Semi-rotating kettle device of sewing machine

A sewing machine, semi-rotating technology, applied in the direction of sewing machine components, sewing machine ring mechanism, sewing equipment, etc., can solve the problems of sewing needle breakage, thread jumping, tip damage, etc., and achieve the effect of improving sewing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

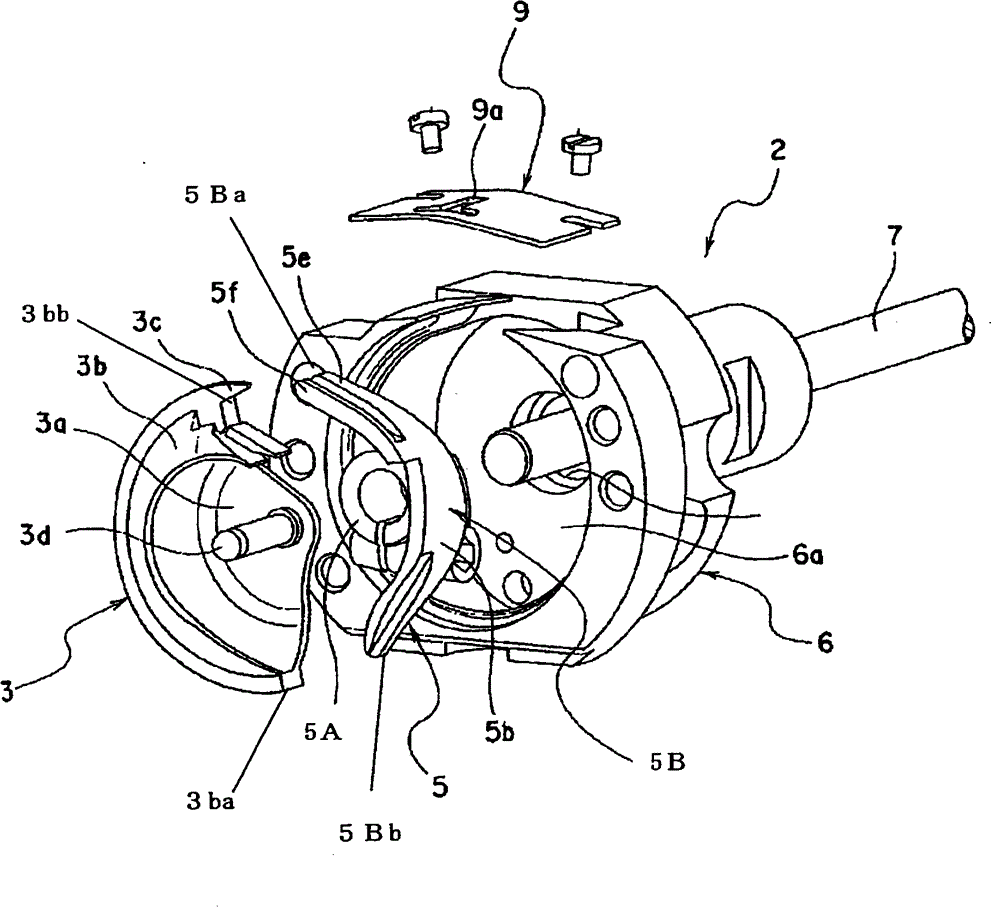

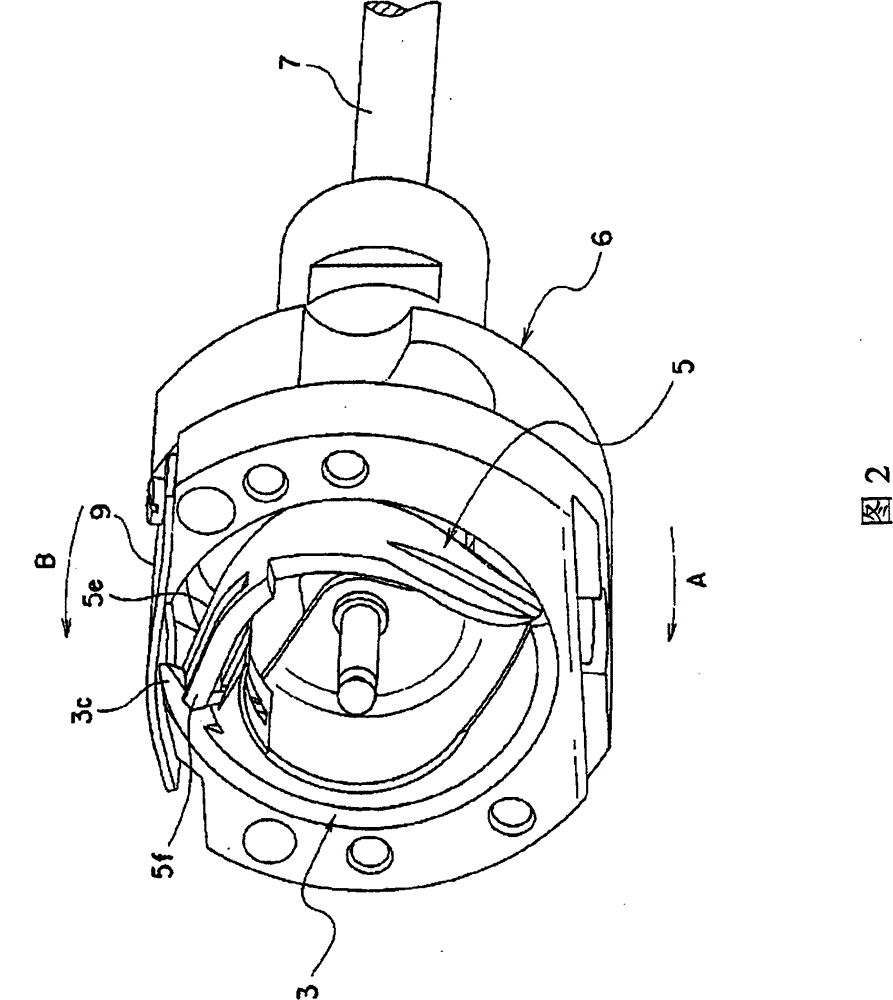

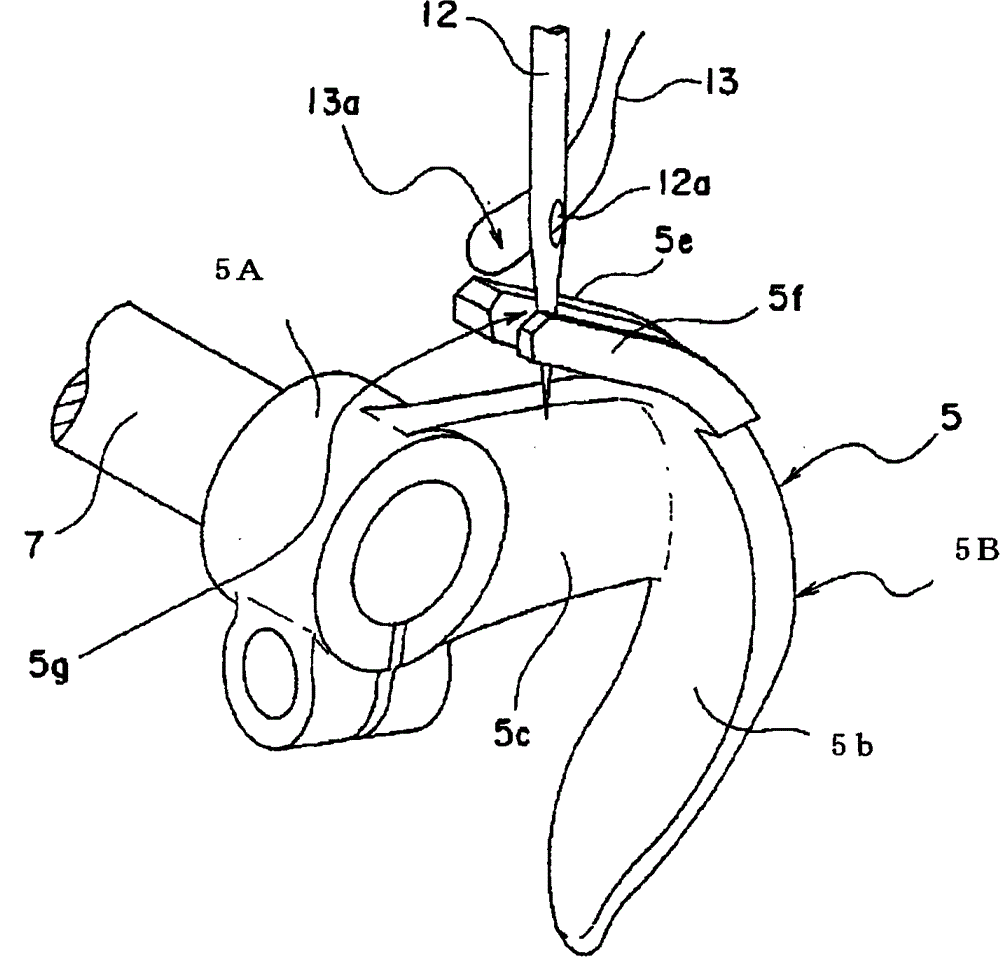

[0023] Below, refer to Figure 1 to Figure 5 One embodiment of the sewing machine according to the present invention will be described. Here, in this embodiment, a sewing machine will be described in which the side operated by the operator of the sewing machine is defined as the front side, and the opposite side is defined as the rear side as a kettle mechanism for interlacing the lower thread and the upper thread. A semi-rotary tank that rotates the middle tank in a reciprocating direction at a predetermined angle (reciprocating half-rotation) is used.

[0024] Such as figure 1 and figure 2 As shown, the semi-rotary kettle 2 of the sewing machine related to this embodiment has: a middle kettle 3, which holds the same unillustrated bobbin housing as the prior art; The middle kettle 3 is held rotatably.

[0025] The driver 5 and the large kettle 6 that make the middle kettle 3 reciprocatingly rotate are fixedly installed under the needle plate not shown in the figure at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com