Dicing tape for processing semiconductor

A semiconductor and dicing technology, which is applied in semiconductor devices, semiconductor/solid device manufacturing, adhesives, etc., can solve the problems of ring frame reuse obstacles, unclear laser marking, low heat resistance, etc., to reduce pollution and prevent The effect of edge collapse and suppression of scatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

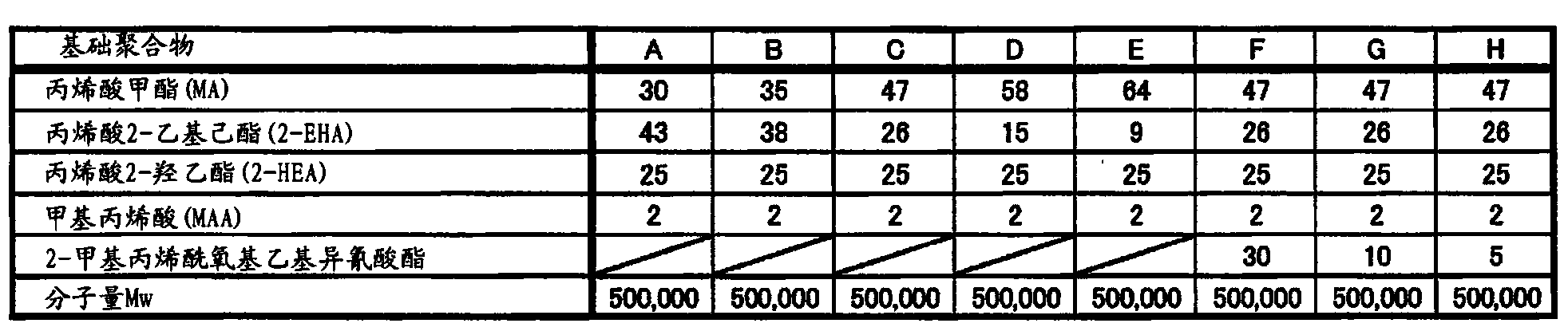

[0068] With respect to 100 parts by mass of the base polymer B, 50 parts by mass of a radiation-curable oligomer obtained by reacting pentaerythritol triacrylate and diisocyanate (the average content of carbon-carbon double bonds per molecule is 6 pieces) was used as a curing method. 2 parts by mass of a polyisocyanate compound (manufactured by Nippon Polyurethane Co., Ltd., trade name CORONATE L) and 3 parts by mass of a photopolymerization initiator (manufactured by Ciba Specialty Chemicals Inc., trade name IRUGACURE651) were mixed to obtain an adhesive combination things.

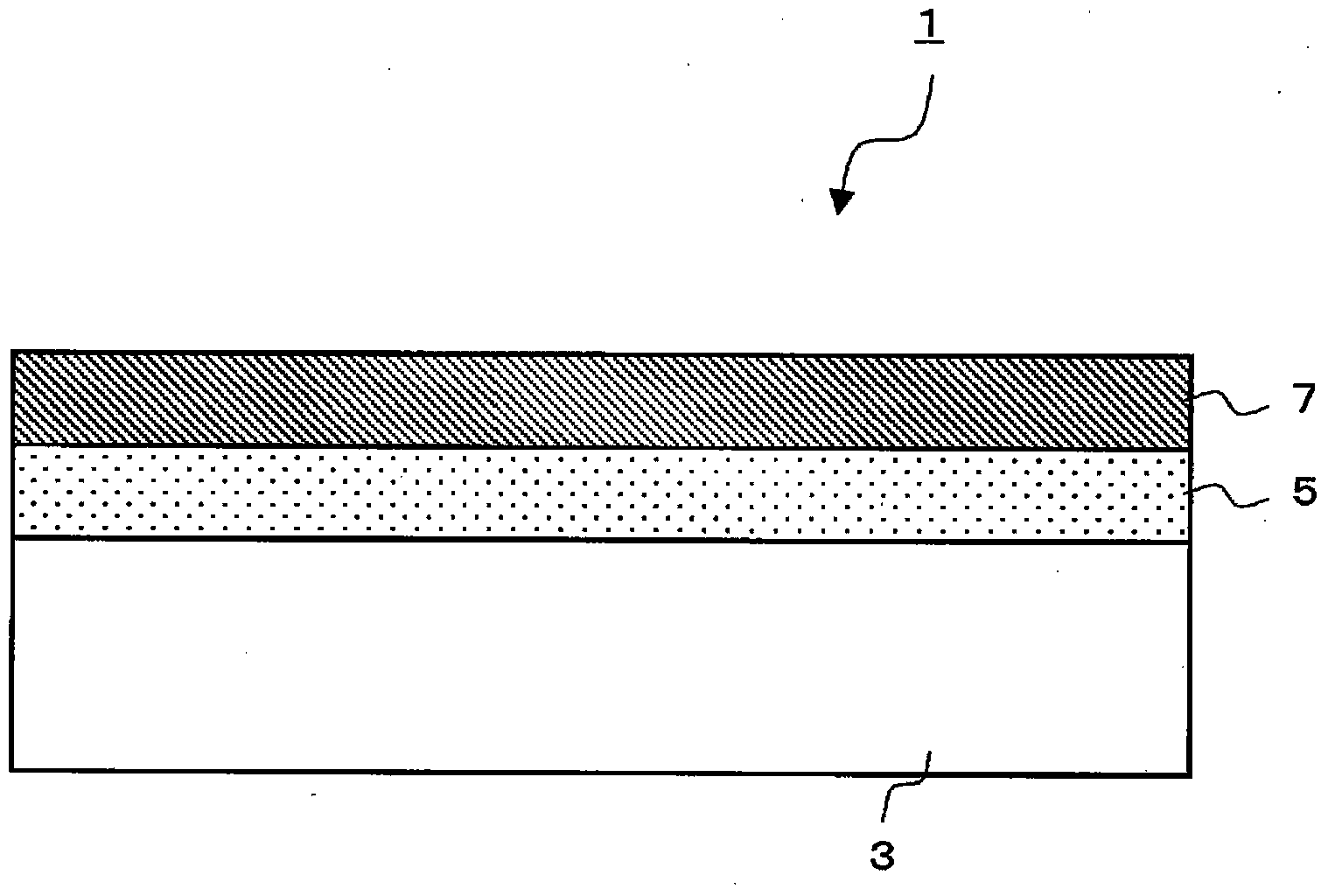

[0069] The obtained adhesive composition was coated on the corona-treated surface of the base film so that the thickness was 20 μm, and a dicing tape for semiconductor processing was produced.

Embodiment 2

[0071] Except having changed the base polymer in an adhesive composition into C, it carried out similarly to Example 1, and obtained the dicing tape for semiconductor processing.

Embodiment 3

[0073] Except having changed the compounding ratio of a radiation-curable oligomer into 25 mass parts, it carried out similarly to Example 2, and obtained the dicing tape for semiconductor processing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com