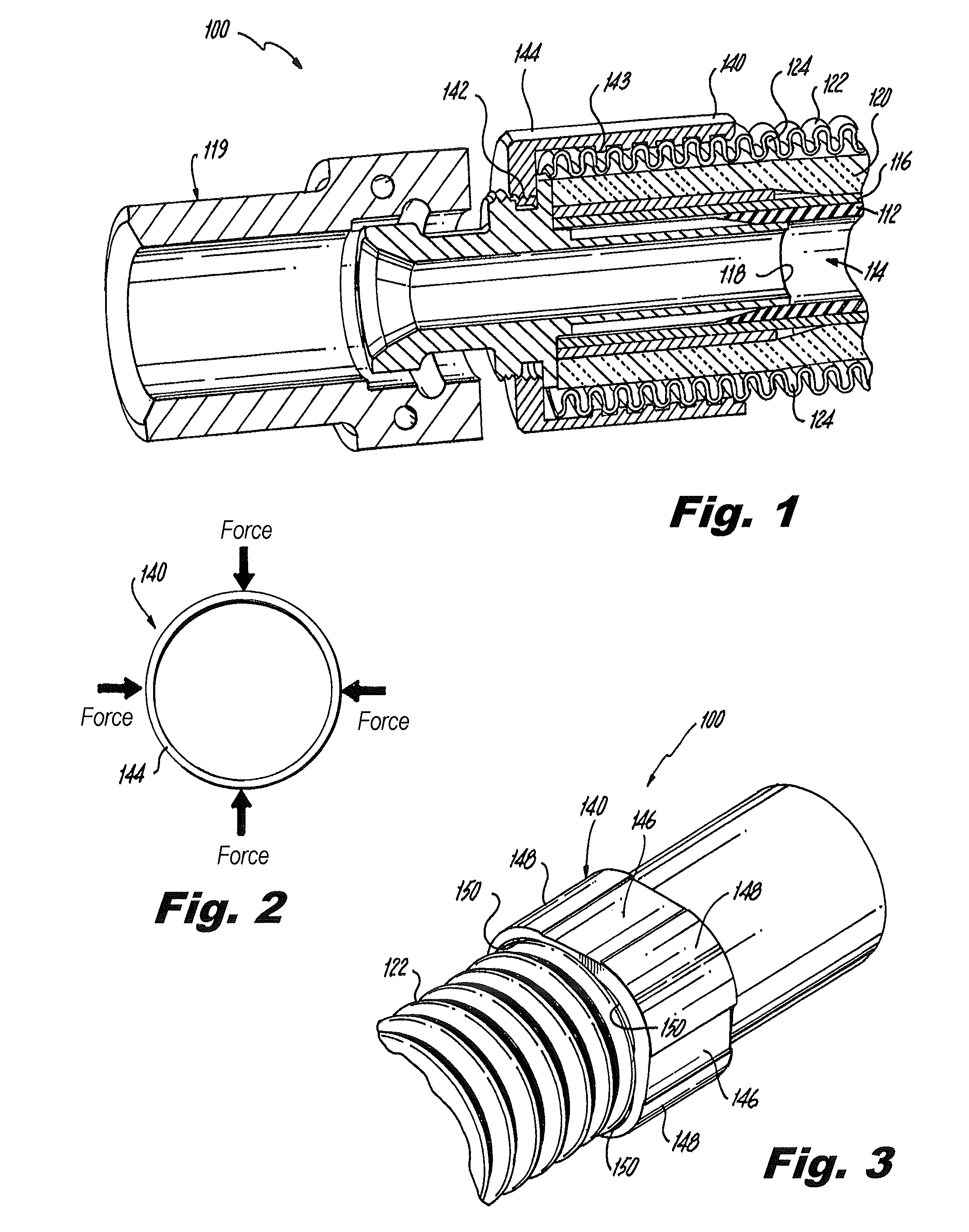

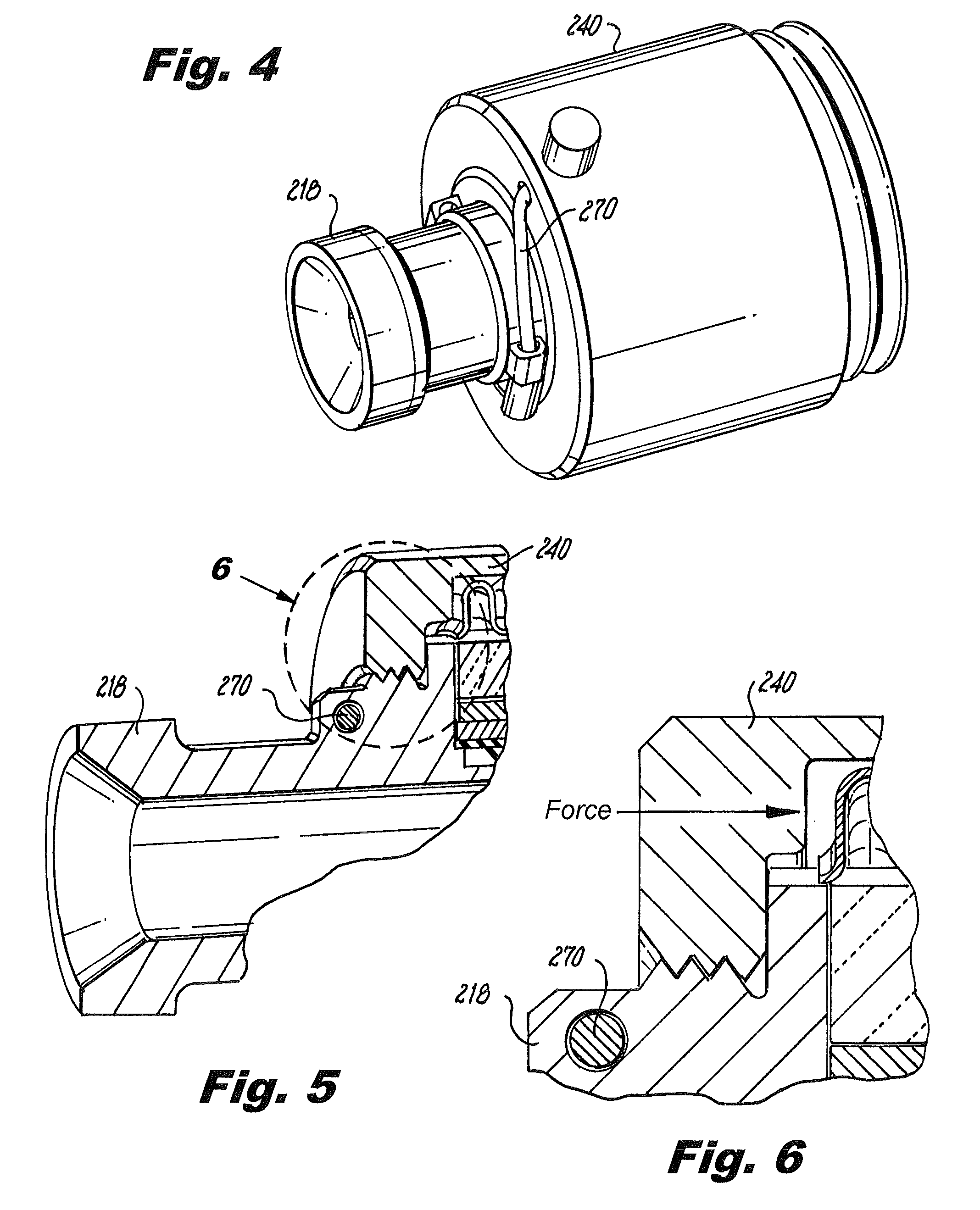

High temperature fuel manifold for gas turbine engines

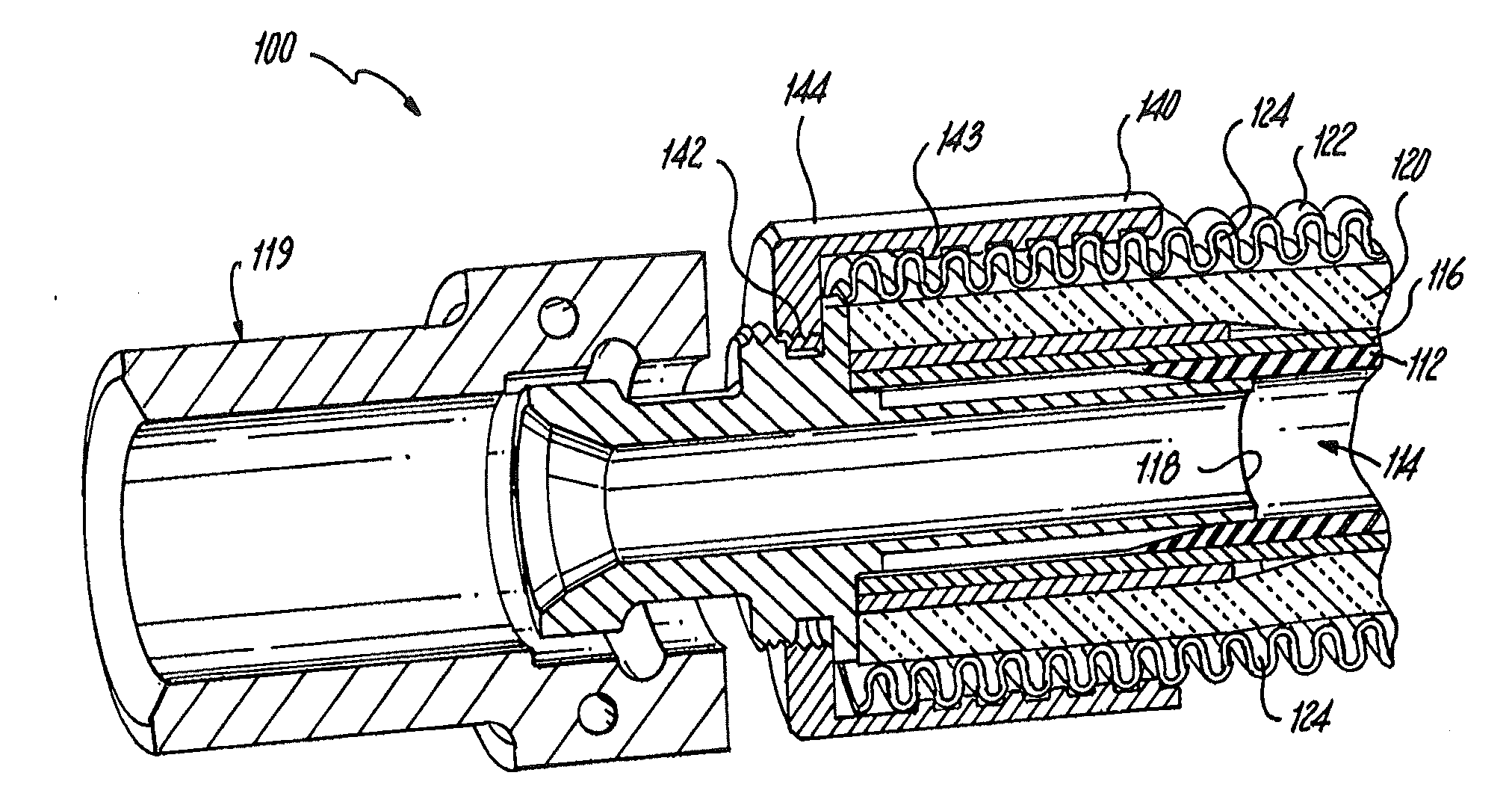

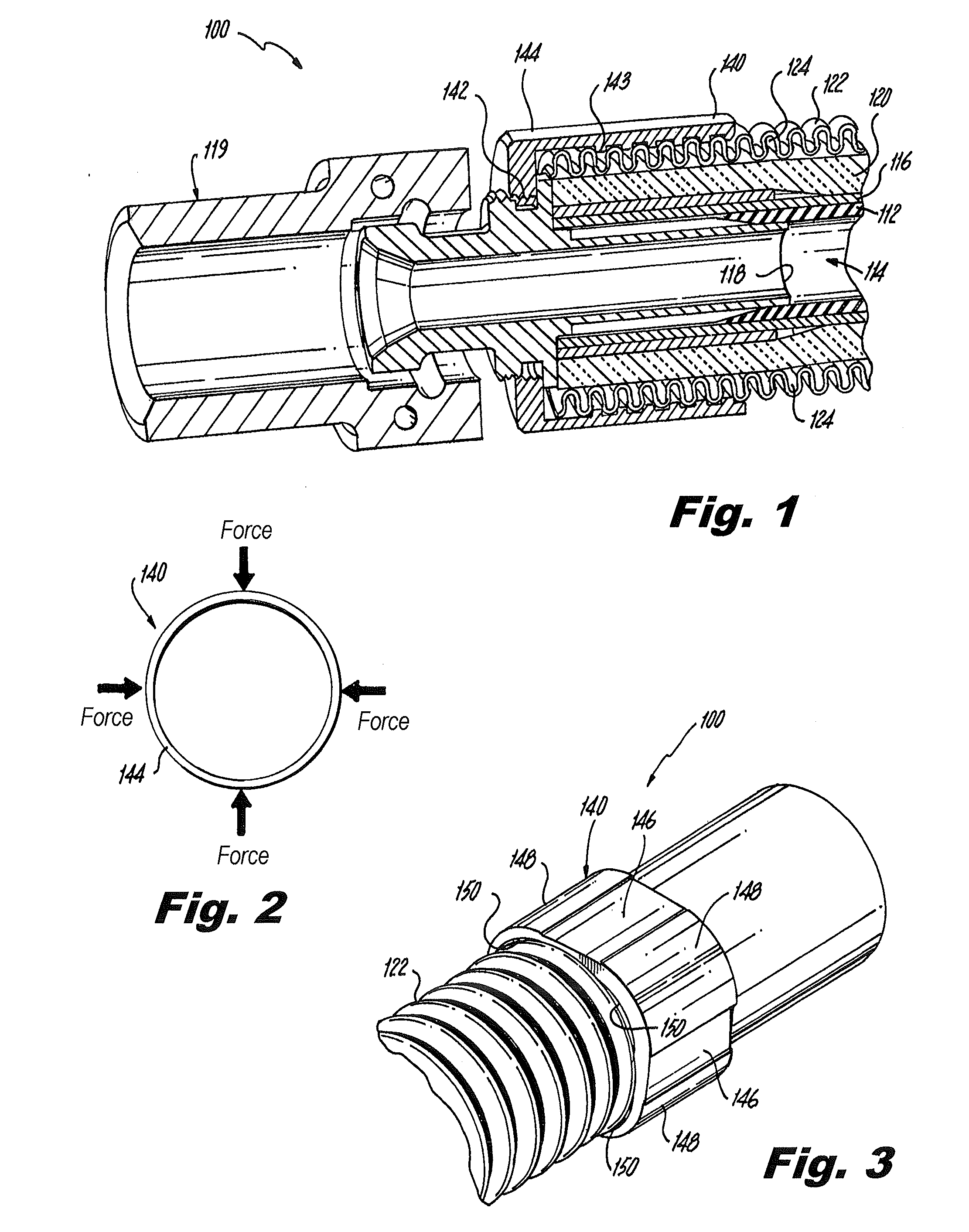

ActiveUS20130263602A1Prevent offlineEngine manufactureTurbine/propulsion fuel flow conduitsThermal isolationEngineering

A segment of a fluid manifold includes a flexible thermal shield with an insulation space defined inboard of the thermal shield to provide thermal isolation from conditions external to the thermal shield. The thermal shield includes a helically corrugated metal tube having opposed first and second ends. An outer collar is threaded to an end of the helically corrugated metal tube. The outer collar includes a crimped portion and an uncrimped portion. The uncrimped portion is spaced apart from the corrugated helical metal tube more than the crimped portion to define a vent between the outer collar and the corrugated helical metal tube in venting communication with the insulation space to vent hot gases.

Owner:COLLINS ENGINE NOZZLES INC

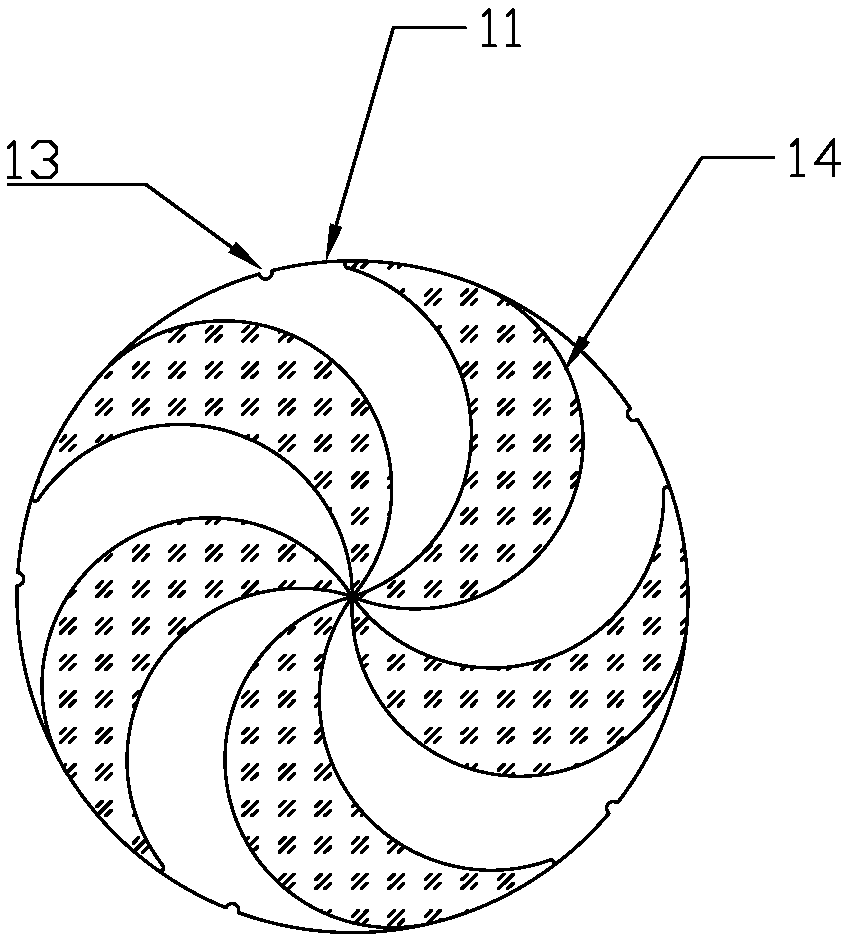

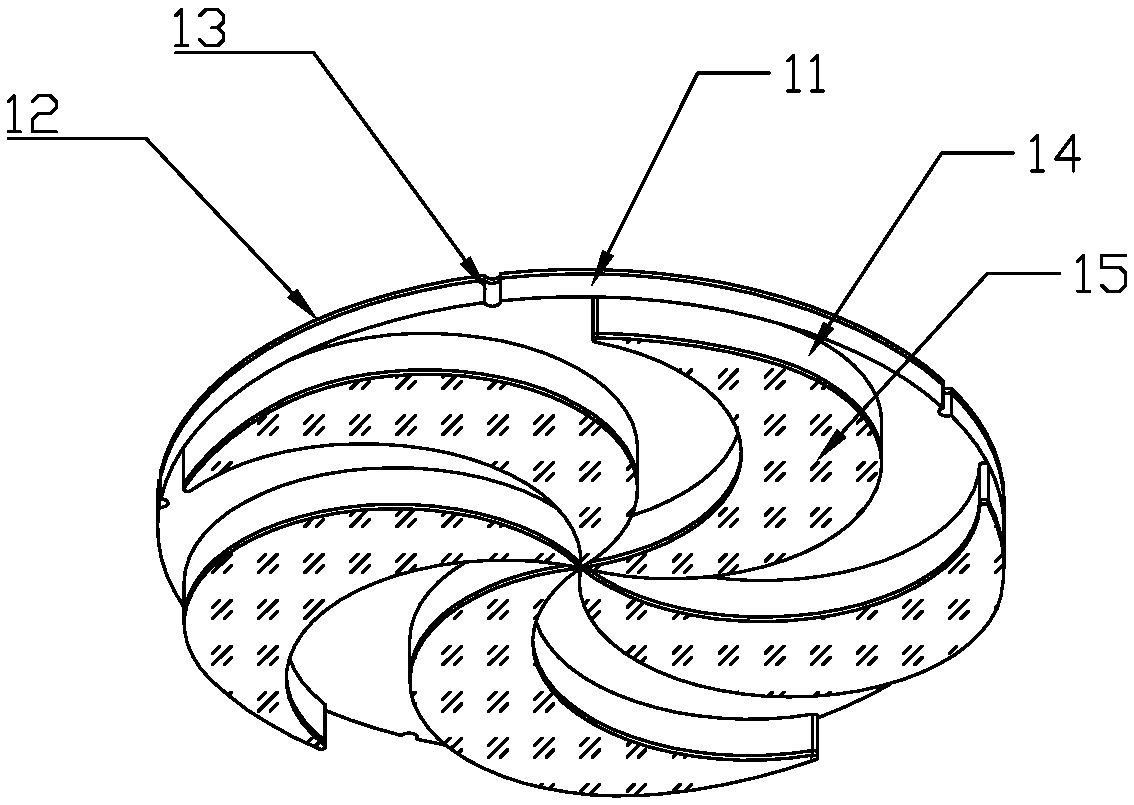

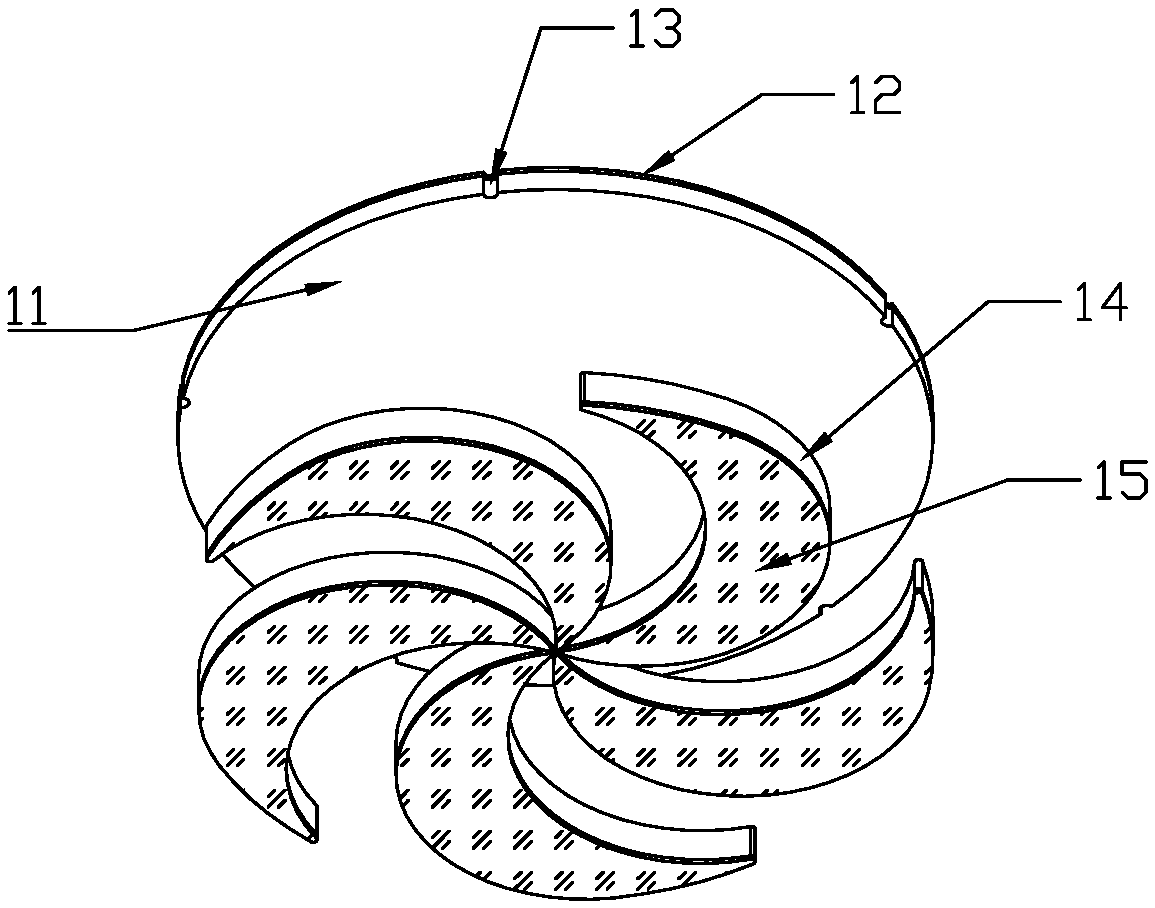

Cleaning head for electric rotating mop

InactiveCN109846426AGood cleaning effectEasy to processCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention discloses a cleaning head for an electric rotating mop. The cleaning head comprises a disc and a plurality of cleaning bodies which are arranged under the disc, distributed at intervalsin the circumferential direction and bent in the same direction, wherein the bending direction of the cleaning bodies is consistent with the rotating direction of the cleaning head during work; one ends of the cleaning bodies are connected to the center of the disc; the spacing between every two adjacent cleaning bodies is gradually reduced from outside to inside; garbage on the ground is wiped and gathered by the cleaning bodies into the gap between every two adjacent cleaning bodies and clamped and kept in the gap between every two adjacent cleaning bodies. The cleaning head can be directlyused for replacing a circular mop cloth used by an existing product without changing the existing electric mop, dirt can be gathered, and the garbage left on the ground is reduced.

Owner:阳珉

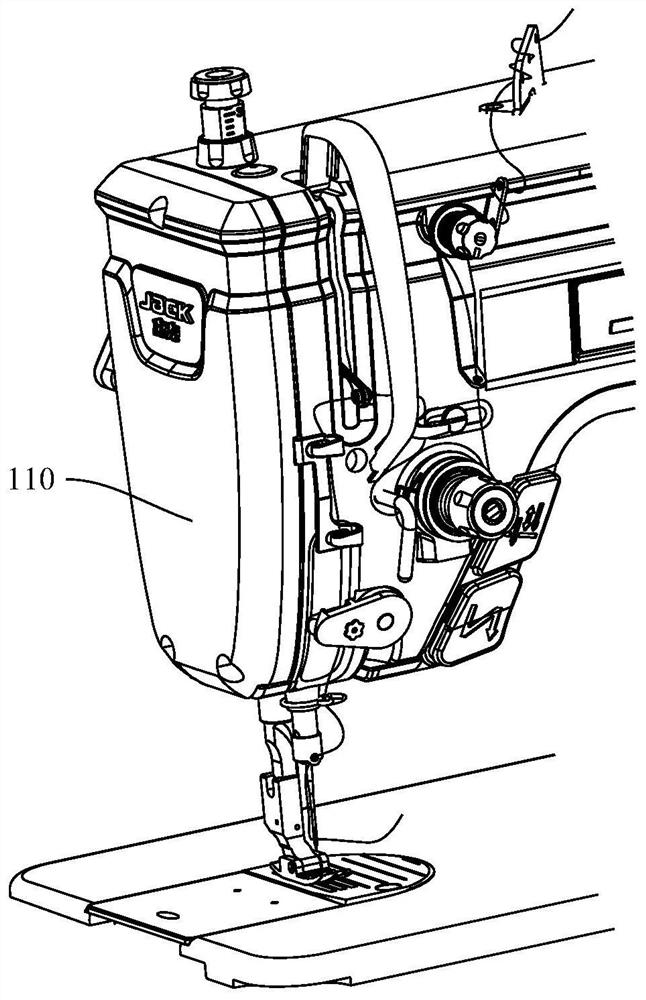

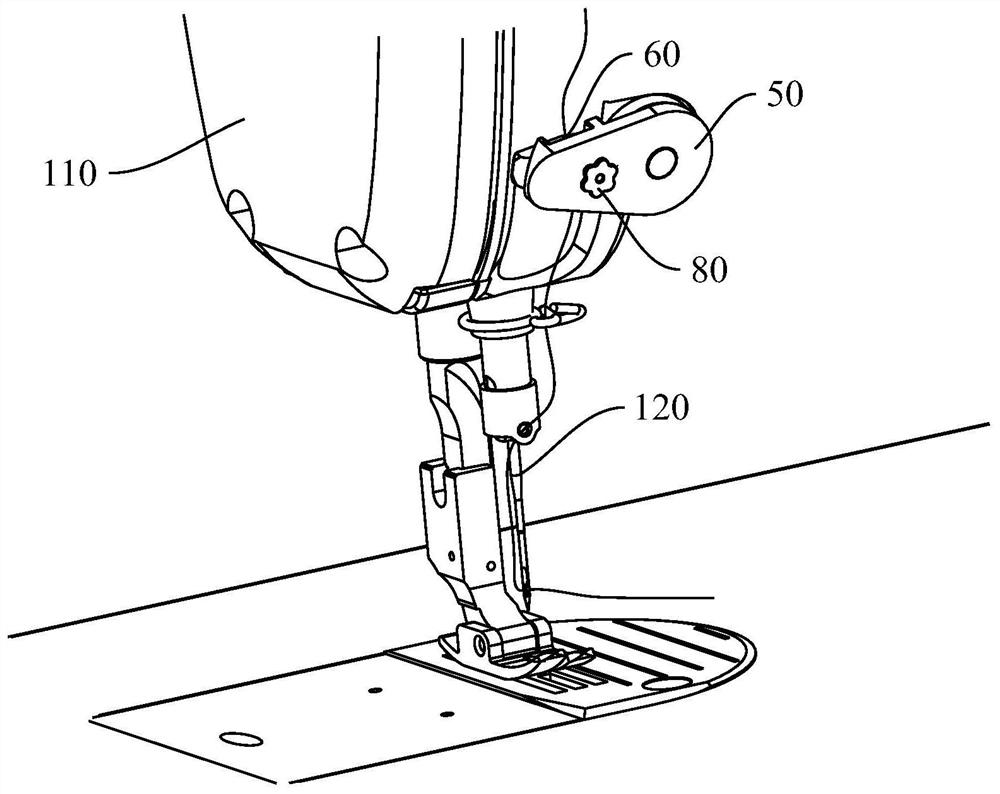

Electronic yarn trapper and sewing machine

The invention provides an electronic yarn trapper. The electronic yarn trapper comprises an electromagnet housing, an electromagnet coil, an iron core, a return spring, a yarn trapping cover plate, anadjusting bolt and an adjusting nut, wherein the electromagnet coil is mounted in the electromagnet housing; the iron core is matched with the electromagnet coil; the yarn trapping cover plate is fixed to the iron core; the adjusting bolt is parallel to the iron core; and the adjusting nut is connected with the adjusting bolt through threads; the two ends of the return spring abut against the electromagnet housing and the iron core, respectively; a yarn through groove allowing an upper thread to penetrate through is formed between the electromagnet housing and the yarn trapping cover plate; and the adjusting nut is arranged on one side, far away from the yarn through groove, of the yarn trapping cover plate and abuts against the yarn trapping cover plate. According to the electronic yarntrapper, the size of the yarn through groove is adjustable; when the thickness of the upper thread and the sewing speed of a first stitching of the sewing machine are changed, the working delay angleof the yarn trapper can be adjusted by adjusting the size of the yarn through groove so that the working delay angle of the yarn trapper is always kept within a range; and therefore, the working delayangle of the yarn trapper is controllable, and the stability of the working delay angle of the electronic yarn trapper is improved.

Owner:JACK SEWING MASCH CO LTD

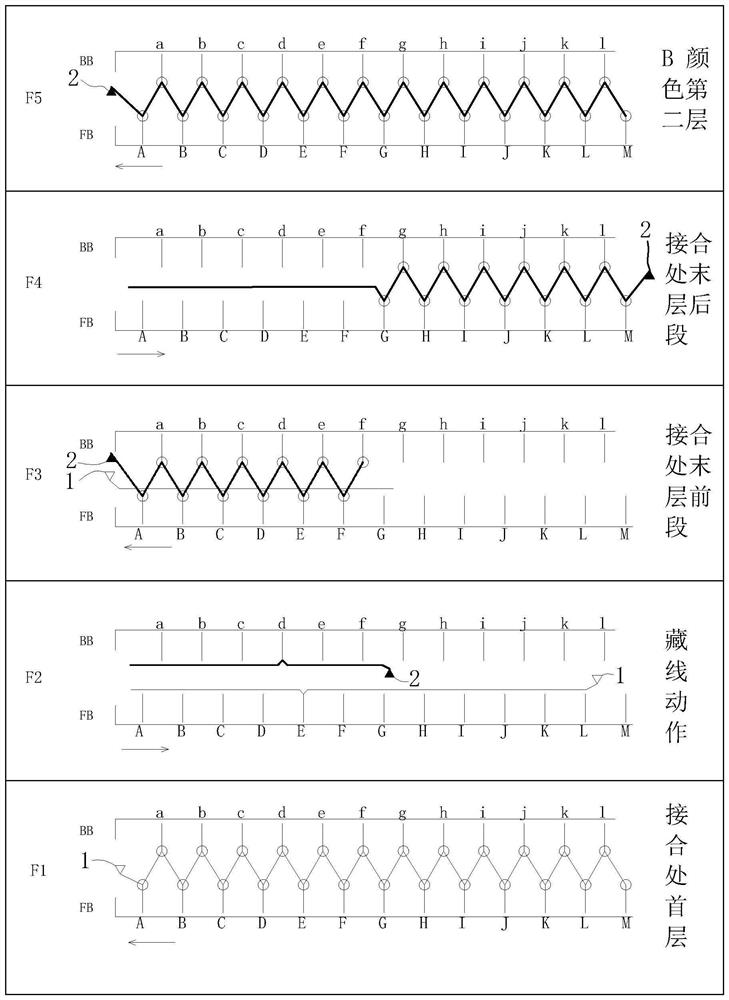

Anti-thread-off technology for double-faced fabric

The invention provides an anti-thread-off process for a double-sided fabric, which is used for weaving the joint of every two color fabric weaves of a multi-color and inter-color double-sided fabric, adopts a flat knitting machine with a front needle bed and a rear needle bed for weaving, and comprises the following steps: step 1, weaving an A color fabric weave, and taking the tail layer of the A color fabric weave as the first layer of the joint; secondly, after the first layer of the joint is woven, yarn hiding action is conducted on the yarn of the color A in the direction opposite to the first layer of the joint in the first step, yarn of the color B is supplied, and yarn hiding action is conducted on the yarn of the color B in the direction opposite to the first layer of the joint in the first step by the distance of a plurality of needles; 3, weaving the front section of the last layer of the joint, wherein the yarn in the color B is used for weaving the front section of the last layer of the joint from the starting needle of the front section of the last layer of the joint in the direction opposite to the yarn hiding action in the step 2; 4, weaving the rear section of the tail layer at the joint; and step 5, weaving a B-color fabric weave.

Owner:福建泉州凹凸精密机械有限公司

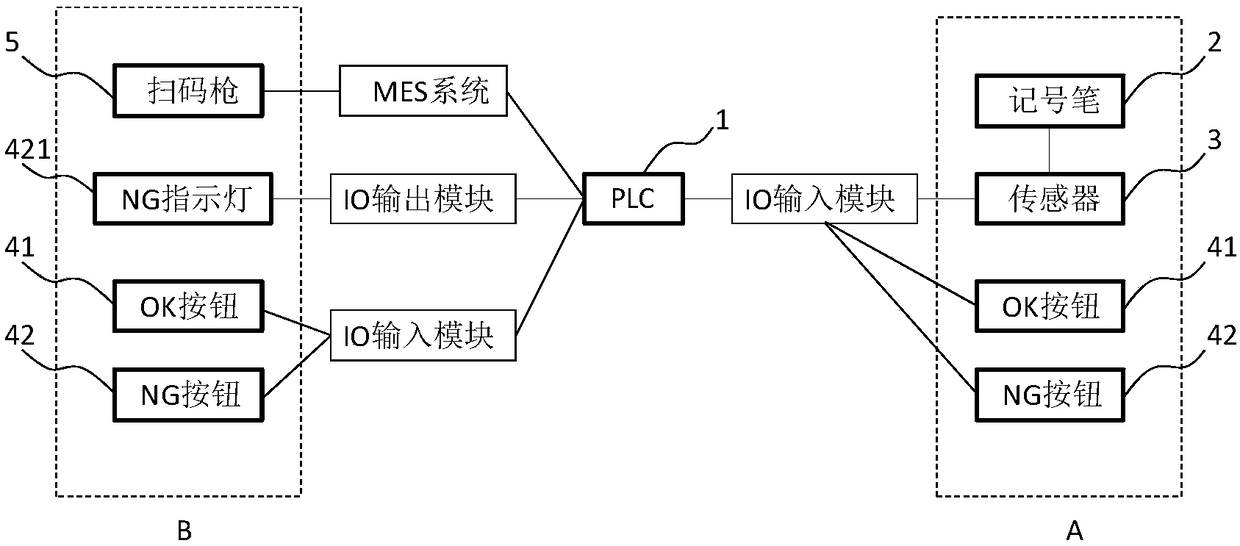

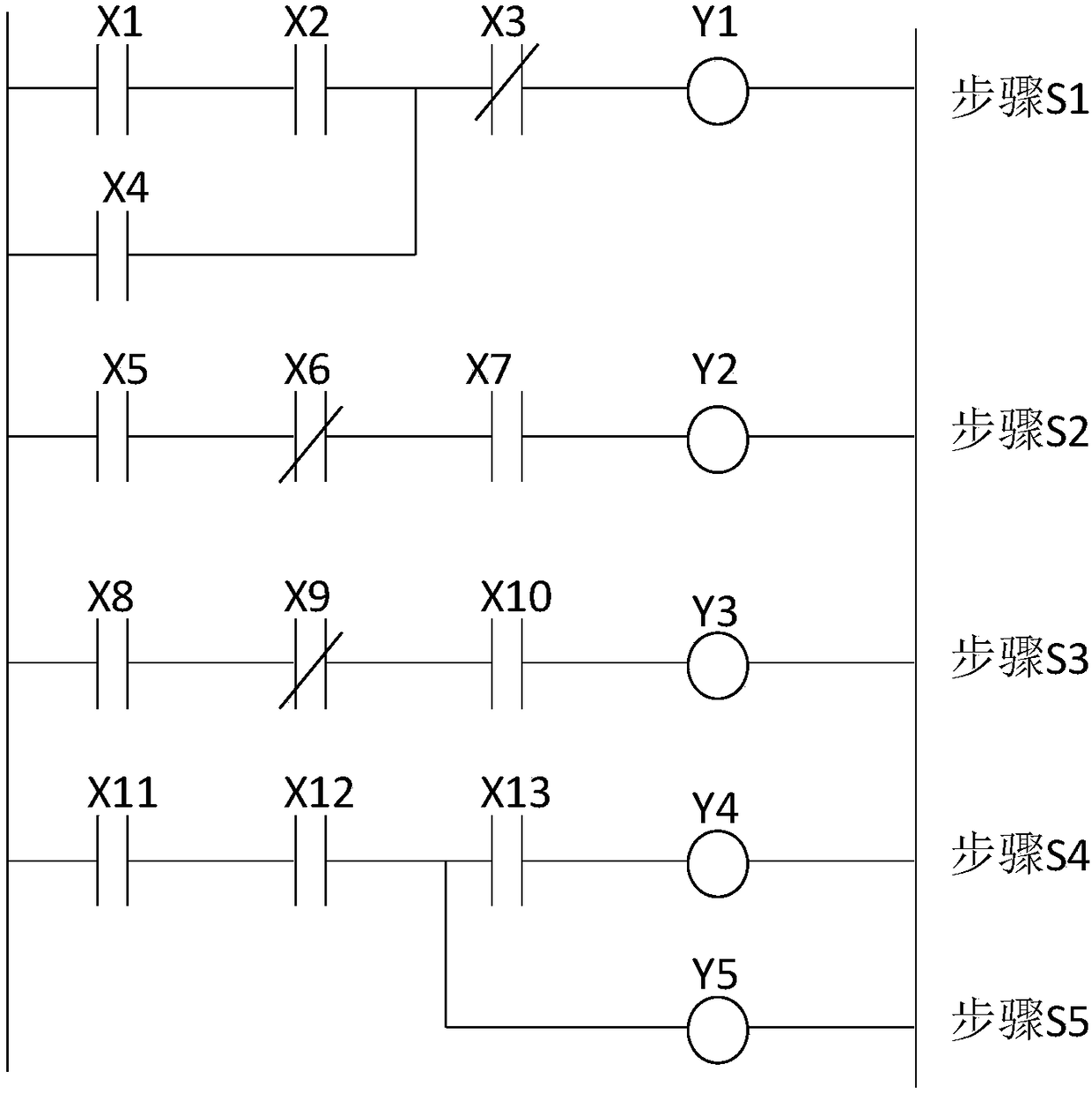

Product appearance detection device and method

InactiveCN108459024ASolve missing checksSolve the bad mark that can't be foundMaterial analysis by optical meansProgramme control in sequence/logic controllersProduction lineEngineering

The invention relates to the technical field of product appearance detection, and discloses a product appearance detection device and method. A controller of the device judges the quality of the appearance of a product according to a signal acquired by a sensor; when judging that the product is in a disqualified state, the controller controls an NG button switch to output a product NG state signal; through the adoption of a human-machine mode for detection, the assurance capacity of detection of a working procedure is improved, so that the disqualified product outflow probability of the product is P which is less than 0.00006 percent, delivery out of the production line of disqualified products is effectively avoided, and the factory quality of the product is guaranteed. According to the detection method, the controller judges the appearance quality state of the product to control the state signal of the product; when judging that the appearance of the product is in the disqualified state, the controller controls the NG button switch to output the NG state signal of the product, so that the usual phenomenon that defective products are delivered due to a fact that detection personnel omits inspection or does not find a disqualification mark in the prior art is avoided.

Owner:GUANGQI HONDA

High temperature fuel manifold for gas turbine engines

ActiveUS9556796B2Prevent offlineEngine manufactureTurbine/propulsion fuel flow conduitsThermal isolationEngineering

A segment of a fluid manifold includes a flexible thermal shield with an insulation space defined inboard of the thermal shield to provide thermal isolation from conditions external to the thermal shield. The thermal shield includes a helically corrugated metal tube having opposed first and second ends. An outer collar is threaded to an end of the helically corrugated metal tube. The outer collar includes a crimped portion and an uncrimped portion. The uncrimped portion is spaced apart from the corrugated helical metal tube more than the crimped portion to define a vent between the outer collar and the corrugated helical metal tube in venting communication with the insulation space to vent hot gases.

Owner:COLLINS ENGINE NOZZLES INC

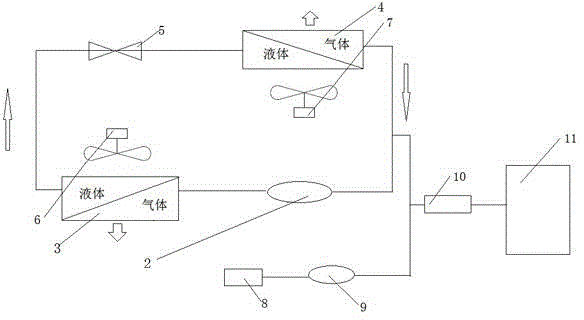

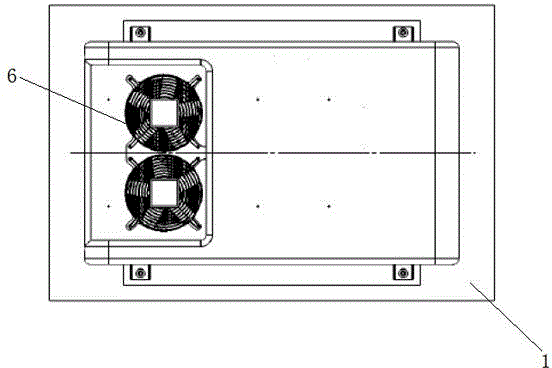

Overhead alternating-current air conditioner of locomotive and working method thereof

ActiveCN104964423AAdjustable temperatureImprove air qualityCompressorSpace heating and ventilation detailsRefrigeration compressorControl system

The invention discloses an overhead alternating-current air conditioner of a locomotive. The overhead alternating-current air conditioner comprises a shell, a totally-enclosed refrigeration compressor, a condenser, an evaporator, a throttling device, a condensate fan, an evaporating fan, a high-low voltage switch, a heater, a temperature relay and a control system. An air outlet and a return air inlet are arranged on the shell. The air outlet is composed of an ordinary air outlet and an adjustable air outlet. A mounting foot is arranged on the shell and fixed at the top of the locomotive by means of a bolt and reinforced by a locking bolt. An anti-vibration pad is arranged between the installing foot and the locking bolt. The overhead alternating-current air conditioner of the locomotive is capable of effectively adjusting temperature in the locomotive and effectively protecting internal staff of the locomotive against influence of the poor environment; and a filter net arranged in an air return grille is used for filtering air in the locomotive such that air quality of the locomotive is well improved and a protection effect upon body health of staff in the locomotive is achieved.

Owner:BIHE ELECTRIC TAICANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com