Multi-needle-bar sewing machine

A multi-needle bar, sewing machine technology, applied in the direction of sewing machine components, sewing machine needle holders, sewing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

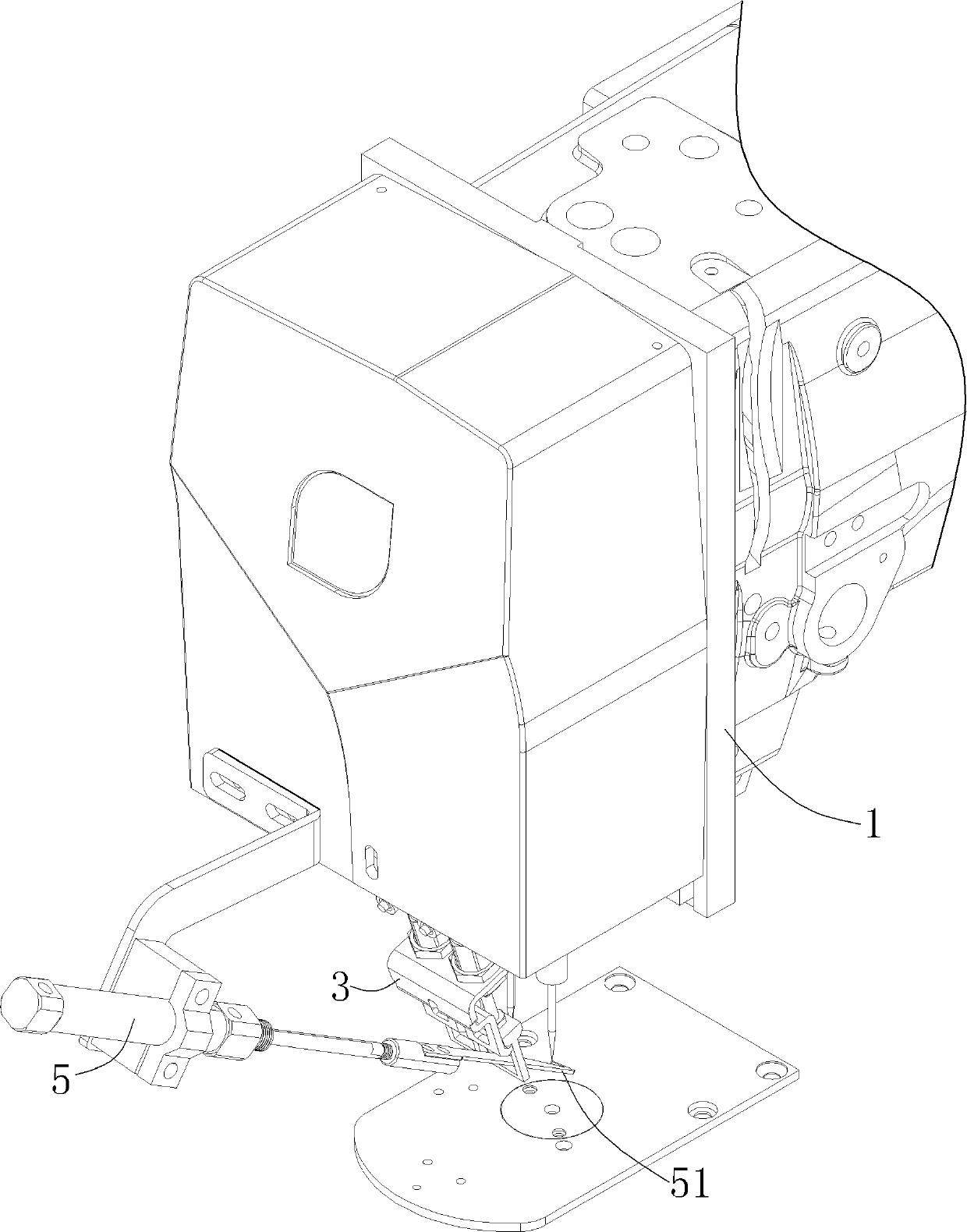

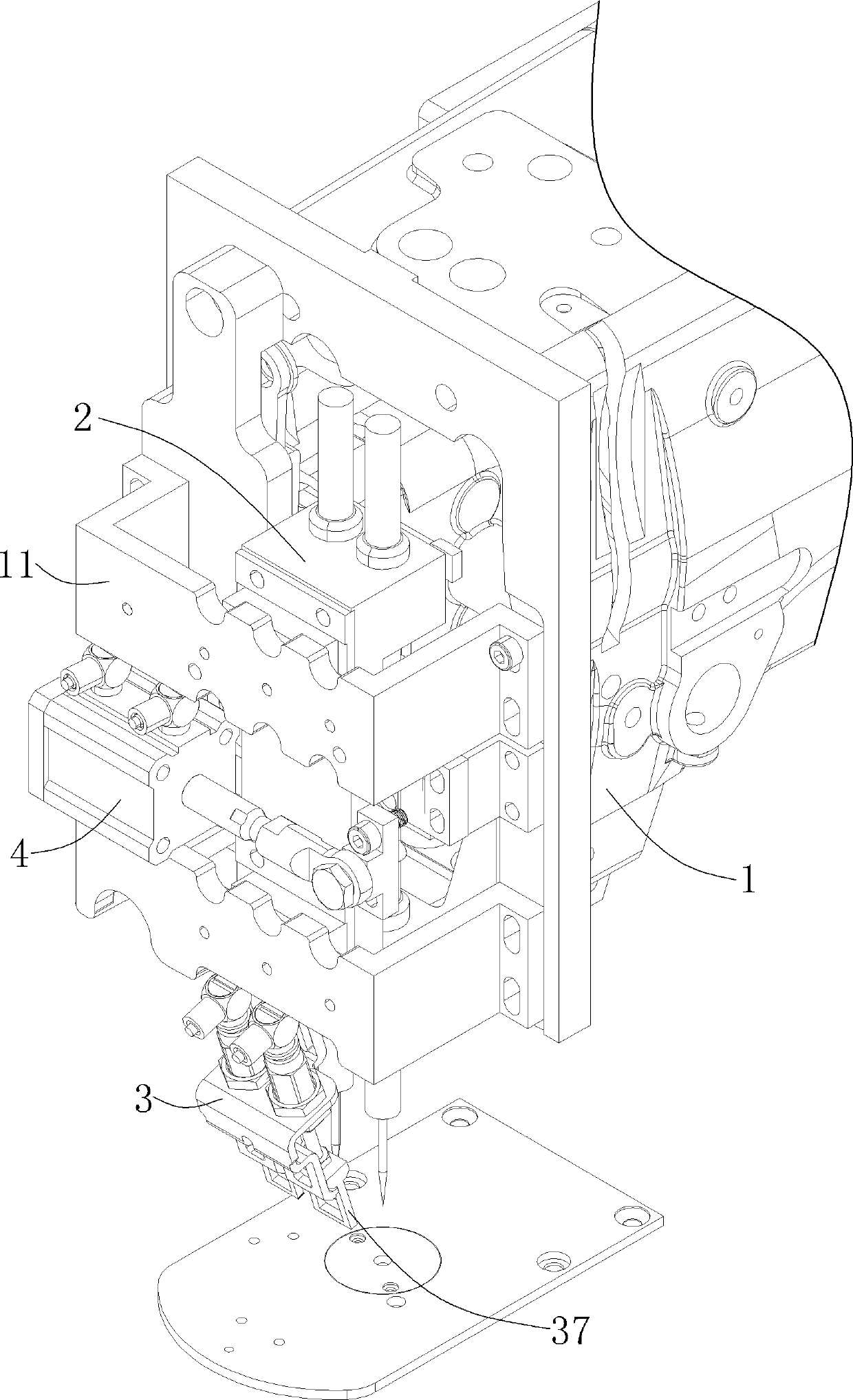

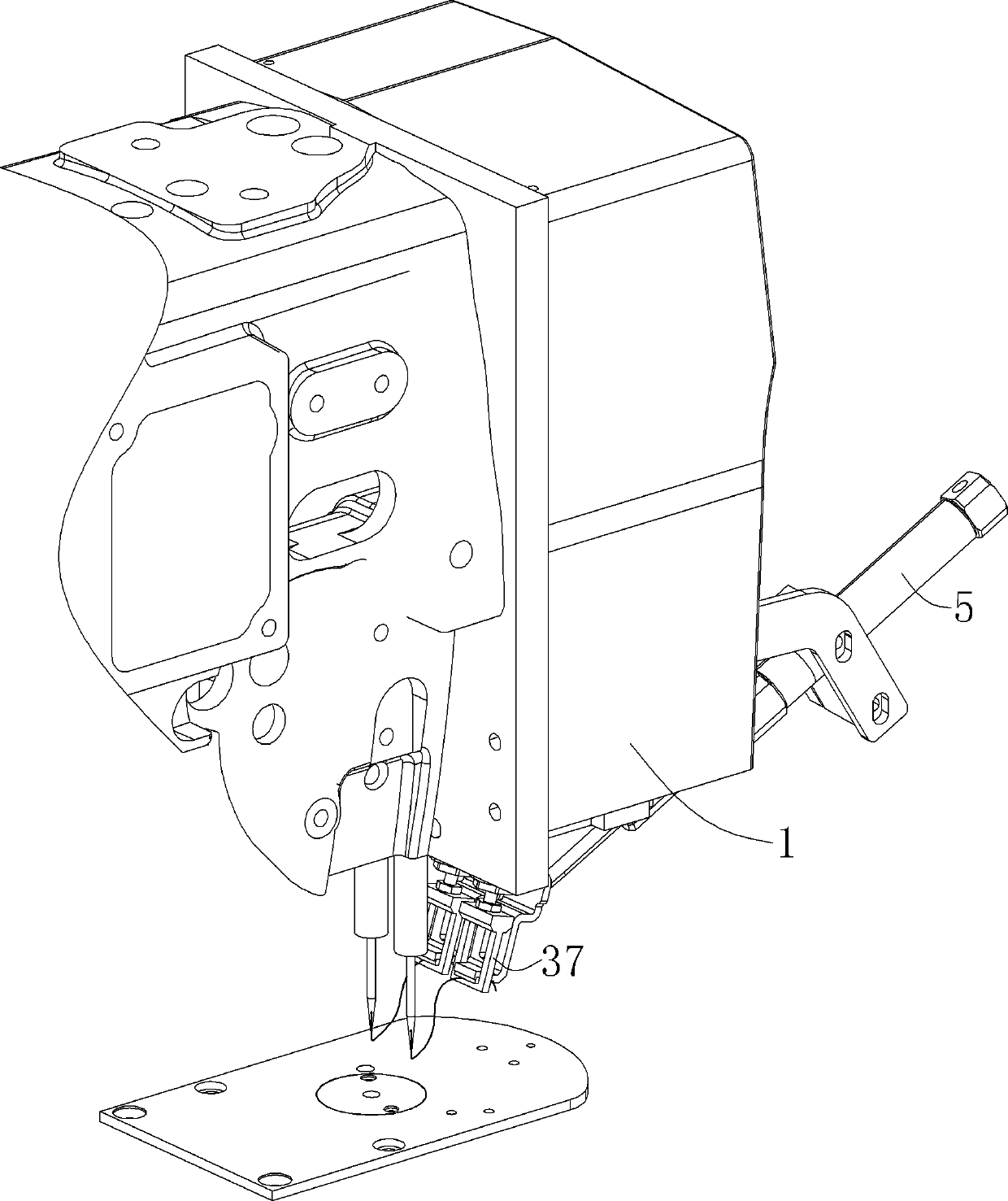

[0021] Figure 1 to Figure 8 Shown is the structural representation of the present invention.

[0022] The reference signs therein are: machine head housing 1, mounting bracket 11, multi-needle bar module 2, positioning bracket 3, first thread clamping part 31, second thread clamping part 32, fixing part 33, first driver 34, The second driver 35, the first wire pressing block 36, the second wire pressing block 37, the switching cylinder group 4, the wire pulling cylinder 5, and the wire pulling hook 51.

[0023] Such as figure 1 and figure 2 As shown, the multi-needle bar sewing machine of the present invention includes a machine head housing 1 and a sewing control system, and also has a mounting bracket 11 fixed on the machine head housing 1, and the mounting bracket 11 is horizontally slidably mounted with at least two needle bars The mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com