Voile dispersing mechanism for sartorius

A yarn splitter and sewing machine technology, which is applied in the direction of sewing equipment, sewing machine components, sewing machine thread take-up devices, etc., can solve problems such as inability to sew, difficult to correspond to high-speed operation of sewing machines, provocation or unstable wires, etc., to prevent unconscious The effect of jumper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

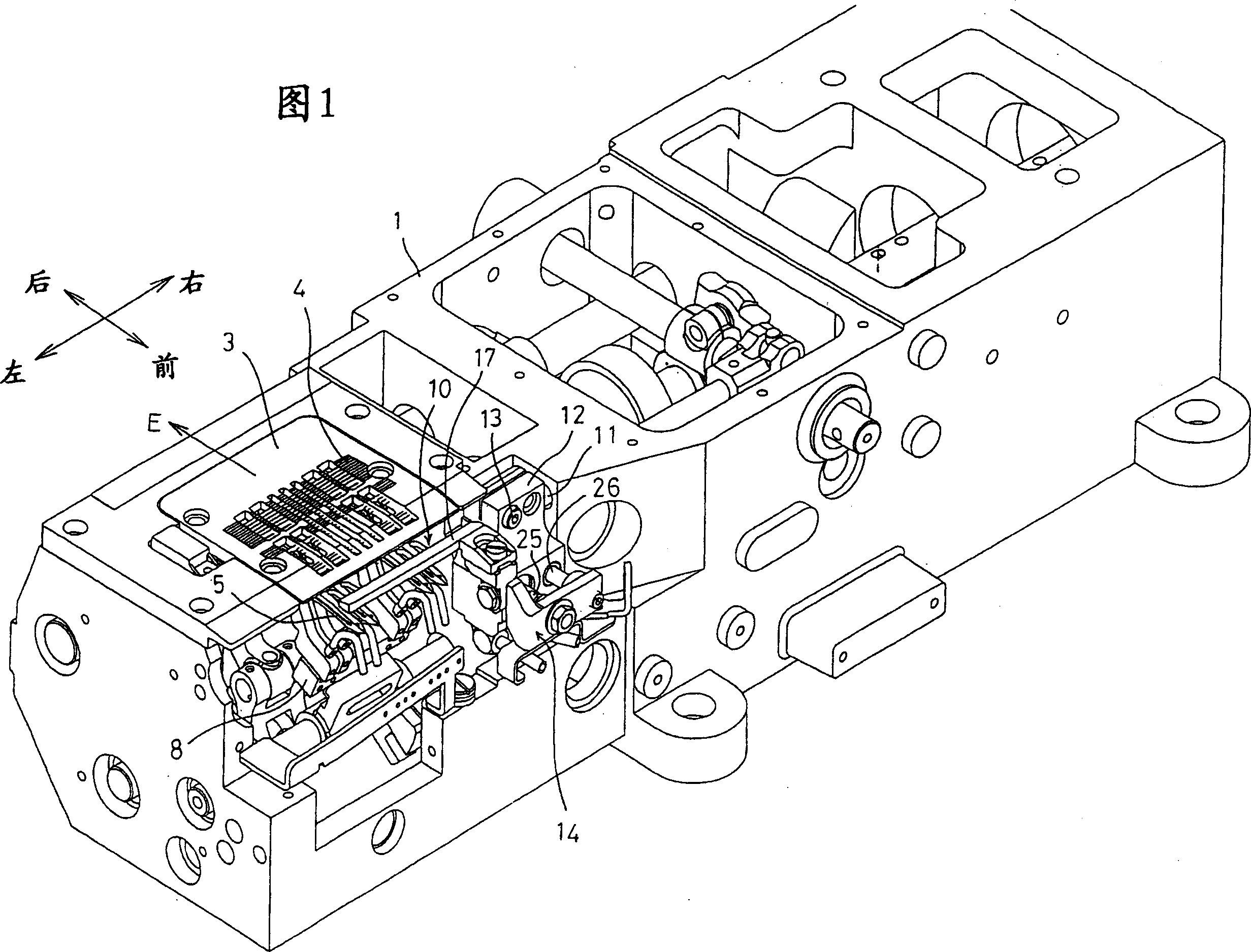

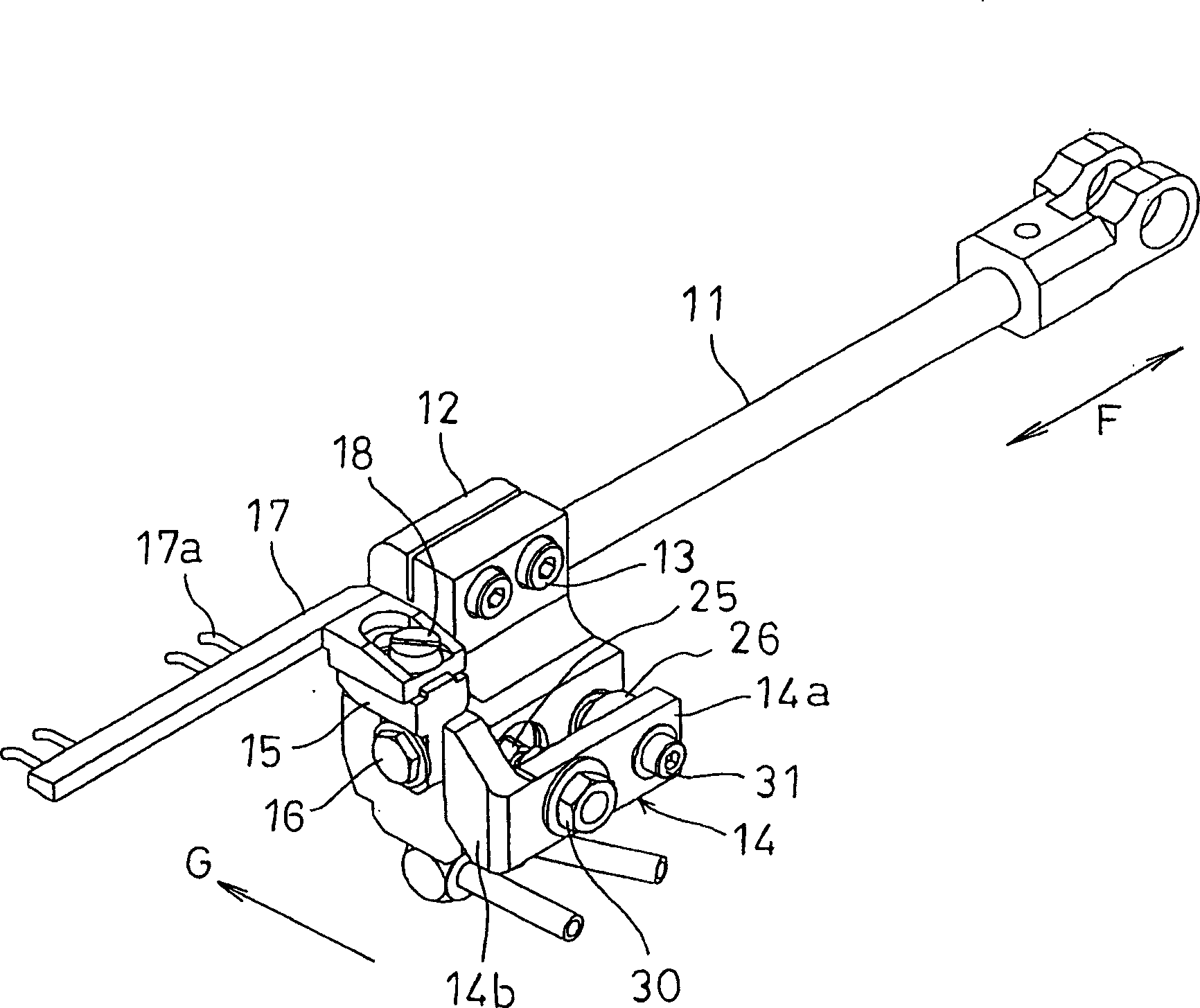

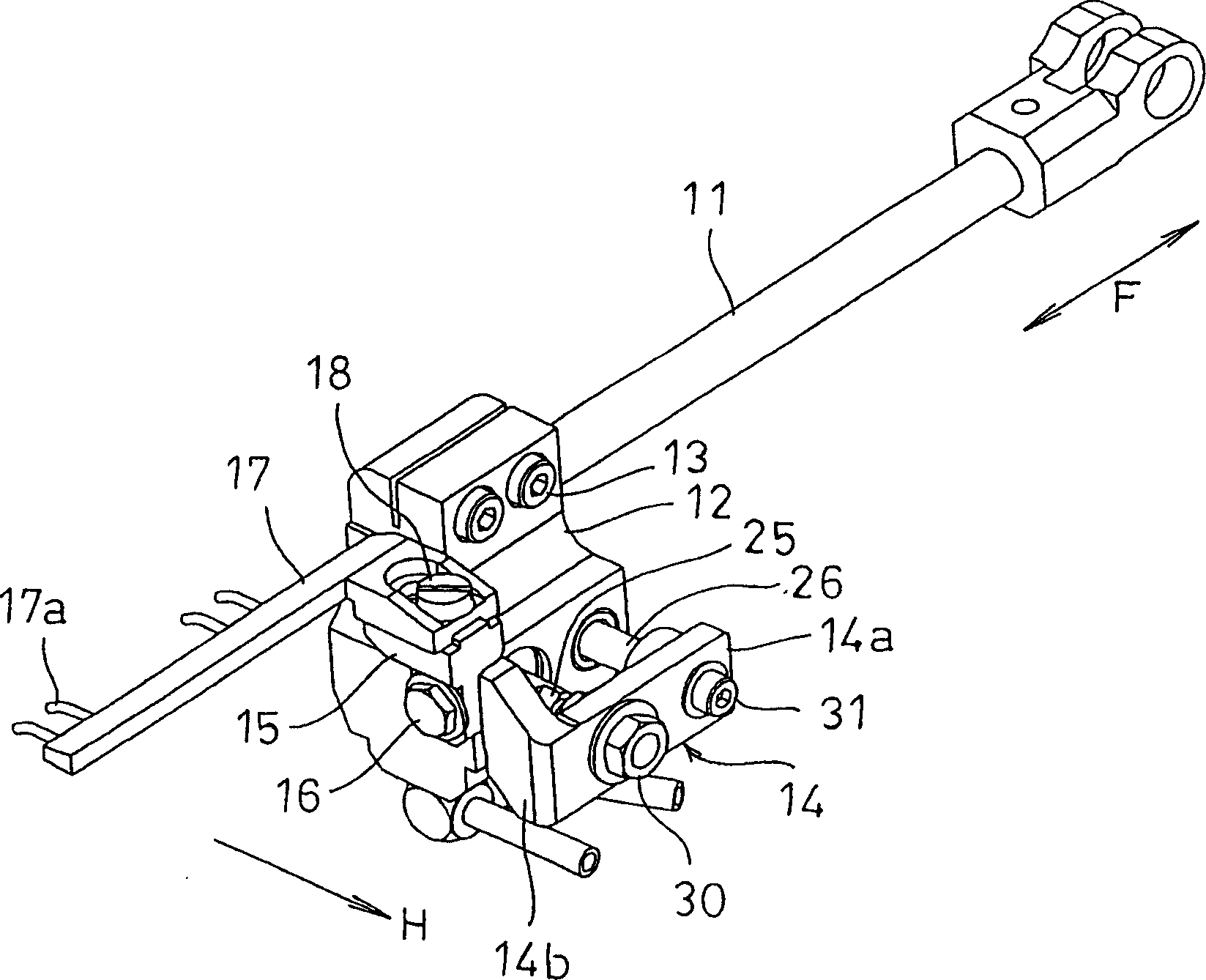

[0029] Preferred embodiments of the present invention will be described with reference to the drawings. Fig. 1 is a perspective view showing a base portion of a sewing machine having a yarn divider mechanism according to an embodiment of the present invention, figure 2 It is a perspective view showing the yarn divider mechanism in a state where the yarn divider is moved to the guide wire position, image 3 is a perspective view showing the splitter mechanism in a state where the splitter has been moved to a retracted position, Figure 4 It is a side view showing the splitter mechanism in a state where the splitter has been moved to the wire position, Figure 5 is a side view showing the splitter mechanism in a state where the splitter has been moved to a retreat position, Figure 6 It is a front view showing the yarn divider of the yarn divider mechanism, and Fig. 7(a) shows the state where the yarn divider is moved to the guide wire position. Figure 6 The X-X line sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com