Electronic yarn trapper and sewing machine

A thread clamp and electronic technology, which is applied in the field of sewing machines, can solve the problems of premature loosening of the electronic thread clamp, unstable and uncontrollable working delay angle of the electronic thread clamp, and improve sewing quality and sewing efficiency. , avoid premature loosening of thread clamping, and improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

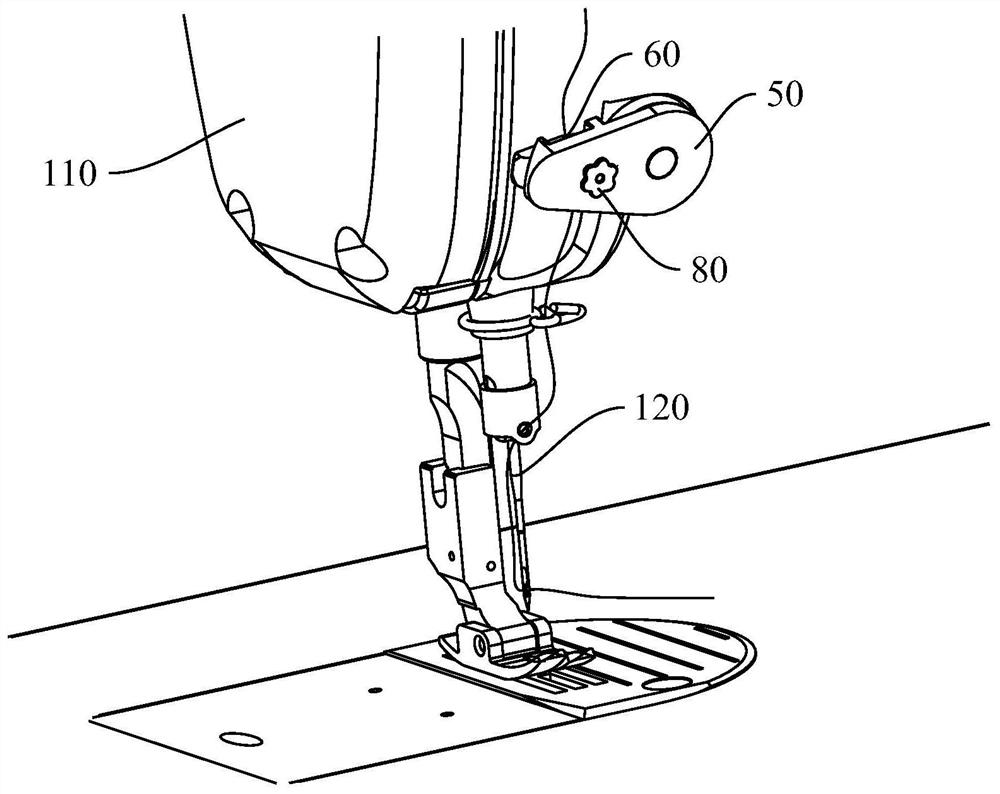

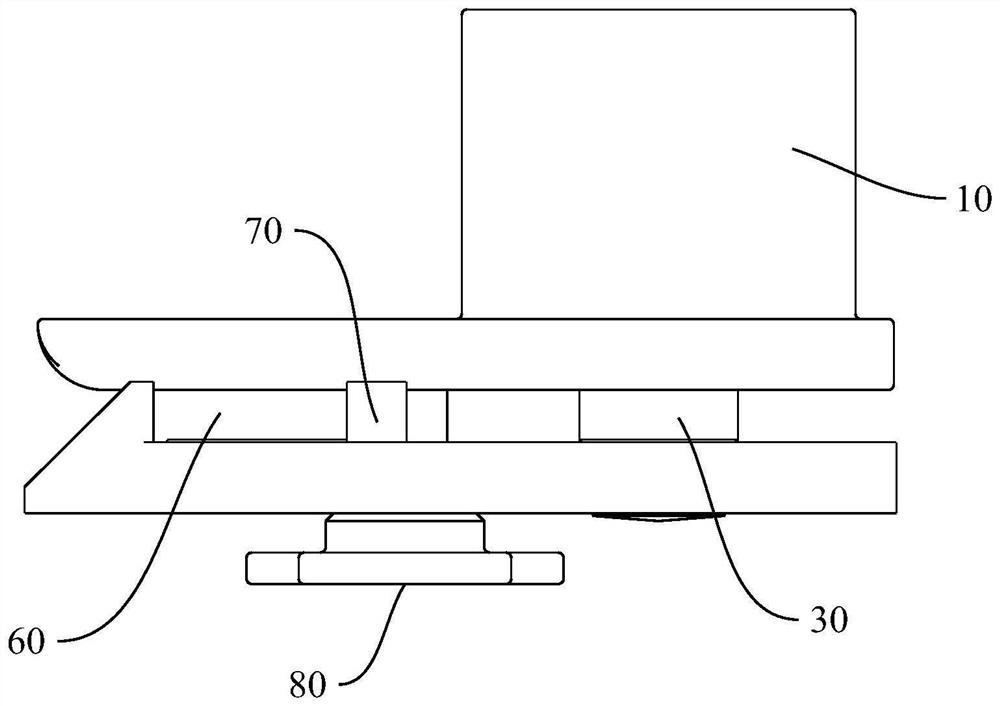

[0073] Embodiment one, as image 3 and Figure 4 As shown, the adjusting screw 70 includes a first threaded portion 71, a guide portion 72, and a second threaded portion 73 that are sequentially connected along its axial direction from front to back. The front clamping portion 11 of the electromagnet housing 10 is provided with a The threaded portion 71 is threaded into the threaded hole 12 , and the rear clamping portion 51 of the clamping cover 50 is provided with a guide hole 52 that guides and cooperates with the guide portion 72 . The second threaded portion 73 is threaded into the adjusting nut 80 . In this embodiment, the front end of the adjusting screw 70 is fixed in the front clamping portion 11 of the electromagnet housing 10 . Preferably, the outer diameter of the guide portion 72 is greater than the outer diameter of the second threaded portion 73 , and at the same time, the outer diameter of the guide portion 72 is also greater than the outer diameter of the fir...

Embodiment 2

[0074] Embodiment two, such as Figure 6 As shown, a first through hole 13 is opened in the front clamping part 11, a second through hole 53 is opened in the rear clamping part 51, and the adjusting screw 70 is penetrated in the first through hole 13, and the two guide and cooperate to adjust The screw 70 is passed through the second through hole 53 , and the two guide and cooperate. In this embodiment, the adjusting screw 70 is only passed through the front clamping portion 11 of the electromagnet casing 10 and the rear clamping portion 51 of the wire clamping cover 50 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com