Wire arranging location mechanism of ring-shaped winding machine

A winding machine and wire positioning technology, which is applied in the manufacture of coils, electrical components, inductors/transformers/magnets, etc., can solve the problems of affecting the winding quality, overlapping or crossing wires, and scrapping coils, so as to avoid jumping wires or Effects of overlapping lines, avoiding overlapping, and stabilizing the sliding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

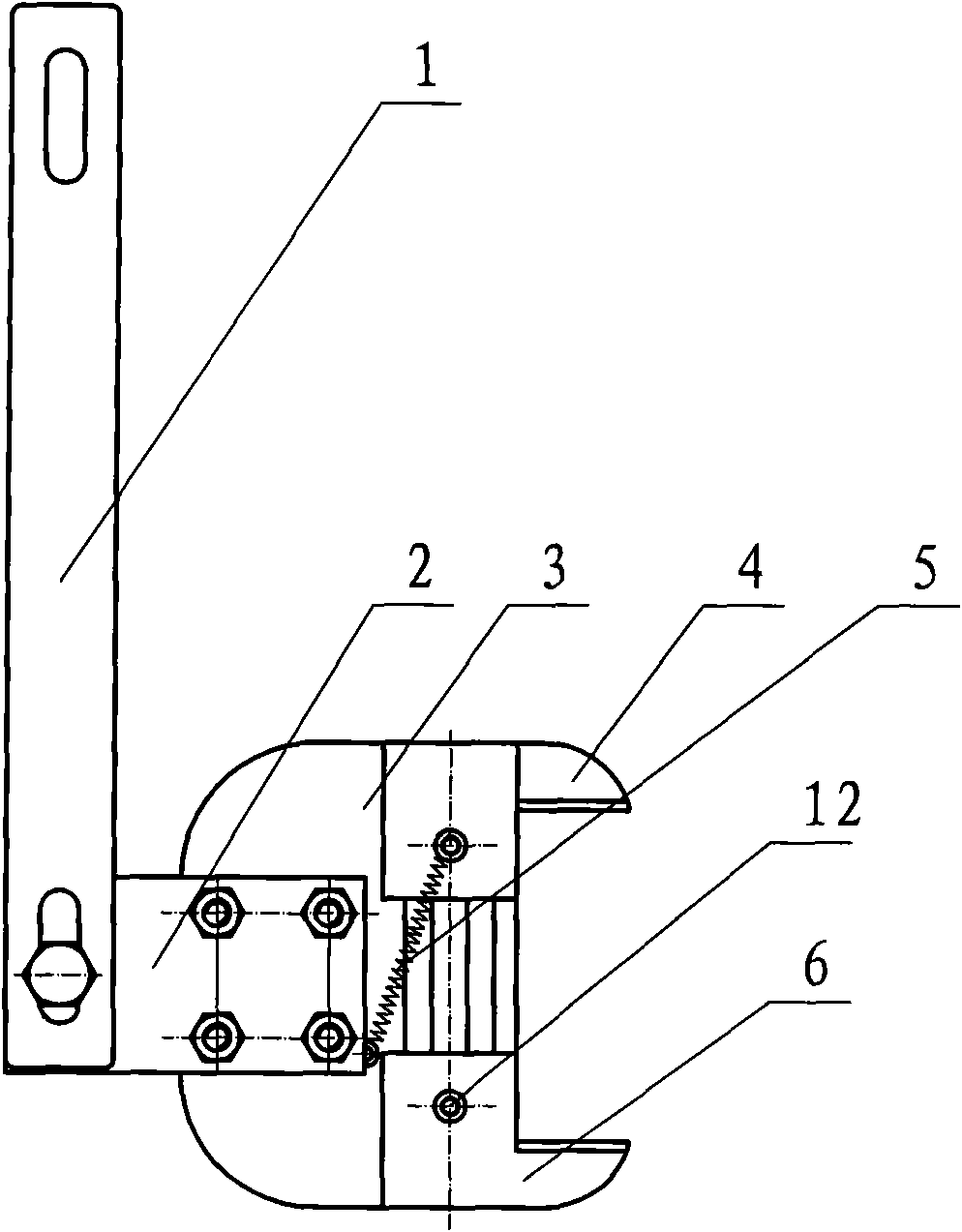

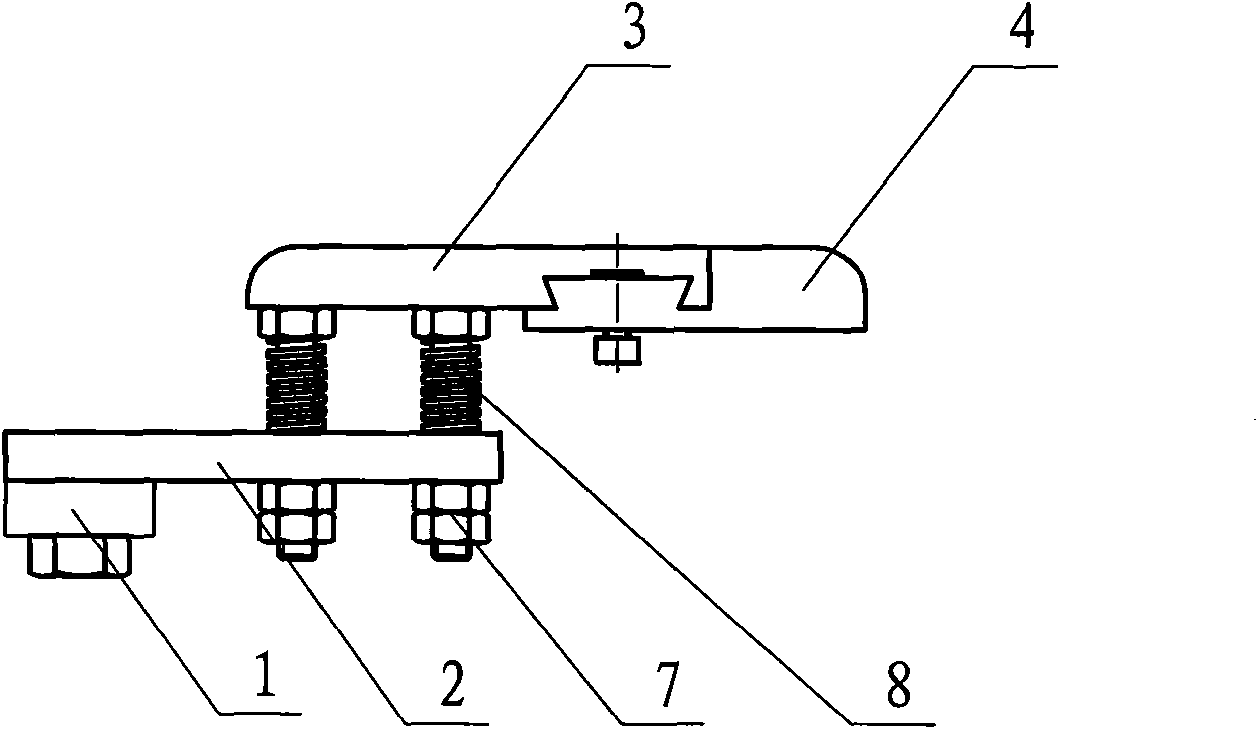

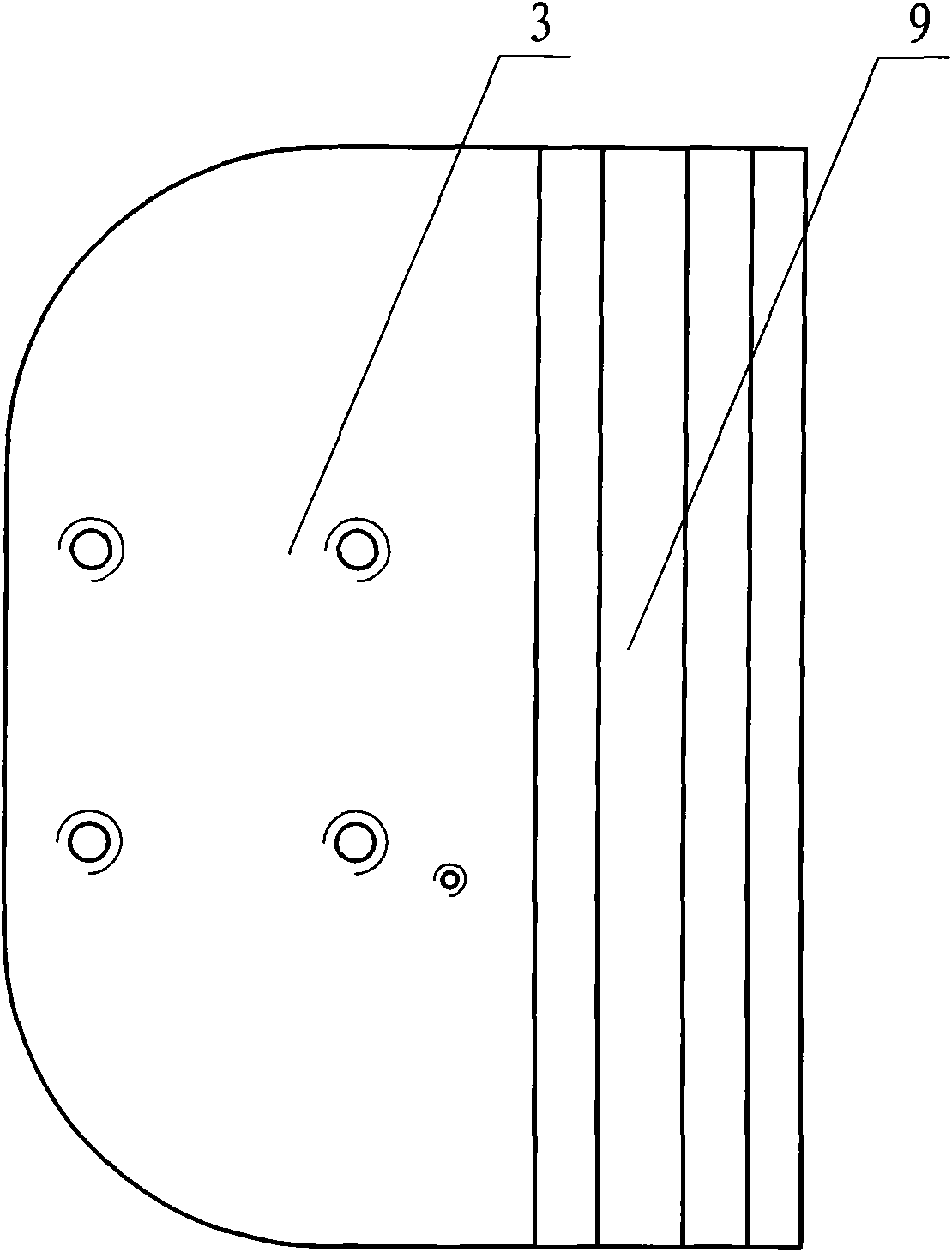

[0014] Referring to the accompanying drawings, the wire arrangement positioning mechanism of the annular winding machine includes a mounting rod 1, a baffle body 3, a connecting plate 2, an upper positioning head 4 and a lower positioning head 6, and the baffle body 3 passes through the connecting plate 2 Connected with the installation rod, the upper positioning head 4 is slidably installed on the baffle main body 3 ; the lower positioning head of the present invention can also be adjusted when installed on the baffle main body 3 . The upper positioning head 4 and the lower positioning head 6 of the present invention are installed on the baffle body 3 as follows: the baffle body 3 is provided with a dovetail groove 9, and the upper positioning head 4 and the lower positioning head 6 are provided with dovetails Structures 10 and 11 . The dovetail structures 10 and 11 are matched with the dovetail grooves 9 , so that the upper positioning head 4 can slide stably in the dovetail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com