Cutting method of cutting ultrasonic auxiliary lines and apparatus thereof, and a method of producing wafers

A technology of cutting device and cutting method, which is applied to fine working devices, manufacturing tools, stone processing equipment, etc., can solve the problems of cutting energy loss of cutting wire mesh 15, jumper wire and disconnection of cutting wire mesh 15, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

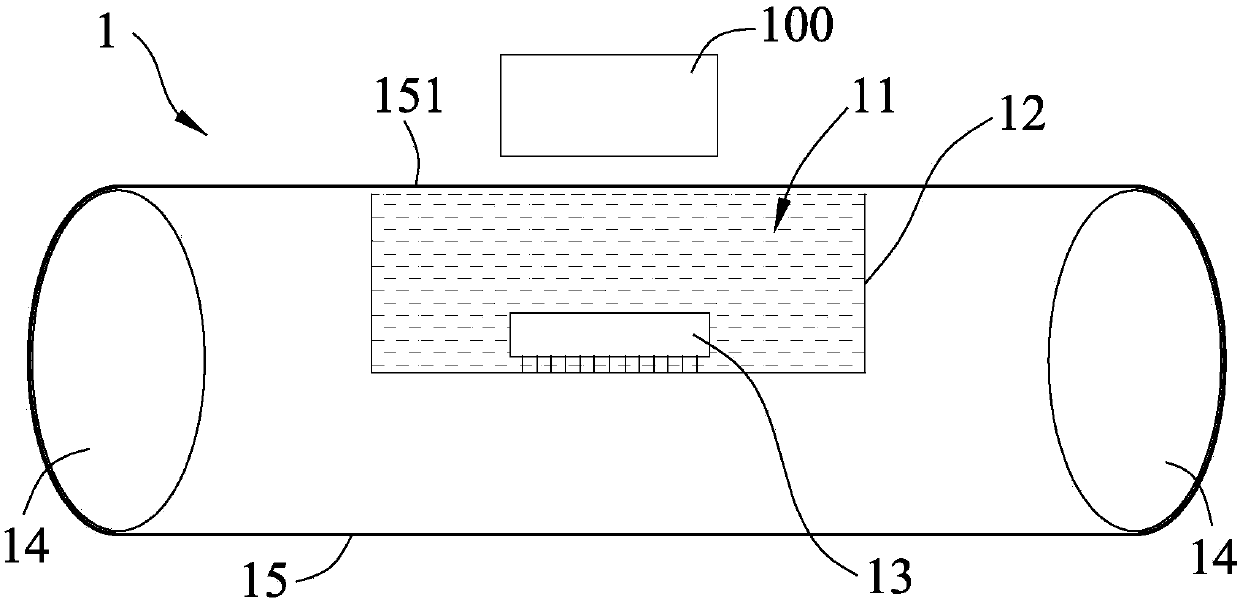

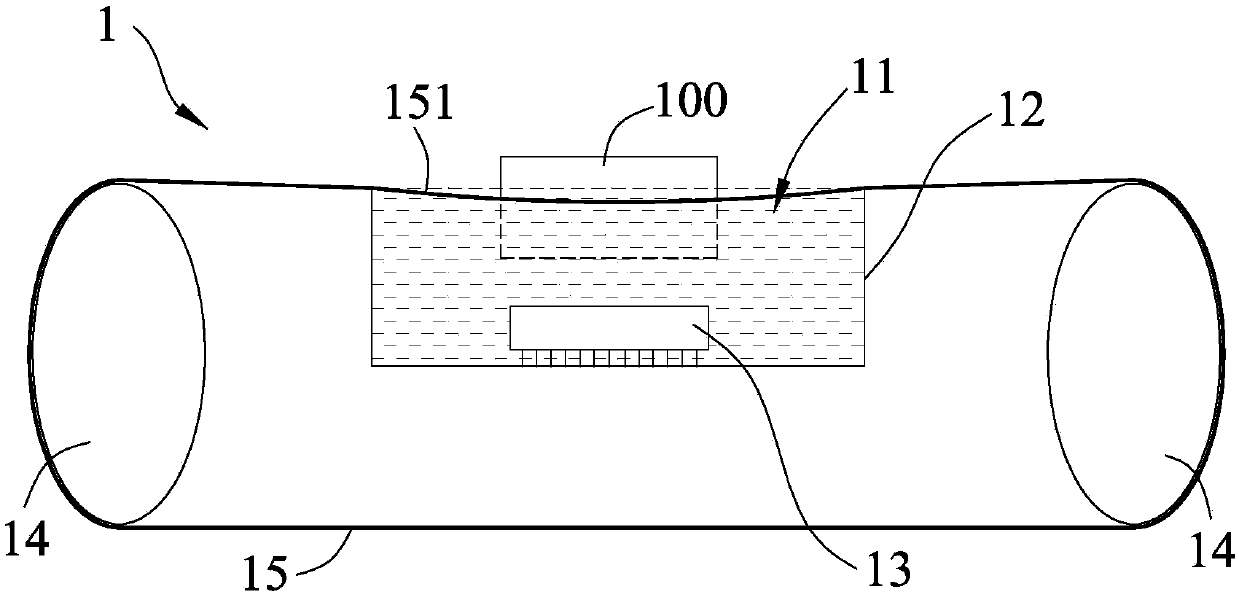

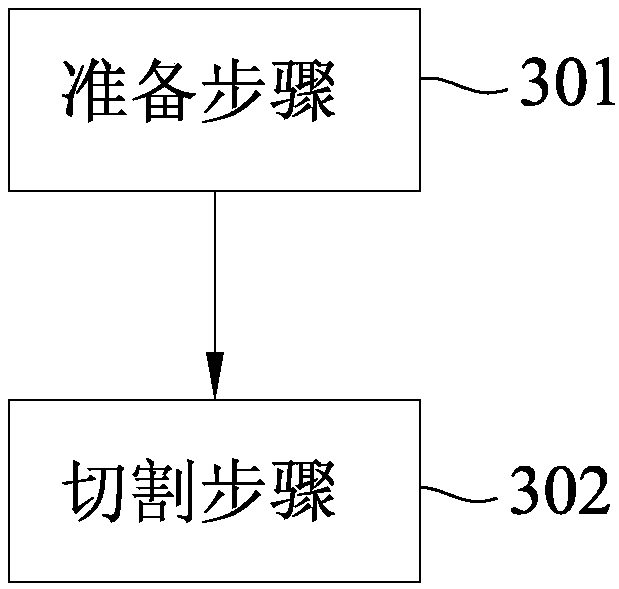

[0048] refer to image 3 , an embodiment of the ultrasonic-assisted wire cutting method of the present invention includes a preparation step 301 and a cutting step 302 .

[0049] Cooperate with reference Figure 4 , first perform the preparation step 301 , prepare an ultrasonic assisted wire cutting device 2 , and inject a cutting fluid 200 into the ultrasonic assisted wire cutting device 2 .

[0050] Specifically, refer to Figure 5 , Figure 5 display edge Figure 4 A section view obtained by a secant line V-V. The ultrasonic auxiliary wire cutting device 2 includes a base body 20, an ultrasonic oscillator 3 arranged on the base body 20, two control devices 5 arranged on opposite sides of the base body 20, and a plurality of control devices 5 corresponding to the control device 5. The cutting line 4 is connected so as to be located on the base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com