Slot structure of guide wheel of linear cutting machine

A cutting machine and wire trough technology, which is applied to work accessories, stone processing equipment, manufacturing tools, etc., can solve the problems of inconsistent thickness chip slicing, wire splicing in cutting operations, and increased wire shaking, etc., to improve yield, Avoid jumpers, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

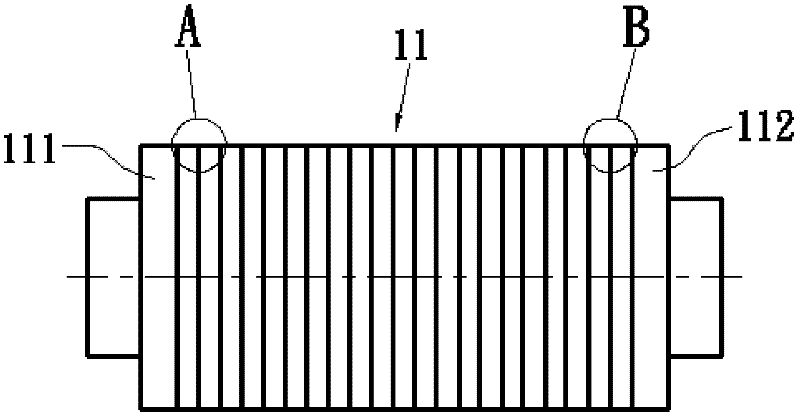

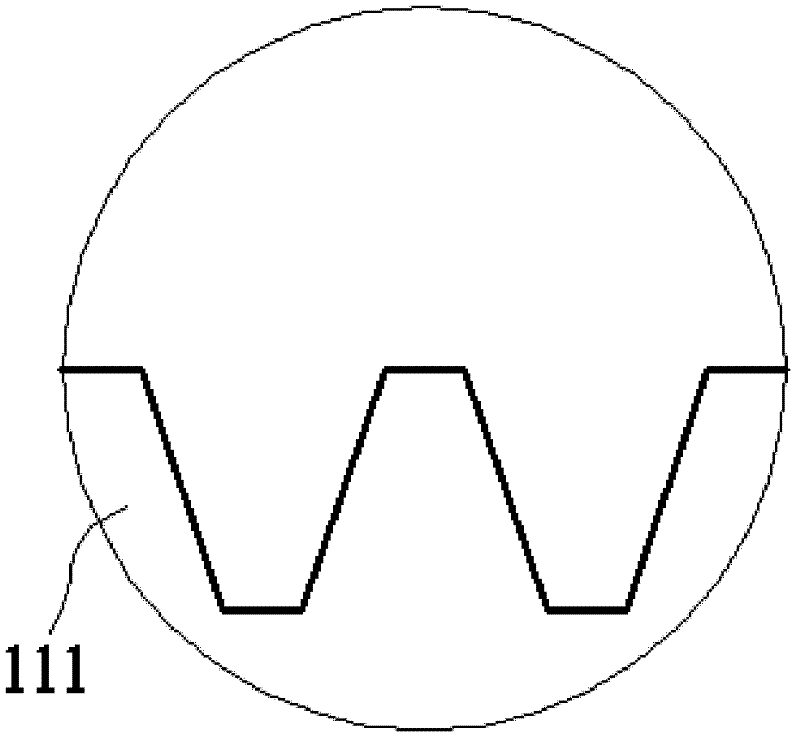

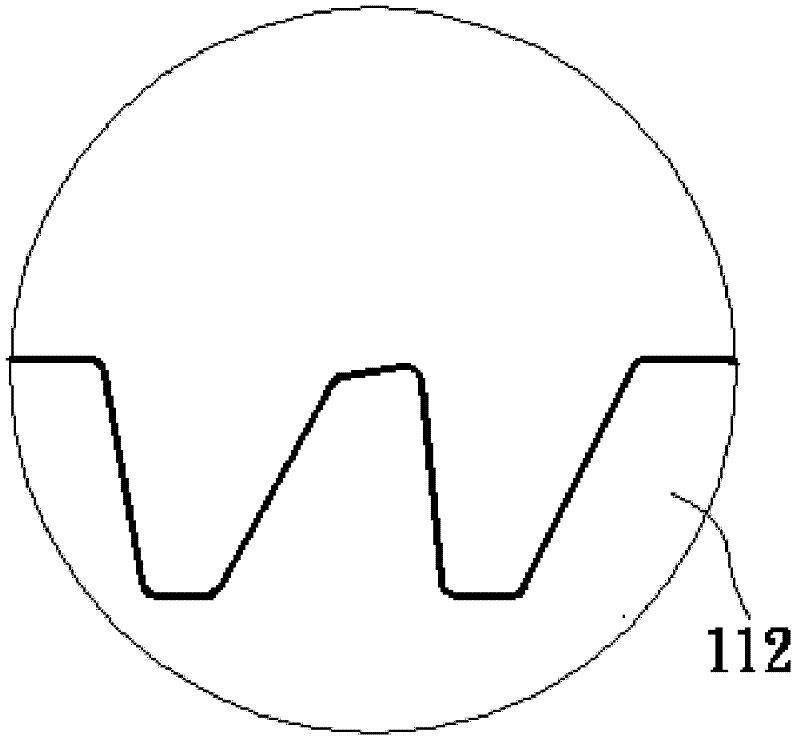

[0021] Embodiment: A wire groove structure of a guide wheel of a wire cutting machine, the guide wheel 11 has an opposite wire-entry end 111 and a wire-out end 112, and the guide wheel is located at the wire-entry end and the wire-outlet end. There are several parallel annular wire grooves 12 in the position between the ends, and the wire 2 of the linear cutting machine is wound between adjacent guide wheels along the annular wire grooves to form several parallel tangent lines. The annular wire slot near the outlet end is the first wire slot 121, the first wire slot is composed of a U-shaped slot 1211 and an arc-shaped slot 1212 integrally connected, and the upper end of the U-shaped slot is integrally formed with the arc-shaped slot The width of the opening 1213 at the upper end of the arc-shaped groove is the same as the diameter of the wire 2 (referring to the initial diameter of the wire).

[0022] The bottom surface of the U-shaped groove is arc-shaped.

[0023] The groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com