Method for manufacturing charcoal / charcoal pantograph pan in use for electric locomotive

A technology for pantograph slides and electric locomotives, applied in cable/conductor manufacturing, electric vehicles, conductive materials dispersed in non-conductive inorganic materials, etc. To solve problems such as poor impact performance, achieve the effects of good lubricating performance, small wear, excellent mechanical properties and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

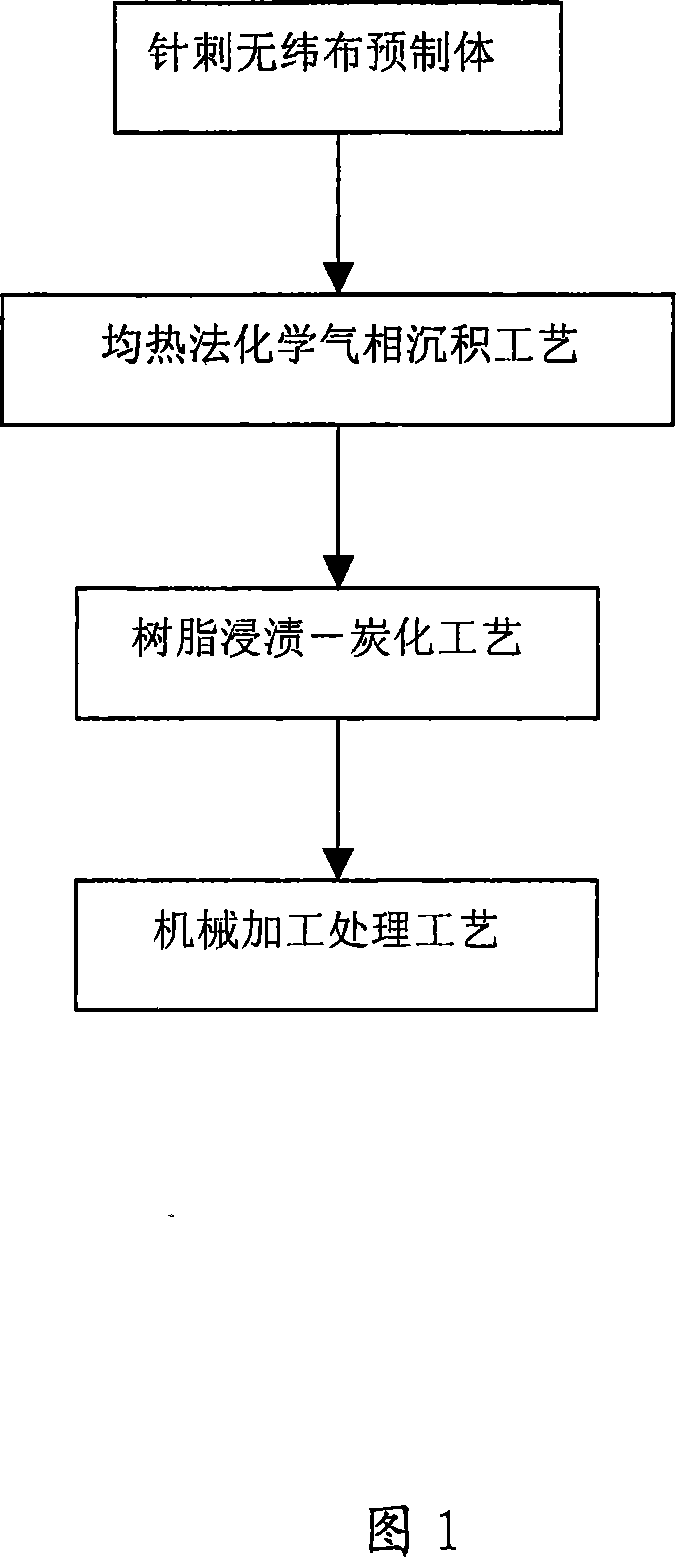

Image

Examples

Embodiment 1

[0022] (1) The quasi-three-way structure prefabricated body is adopted with full carbon fiber acupuncture without weft cloth;

[0023] (2) Perform homogeneous chemical vapor deposition on the quasi-three-dimensional prefabricated body, the deposition temperature is 920 ° C, the deposition time is 168 hours, and the deposition density is ≥ 1.20 g / cm 3 Time-transferred furfurone resin impregnation-carbonization densification;

[0024] (3) Furfurone resin impregnation-carbonization densification process, the furfurone resin is preheated at 60°C, impregnated at a pressure of 1.8MPa for 5h, the curing temperature is 160°C and then transferred to a carbonization furnace for carbonization treatment at 800°C;

[0025] (4) Product density ≥ 1.70g / cm 3 When the densification process is over, the carbon / carbon pantograph slide plate for electric locomotive can be obtained after mechanical processing according to the pattern.

Embodiment 2

[0027] (1) Acupuncture non-weft full carbon fiber quasi-three-way structure prefabricated body;

[0028] (2) Perform homogeneous chemical vapor deposition on the quasi-three-dimensional structure preform, the deposition temperature is 940°C, the deposition time is 120 hours, and the deposition is to a density ≥ 1.20g / cm 3 Time-transferred furfurone resin impregnation-carbonization densification;

[0029] (3) Furfurone resin impregnation-carbonization densification process, the furfurone resin is preheated at 60°C, impregnated at a pressure of 1.4MPa for 5 hours, the curing temperature is 180°C, and then transferred to a carbonization furnace for carbonization at 900°C;

[0030] (4) Product density ≥ 1.70g / cm 3 When the densification process is over, the carbon / carbon pantograph slide plate for electric locomotive can be obtained after mechanical processing according to the pattern.

Embodiment 3

[0032] (1) Acupuncture non-weft full carbon fiber quasi-three-way structure prefabricated body;

[0033] (2) Perform homogeneous chemical vapor deposition on the quasi-three-dimensional structure preform, the deposition temperature is 960°C, the deposition time is 144 hours, and the deposition is to a density ≥ 1.20g / cm 3 Time-transferred furfurone resin impregnation-carbonization densification;

[0034] (3) Furfurone resin impregnation-carbonization densification process, the furfurone resin is preheated at 60°C, impregnated at a pressure of 1.2MPa for 5 hours, the curing temperature is 200°C and then transferred to a carbonization furnace for carbonization treatment at 1000°C;

[0035] (4) Product density ≥ 1.70g / cm 3 When the densification process is over, the carbon / carbon pantograph slide plate for electric locomotive can be obtained after mechanical processing according to the pattern.

[0036] The invention introduces the carbon / carbon composite material to be used fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com