Slitting system for papermaking and papermaking slitting method thereof

A paper roll and paper technology, applied in the field of slitting systems for papermaking, can solve the problems affecting paper forming quality, offset, uneven ends of paper rolls, etc. The effect of volume quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

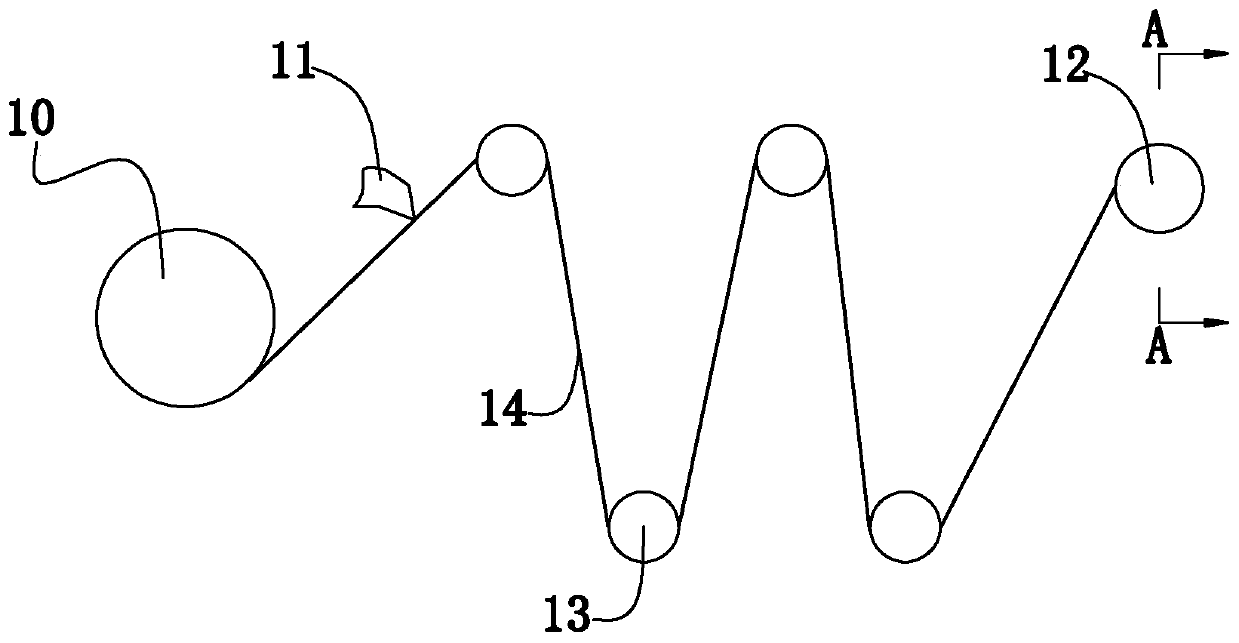

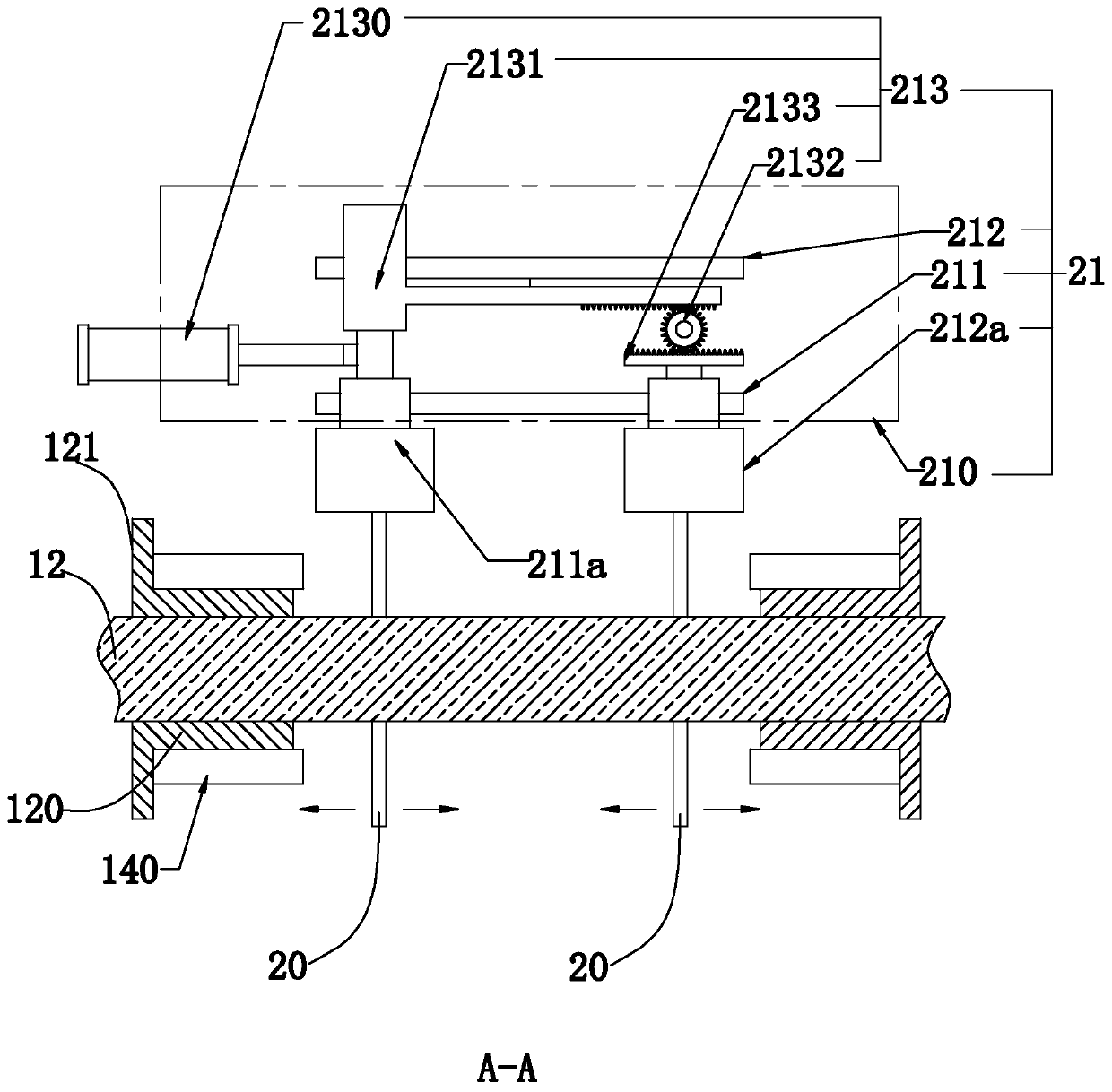

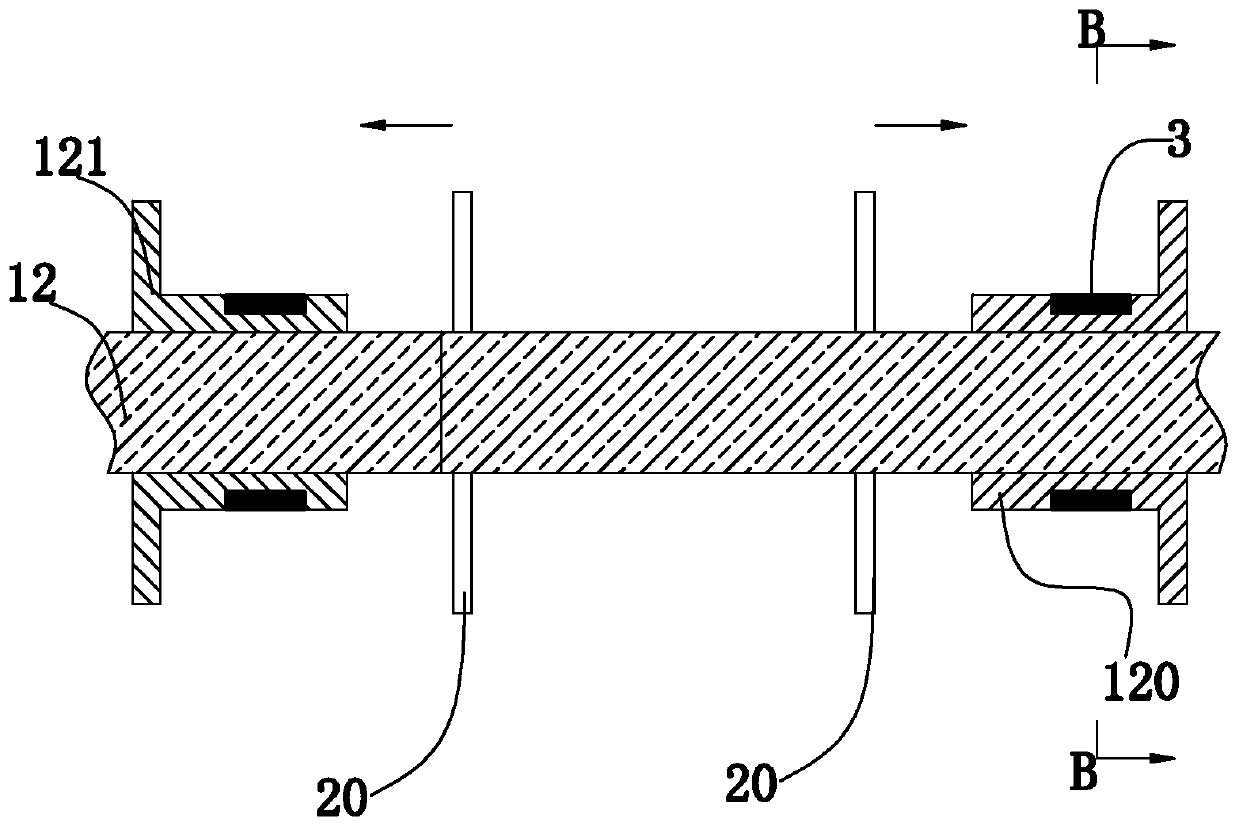

[0049] Such as Figure 1-Figure 2 As shown, the present invention discloses a slitting system for papermaking, including a supply roll 10 for installing a paper roll, a cutter 11 for cutting paper 14, and a paper 14 for rewinding and having at least two rewinding sections The rewinding roller 12 of 120, in a specific embodiment of the present invention, includes at least two sorting parts 20 that move on the rewinding roller 12 and are used to organize the end of the paper roll 140 on the rewinding part 120 and for A driving device 21 for driving the finishing unit 20 to move.

[0050] In a specific embodiment of the present invention, the paper rolls of the supply roll 10 and the rewind roll 12 may be provided with several tension rolls 13 .

[0051] In a specific embodiment of the present invention, a limiting portion 121 may be provided on the side of the rewinding portion 120 away from the finishing portion 20 .

[0052] In a specific embodiment of the present invention,...

Embodiment 2

[0065] Embodiment 2, the difference with embodiment 1 is that

[0066] Such as Figure 3-Figure 5 As shown, in the specific embodiment of the present invention, it also includes a dust shaking module 3 installed on the rewinding part 120; The annular body 30 on the rewinding part 120, at least one pressure sensor 31 disposed in the annular body 30 and capable of generating a pressure signal, at least one disposed in the annular body 30 and used to receive A pressure signal and a processor 32 for processing the pressure signal, a vibrating body 33 connected to the annular body 30 and located inside the rewinding portion 120, and a vibration generating device 34 arranged in the vibrating body 33; wherein, The processor 32 can generate a vibration control signal according to the pressure signal of the pressure sensor 31, and send the vibration control signal to the vibration generating device 34, and the vibration generating device 34 vibrates based on the vibration control sign...

Embodiment 3

[0075] Embodiment 3, the difference with embodiment 2 is that

[0076] Such as Figure 6-Figure 10 As shown, in the specific embodiment of the present invention, it also includes a dust suction device 5 connected to the finishing part 20; wherein, the dust suction device 5 includes a dust suction body 50 with an arc-shaped dust suction surface 5a, several sets of spacers The suction hole 51 provided on the dust suction surface 5a, a plurality of suction pipes 52 which are arranged inside the dust collection body 50 and communicate with each group of suction holes 51, and the suction pipes 52 for communicating with each other Exhaust pipe 53, several blockage components 54 that can enter the suction pipe 52 and are used to disconnect the suction hole 51 from the suction pipe 52, and the air suction system 55 and pulse system communicated with the exhaust pipe 53 56.

[0077] In a specific embodiment of the present invention, the blocking assembly 54 includes a hollow blocking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com