Anti-falling-off type wire passing wheel of cutting machine

A wire-passing wheel and cutting machine technology, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of rubber ring skipping, production speed reduction, and affecting product processing and production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

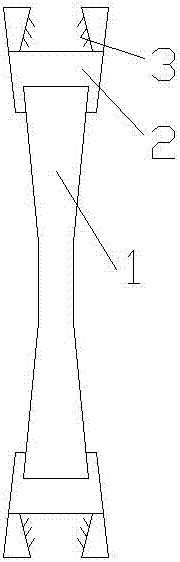

[0013] Described in the present invention is a kind of wire-passing wheel of anti-off type cutting machine, such as figure 1 As shown, it includes an aluminum alloy frame 1 and a rubber ring 2. The rubber ring 2 is placed outside the aluminum alloy frame 1. The cut surface of the aluminum alloy frame 1 becomes larger from the inside to the outside. The rubber ring 2 It includes an inner groove and an outer groove, the section of the inner groove becomes smaller sequentially from the inside to the outside, the outer end of the aluminum alloy skeleton 1 is correspondingly embedded in the inner groove, and the outer groove The two opposite side walls are also respectively provided with baffles 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com