A scanning mobile device for tower fault detection

A technology of fault detection and scanning movement, which is applied in the direction of measuring devices, specific gravity measurement, material analysis using wave/particle radiation, etc. It can solve the problems of energy consumption, limited length, large wind resistance, etc., and achieve uniform and neat wiring and poor expansion and contraction performance , to prevent the effect of messy lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

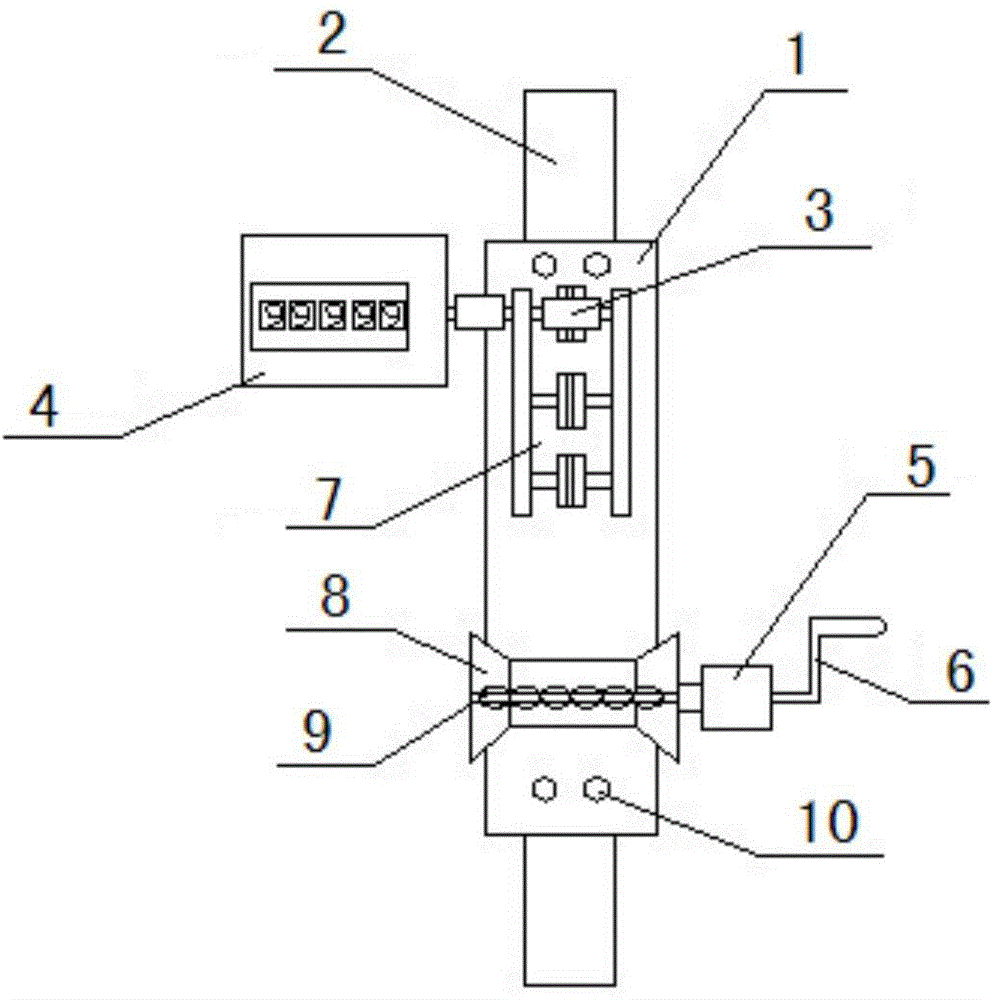

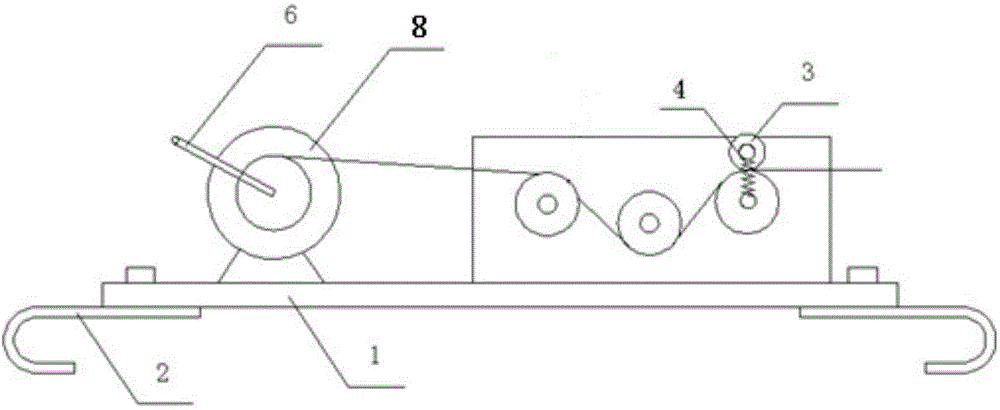

[0022] A scanning mobile device for tower fault detection such as figure 1 As shown, the device includes a reel 8, a router 9, a handle 6, a worm reducer 5, a pulley block 7, a crimping device 3 and a base 1, and the key is that the reel 8 and the worm reducer 5 Connected with the handle 6, the wire rope of the reel 8 is positioned through the pulley block 7, and there is a crimping device 3 on the pulley farthest from the reel 8 in the pulley block 7, and the rotation axis of the pulley is in phase with the mechanical rotation counter 4 Connection; the winding wheel 8 and the pulley block 7 are installed on the base 1 together.

[0023] The router 9 is a two-way screw structure, and the screw of the router 9 cooperates with the central axis of the winding wheel 8 by a set of gears to realize the synchronization of winding and wiring.

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com