Numerical control polycrystalline silicon diamond wire high-speed cutting-off machine

A diamond wire and cutting machine technology, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problem that the loading, unloading and working areas are not independent, the freedom of worktable coordination is limited, and the worktable is not loaded. Convenience and other issues, to achieve the effect of shortening the truncation processing time, facilitating the feeding and cutting of the knife, and reducing the auxiliary processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

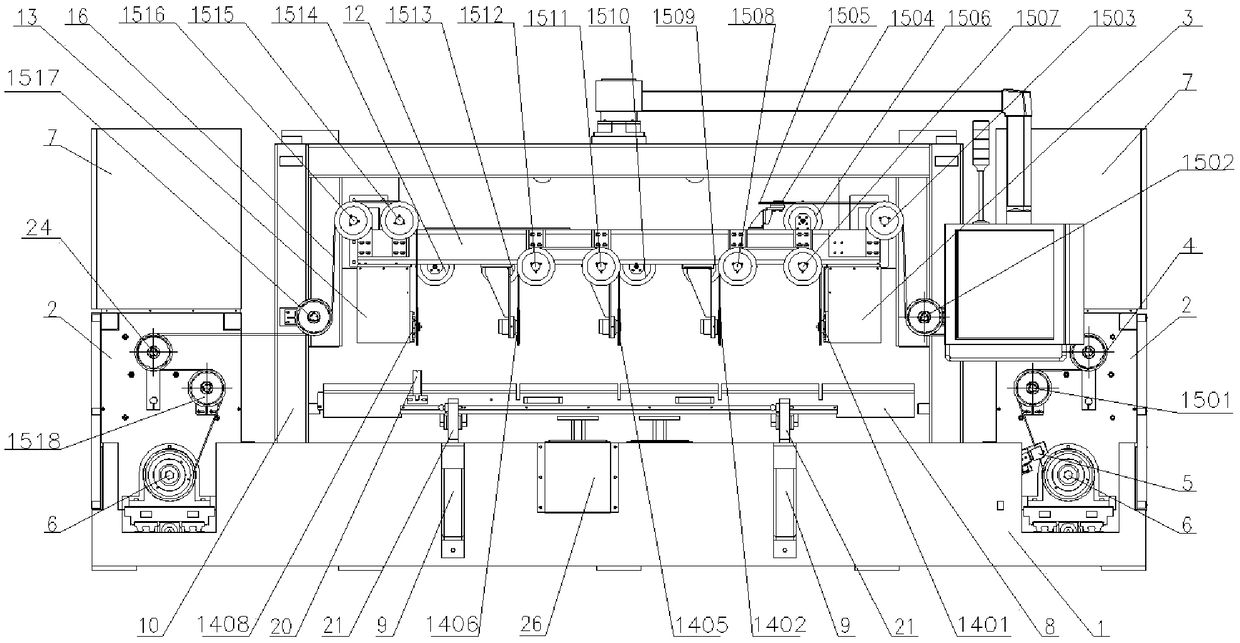

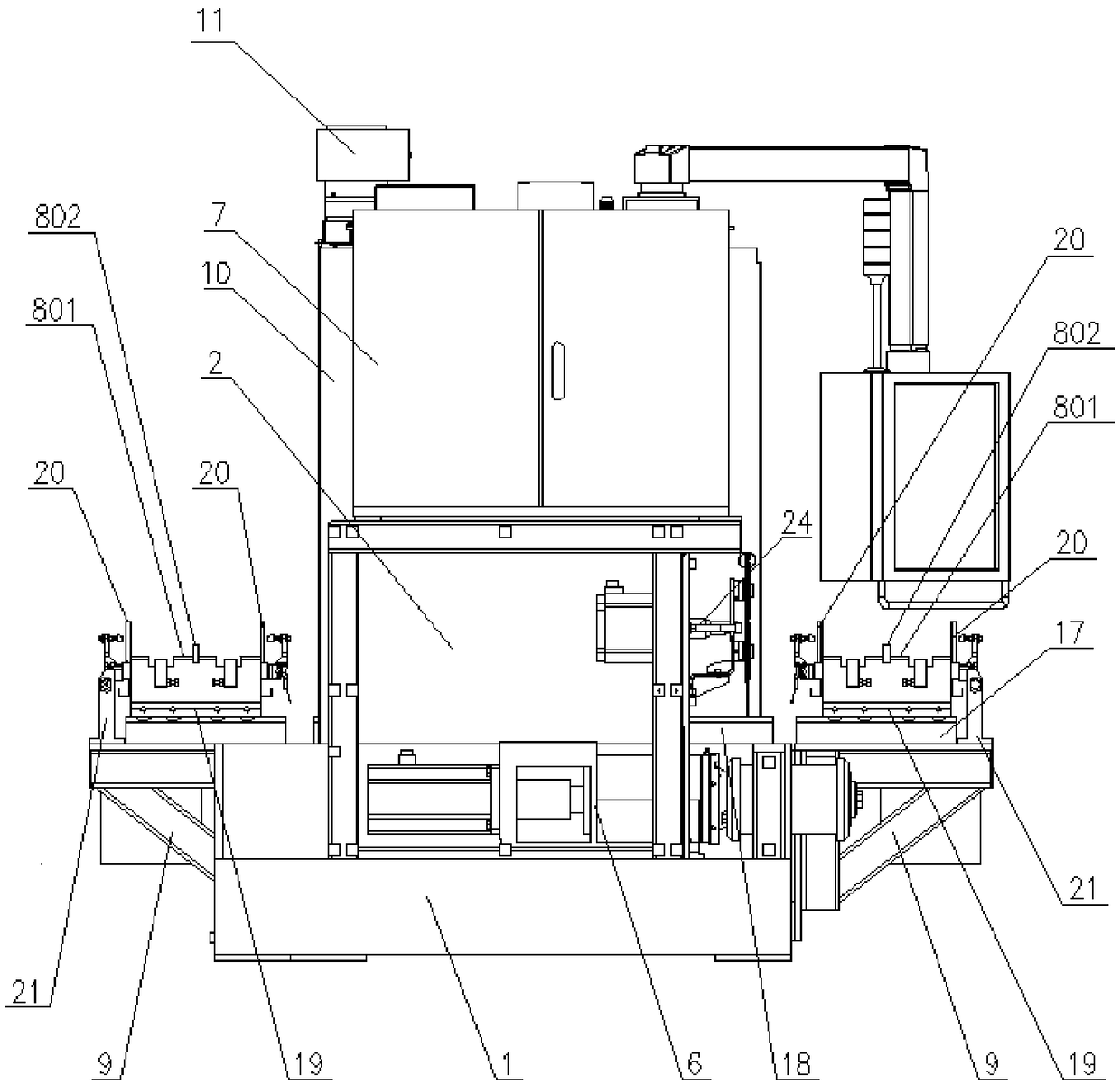

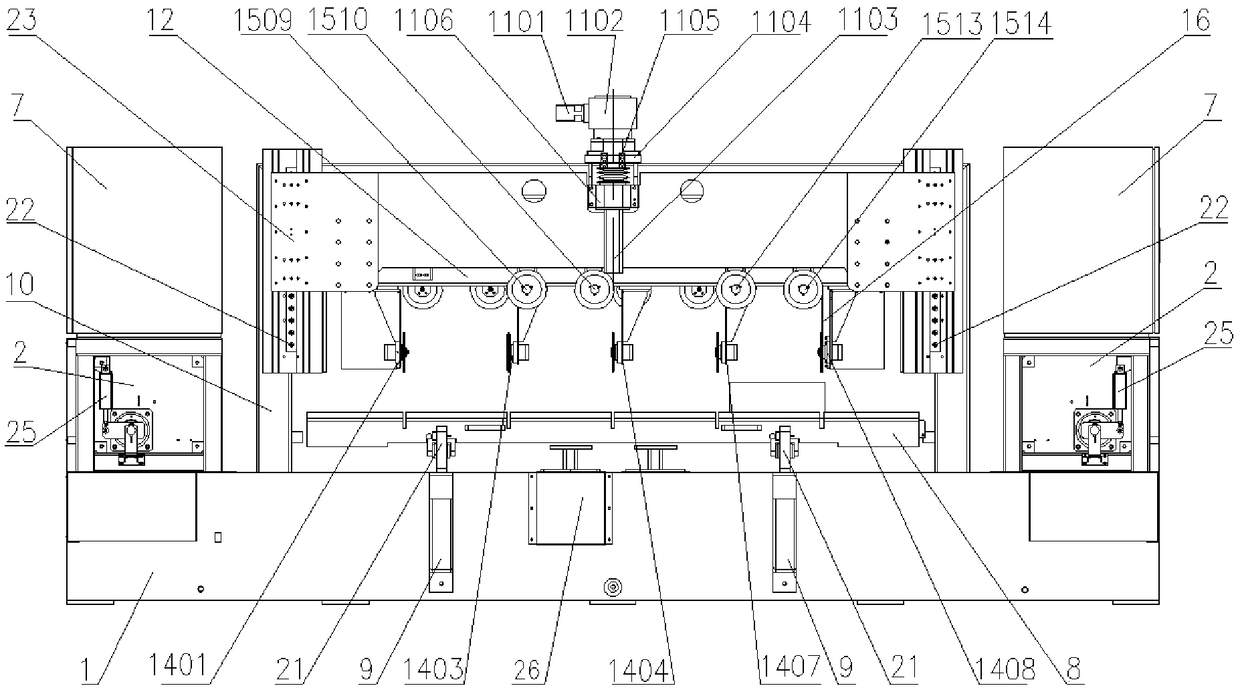

[0031] Such as figure 1 , figure 2 with image 3 As shown, the CNC polysilicon diamond wire high-speed cutting machine of this embodiment includes a bed 1, and the two ends of the bed 1 are respectively equipped with a take-up and release chamber 2, and an electric box 7 is fixedly installed on the upper part of the take-up and take-off chamber 2, and two retractable The four corners of the bed 1 between the wire chambers 2 are respectively fixed with upright columns 10, and two workbenches 8 are respectively installed between the two upright columns 10 on both sides of the bed 1 through the guide rail bracket 9, and the guide rail bracket 9 and the The worktables 8 are connected by short steel guide rails 17; the outer ends of the two columns 10 on the rear side are respectively installed with a sliding plate 23 through the linear guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com