Wire regulating device of multi-wire cutting machine steel wire

A technology of multi-wire cutting machine and wire adjusting device, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc., and can solve problems that cannot meet the needs of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

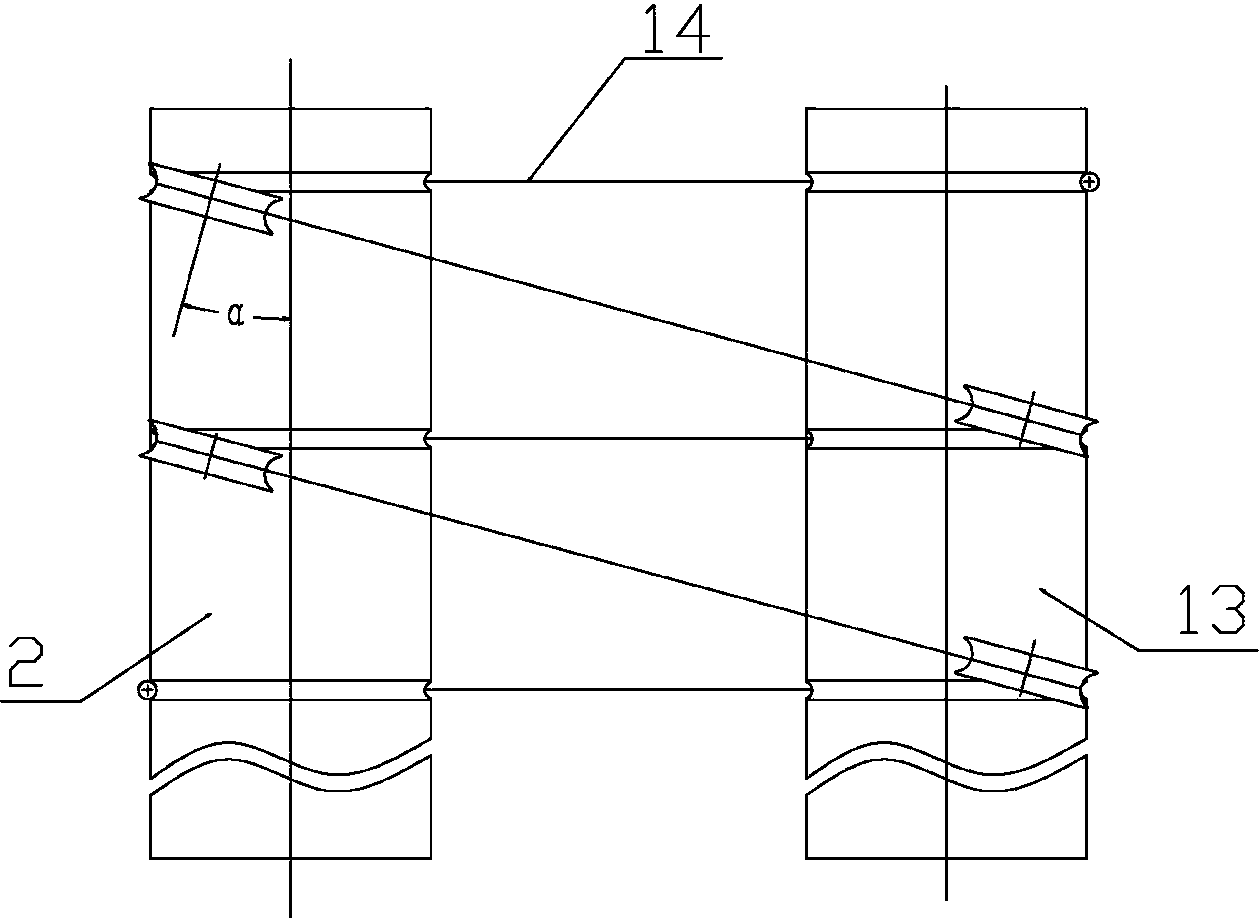

[0018] The present invention adopts the method of adjusting the thread on the guide wheel group instead of completing the thread adjustment on the cutting roller. That is, by adjusting the angle between the guide wheel and the cutting roller, and between the guide wheel and the guide wheel, the ideal state that the steel wire enters and exits the cutting roller and the guide wheel in the same plane and tangent to the cutting roller groove and the guide roller groove is realized.

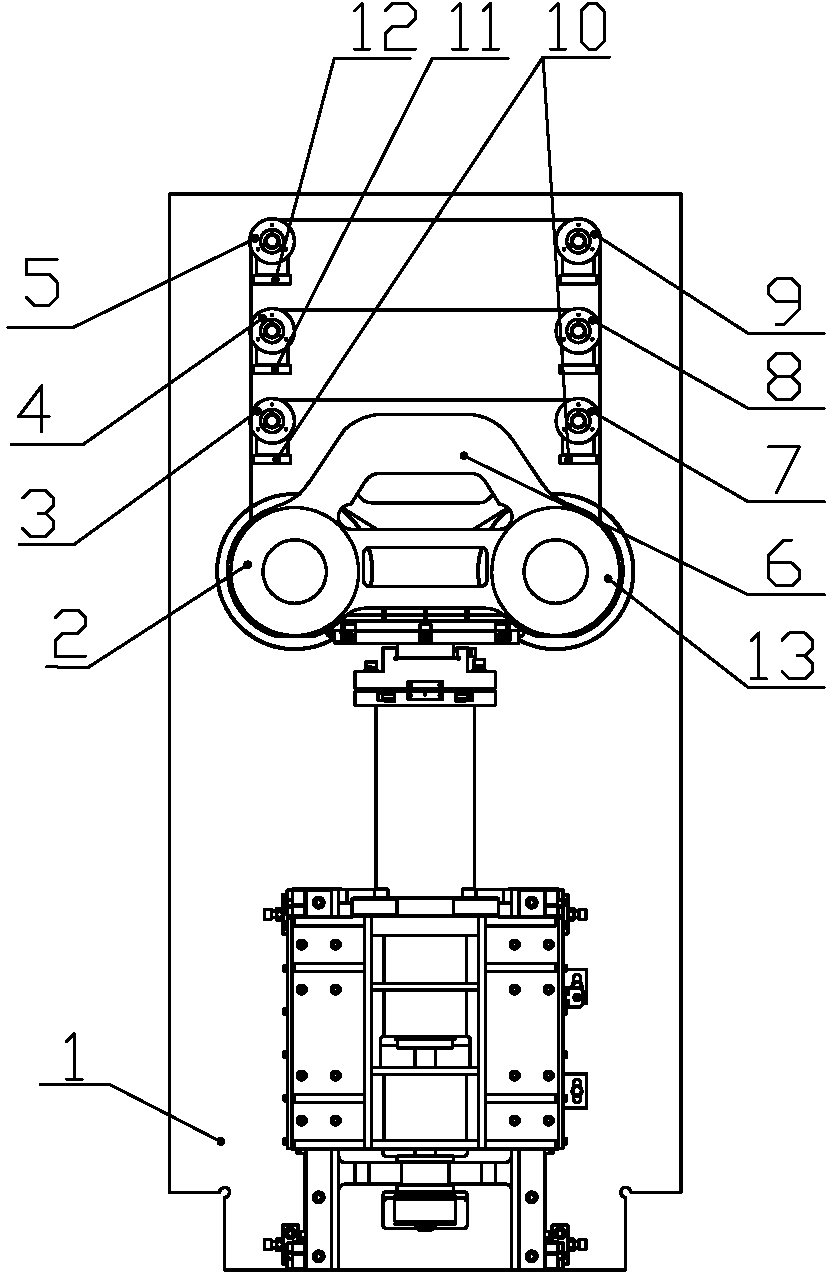

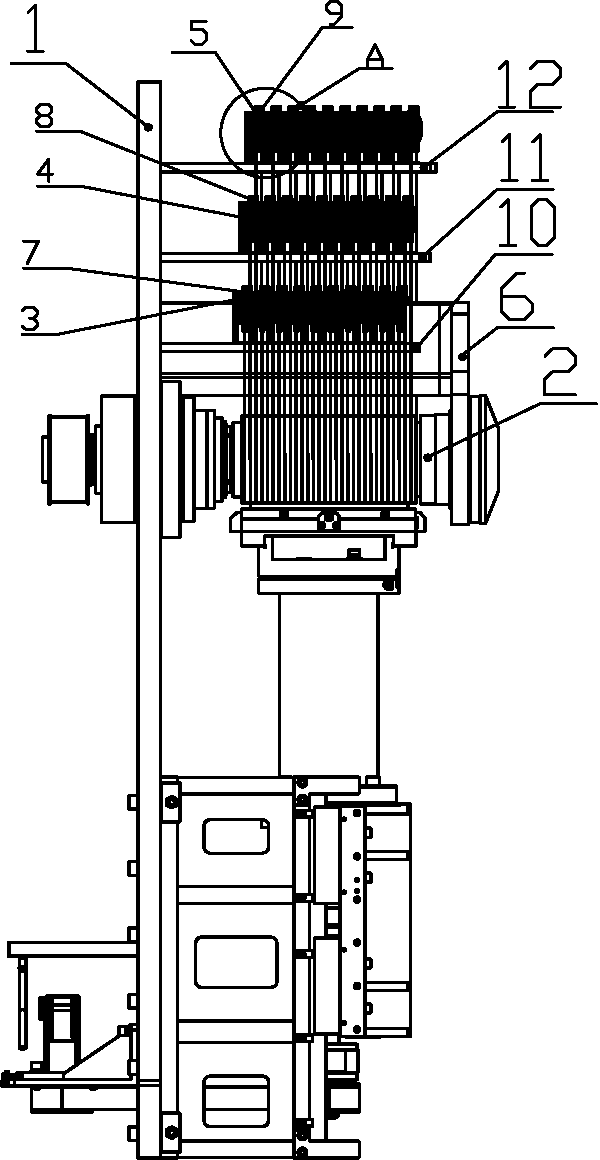

[0019] A wire adjustment device for steel wires of a multi-wire cutting machine, which includes a left cutting roller 2 and a right cutting roller 13 installed on the front fixing plate 6 and the rear main board 1 with the same size, number of wire grooves, and groove spacing, and the rear main board 1 A guide wheel mounting plate is provided, and the guide wheel mounting plate is respectively provided with an incoming line guide wheel set and an outgoing line guide wheel set; each guide wheel on the ...

Embodiment 2

[0023] In order to realize the cutting requirements of different thicknesses and ensure the installation position of the guide wheel, the figure 1 , figure 2 It can be seen that the guide wheel mounting plate of the present invention comprises a lower guide wheel mounting plate 10, a middle guide wheel mounting plate 11, an upper guide wheel mounting plate 12, and the lower guide wheel mounting plate 10 is respectively provided with a lower incoming line guide wheel group 3 , Outgoing wire guide wheel group 7 below; The middle guide wheel mounting plate 11 is respectively provided with middle incoming wire guide wheel group 4, middle outlet wire guide wheel group 8; The upper guide wheel mounting plate 12 is respectively provided with upper incoming wire guide wheel group 5, The upper outgoing line guide wheel set 9; the sum of the numbers of the guide wheels on the lower incoming line guide wheel set 3, the middle incoming line guide wheel set 4, and the upper incoming line ...

Embodiment 3

[0026] Depend on image 3 It can be known that the angle α is 15.13°. Remaining with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com