Anti-thread-off technology for double-faced fabric

A double-sided fabric and thread prevention technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of high labor cost and time-consuming, and achieve the effect of avoiding thread threading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below through specific embodiments.

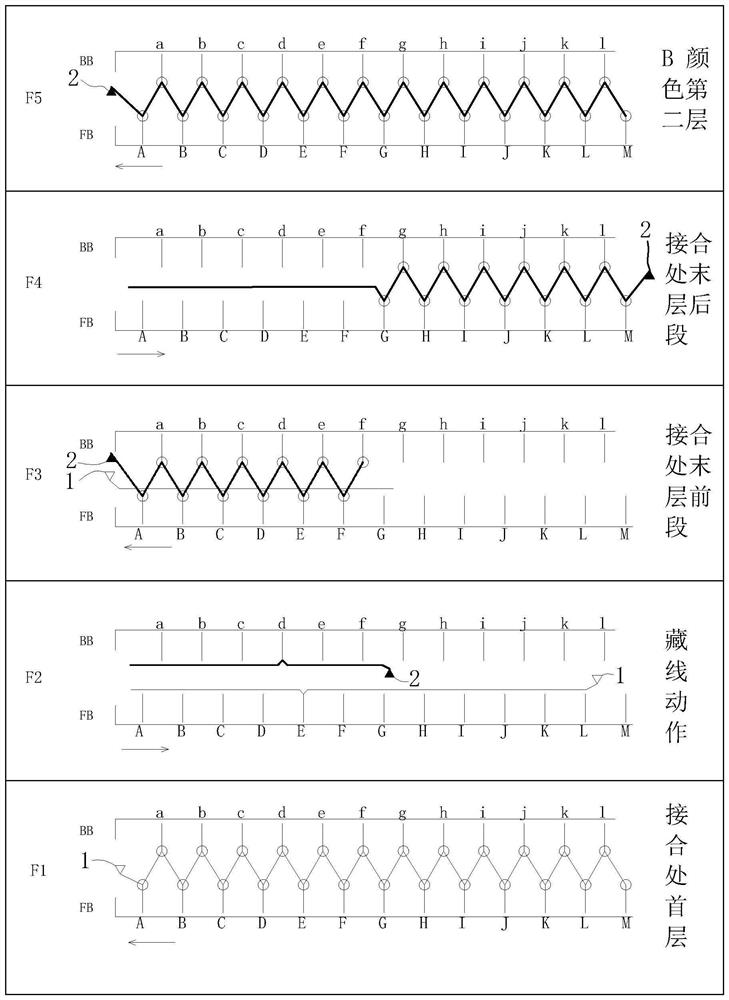

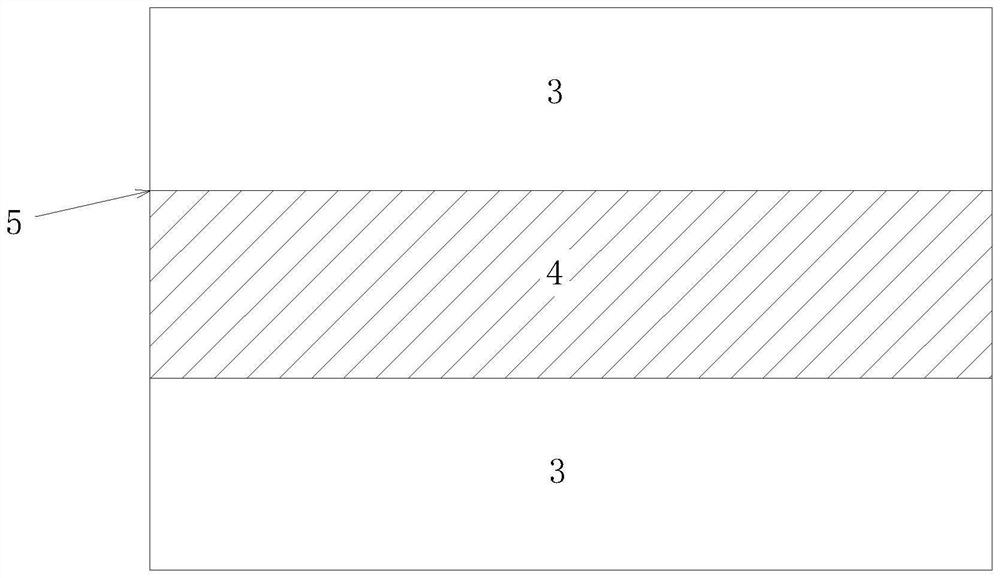

[0024] refer to figure 1 and figure 2 , a double-sided fabric anti-off-line process of the present invention is used to weave the junction 5 of every two color fabrics of multi-color intercolor double-sided fabrics, and is woven by a flat knitting machine with front and rear needle beds. Wherein, a round trip or return of the flat knitting machine head is a knitting cycle, and each knitting cycle is marked with F1-F5 in the figure; the yarn of color A is represented by a thin solid line, and the yarn of color B is represented by a thick solid line, Dotted lines indicate the underlying yarn; odd numbered loops are knit from right to left, even numbered loops are knit from left to right.

[0025] The weaving process includes the following steps:

[0026] Step 1. Knitting color A fabric weave 3. The color A fabric weave is full-needle rib weave, but not limited to full-needle rib weav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com