Patents

Literature

64results about How to "Reduce processing auxiliary time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

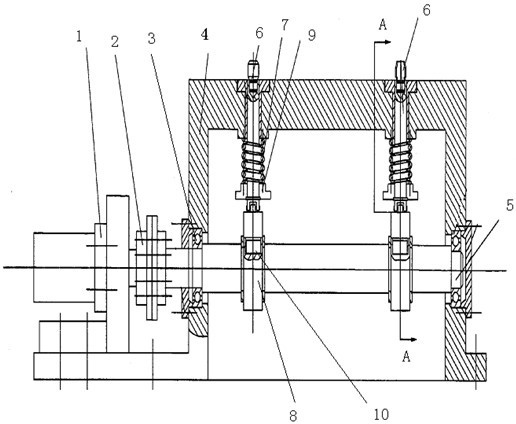

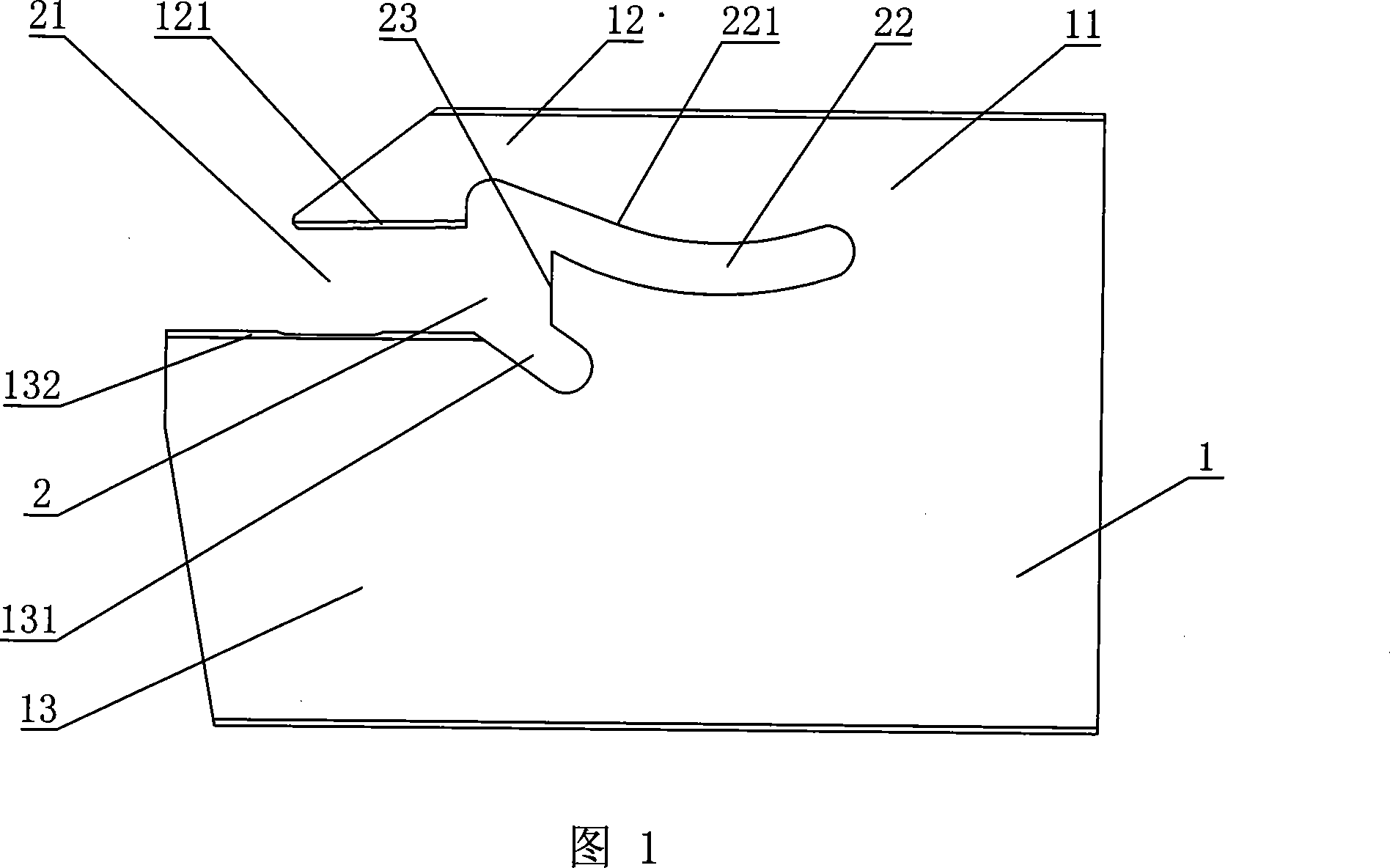

Fast clamping mechanism of machine tool

InactiveCN103433777AReduce processing auxiliary timeFast clamping speedPositioning apparatusMetal-working holdersControl engineeringProcess engineering

The invention discloses a fast clamping mechanism of a machine tool, and belongs to the field of machine tool clamps. The fast clamping mechanism comprises a sliding rail, an adjusting screw rod, a movable block and a clamping block, wherein the upper end of the sliding rail is clamped on the concave edge of the lower end of the movable block, the lower end of the clamping block is pressed on a concave edge of the upper end of the movable block, and the adjusting screw rod is meshed with the movable block. The fast clamping mechanism solves the problems that an existing machine tool clamping mechanism is long in clamping face moving time, large in labor intensity and low in work efficiency, and has the advantages of being simple in structure, reasonable in design and easy to manufacture.

Owner:WUXI YICHEN MOLD TECH

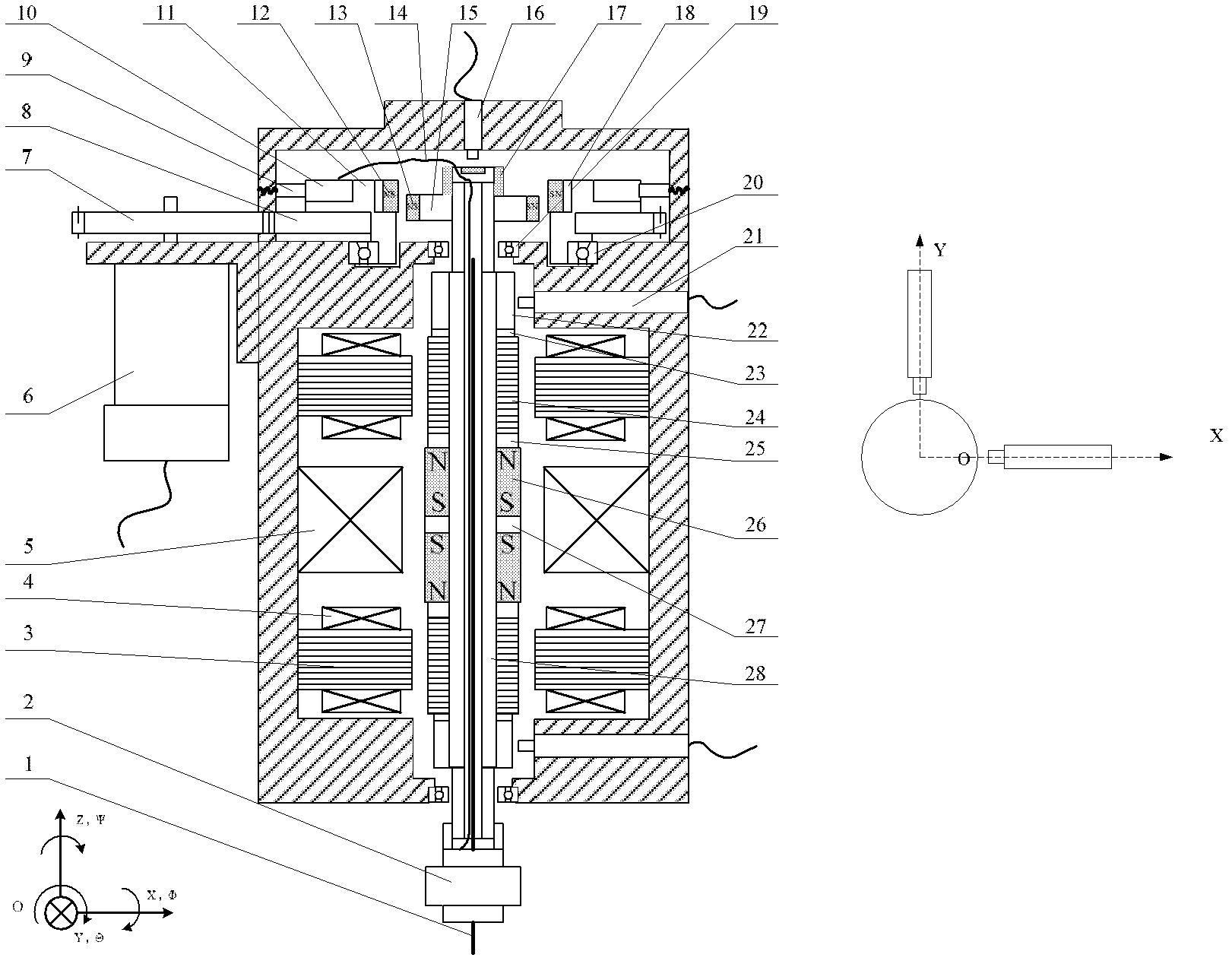

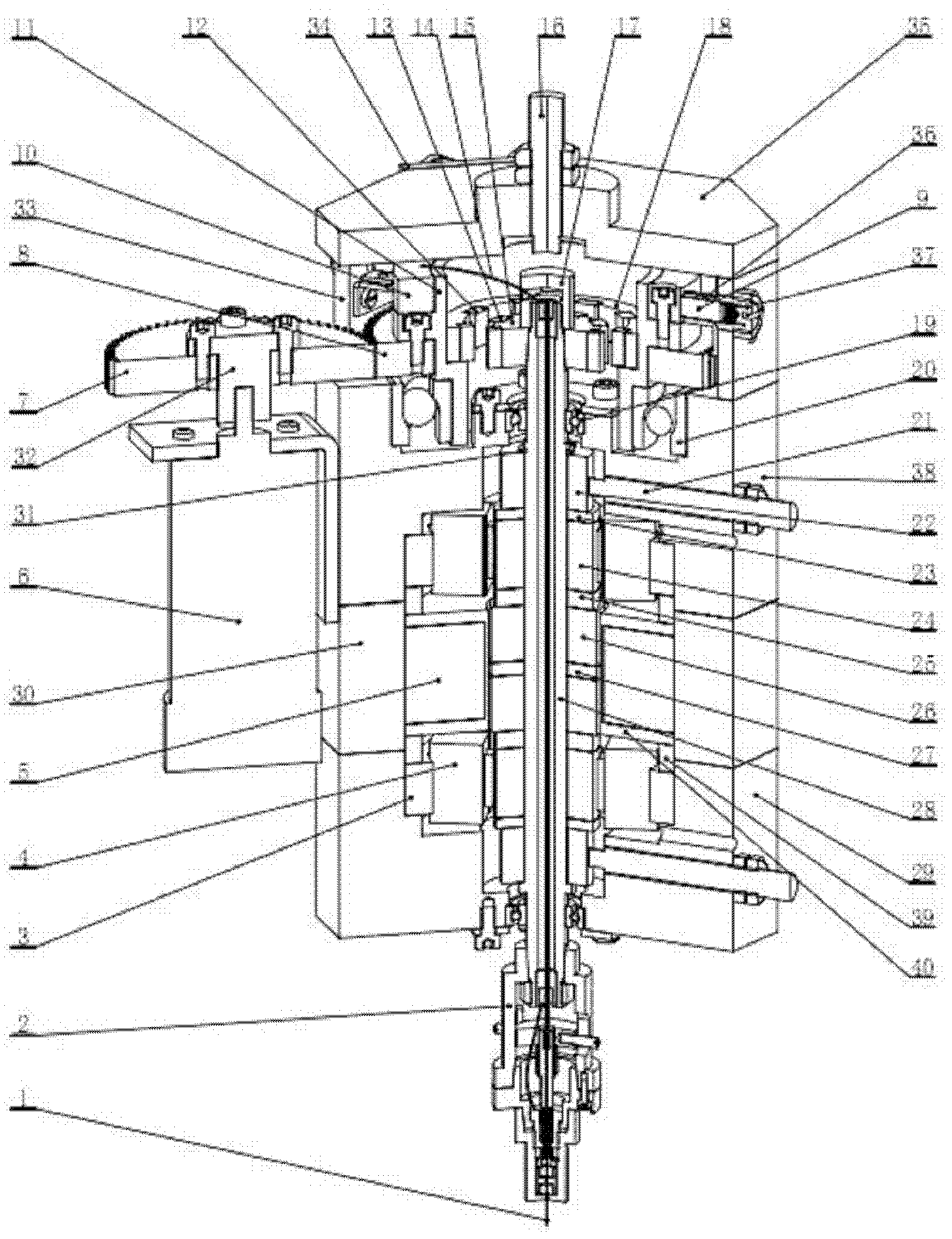

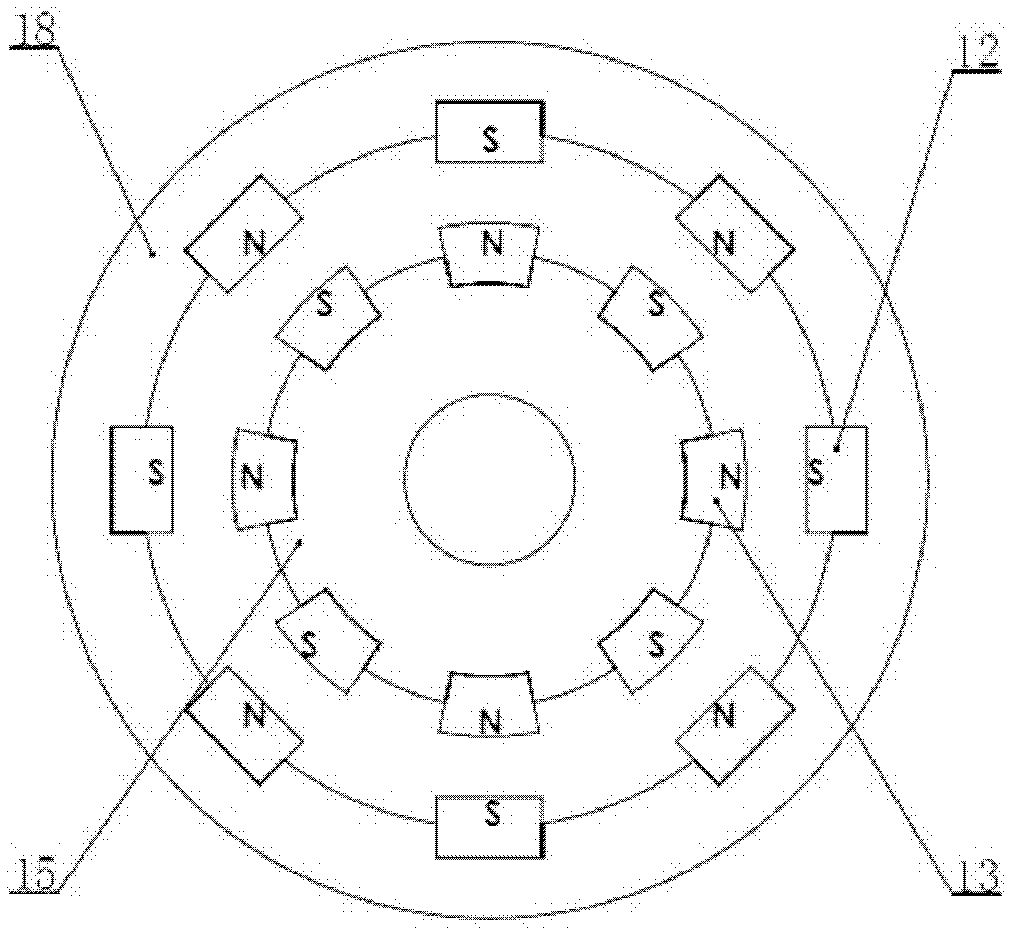

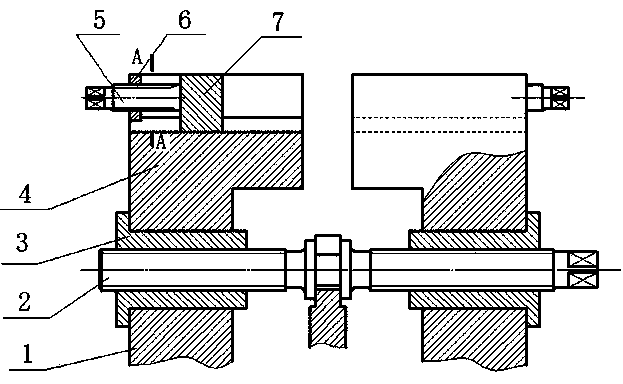

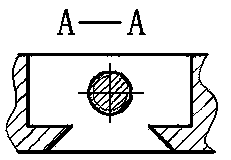

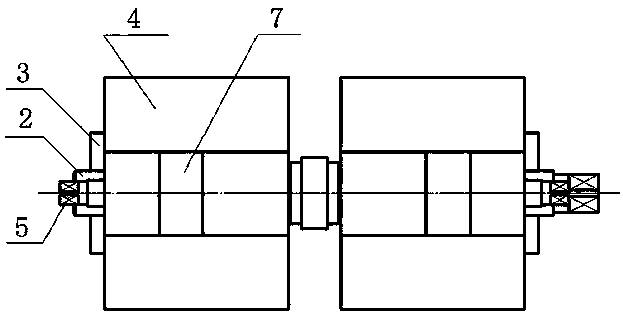

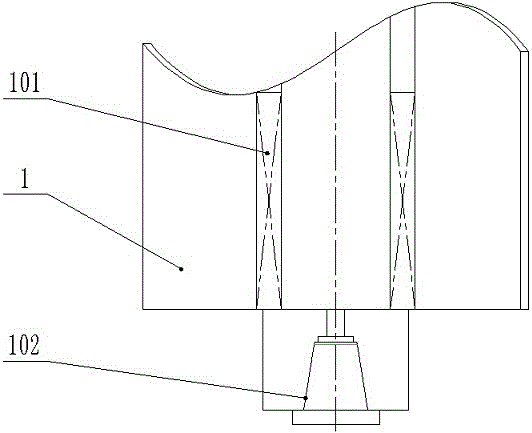

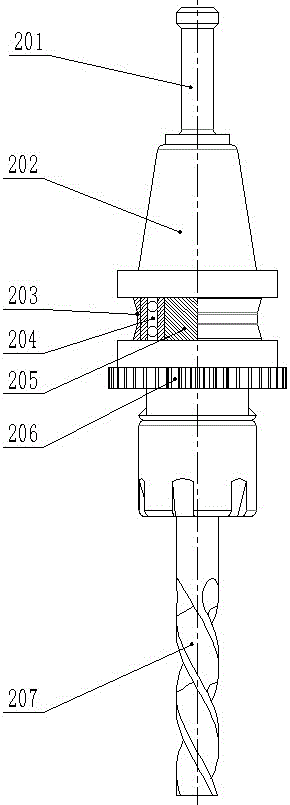

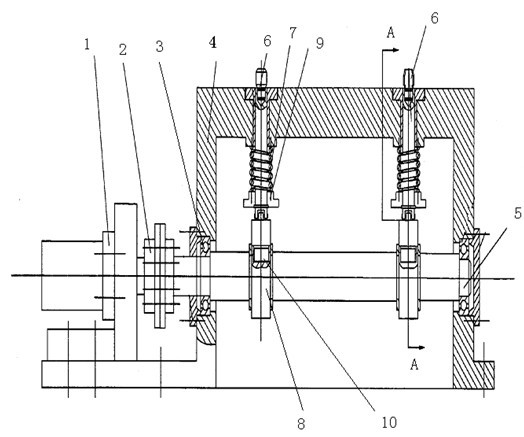

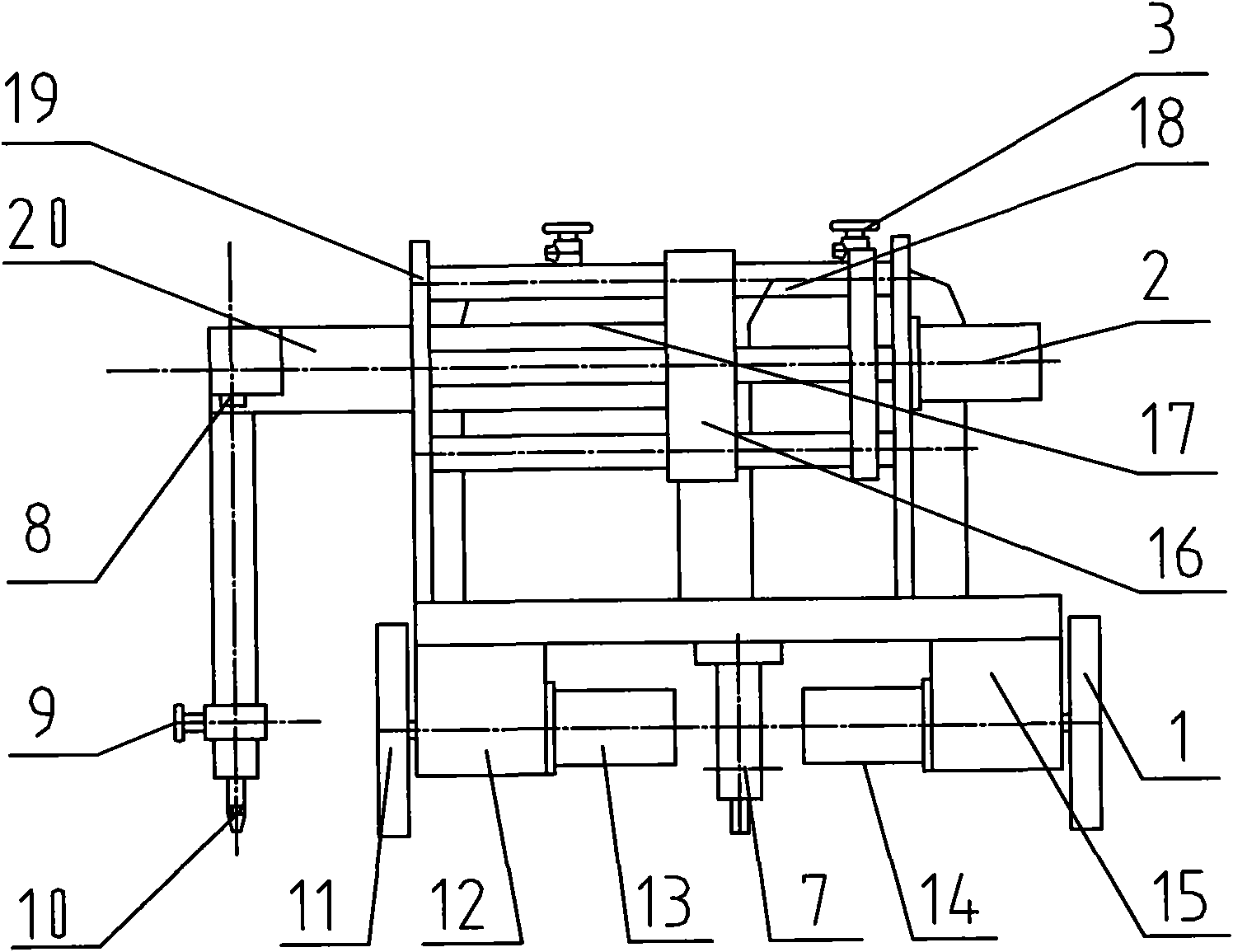

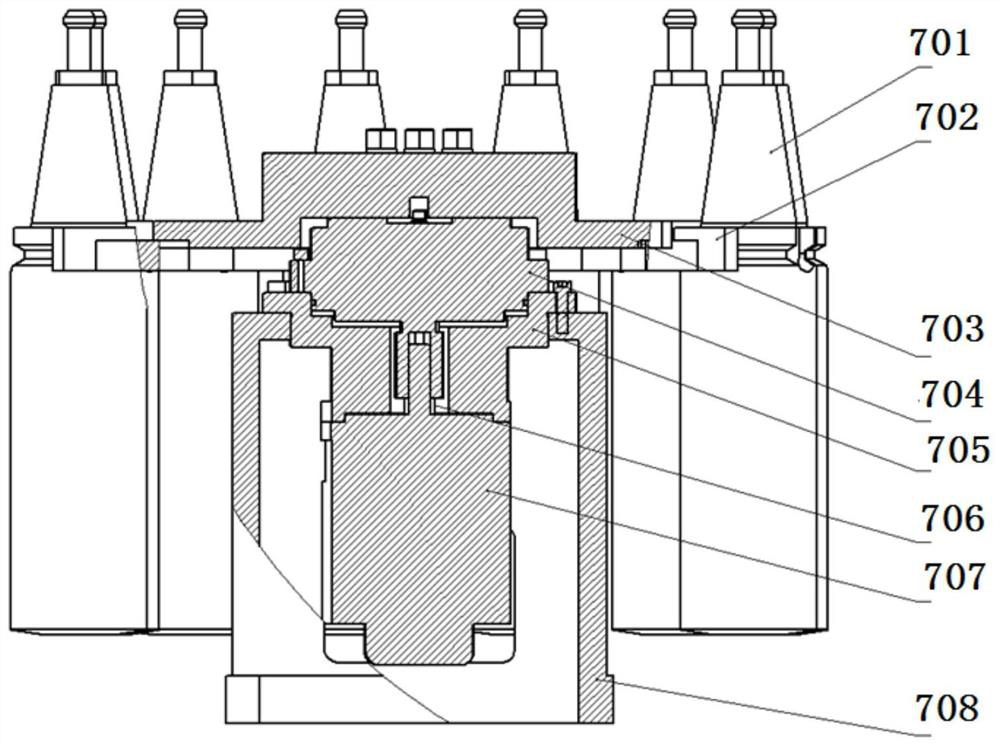

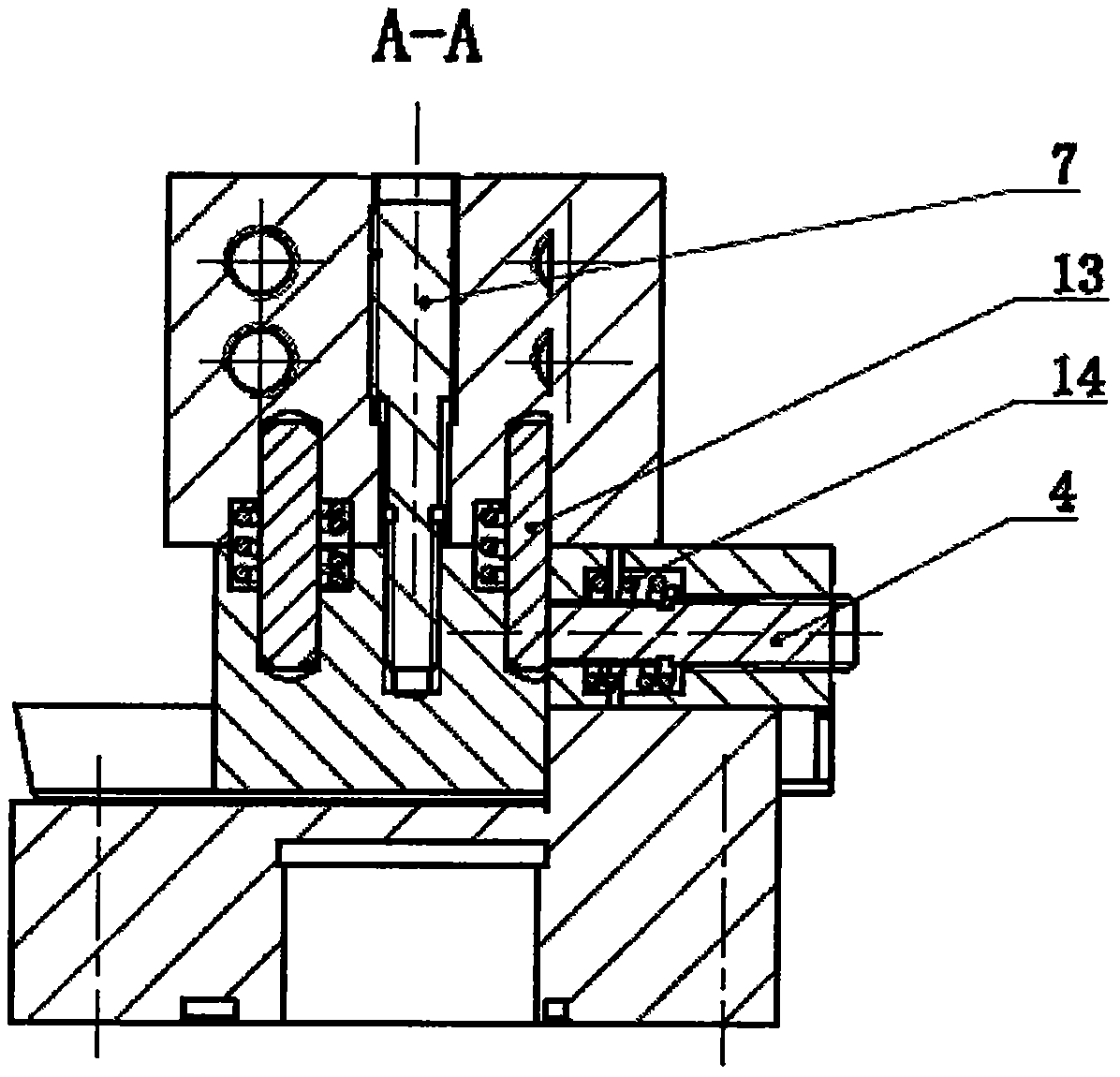

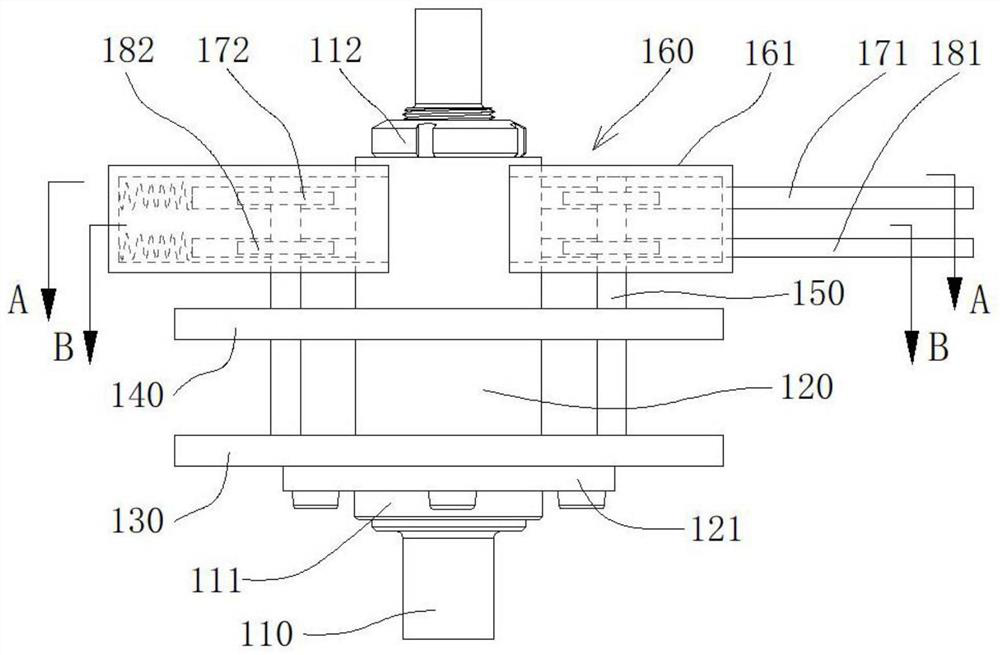

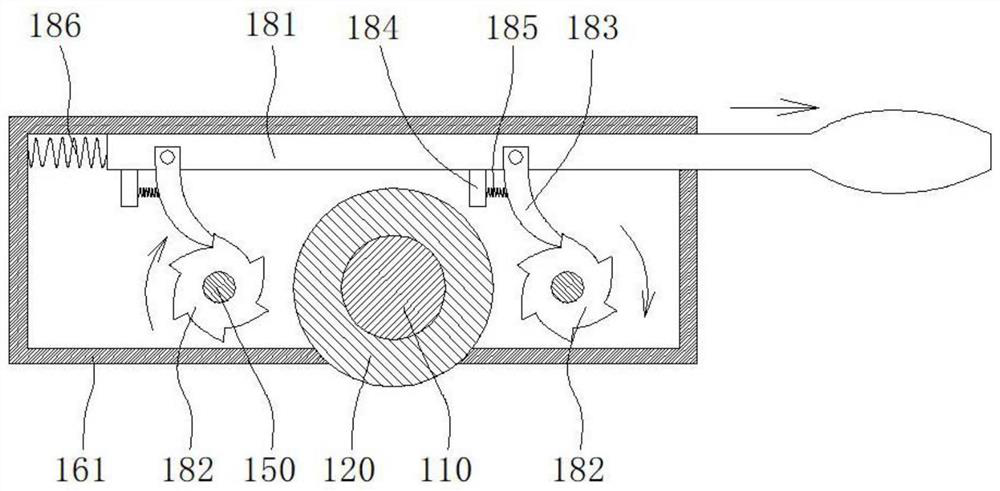

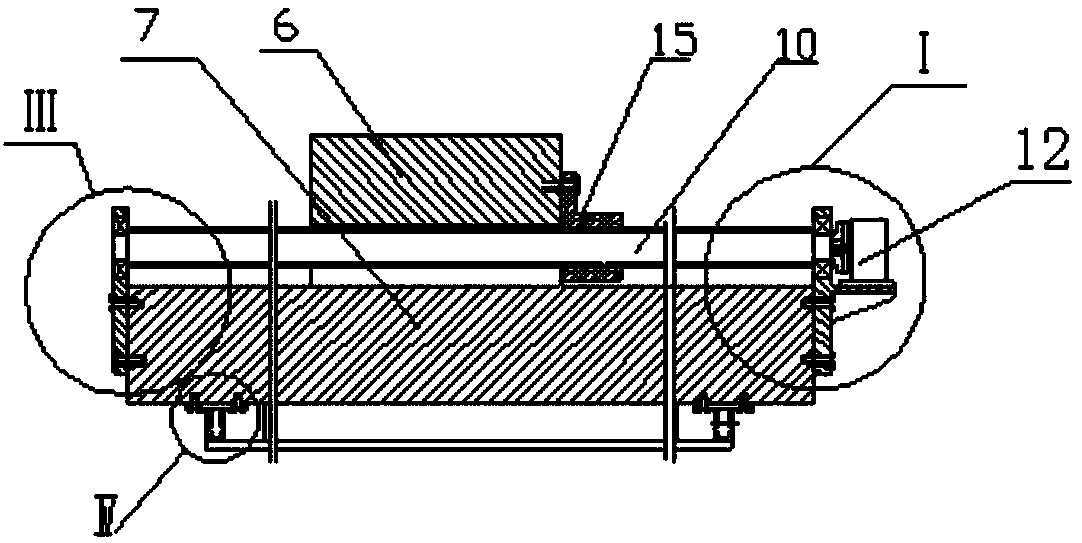

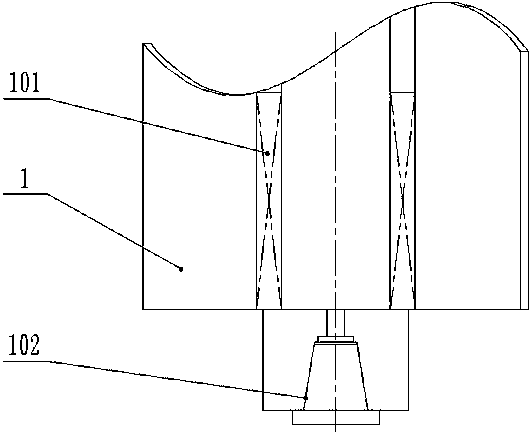

Spindle device for processing micro-hole electric spark based on magnetic levitation servo drive

ActiveCN102601473AIncrease servo tracking speedEasy to adjustMagnetic holding devicesElectrical-based auxillary apparatusBall bearingCoupling

The invention relates to a spindle device for processing a micro-hole electric spark based on a magnetic levitation servo drive. A magnetic coupling inner rotor is fixedly connected with an upper part of a hollow mandrel; a rotor end cover is arranged on the hollow mandrel at an upper part of the magnetic coupling inner rotor; a flexible lead enters in a cavity of the hollow mandrel through the rotor end cover; an inner rotor permanent magnet is arranged on the magnetic coupling inner rotor; a radical eddy current displacement sensor is fixed inside an upper shell; a lower end of an insulatedturntable is arranged on the upper shell at an inner side of an angular contact ball bearing; a magnetic coupling outer rotor is fixed on an upper part of the insulated turntable; and an outer rotor permanent magnet is fixed on the magnetic coupling outer rotor. According to the invention, the spindle device provided by the invention is helpful for discharging an electrolytic corrosion product intime and improving discharge condition of a discharge gap; and is helpful for improving the quality and efficiency of electric spark micro-hole processing. The spindle device can realize processing of micro-straight holes, taper holes and stepped holes of hole diameters phi ranging from 100mum to 300mum according to different processing requirements.

Owner:HARBIN INST OF TECH

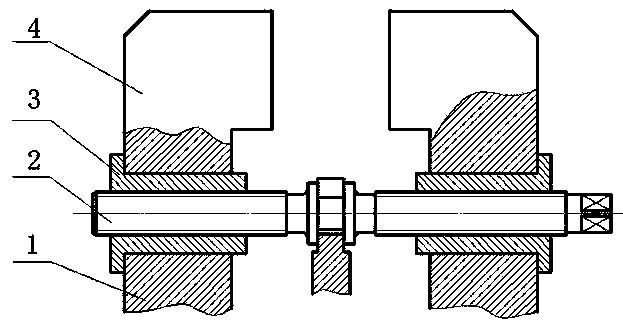

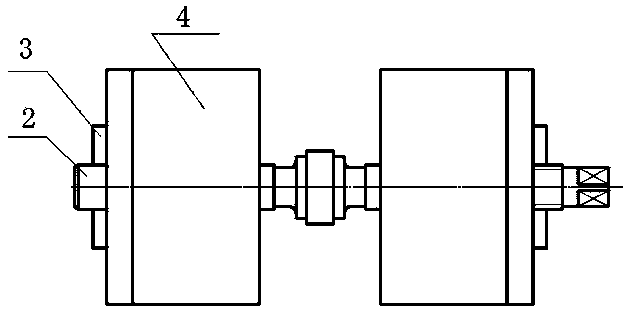

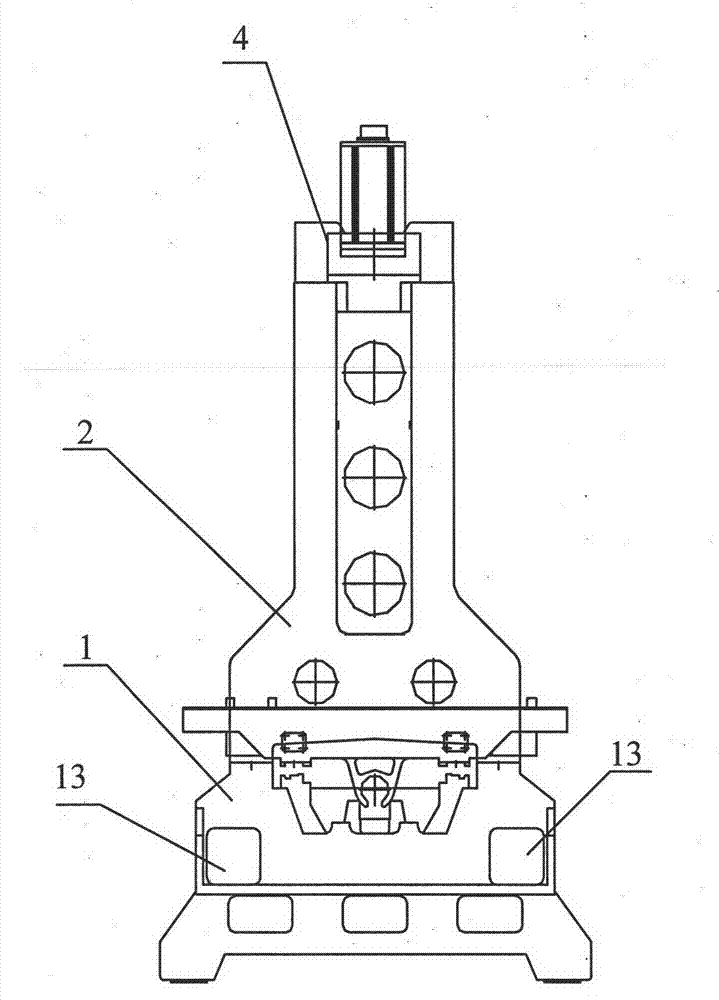

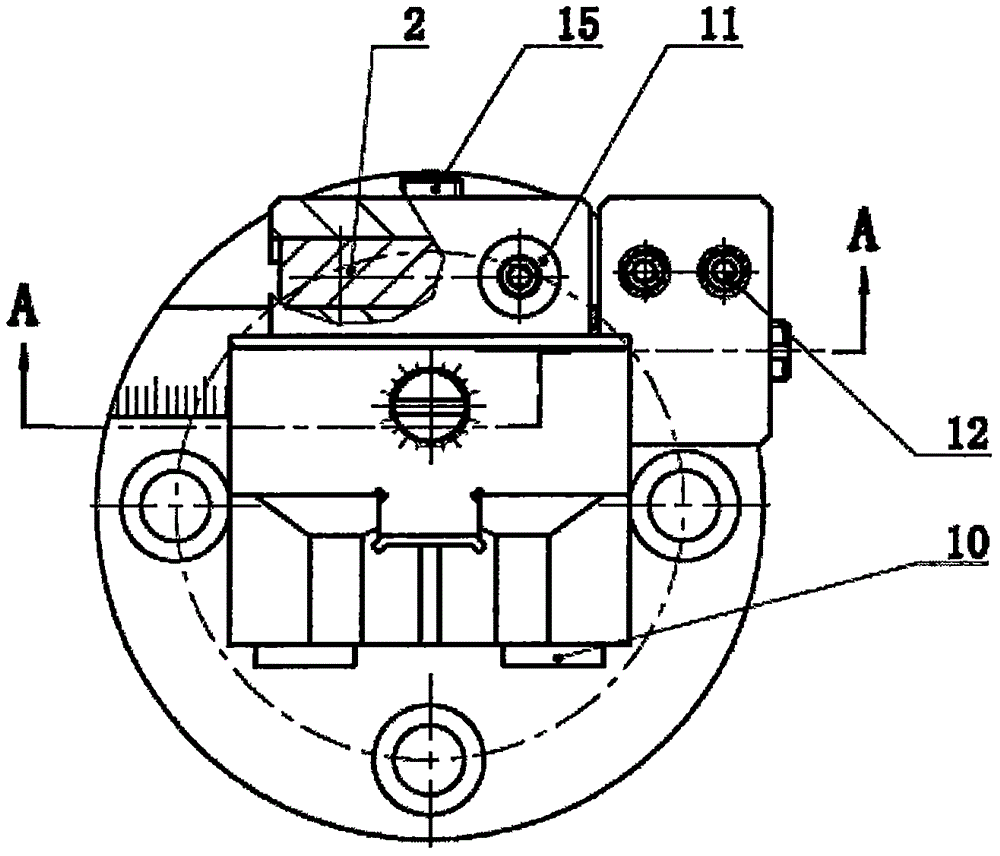

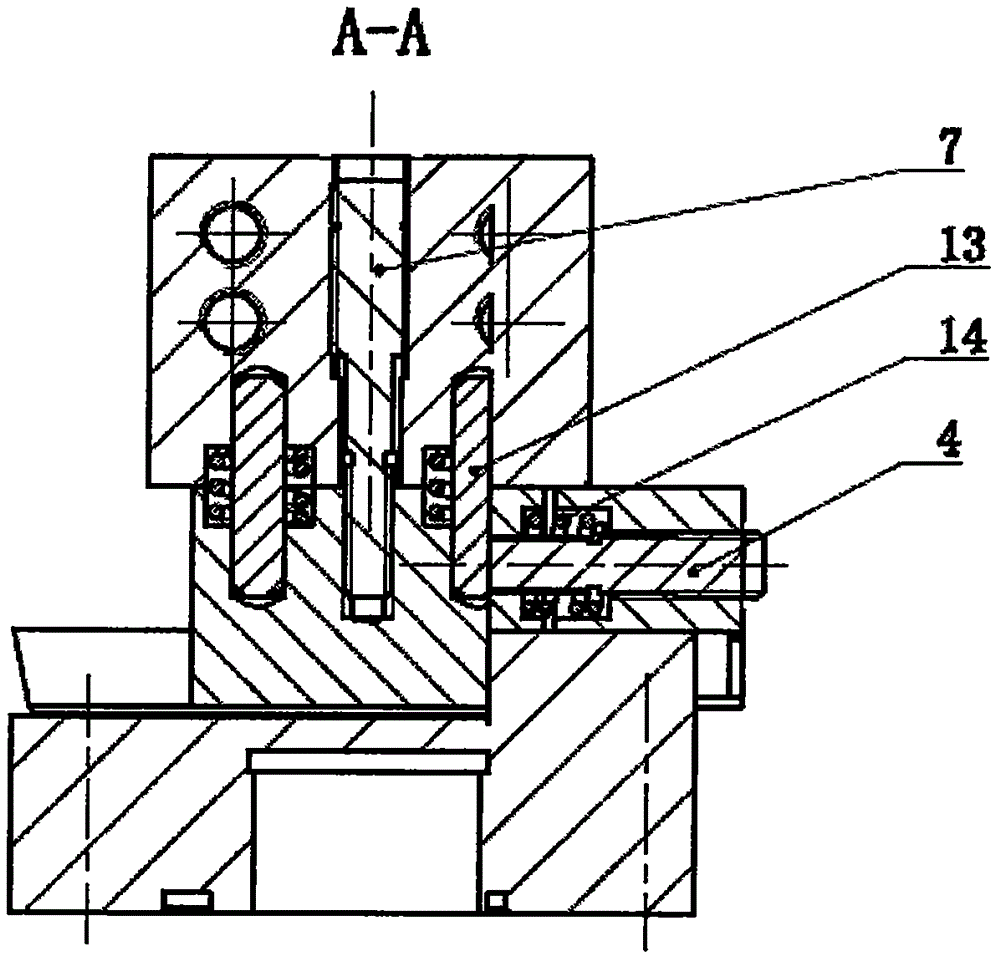

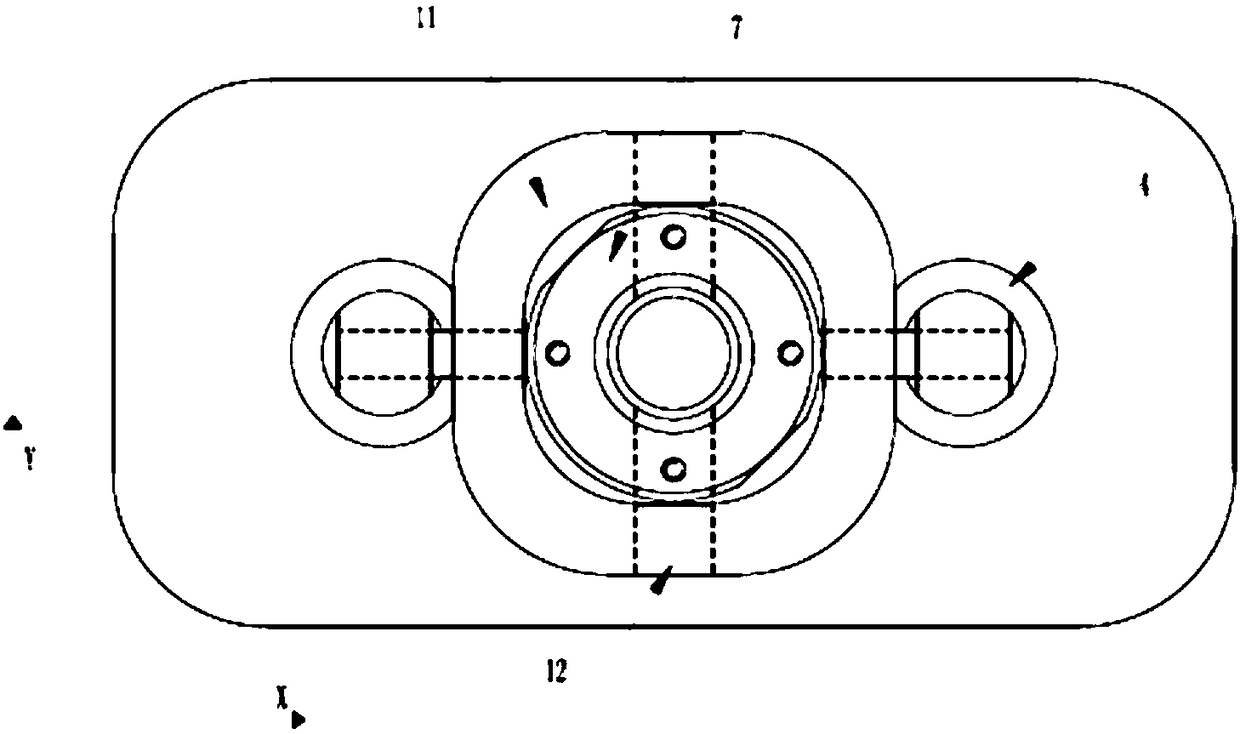

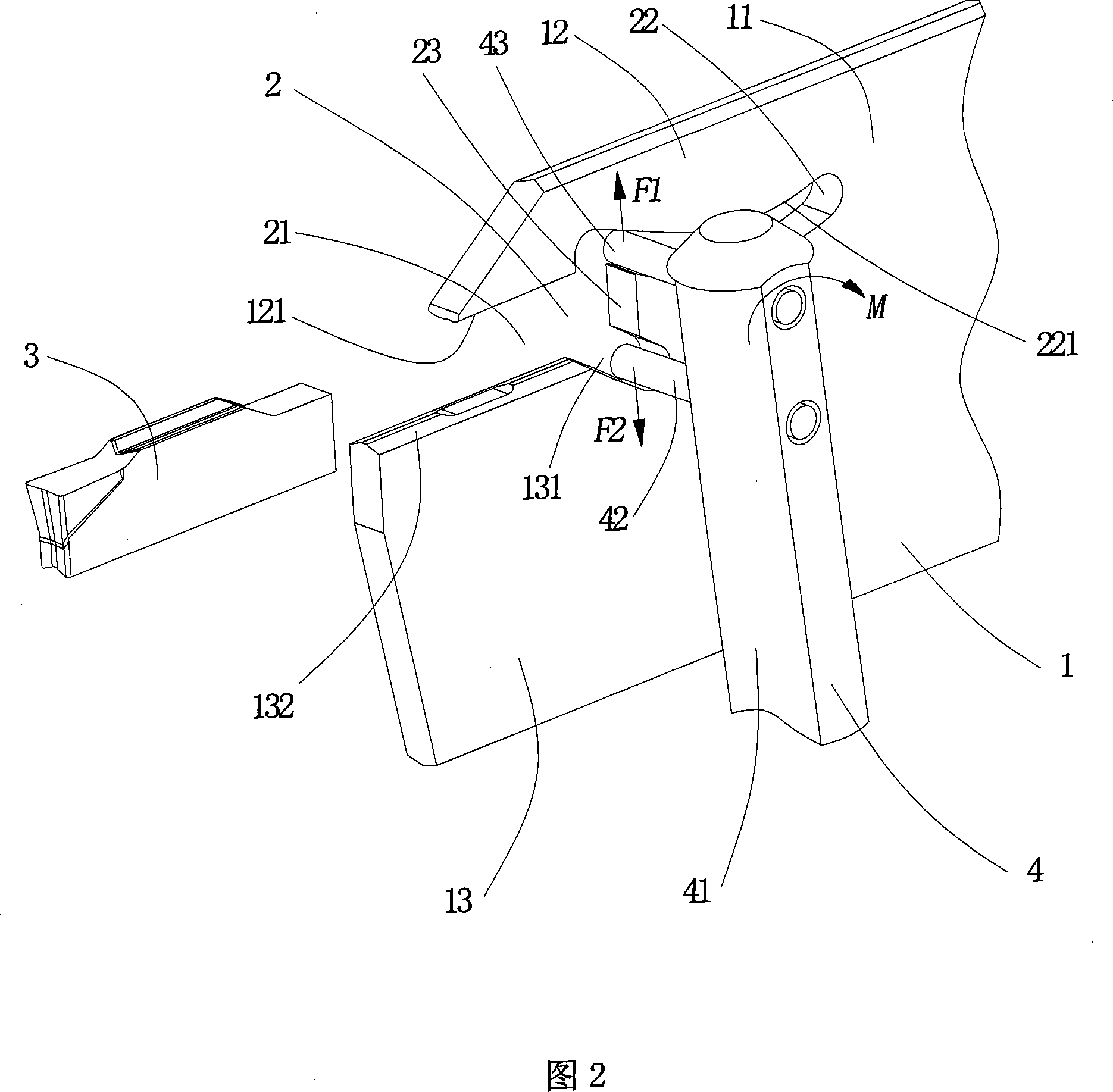

Compound clamping mechanism of machine tool

InactiveCN103419047AImprove versatilityAvoid replacementPositioning apparatusMetal-working holdersMachine toolIndustrial engineering

The invention discloses a compound clamping mechanism of a machine tool, which belongs to the field of machine tool fixtures. The compound clamping mechanism of the machine tool comprises a sliding rail, a large adjusting screw rod, a moving block, a large clamping block, a small adjusting screw rod, a fixed block and a small clamping block, wherein the upper end of the sliding rail is clamped on a flange at the lower end of the moving block; the large adjusting screw rod is engaged with the moving block; the lower end of the small clamping block is embedded into a dovetail groove at the lower end of a groove of the large clamping block; the small adjusting screw rod is engaged with the fixed block; one end of the small adjusting screw rod is fixedly connected with the small clamping block. The compound clamping mechanism of the machine tool solves the problems that according to the existing clamping mechanism, the labor intensity is large, the auxiliary time for parts processing is long, the universality is low due to a special fixture, and the like, and has the advantages of simple structure, reasonable design, and easiness in manufacturing.

Owner:WUXI YICHEN MOLD TECH

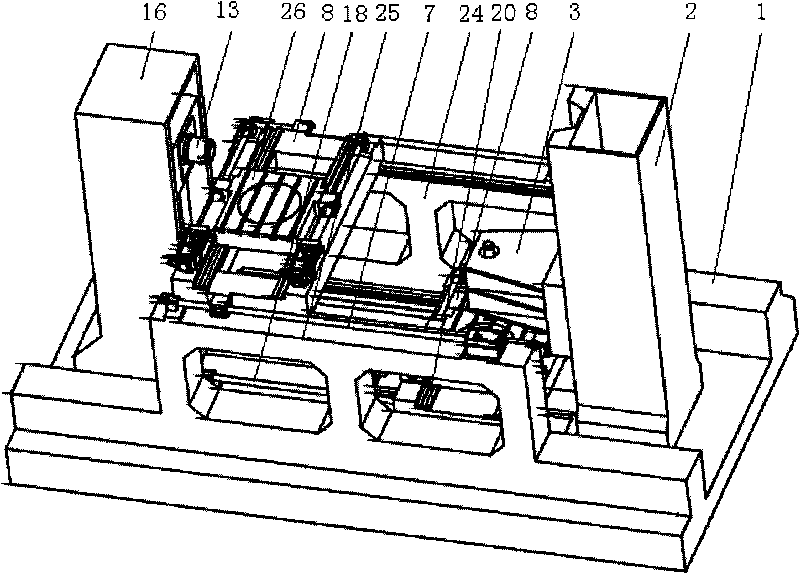

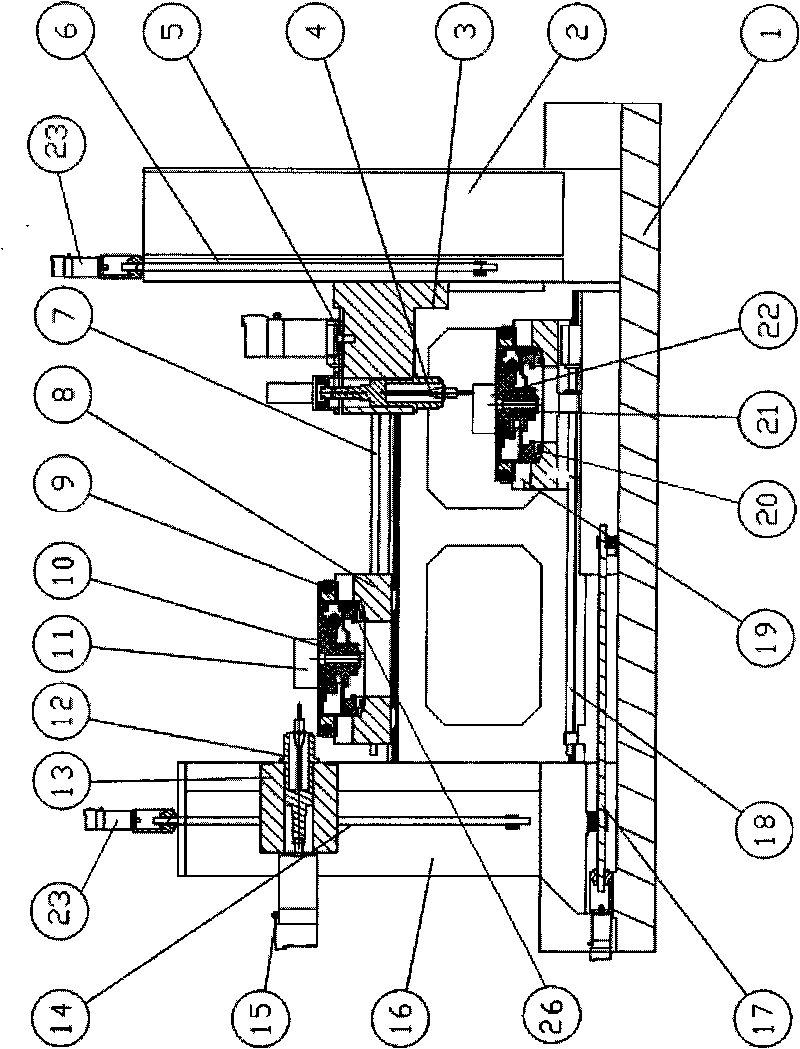

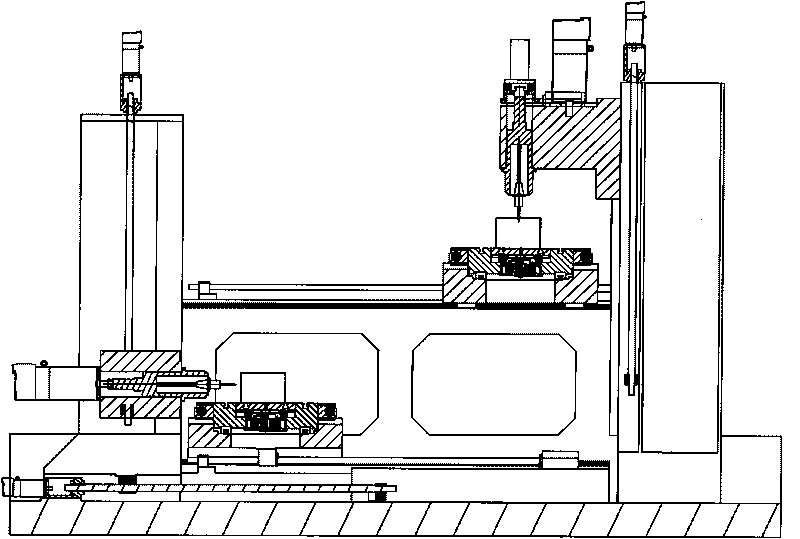

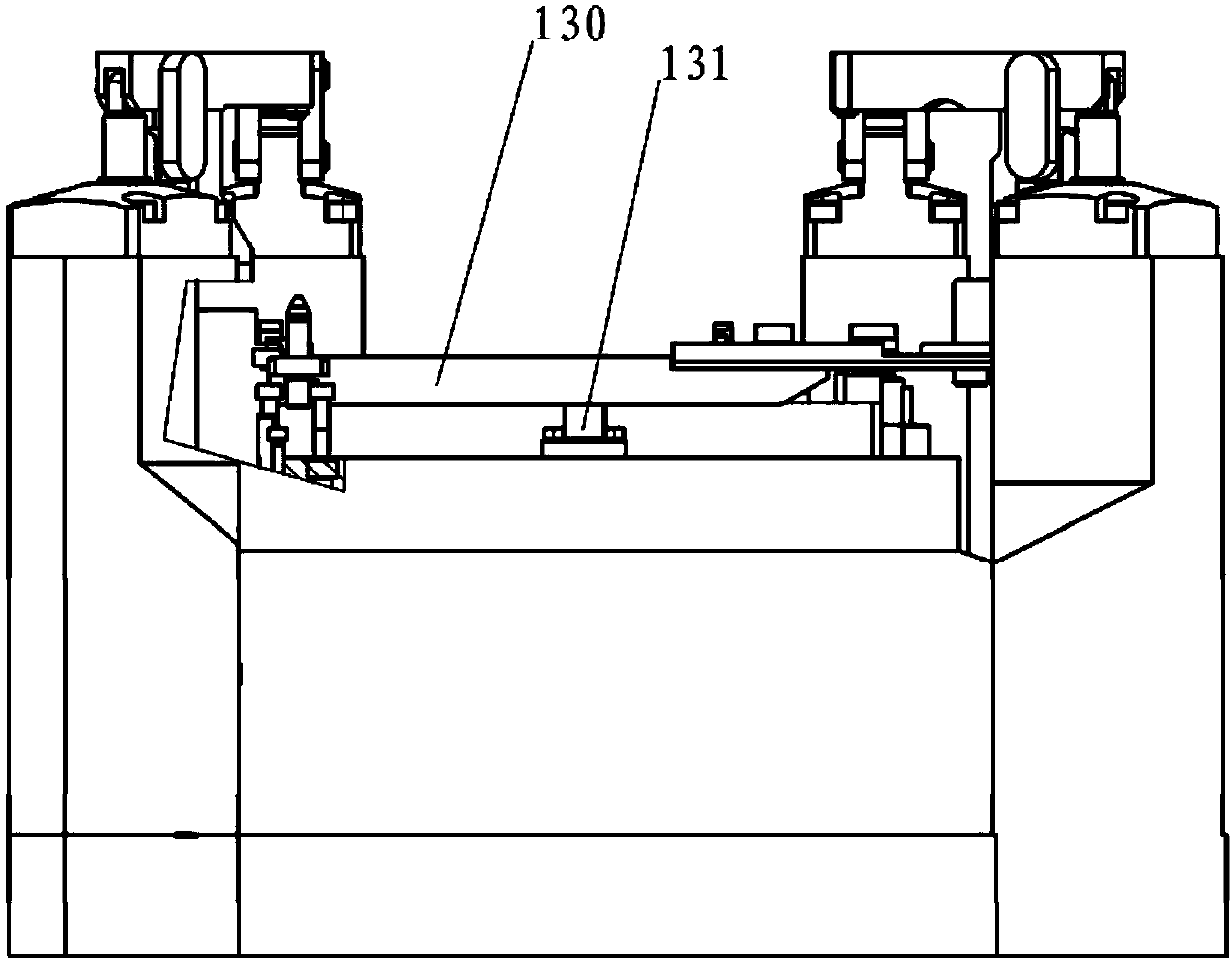

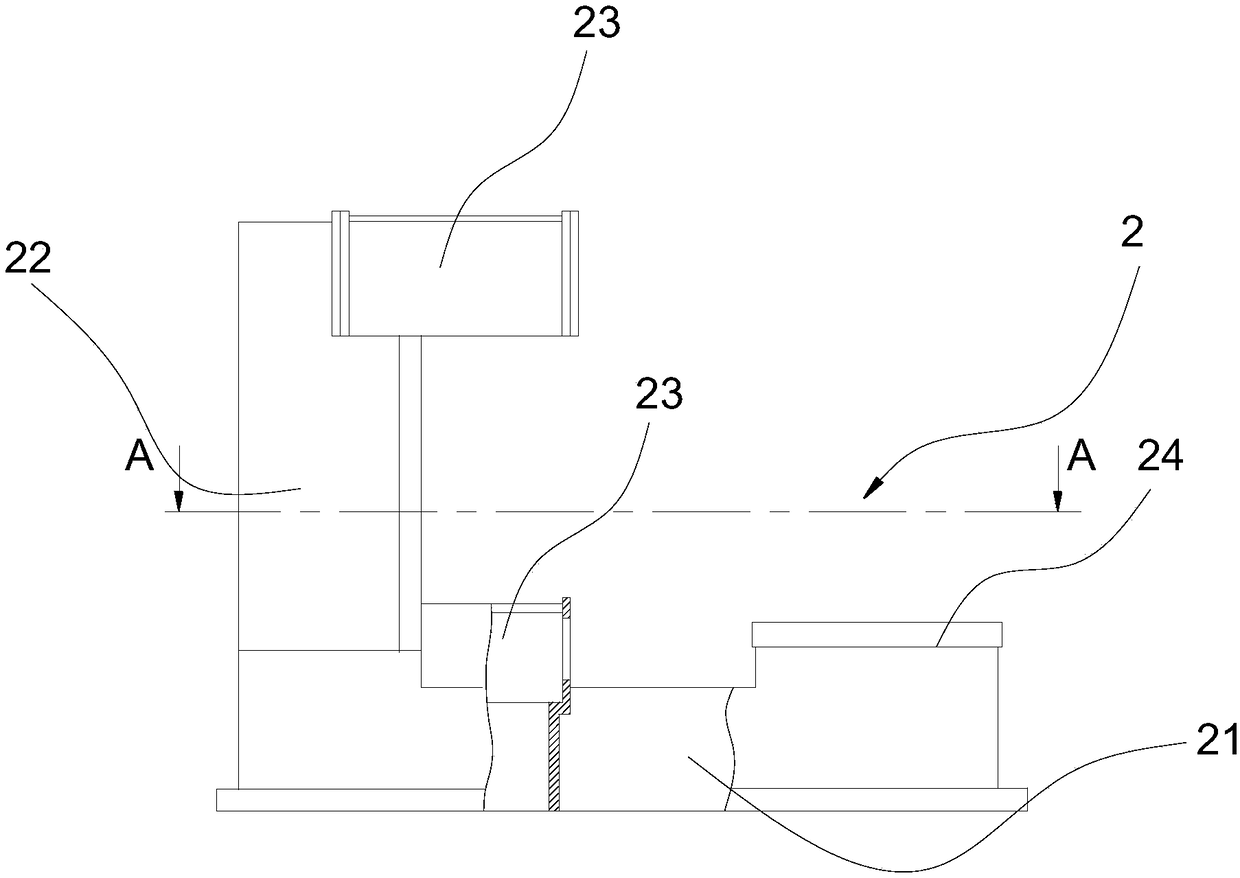

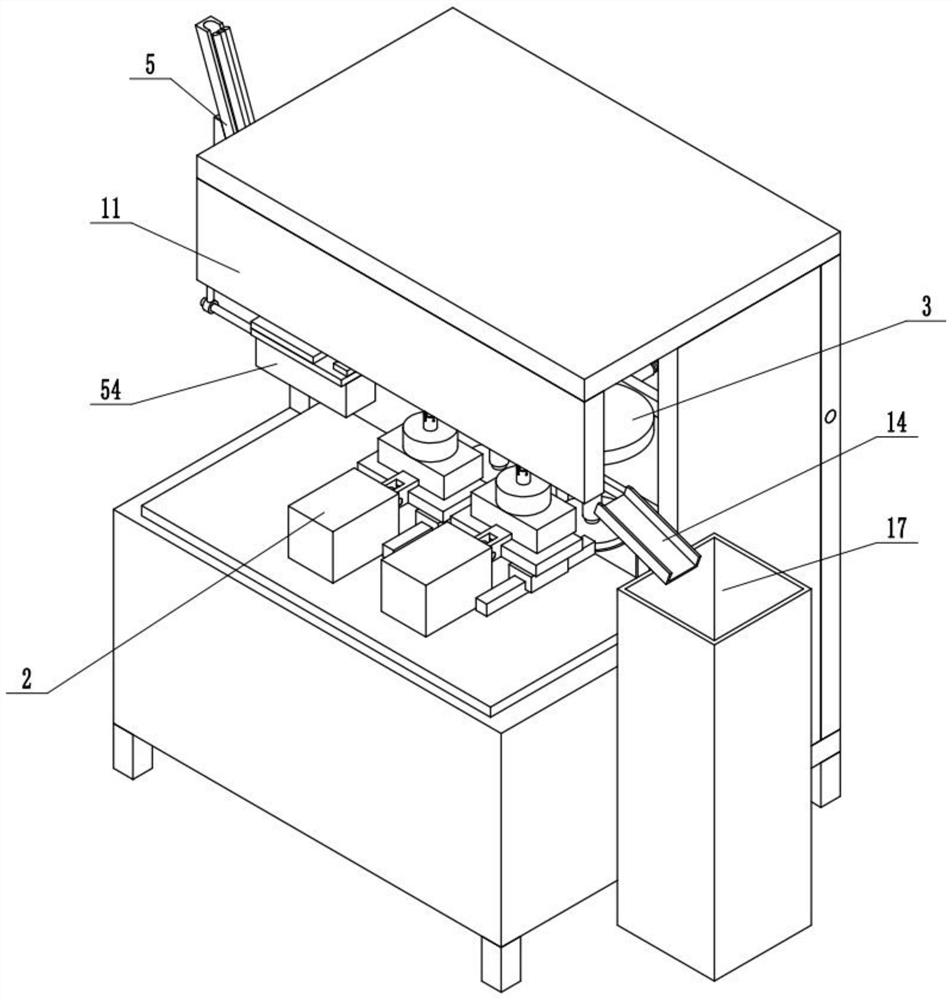

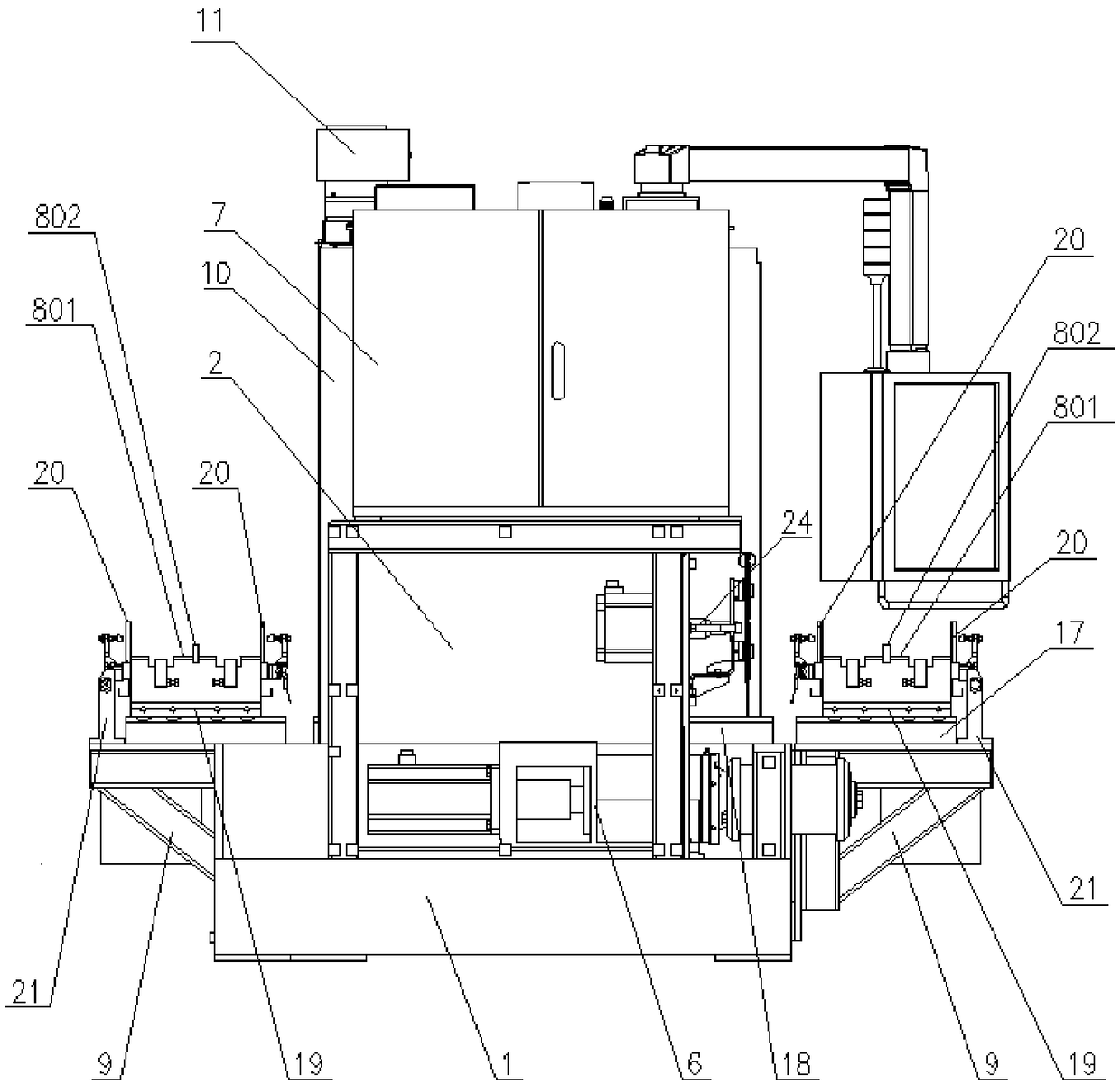

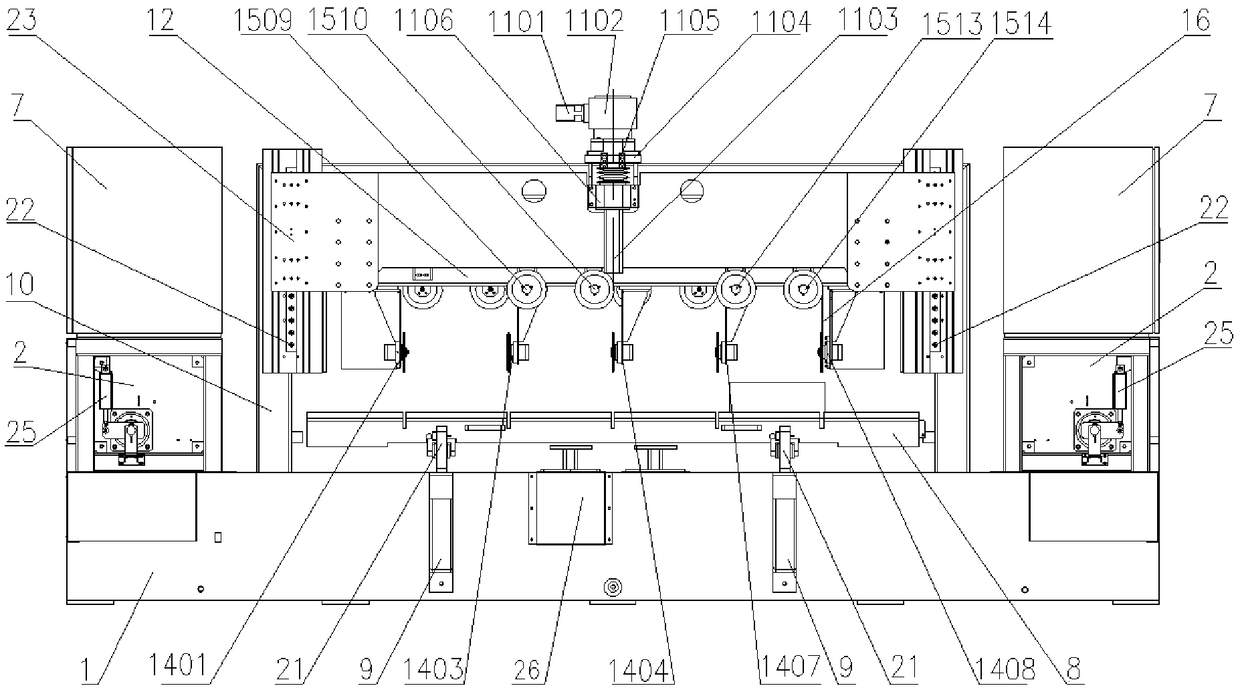

Double-layer vertical and horizontal processing central machine tool

The invention discloses a double-layer vertical and horizontal processing central machine tool which comprises a base, vertical posts, screw rods, main spindle boxes and a numerically controlled unit for controlling each numerically controlled component to work, wherein a fixed vertical post, a movable vertical post, an upper workbench device and a lower workbench device are arranged on the base; the lower workbench device is arranged on the base, the lower end of a sliding frame in the lower workbench device is connected with the base through a lower driving screw rod, a front bracket and a back bracket are respectively arranged at the front side and the back side of the lower workbench device, and the movable vertical post and the fixed vertical post are respectively arranged at the left side and the right side of the lower workbench device; the lower ends of the front bracket and the back bracket are respectively connected fixedly with the base, and the upper ends of the front bracket and the back bracket are in slide connection with a sliding frame in the upper workbench device through sliding frames; two ends of the sliding frame in the upper workbench device are articulated with the driving screw rods which are arranged on the front bracket and the back bracket; the fixed vertical post is fixedly connected with the base; the movable vertical post is connected with the base through the driving screw rod which is fixed on the base; a horizontal main spindle box is arranged on the movable vertical post; and a vertical main spindle box is arranged on the fixed vertical post. The invention has the advantages of novel structure, reduction of auxiliary processing time, reduction of floor space, and the like.

Owner:WEIHAI HUADONG AUTOMATION

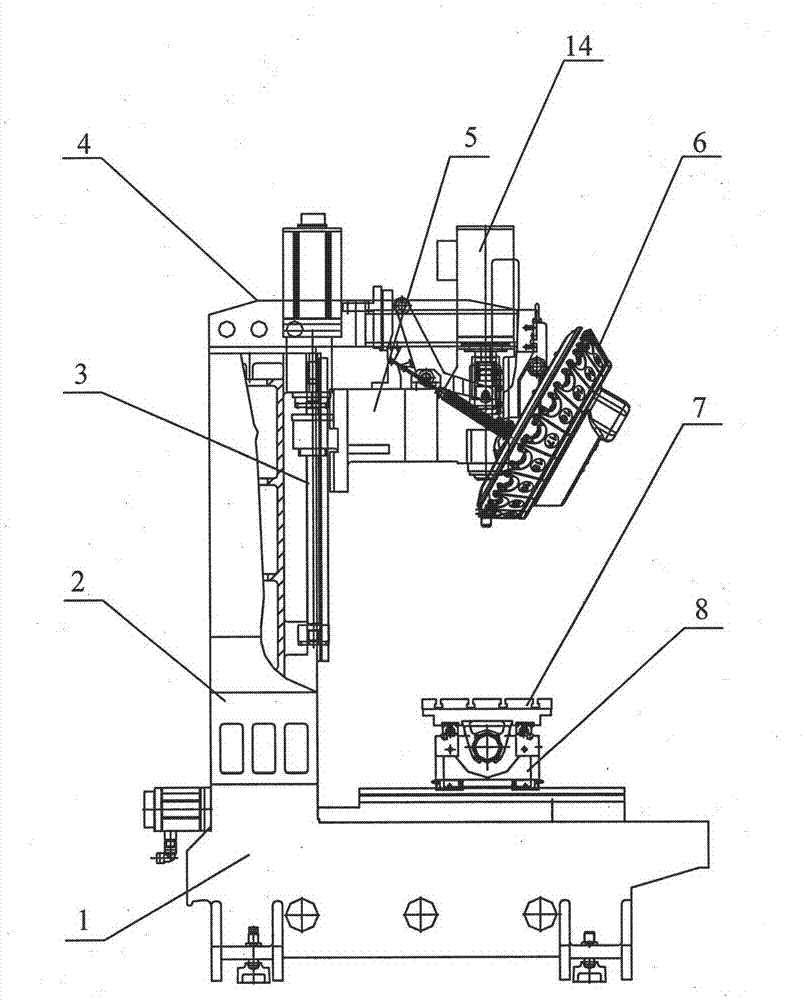

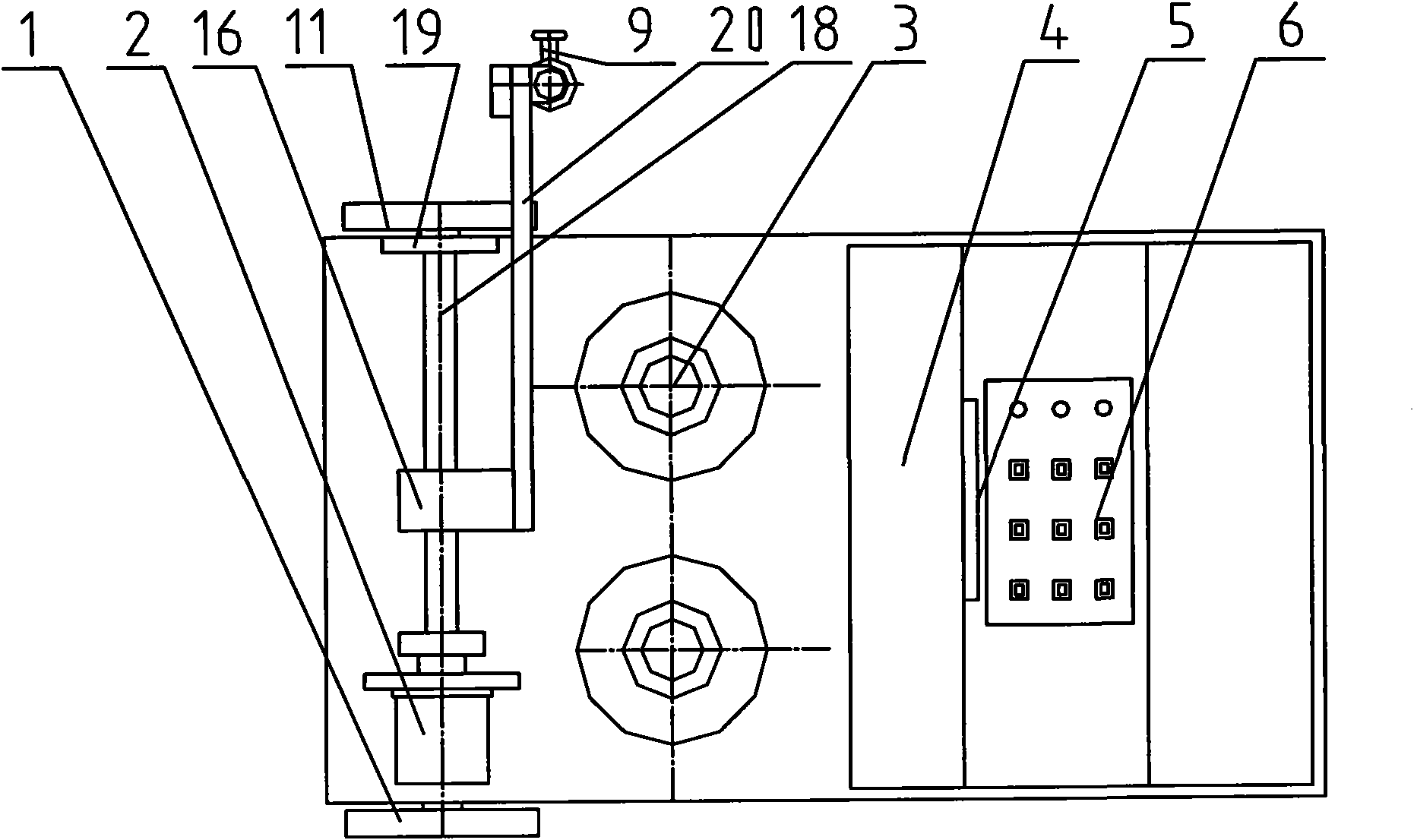

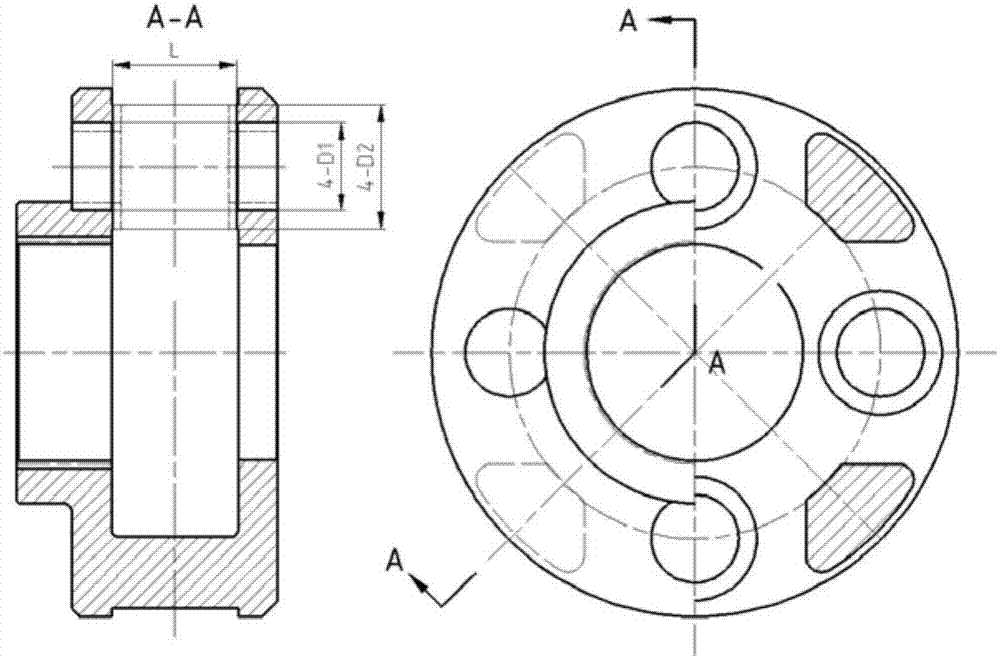

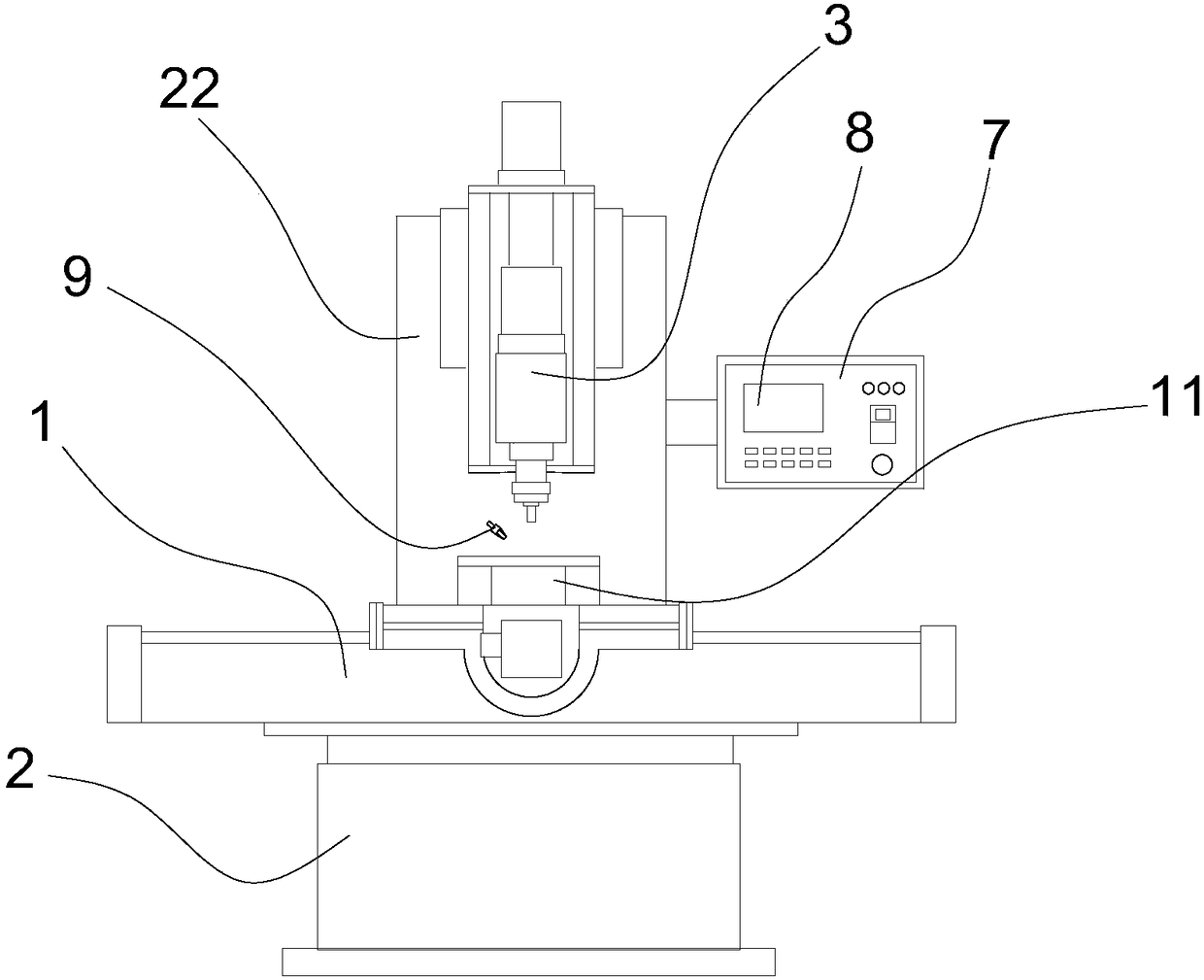

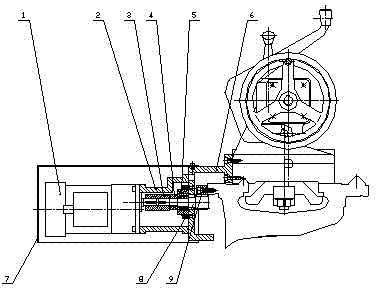

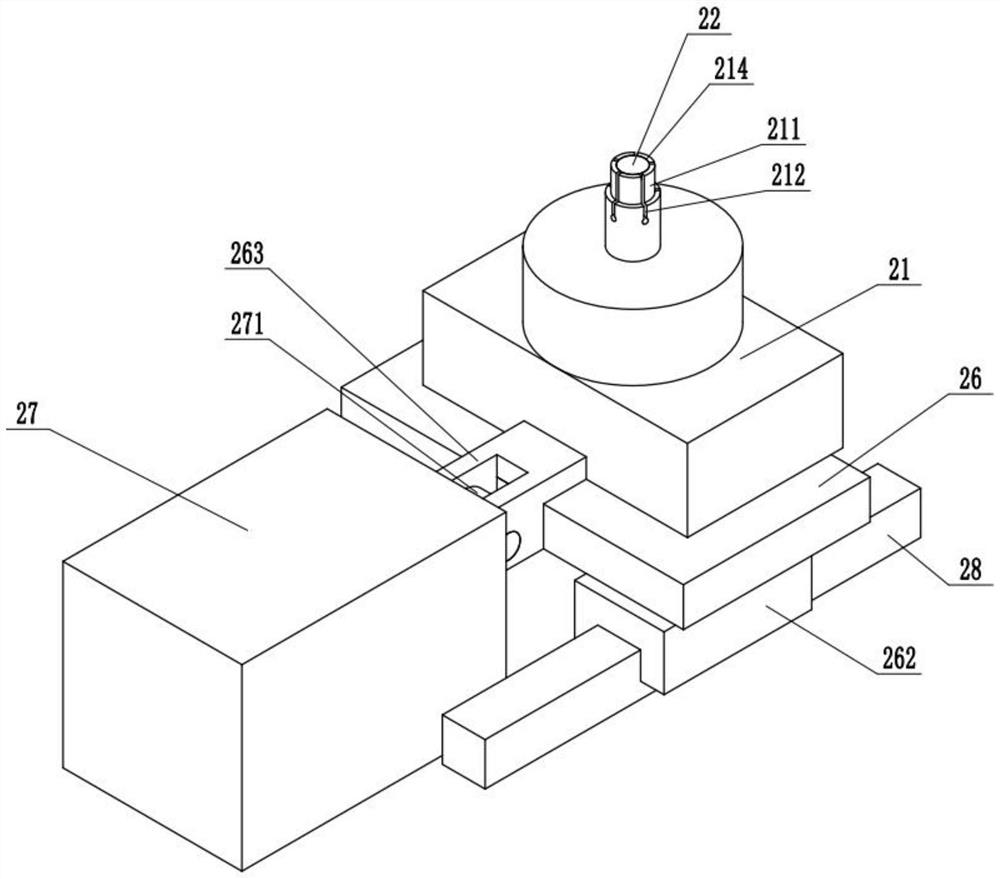

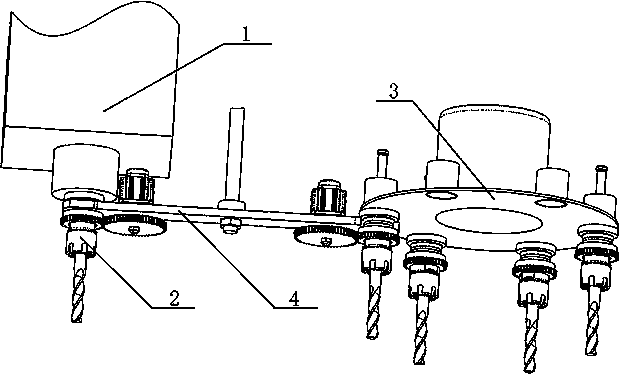

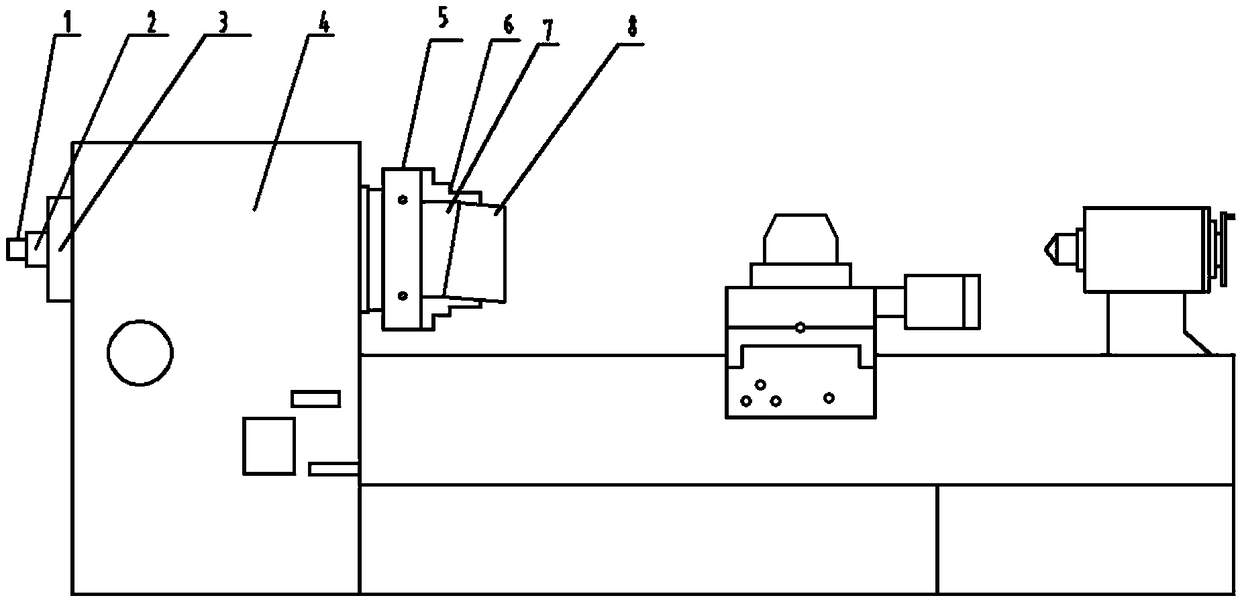

Numerical-controlled high-speed drilling and milling device

InactiveCN103240602AGood workmanshipReduce processing auxiliary timeOther manufacturing equipments/toolsLarge fixed membersNumerical controlBall screw

The invention discloses a numerical-controlled high-speed drilling and milling device comprising a lathe bed, a stand column, a ball screw rod, a tool changer support, a spindle box, a tool changer, a workbench and a carriage. The stand column is fixed on the lathe bed, the ball screw rod is positioned on one side of the stand column, the tool changer support is fixed on the stand column, the spindle box is fixed below the tool changer support, the tool changer is connected with the tool changer support, and the workbench and the carriage are arranged on the lathe bed. The numerical-controlled high-speed drilling and milling device has an optimized structure, production efficiency can be improved and production cost can be greatly reduced.

Owner:上海莱必泰精密机电有限公司

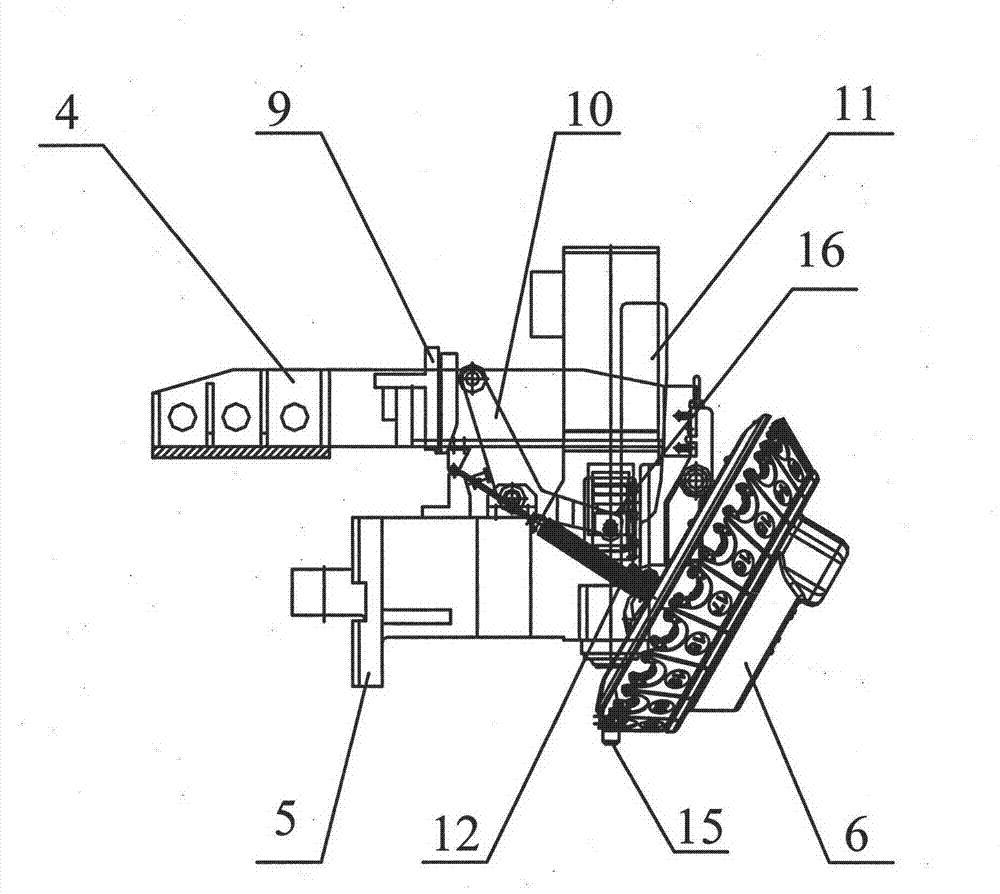

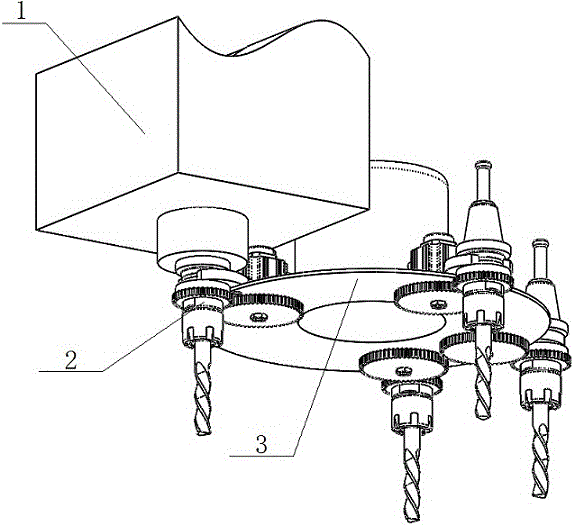

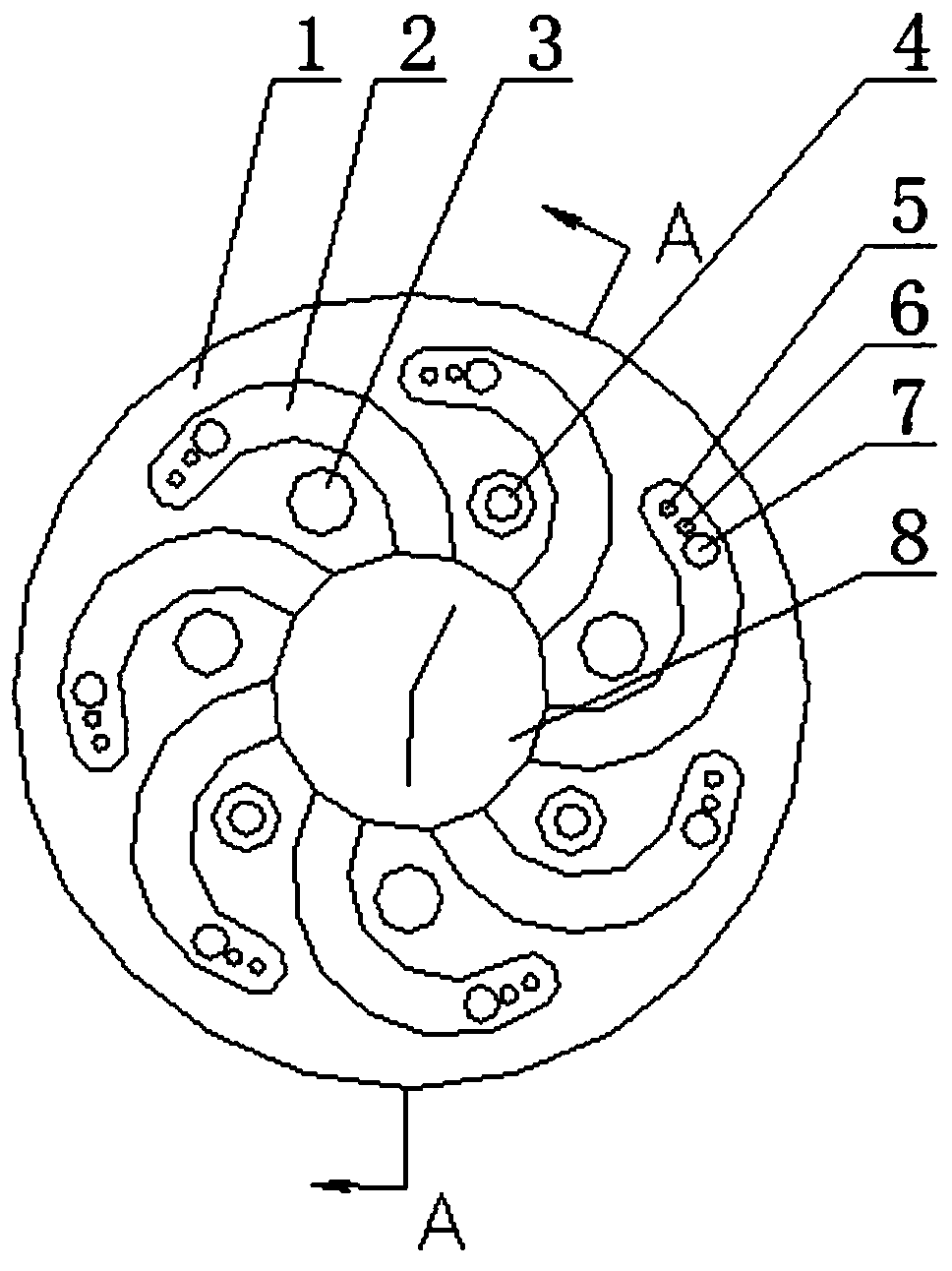

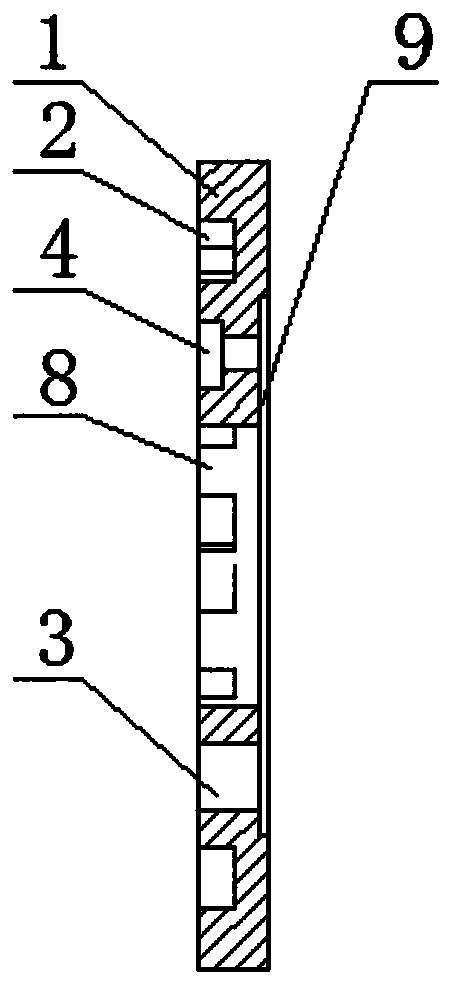

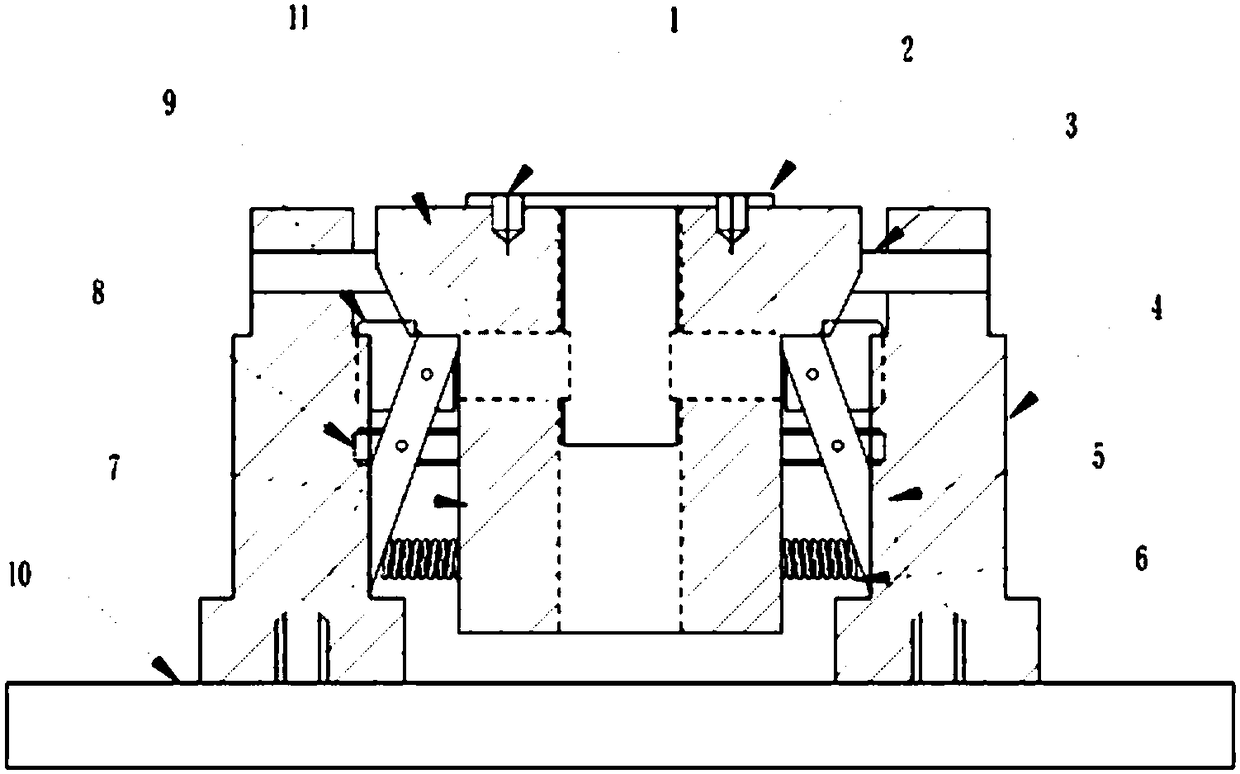

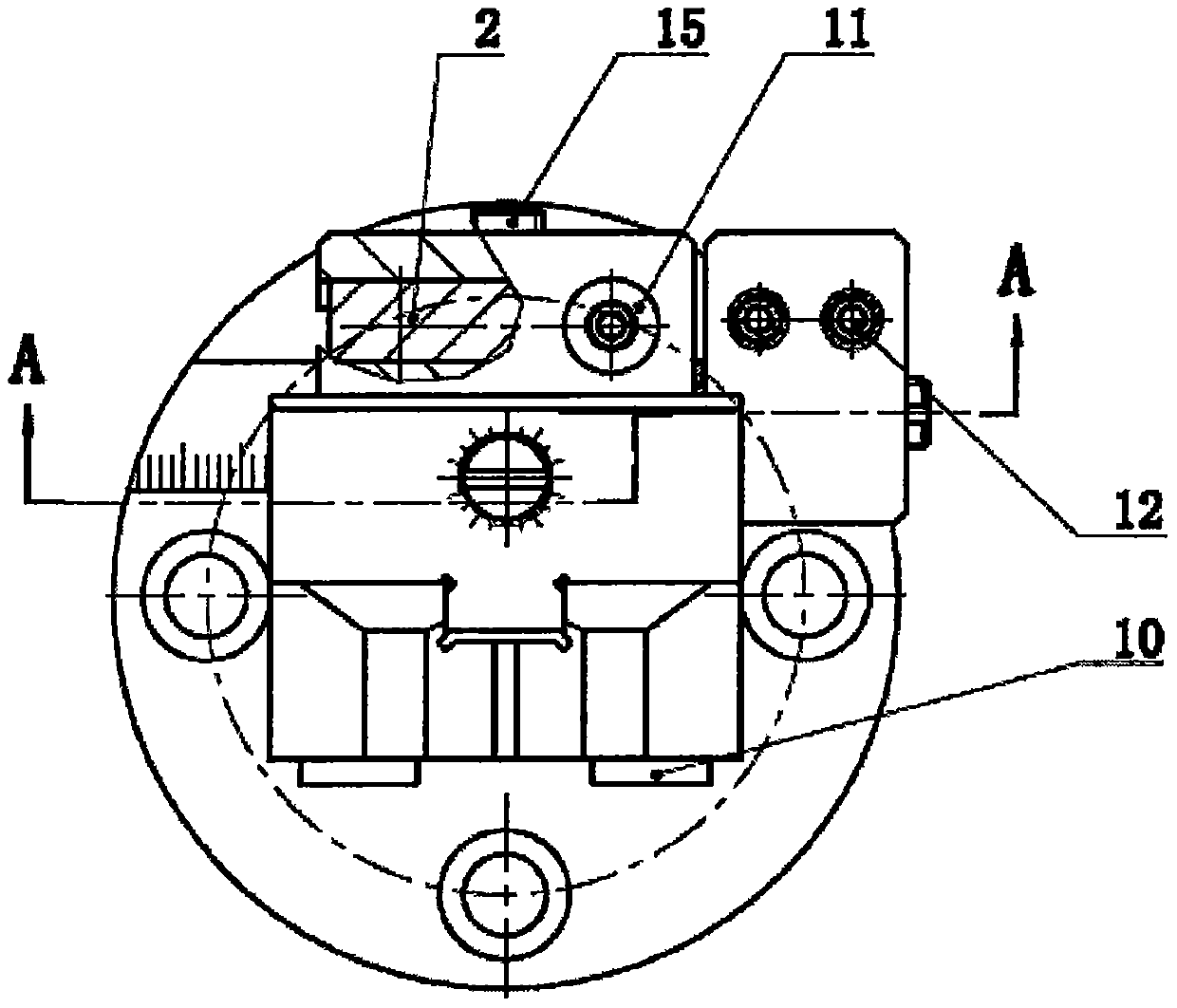

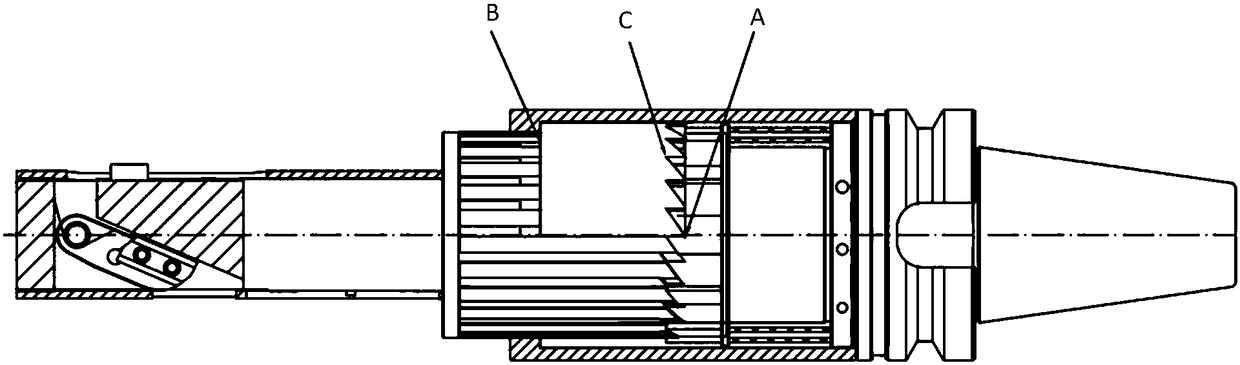

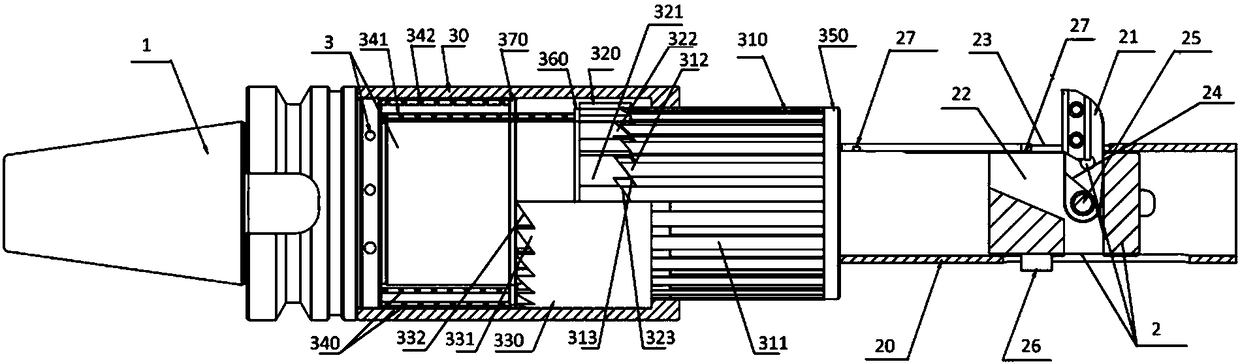

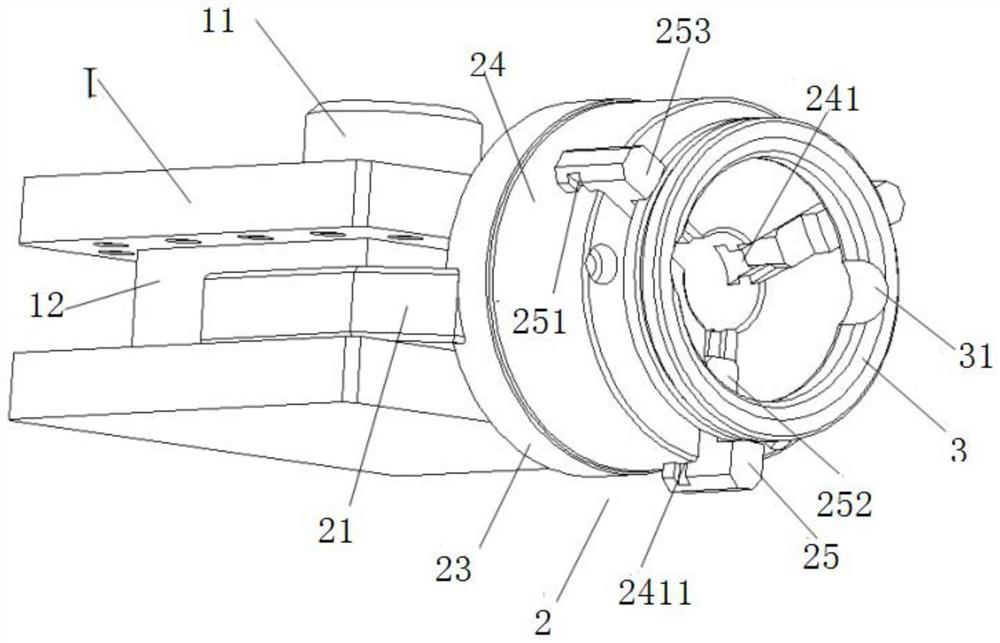

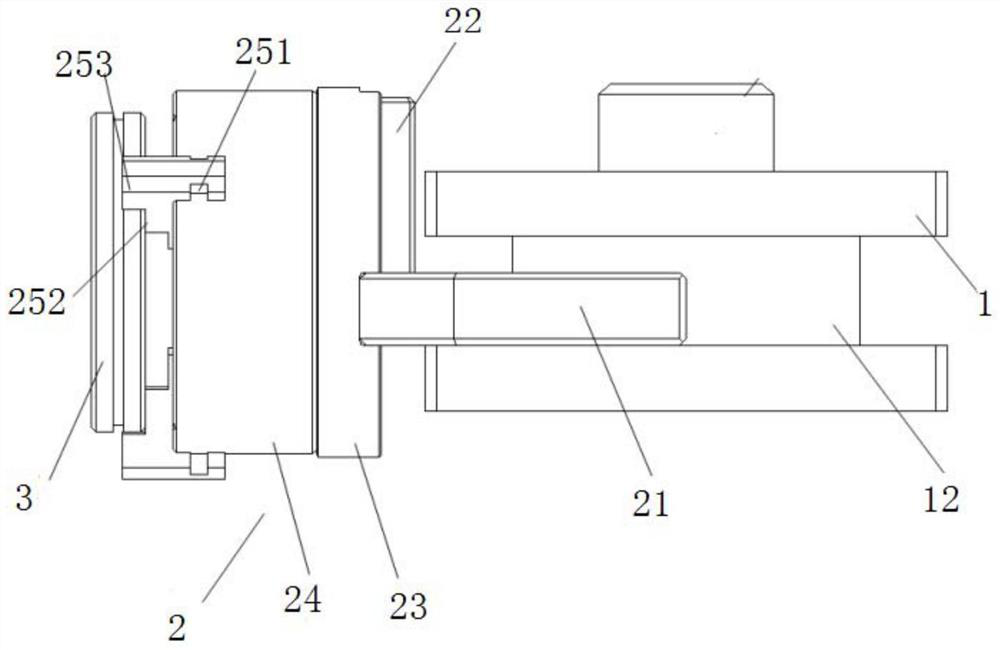

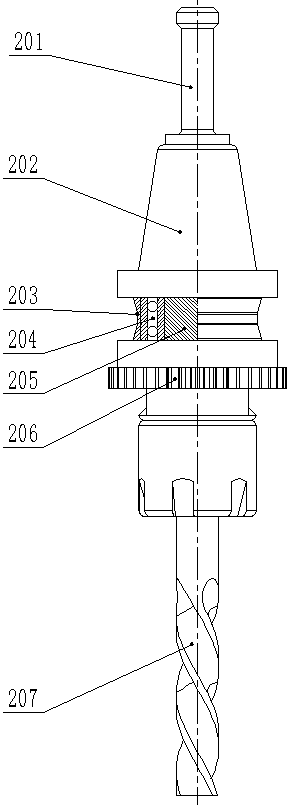

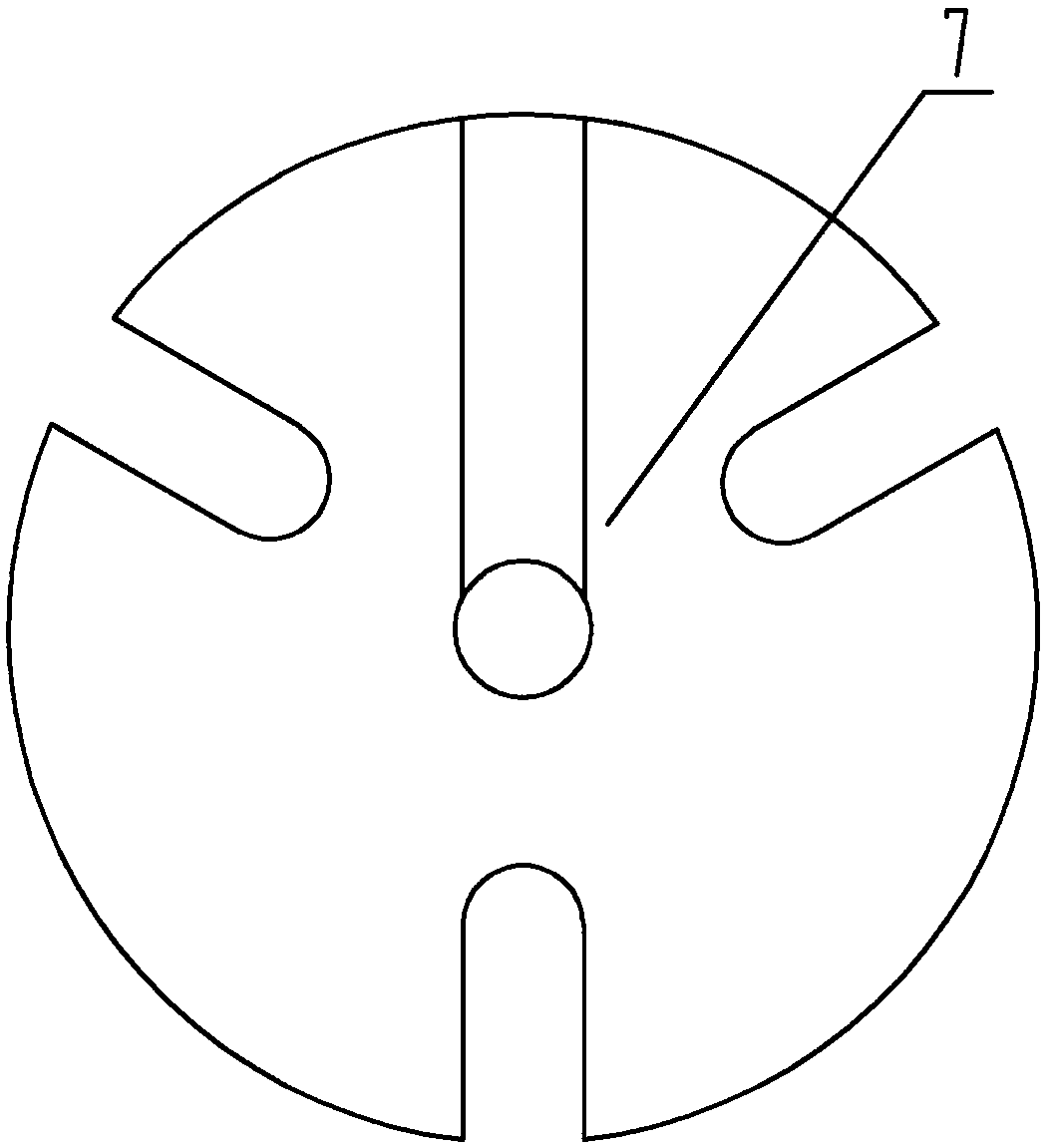

Manipulator-free device for automatically changing tools under condition of continuous rotation of spindle for machining center

ActiveCN105690163AGuaranteed speedCircumferential position consistentPositioning apparatusMetal-working holdersDrive motorEngineering

The invention belongs to the field of numerical control machining devices, in particular to a manipulator-free device for automatically changing tools under the condition of continuous rotation of a spindle for a machining center. The device comprises the spindle, tool handles, a tool repository and a numerical control system, wherein the spindle is provided with a speed regulating function and a circumferential-position real-time detecting and regulating function; each tool handle comprises an outer tapered handle body coaxially connected with the spindle, a tool body, a bearing arranged on the tool body in a sleeving manner, a groove, an A engaging unit and a tool; the tool repository comprises a plurality of tool positions and a tool position changing unit; each tool position comprises a tool clamp for clamping the corresponding tool, a tool driving motor for driving the corresponding tool to rotate, a circumferential-position real-time detecting and regulating system, and a B engaging unit engaged with the corresponding tool. The device for automatically changing tools under the condition of continuous rotation of the spindle can achieve rapid changes between the tools on the spindle of the machining center and tools in the tool repository under the condition of continuous rotation of the spindle, accordingly, auxiliary machining time during machining of the machining center is saved, the use efficiency of a numerical-control machine tool is improved, the machining cost is reduced, and the application prospect is broad.

Owner:NANTONG OUKE CNC EQUIP CO LTD

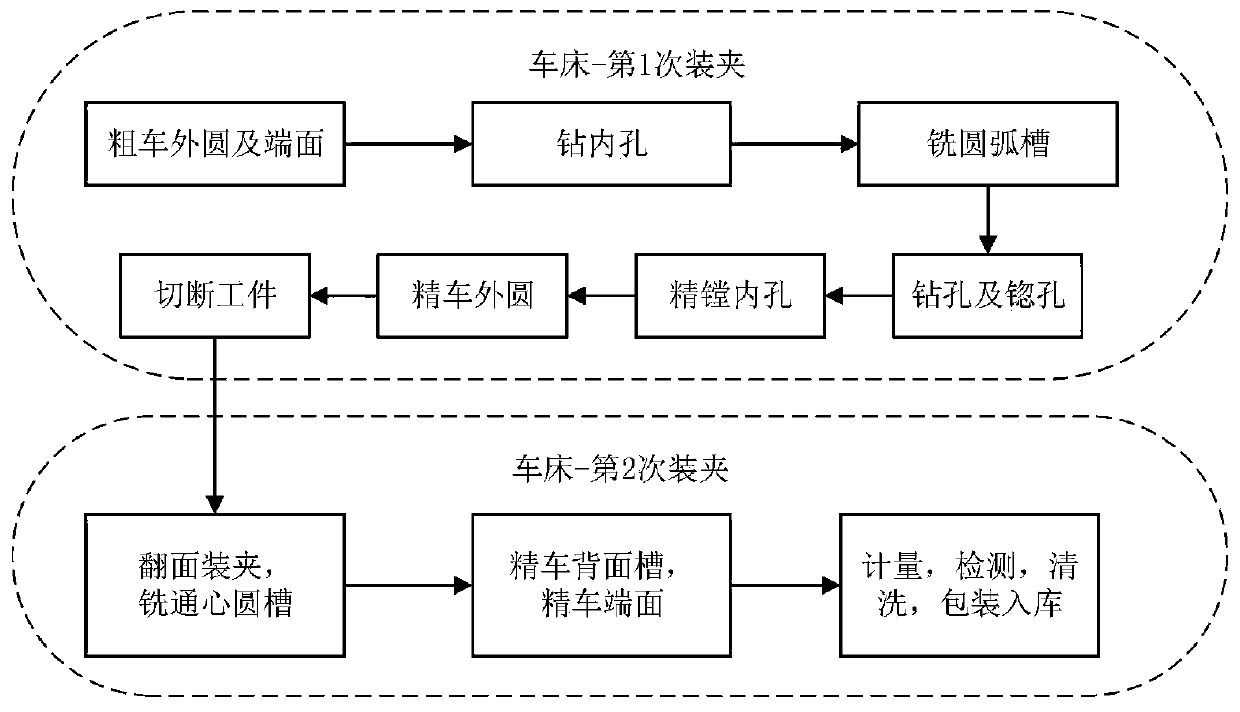

Turn-milling machining process method for gyroscope wire protecting plate

ActiveCN110948180AGuaranteed geometric toleranceReduce the number of clampingGyroscopeMachining process

The invention relates to a turn-milling machining process method for a gyroscope wire protecting plate. The method comprises the step (1) of clamping a workpiece on a lathe for the first time; the step (2) of drilling concentric inner hoes on the lathe; the step (3) of milling an arc groove on the lathe; the step (4) of performing drilling and counter boring on the lathe; the step (5) of fine boring the inner holes on the lathe; the step (6) of finish-turning an outer circle on the lathe; the step (7) of cutting off the workpiece on the lathe; the step (8) of turning over and clamping the workpiece on the lathe for the second time; the step (9) of turning a back side groove and finish-turning the end face on the lathe; and the step (10) performing metering, detection, cleaning, packaging and warehousing. According to the method, a turn-milling machining process is adopted in the machining process of the gyroscope wire protecting plate creatively, and the machining of the workpiece canbe finished on the lathe only; the clamping number of the process is decreased to 2 from 5, and the clamping number of the workpiece is decreased effectively; the auxiliary machining time is shortenedgreatly, and the part machining cost is reduced; the machining efficiency is improved; the method can meet the requirements of small-batch production and large-batch production of the gyroscope wireprotecting plate, and can be popularized in the production and machining of related sheet parts.

Owner:TIANJIN NAVIGATION INSTR RES INST

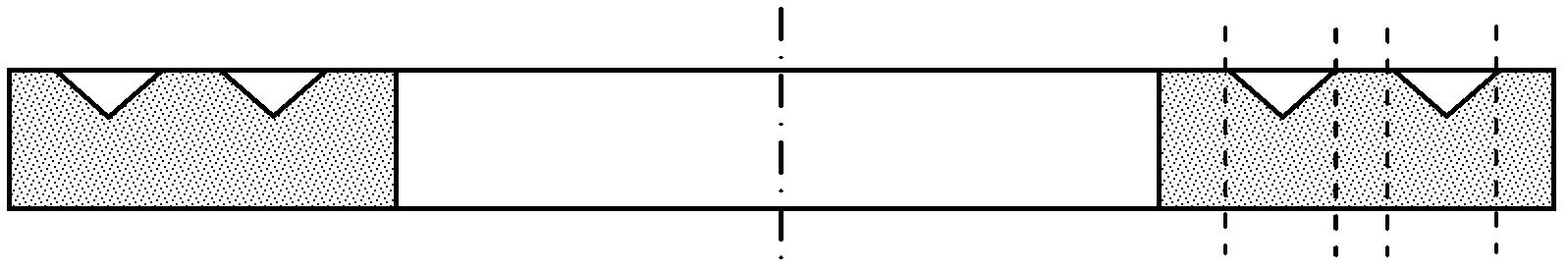

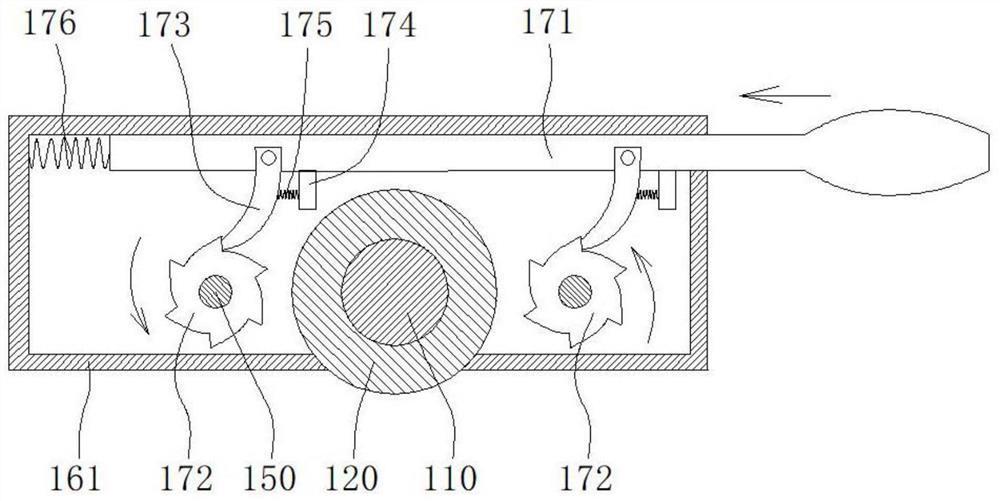

Ceramic ball lapping method based on combined-type fixation abrasive material grinding disc

InactiveCN102528641AAvoid wastingIncrease profitLapping machinesGrinding devicesMachining processCeramic

The invention relates to a ceramic ball lapping method based on a combined-type fixation abrasive material grinding disc. The method comprises the following steps of: 1): a manufacturing procedure of the combined-type fixation abrasive material grinding disc: (1.1) selecting a cast iron grinding disc as a basic structure, and processing an annular groove on the cast iron grinding disc; (1.2) preparing ingredients of a fixation grinding apparatus; (1.3) manufacturing a combined-type fixation grinding disc; (1.4) forming a V-shaped groove on the upper end of the combined-type fixation abrasive material grinding disc according to the diameter of a ceramic ball to be processed, wherein the V-shaped groove takes the annular groove filled with a fixation abrasive material as a centre; and (2) arranging the combined-type fixation abrasive material grinding disc on a lower plate of a lapping machine, wherein an upper plate adopts the cast iron grinding disc or the combined-type fixation abrasive material grinding disc; placing the ceramic ball to be processed in a raceway of the lower plate; and starting the lapping machine so as to realize finish machining on the ceramic ball. The lapping method provided by the invention has the advantages of improving the utilization ratio of the fixation abrasive material, reducing the difficulty in forming a processing groove on the grinding disc and finishing, reducing the production cost, reducing the processing non-cutting time, and improving the processing efficiency.

Owner:江苏智邦精工科技有限公司

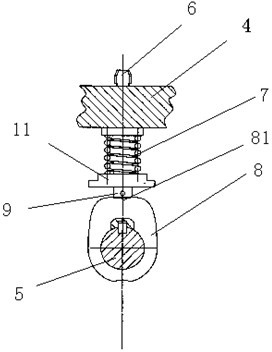

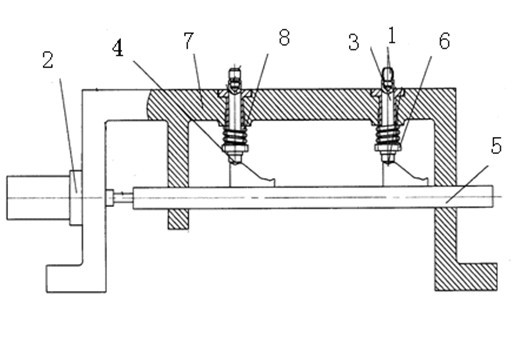

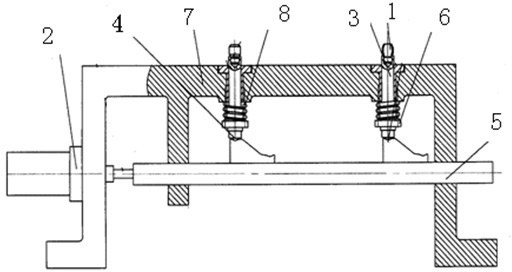

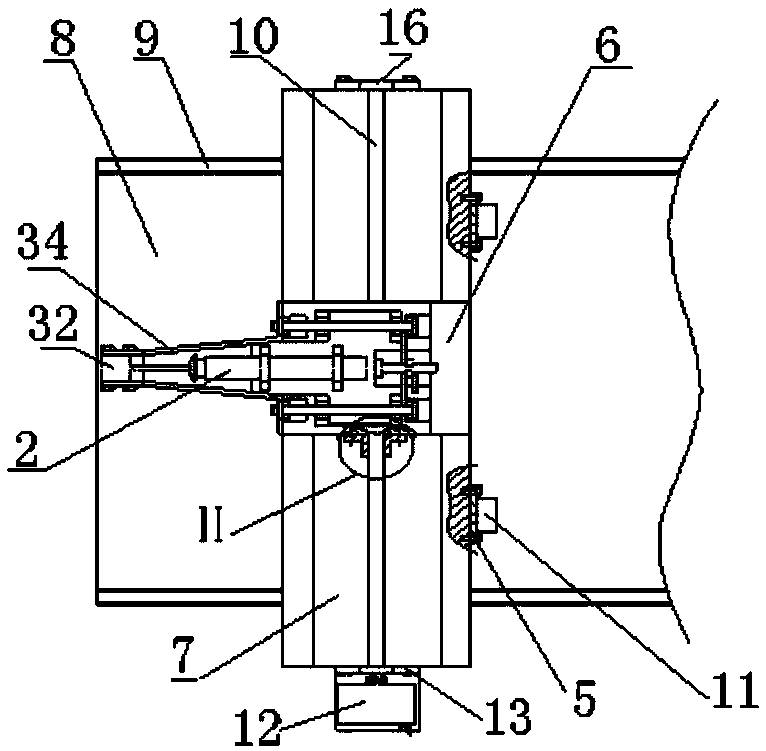

Telescopic pin fast positioning device

InactiveCN102490036AGuaranteed stabilityContinuous and smooth transmissionPositioning apparatusMetal-working holdersHydraulic motorEngineering

The invention discloses a telescopic pin fast positioning device, which comprises a hydraulic motor, a shaft, a cam, a push rod, a clamp body, a pin body and a spring, wherein the hydraulic motor is connected with the shaft arranged on the clamp body, the cam is arranged on the shaft, the lower end of the push rod is matched with the cam, the upper end of the push rod extends out of the clamp body, the pin body is arranged at the top end of the push rod, and the spring is sheathed on the push rod and is positioned between the clamp body and the lower end of the push rod. The fast positioning device disclosed by the invention has the advantages that the structure is simple, the operation is convenient, and the labor is saved.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

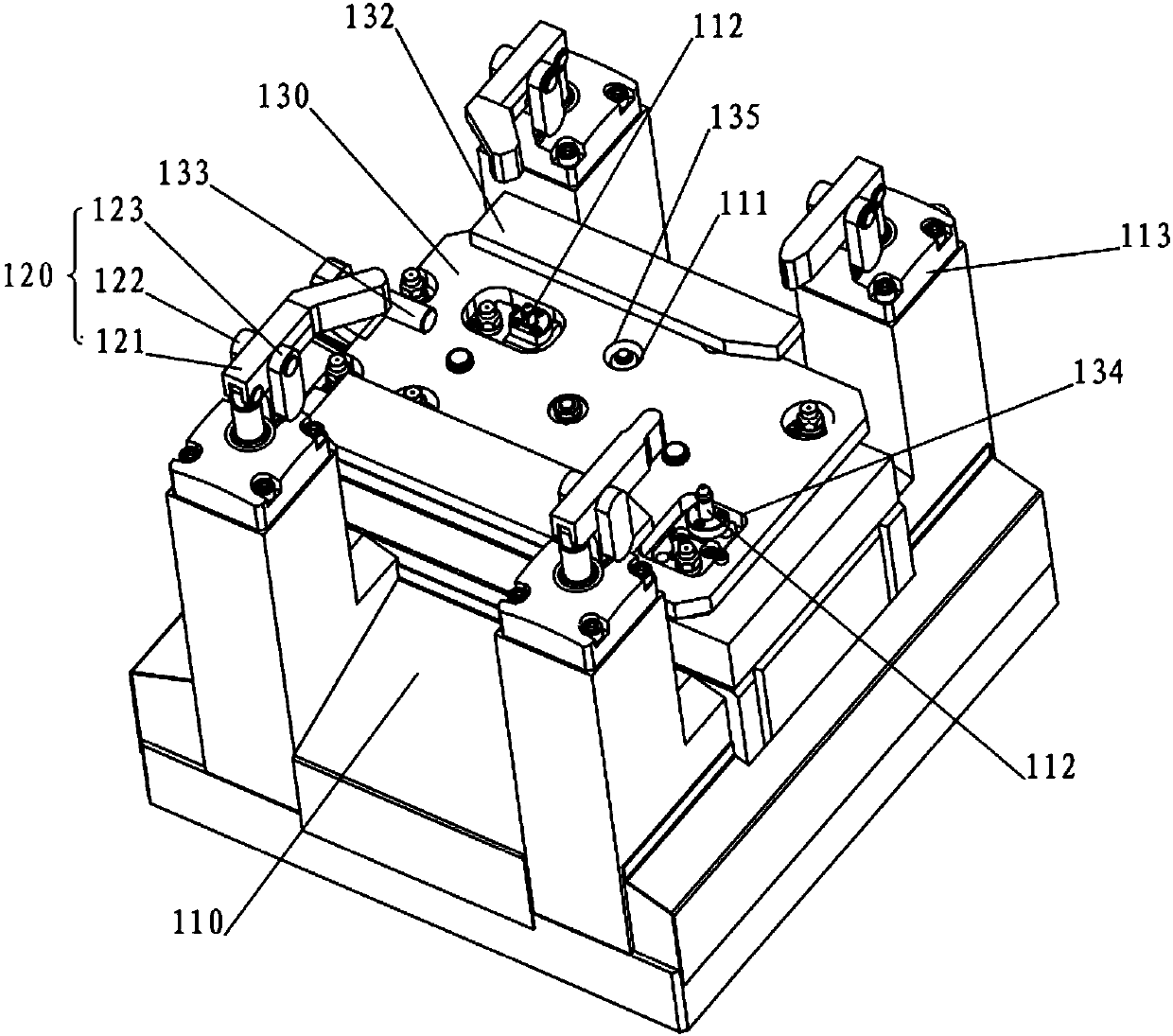

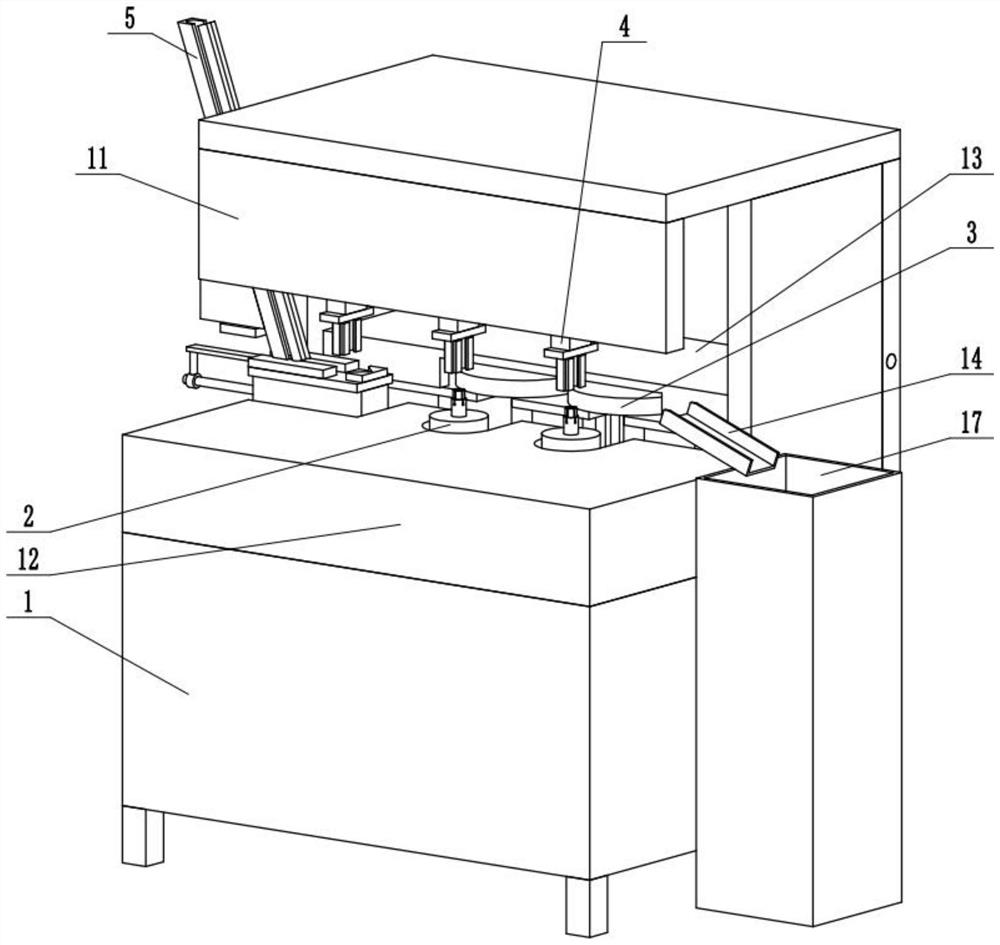

Engine cylinder cover machining clamp

InactiveCN107825198AReduce processing auxiliary timePerfect degree of automationPositioning apparatusMetal-working holdersTelescopic cylinderEngineering

The invention discloses an engine cylinder cover machining clamp which comprises a pedestal, a clamping mechanism and a lifting tray, wherein a first telescopic cylinder is arranged on the pedestal; apositioning surface and a positioning pin are also arranged on the pedestal; the clamping mechanism is connected with the first telescopic cylinder; the first telescopic cylinder drives the clampingmechanism to operate; the lifting tray is arranged above the pedestal; the bottom of the lifting tray is connected with a second telescopic cylinder arranged on the pedestal; a first opening, a secondopening, a guide strip and a limiting piece are arranged on the lifting tray; the guide strip is arranged in the push-in direction of a workpiece; the limiting piece is arranged on the side, perpendicular to the push-in direction of the workpiece, of the lifting tray; the positioning pin penetrates through the first opening; the second opening is used for exposing the positioning surface. The clamp is used for automatically clamping a cylinder cover instead of manual clamping by a worker, so that the machining assisting time is greatly shortened.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Hydraulic telescopic type positioning pin

InactiveCN102490035AImplement auto-scalingReduce processing auxiliary timePositioning apparatusMetal-working holdersHydraulic cylinderAgricultural engineering

The invention discloses a hydraulic driving telescopic type positioning pin, which comprises a pin body, a hydraulic cylinder, a telescopic rod, a flat plate cam, a push rod, a roller and a clamp body, wherein the hydraulic cylinder, the push rod and the telescopic rod are arranged on the clamp body, the hydraulic cylinder is connected with one end of the push rod, the flat plate cam is fixedly arranged on the push rod, a spring is sheathed outside the telescopic rod, the roller matched with the flat plate cam is arranged on the telescopic rod and is positioned at the lower end of the spring, and the pin body is arranged on the telescopic rod and is positioned at the upper end of the spring. The hydraulic driving telescopic type positioning pin is used for processing and positioning a box body type workpiece with two holes at one side, the structure is simple, the operation is simple and convenient, and the positioning is reliable.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

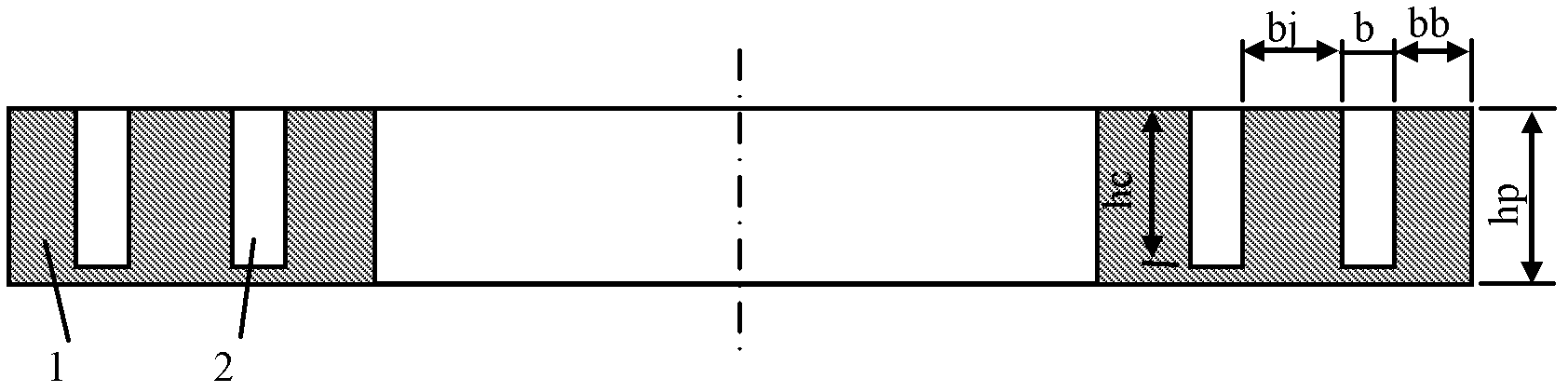

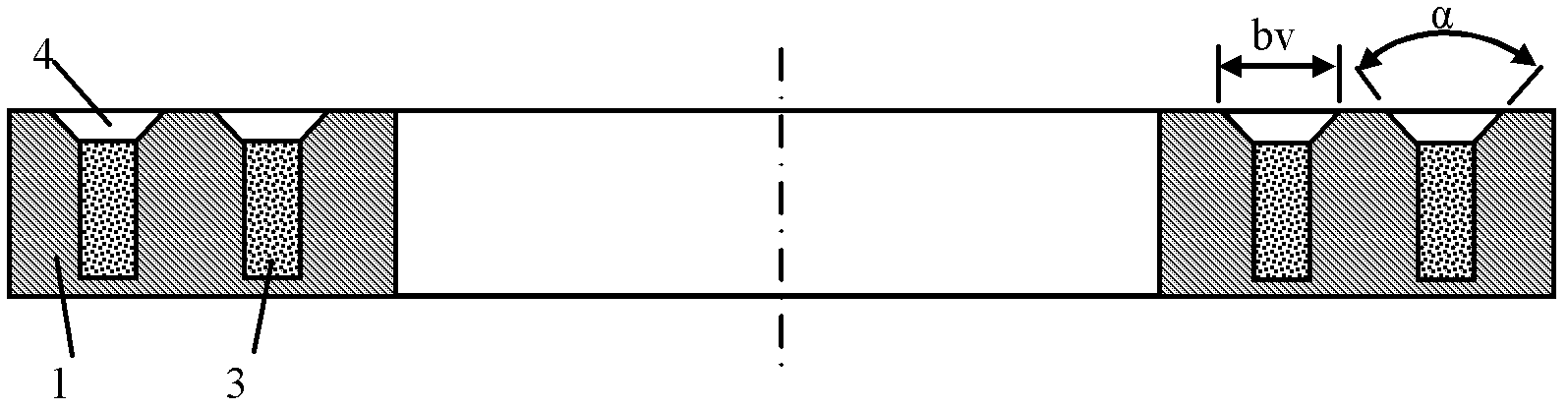

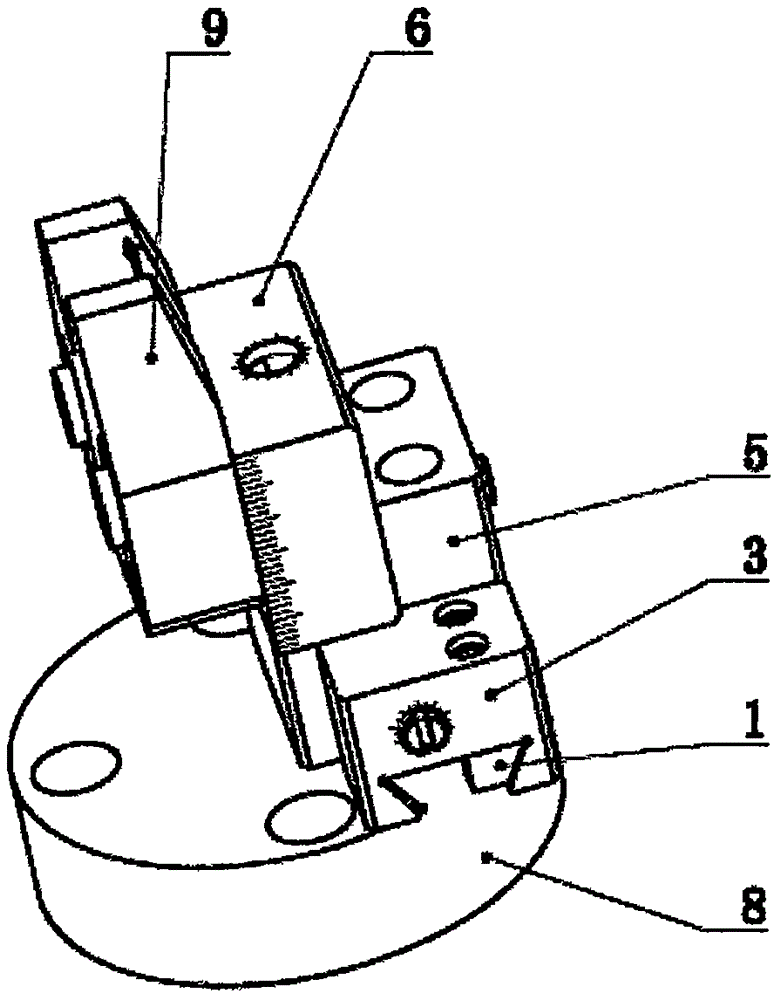

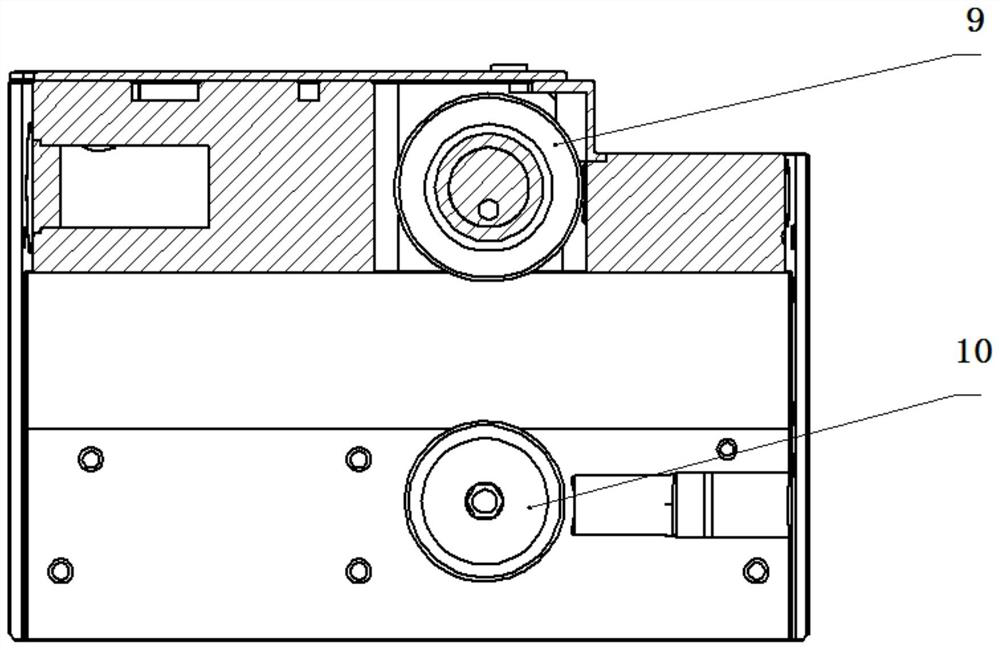

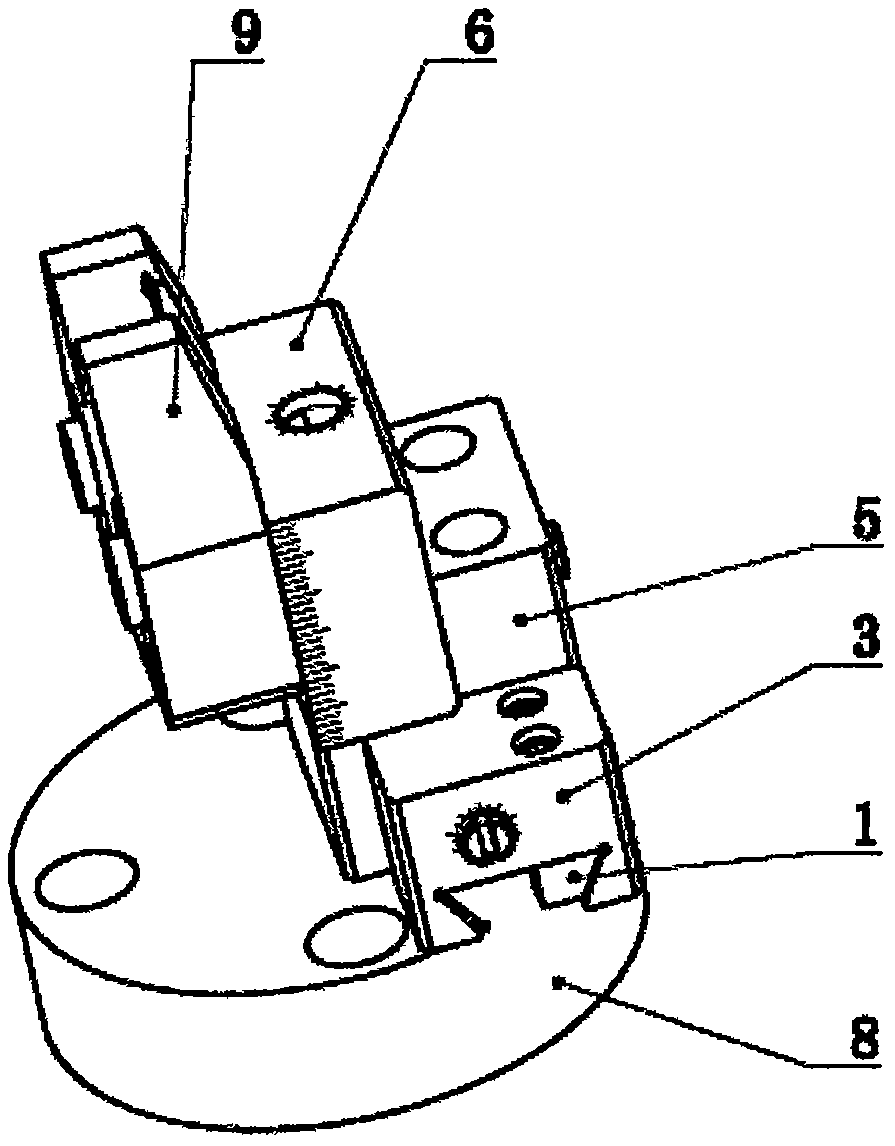

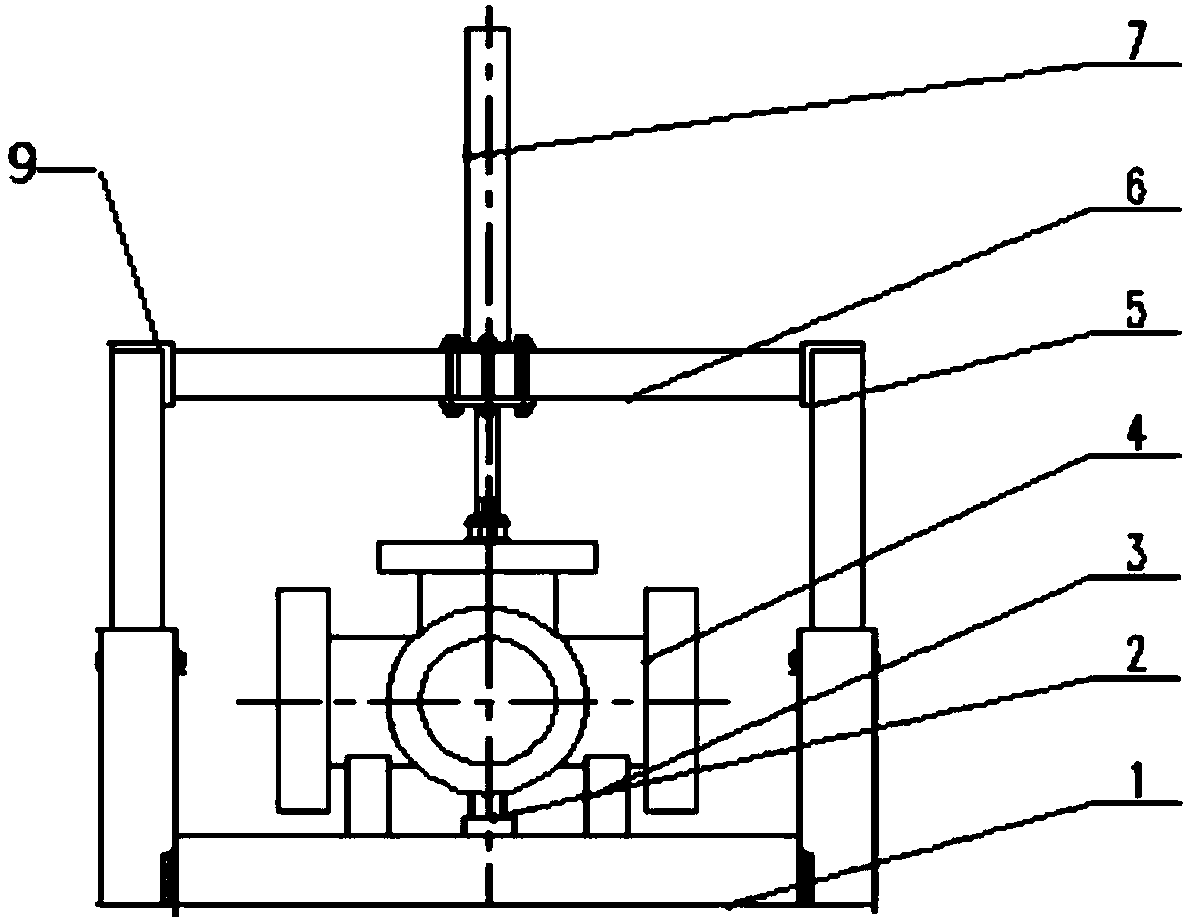

Blade clamping centering adjusting device of indexable insert periphery grinding machine

ActiveCN106239278AImprove processing efficiencyImprove machining accuracyGrinding feed controlOther manufacturing equipments/toolsDifferential screwEngineering

A blade clamping centering adjusting device of an indexable insert periphery grinding machine is characterized by comprising a V-shaped locating block, a vertical moving block, a horizontal moving block, a guide fixed block, a flange base, a horizontal differential screw, a vertical differential screw, a wedge block A, a wedge block B, a guide post and a compression spring. The V-shaped locating block is installed on the vertical moving block, the horizontal moving block is connected with the flange base through a dovetail groove in the horizontal moving block and the wedge block B, the guide fixed block is connected with the flange base through a dovetail groove in the guide fixed block and the wedge block A, the vertical differential screw is connected with the vertical moving block and the horizontal moving block, and the horizontal differential screw is connected with the guide fixed block and the horizontal moving block. The blade clamping centering adjusting device is simple in structure, small in size and low in manufacturing cost, does not rely on operation workers' experience level in use, does not need to be by means of other auxiliary tools, is high in efficiency and centering precision, greatly shortens processing auxiliary time and improves processing efficiency and precision of an indexable insert.

Owner:HUNAN TECHN COLLEGE OF WATER RESOURCES & HYDROPOWER

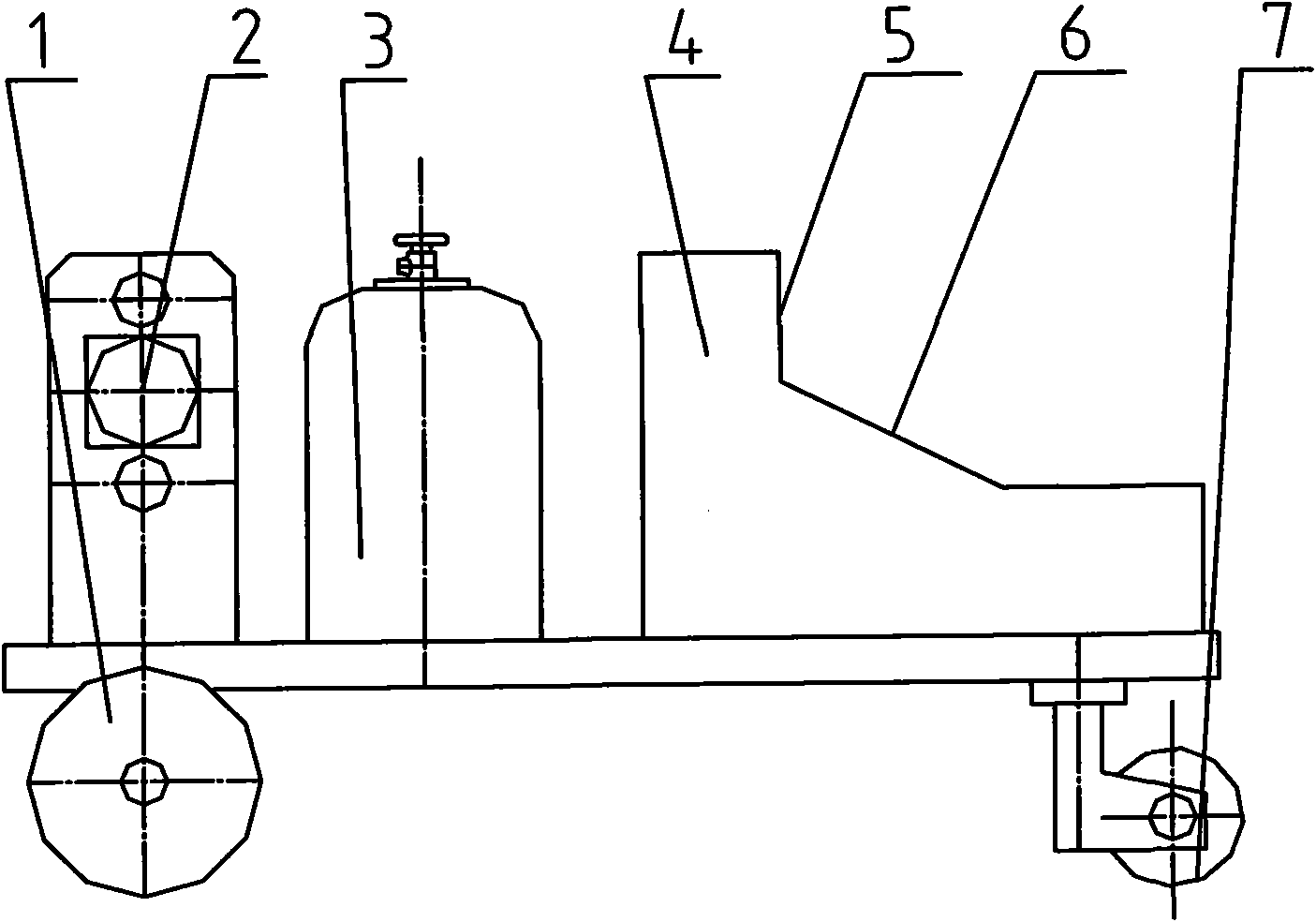

Self-tracking steel plate cutting robot

InactiveCN101850452AHigh precisionImprove programmabilityGas flame welding apparatusSheet steelControl system

The invention relates to a self-tracking steel plate cutting robot and belongs to the field of robot engineering. A flexible cutting mechanism is fixedly connected with one end of the upper part of a movable trolley; a flame cutting device is fixedly connected with the middle of the movable trolley; and a robot controller is fixedly connected with the other end of the upper part of the movable trolley. The robot has the advantages that: the robot has a novel structure; a cutting line is tracked in a self-tracking mode by using a charge-coupled device (CCD) image acquiring and processing system, so the accuracy of cutting size is enhanced; a cutting system and a control system are integrated with each other, a cutting air source and an electric power supply are loaded and no external device is needed, so the requirement on system operation is lowered and the adaptability of the system is enhanced; and the robot has small occupied space, reduces processing assisting time of the system, improves processing efficiency and has simple operation and high use flexibility.

Owner:ZHEJIANG NORMAL UNIVERSITY

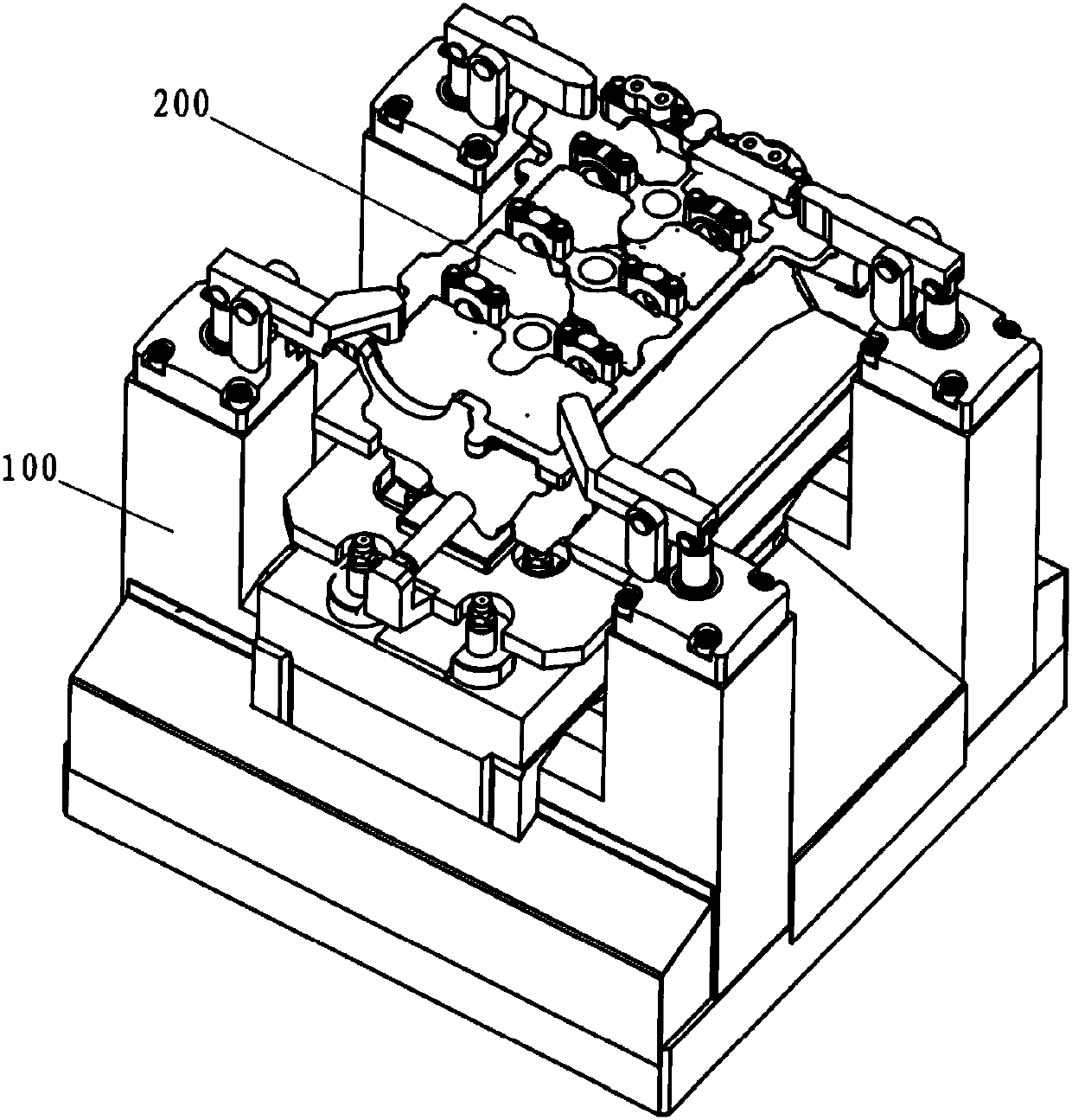

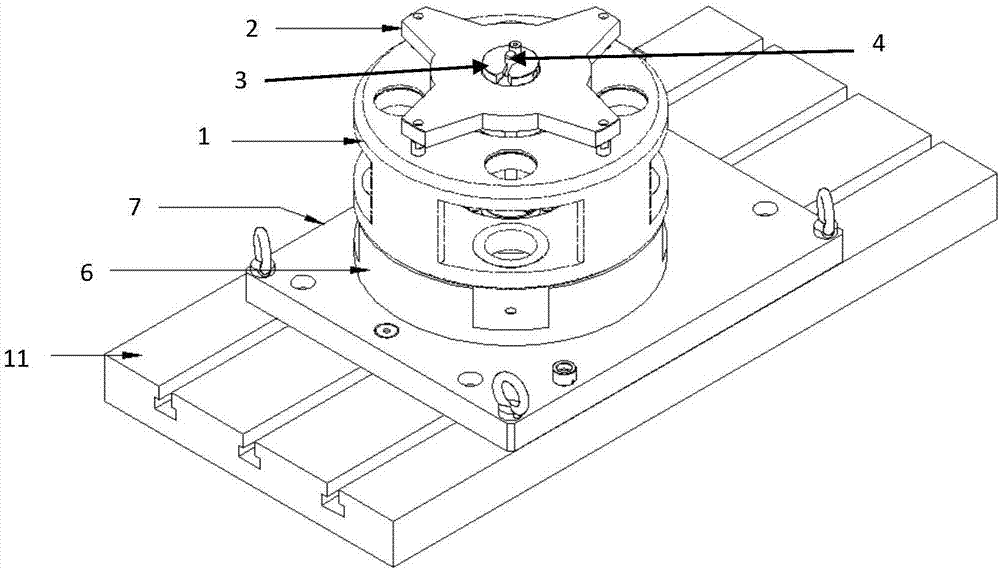

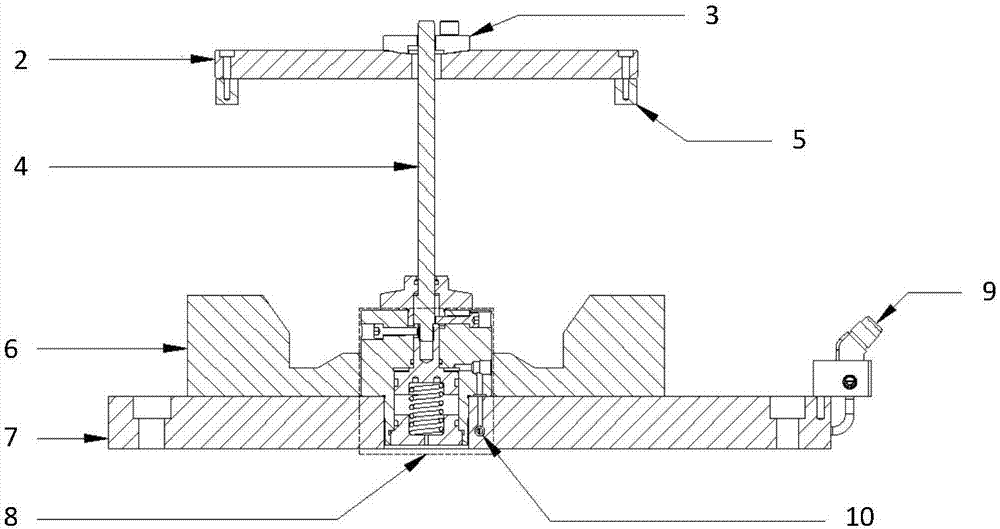

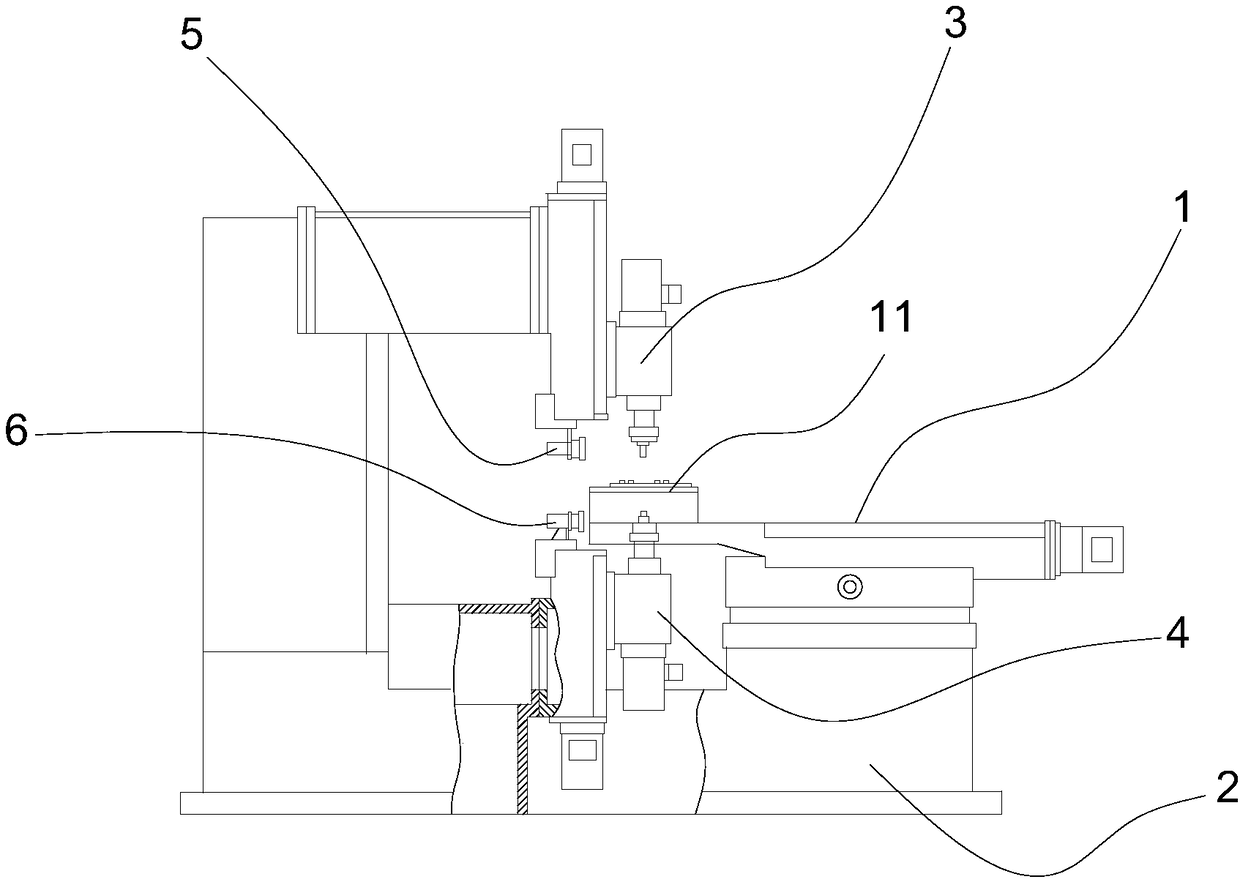

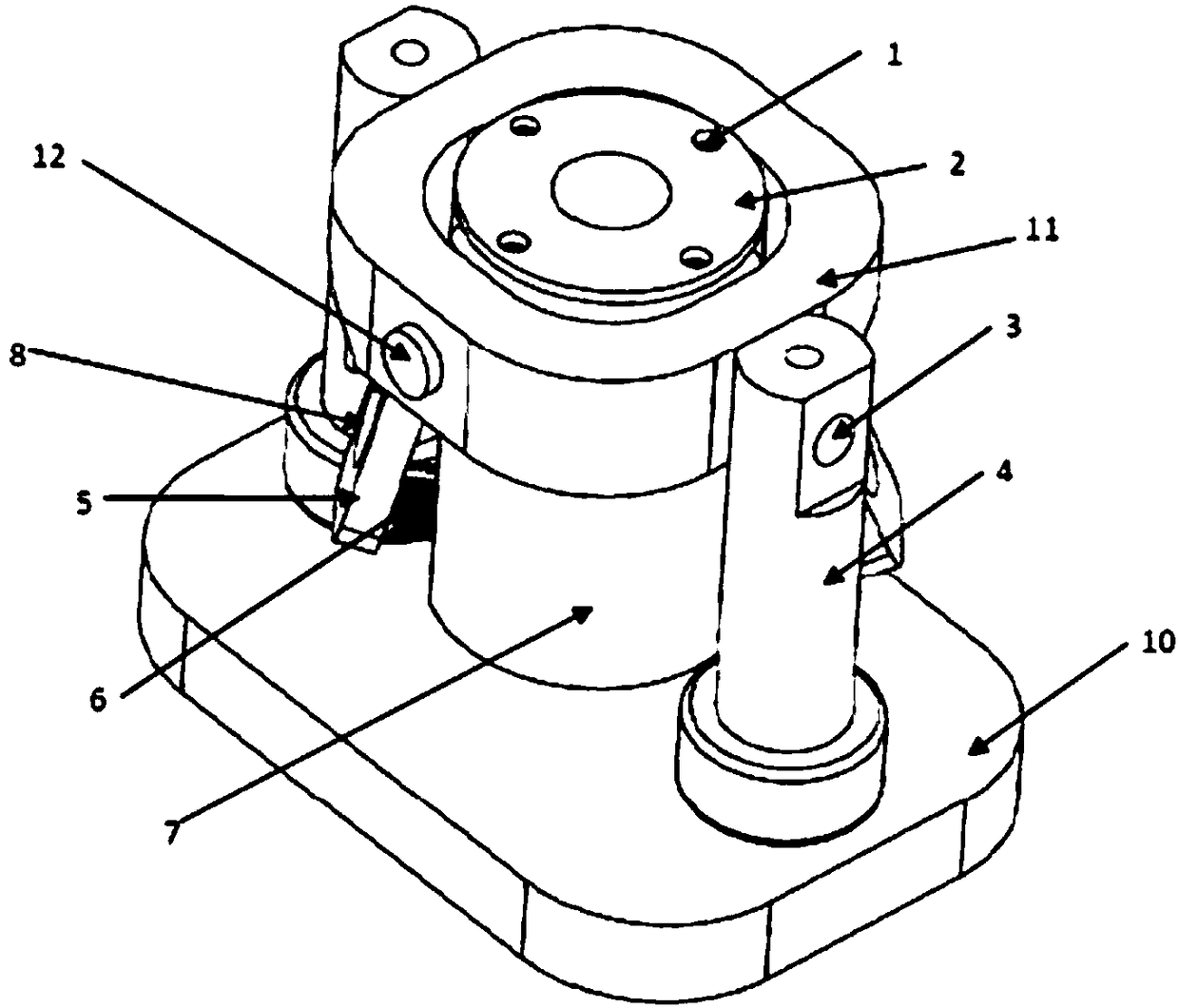

Hydraulic tool and processing method for processing dual-arm planet carrier

ActiveCN107414557AReduce processing auxiliary timeReduce logistics turnaround timeOther manufacturing equipments/toolsPositioning apparatusHydraulic cylinderEngineering

The invention discloses a hydraulic tool and a processing method for processing a dual-arm planet carrier. The hydraulic tool comprises a pull rod pressure plate, a part pressure plate, a pull rod, a supporting seat, a tool bottom plate, a hydraulic cylinder and a countersinking cutter. The processing method comprises the following steps of placing the dual-arm planet carrier to be processed between the part pressure plate and the supporting seat of the hydraulic tool, and then calling the hydraulic cylinder to finish automatic clamping according to a command of a machine tool; calling a trigger type optical measuring head to carry out online detection and automatic compensation of the position of the dual-arm planet carrier; using a drilling cutter to carry out drilling processing on a planet hole bottom hole of the dual-arm planet carrier; using a boring cutter to bore the size of a planet hole, and using the trigger type optical measuring head to carry out online detection on the planet hole subjected to boring; using the countersinking cutter of the hydraulic tool to countersink the size of an inner gear surface of the dual-arm planet carrier; and controlling the dual-arm planet carrier to loosen the clamping portion of the dual-arm planet carrier, i.e. taking down the dual-arm planet carrier after processing is finished.

Owner:YINCHUAN WEILI REDUCER MACHINERY

Ultrathin tempered glass automatic drilling machine tool based on binocular camera shooting and recognition

PendingCN108214941AMeet the needs of fully automated processingImprove product qualityTelevision system detailsColor television detailsEngineeringData treatment

The invention discloses an ultrathin tempered glass automatic drilling machine tool based on binocular camera shooting and recognition. Automation of ultrathin tempered glass drilling can be achieved,and meanwhile drilling efficiency can be improved. The ultrathin tempered glass automatic drilling machine tool based on binocular camera shooting and recognition comprises a two-dimensional work platform, a drilling machine rack, a servo driving spindle system, a binocular camera shooting system, a data processing and control system and an image library module processing system. High-definitionimages of a drill bit in the drilling process are collected through the binocular camera shooting system, then the image library module processing system refers to an ideal image in an image library,processing is carried out through a data processing unit in the data processing and control system, and a quantized value for evaluating the current abrasion state of the drill bit is obtained; and feedback control is carried out, and the feeding amount of the drill bit is compensated for in real time. By means of the ultrathin tempered glass automatic drilling machine tool based on binocular camera shooting and recognition, it can be guaranteed that the drill bit automatically completes drilling within the service life, the product quality is stable, and the machining assisting time is greatly shortened.

Owner:GUILIN UNIV OF ELECTRONIC TECH

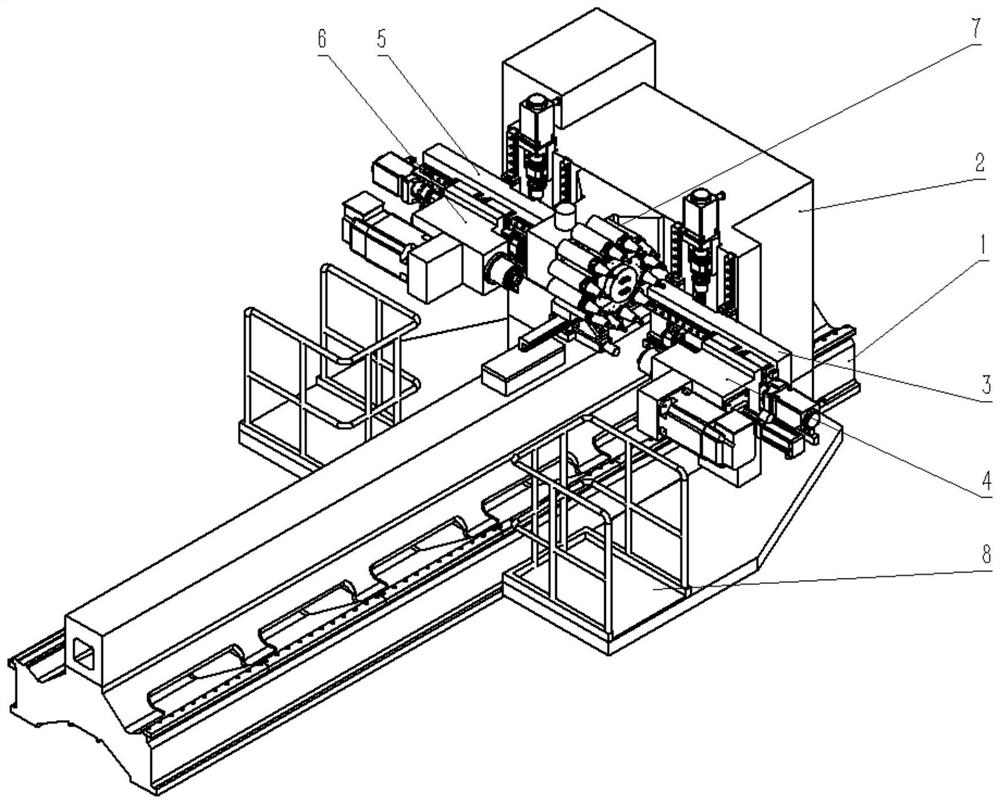

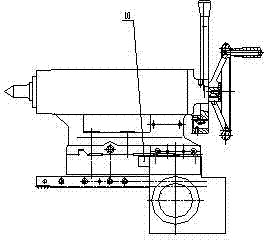

Double-spindle movable gantry ultra-long stroke machining center used for drilling and milling steel rail joint part

PendingCN111660102AReduce setup timeImprove processing efficiencyOther manufacturing equipments/toolsLarge fixed membersEngineeringMachine

The invention provides a double-spindle movable gantry ultra-long stroke machining center used for drilling and milling a steel rail joint part. A gantry frame is arranged on a machine body; a main machining side slide seat and a main machining side spindle box are placed above one side of the machine body; a sub machining side slide seat and a sub machining side spindle box are placed above the other side of the machine body; a fan-shaped servo tool magazine is arranged between the main machining side spindle box and the sub machining side spindle box; an operation platform is arranged on thetwo sides of the machine body; the length of the single machine body is 6m and adopts a structural form of a spliced machine body; the machine body length of a single machine is 30m and the machine body of the single machine can extends for a longest distance of 54m; a gantry is single side drive; and a main guide machining side adopts a linear guide rail with pre-tensioning. The double-spindle movable gantry ultra-long stroke machining center used for drilling and milling the steel rail joint part has the advantages that the blank of special steel rail machining equipment is filled, 27m longsteel rail can be machined at one time, the machine can extend for a longest distance of 54m, and the equipment operation difficulty is reduced. The problem that the repeated positioning accuracy islow due to large parallelism error between two linear guide rails of a traditional structure in a long stroke is solved; and the machining efficiency is enhanced.

Owner:沈阳大道机床有限公司

Honing full-floating tool

The invention discloses a honing full-floating tool. Honing support pillars are fixed onto a base through screws; a honing floating sleeve is connected with the honing support pillars through center pins; a honing core sleeve is connected with the honing floating sleeve through a rotary shaft pin; a reducing sleeve is assembled into the honing floating sleeve and is fixed through positioning screws; handles on two sides are fixed onto honing pins through a way of penetrating screws through installation holes in the upper end; fixed screws are clamped to the middle of a U-shaped port, are connected onto fixed screw caps through a way of penetrating screws through installation holes, and are connected onto the honing support pillars; springs are symmetrically arranged on the surface of the honing core sleeve; one ends of pin heads of the honing pins are inserted into the honing support pillars; the other ends of the pin heads of the honing pins penetrate through side holes of the honingcore sleeve and the reducing sleeve; and a component to be processed is fixed through pressing the surface of the component to be processed, and the honing core sleeve and the reducing sleeve are fixed on the same horizontal line. According to the honing full-floating tool provided by the invention, the dimensional accuracy and the behavior tolerance of the product can be ensured.

Owner:DADONG LINGANG IND PARK ZONE HEBEN PRECISION MACHINERY

A blade clamping and centering adjustment device for an indexable blade peripheral grinder

ActiveCN106239278BImprove processing efficiencyImprove machining accuracyGrinding feed controlOther manufacturing equipments/toolsDifferential screwEngineering

A blade clamping centering adjusting device of an indexable insert periphery grinding machine is characterized by comprising a V-shaped locating block, a vertical moving block, a horizontal moving block, a guide fixed block, a flange base, a horizontal differential screw, a vertical differential screw, a wedge block A, a wedge block B, a guide post and a compression spring. The V-shaped locating block is installed on the vertical moving block, the horizontal moving block is connected with the flange base through a dovetail groove in the horizontal moving block and the wedge block B, the guide fixed block is connected with the flange base through a dovetail groove in the guide fixed block and the wedge block A, the vertical differential screw is connected with the vertical moving block and the horizontal moving block, and the horizontal differential screw is connected with the guide fixed block and the horizontal moving block. The blade clamping centering adjusting device is simple in structure, small in size and low in manufacturing cost, does not rely on operation workers' experience level in use, does not need to be by means of other auxiliary tools, is high in efficiency and centering precision, greatly shortens processing auxiliary time and improves processing efficiency and precision of an indexable insert.

Owner:HUNAN TECHN COLLEGE OF WATER RESOURCES & HYDROPOWER

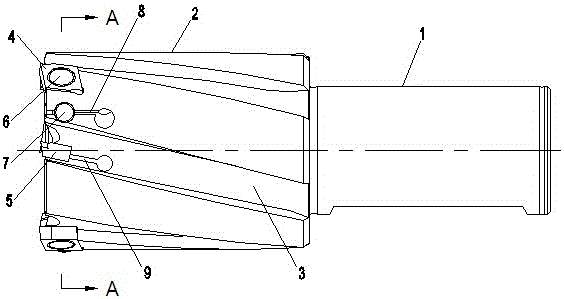

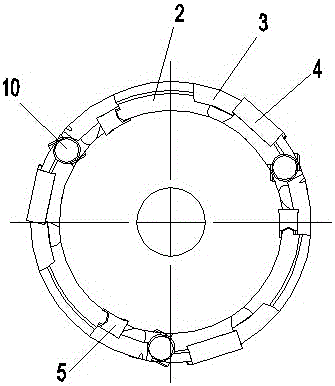

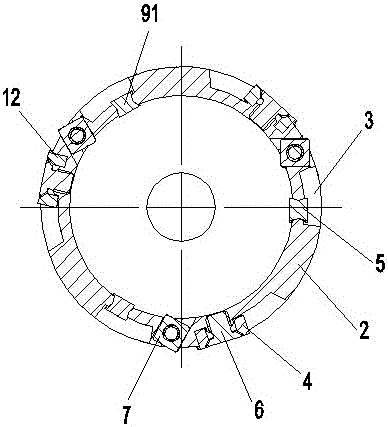

Blade detachable steel plate drill

InactiveCN106180828AFirmly connectedAvoid destructionTransportation and packagingTrepanning drillsSheet steelEngineering

The invention relates to a blade-detachable steel plate drill, which includes a blade and a cutter body. Several blades are combined into a cutting edge system. The cutter body is provided with several chip removal grooves. Each chip removal groove corresponds to a blade. The mounting part matches the positioning structure on the cutter body, and the blade is detachably installed on the cutter body. There are two kinds of positioning structures, and there are two corresponding types of blades. One of the positioning structures is a cuboid positioning groove, and the corresponding blade mounting part is placed in the positioning groove and fixed on the cutter body with screws; the other positioning structure includes Positioning elastic groove, matching elastic groove, nut, the upper part of the positioning elastic groove is symmetrical ∑ shape and cooperates with the corresponding blade fixing part, the lower part of the positioning elastic groove is connected with the upper part, the nut is placed in the matching elastic groove, and the blade fixing part snaps into the positioning elastic The upper section of the groove is fixed on the cutter body. The invention is reasonable in design, concise and practical. Through the replaceable blade structure, different blades can be installed, which is flexible and diverse, saves time and improves efficiency.

Owner:ZHEJIANG XINXING TOOLS CO LTD

Opening and closing of tool clamp capable of being controlled by fixed fork spanner

The invention discloses a toolholder which can be controlled to open and close by a fixing fork spanner and the invention includes a toolholder body. The toolholder body is divided into a neck part, an upper clamping part and a lower supporting part. The neck part, the upper clamping part and the lower supporting part enclose a slot body. The slot body is divided into a blade clamping section and an extending section extended to the neck part. The lower supporting part is provided with a supporting slot that can be cooperated with a supporting fork of the fixing fork spanner. A cut of the supporting slot is arranged at the joint location of the blade clamping section and the extending section. The upper surface of the extending section can keep contact with a rotary fork of the fixing fork spanner to drive the upper clamping part opposite to an elastically rotary supporting surface of the neck part. The toolholder which can be controlled by a fixing fork spanner has the advantages of high intensity of component, convenient for fast blade disassembling and assembling, being able to improve the processing efficiency and reducing the manufacture cost.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Reverse scraper tool for reverse stepped hole machining

The invention discloses a reverse scraping tool for machining a reverse step hole. The reverse scraping tool comprises a tool body, a reverse scraping tool bit assembly and a transposition assembly. The reverse scraping tool bit assembly comprises a tool apron and a sliding sleeve matched with the outer side wall of the tool apron, the tool apron is provided with a groove capable of containing a reverse scraping tool bit, the reverse scraping tool bit is arranged in the groove in the manner that the reverse scraping tool bit can overturn in the preset direction and stretch out of the groove, and the sliding sleeve is provided with an opening for the reverse scraping tool bit to stretch out in the sliding process of the sliding sleeve. The transposition assembly is arranged between the tool body and the reverse scraping tool bit assembly so as to drive the sliding sleeve to slide along the preset track to achieve state switchover for the tool bit to stretch out of the groove, and accordingly, the tool bit assembly can smoothly penetrate a to-be-machined hole in the machining process. According to the reverse scraping tool for machining the reverse step hole, the machining auxiliary time can be effectively shortened, and the production efficiency is improved; and operation risks are reduced, and the effects that the implementation effect is good, the safety coefficient is high, operation difficulty is low, and the production efficiency is effectively improved are achieved.

Owner:MIANYANG MIANGONG TOOLS

Gear chamfering tool assembly and vertical gear chamfering machine

ActiveCN111922446AEasy to operateReduce processing auxiliary timeGear teethIndustrial engineeringMachine

The invention provides a gear chamfering tool assembly and a vertical gear chamfering machine. The gear chamfering tool assembly comprises a spindle. The spindle is sleeved with a tool shaft coaxial with the spindle and capable of achieving axial limiting. The tool shaft is sleeved with an upper tool disc and a lower tool disc which are coaxially connected with the tool shaft. The lower tool discis fixedly connected with the tool shaft. The upper tool disc is fixed peripherally relative to the tool shaft and can move in the axial direction of the tool shaft. The chamfering tool assembly further comprises a driving mechanism which drives the upper tool disc to move in the axial direction on the tool shaft and has the self-locking function. The driving mechanism drives the upper tool disc to move in the axial direction on the tool shaft so as to adjust the distance between the upper tool disc and the lower tool disc, in order to adapt to the chamfering requirement of gears of differentthicknesses. The gear chamfering tool assembly is easy to operate, the chamfering tool assembly does not need to be disassembled from the gear chamfering machine, the machining auxiliary time is shortened, and the machining efficiency is improved.

Owner:CHONGQING NO 2 MACHINE TOOL WORKS

Novel automatic tailstock of lathe

InactiveCN103785865AReduce auxiliary timeRealize self-lockingTailstocks/centresBall bearingTailstock

The invention relates to a novel automatic tailstock of a lathe. The novel automatic tailstock comprises a lathe guide rail. A tailstock body is installed on the lathe guide rail. A moving supporting frame is fixedly installed on the tailstock body. A rack is installed on the lathe guide rail and meshed with a gear shaft. The gear shaft is installed in a bearing block of the moving supporting frame and fixed in the radial direction through two deep groove ball bearings. The axial position of the gear shaft is fixed through a fastening nut. A gear motor is installed on the moving supporting frame through a motor seat. The gear motor is linked with the gear shaft through a coupler. The novel automatic tailstock of the lathe has the advantages that the tailstock body automatically moves and can automatically lock after moving to the designated position, the auxiliary time of the lathe is shortened, labor intensity is relieved and safety is high. The novel automatic tailstock of the lathe is high in generality, free of limitation by the machining length of the lathe, efficient, and capable of shortening the machining auxiliary time and improving the machining efficiency.

Owner:滕州博信机床有限公司

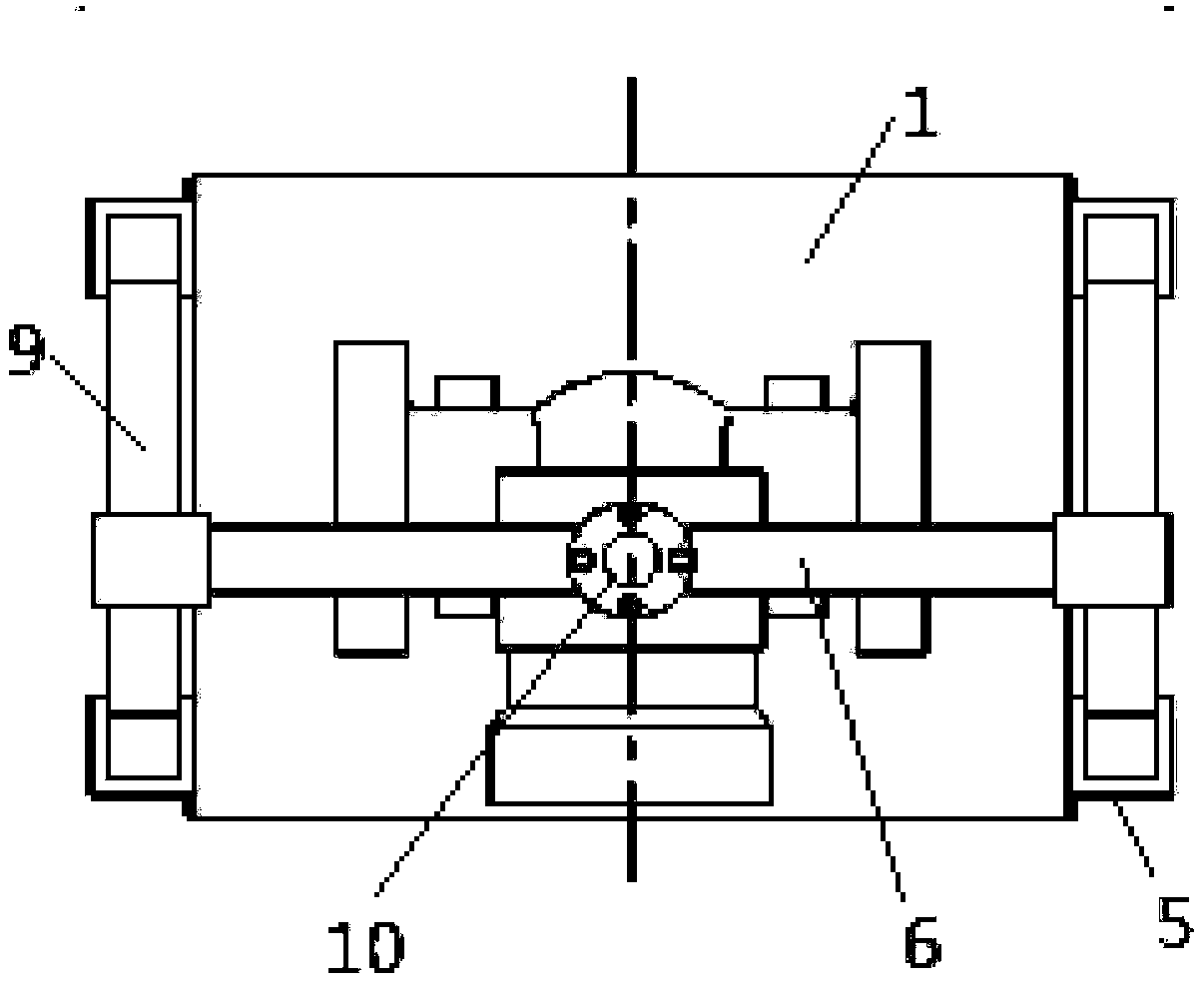

Fast clamping device for valve machining

PendingCN107685238AGuaranteed machining accuracyGuaranteed positioning accuracyLarge fixed membersPositioning apparatusHydraulic cylinderEngineering

The invention discloses a fast clamping device for valve machining. The device comprises a machine tool table, a jack is fixedly connected to the middle portion of the upper side of the machine tool table, a first V-shaped iron part is fixedly connected to the top of the jack, and a machined valve is placed on the first V-shaped iron part; vertical square steel bars are fixedly connected to the periphery of the machine tool table, guiding rails are arranged between the front and rear vertical square steel bars respectively, a horizontal square steel bar is arranged between the two guiding rails, a hydraulic oil cylinder is fixedly connected to the middle portion of the horizontal square steel bar, and a second V-shaped iron part is fixedly connected to the lower end of the hydraulic oil cylinder. The device has the advantages that 1, the machining precision of the valve can be stably guaranteed, by means of the fast clamping device, the valve is clamped, the position precision of the valve relative to a tool and a machine tool is guaranteed by a clamp, and the machining precision of the same valve or a same batch of valves is basically the same; 2, the working efficiency is improved, and fast and convenient clamping can be conducted by the fast clamping device, so that clamping labor-hour of the valve is significantly reduced.

Owner:LANZHOU HIGH PRESSURE VALVE

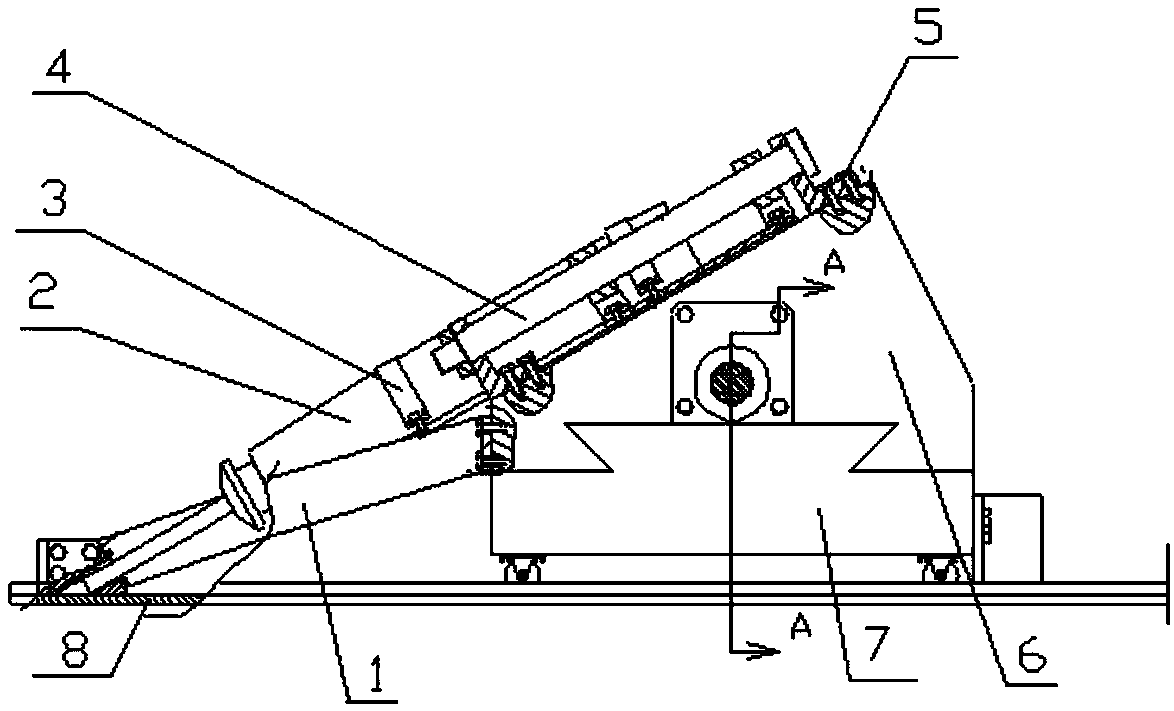

Device for processing inclined hole of flat plate of water diversion trench

ActiveCN108788248AGuaranteed process requirementsReduce auxiliary timeDrill jigsBoring/drilling machinesEngineeringWater diversion

The invention provides a device for processing an inclined hole of a flat plate of a water diversion trench. A body is placed on a guide rail through rolling wheels; one end of a drill bit guide mechanism is fixed to a longitudinally-moving inclined body; the other end of the drill bit guide mechanism is placed at the surface of a to-be-processed workpiece; an electric drill feed mechanism is fixed to the upper surface of the longitudinally-moving inclined bod; the longitudinally-moving inclined bod is positioned at the upper surface of the body; the two ends of a longitudinally-moving screw rod are fixed to the upper portion of the body; a longitudinally-moving screw barrel is installed on the longitudinally-moving screw rod in a sleeving manner and is fixedly connected with the longitudinally-moving inclined bod; and a dividing head is installed at the center of the end face of one end of the longitudinally-moving screw rod. The device provided by the invention has the characteristics of being simple in structure, convenient to operate, easy to implement and low in processing cost; moreover, a drill bit is always positioned inside a guide sleeve hole; direct processing can be implemented without regulation; the processing period is shortened; the device can also be used for processing a plurality of plates simultaneously; and the production efficiency is improved.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

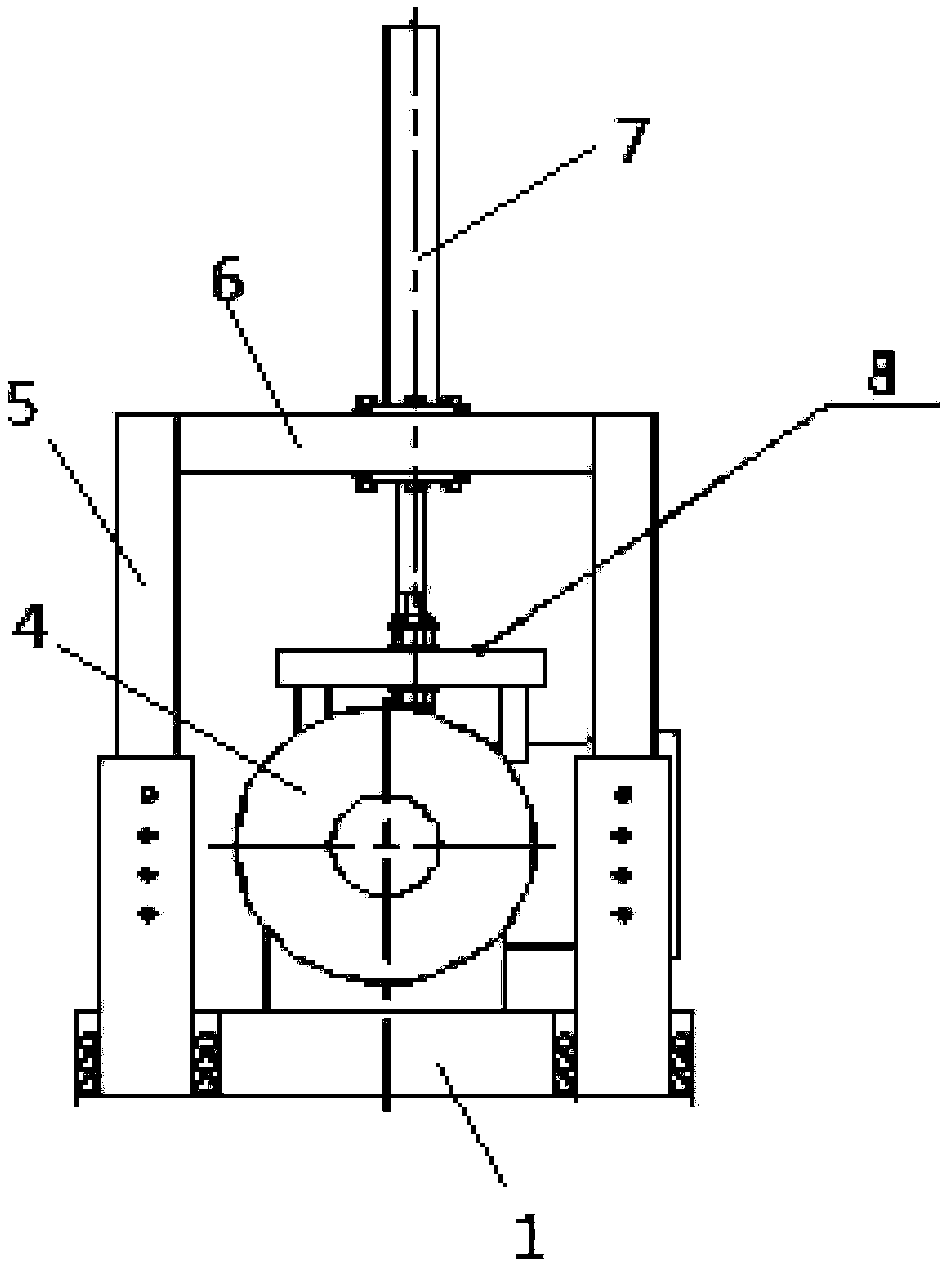

Automatic polishing device for knuckle bearing

PendingCN114346881AReduce labor intensityImprove working conditionsPolishing machinesGrinding drivesPolishingElectric machinery

The automatic polishing device comprises a shell, a locking mechanism and a polishing mechanism, the locking mechanism comprises a working air cylinder installed at the upper end of the shell, the rear end of the working air cylinder is connected with a fixing plate, the fixing plate is slidably connected to the upper end of the shell, and the upper end of the fixing plate is fixedly connected with a rotating air cylinder; a locking rod is installed at the upper end of the rotating air cylinder, a plurality of locking grooves are formed in the locking rod, a big-end-up sliding hole is formed in the locking rod, a locking block is connected into the sliding hole in a sliding mode, the locking block is in a big-end-up circular truncated cone shape, a connecting rod is fixedly connected to the lower end of the locking block, a pull rod is installed at the lower end of the connecting rod, and a bearing is installed on the outer side of the lower end of the pull rod. The polishing mechanism comprises a polishing wheel, the polishing wheel is located at the rear end of a locking rod and corresponds to the locking rod, a polishing motor is installed at the lower end of the polishing wheel, the machining efficiency is high, and use is convenient and fast.

Owner:浙江威尔轴承工业有限公司

Impactor clamping ring machining clamp and method

PendingCN113634773AImprove processing efficiencyReduce conversionAuxillary equipmentLarge fixed membersMilling cutterEngineering

The invention relates to an impactor clamping ring machining clamp. The impactor clamping ring machining clamp comprises a frame body installed on a lathe tool rest and a clamping device detachably connected with the frame body; the clamping device is used for clamping a to-be-machined clamping ring, so that the end surface of the clamping ring can be perpendicular to the axis of a formed milling cutter installed on a lathe, and the clamping device is driven by the lathe tool rest to move in the axial direction of the clamping ring or move in the radial direction of the clamping ring. The invention further relates to an impactor clamping ring machining method. The impactor clamping ring machining clamp is adopted in the impactor clamping ring machining method. The impactor clamping ring machining clamp and the impactor clamping ring machining method are applied to the lathe, clamping ring machining can be completed on one piece of lathe equipment, a ventilation groove is machined in a numerical-control turning mode, the machining efficiency is higher than that of numerical-control milling, and then the machining efficiency of the overall clamping ring is improved.

Owner:CHANGSHA HEIJINGANG IND CO LTD

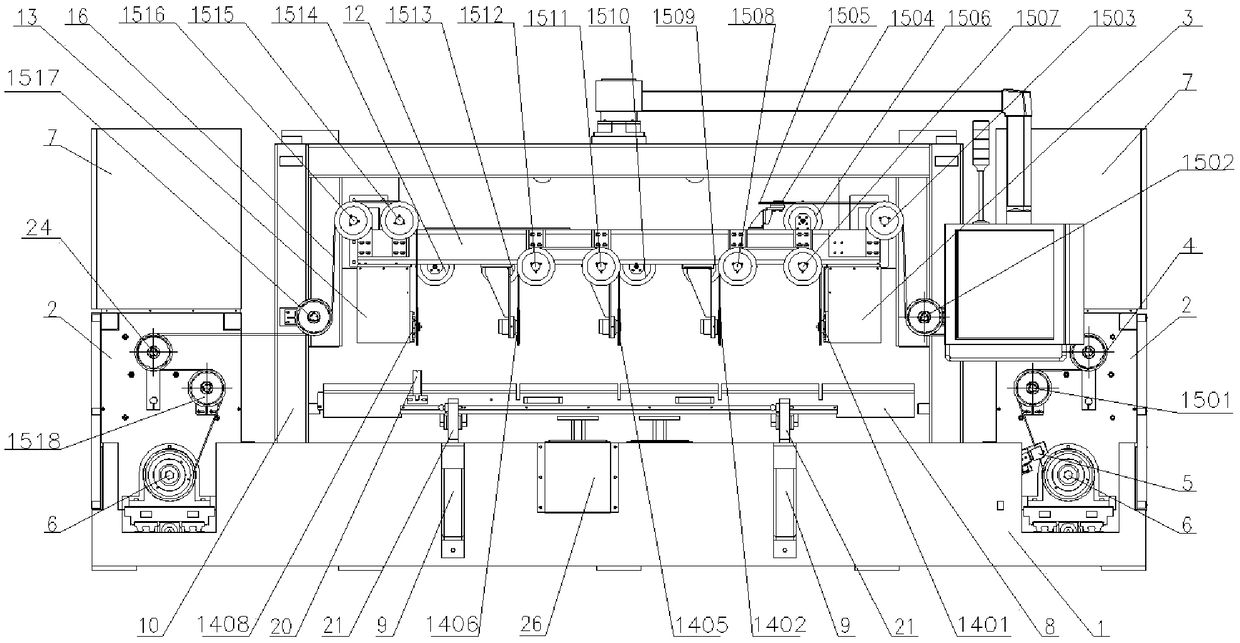

Numerical control polycrystalline silicon diamond wire high-speed cutting-off machine

The invention relates to a numerical control polycrystalline silicon diamond wire high-speed cutting-off machine which comprises a lathe bed and taking-up and paying-off chambers installed at the twoends of the lathe bed. An electric box is fixedly installed on the upper portion of each taking-up and paying-off chamber. Stand columns are installed on the four corners of the lathe bed correspondingly. Two working tables are installed between the two stand columns located on the two sides of the lathe bed through guide rail supports correspondingly. The guide rail supports and the working tables are connected through short steel guide rails. Sliding plates are installed on the two stand columns located on the rear side through linear guide rails correspondingly. The sliding plates drive a cutting wire frame fixed to the lower portions of the sliding plates to move up and down. A first datum motor and a second datum motor are installed at the two ends of the cutting wire frame correspondingly. Multiple diamond wire passing wheels are installed on the two sides of the cutting wire frame. Multiple diamond wire cutting wheels are installed below the cutting wire frame. Diamond wires areguided out from the taking-up and paying-off chamber at one end and sequentially wound around the multiple diamond wire cutting wheels and the diamond wire passing wheels into the taking-up and paying-off chamber at the other end. According to the machine, the diamond wire taking-up, paying-off and distributing quality is improved, and the operation stability and the production efficiency of equipment are improved.

Owner:WUXI SHANGJI AUTOMATION

The spindle of the machining center does not stop rotating, and there is an automatic tool changer for manipulators

ActiveCN105773264BImprove time utilizationImprove equipment utilizationPositioning apparatusMetal-working holdersDrive motorEngineering

The invention belongs to the field of numerical control machining devices and specifically relates to an automatic tool changer (ATC) with a manipulator and an incessantly rotating spindle for a machining center. The ATC comprises the spindle, tool handles, a tool magazine, the tool changing manipulator and a numerical control system. The spindle has the functions of speed governing and circumferential position real-time detection and adjusting. Each tool handle comprises an outer conical handle body coaxially connected with the spindle, a tool body, a bearing arranged on the tool body in a sleeving mode, a groove, a meshing device A and a tool. The tool magazine comprises a plurality of tool positions and a tool position changing device. Each tool position comprises a conical sleeve used for clamping the corresponding tool, tool driving motors, a tool circumferential position real-time detection and adjusting system, and a meshing device B meshing with the corresponding tool. The tool driving motors drive the tools to rotate. Through the ATC, fast tool changing can be achieved between a tool on the spindle of the machining center and the tools in the tool magazine under the circumstance that the spindle rotates incessantly, so that the auxiliary machining time during machining of the machining center is saved, the service efficiency of a numerically-controlled machine tool is improved, the machining cost is reduced, and the application prospects are wide.

Owner:NANTONG OUKE CNC EQUIP CO LTD

Quick clamping positioning tool for processing shutter

PendingCN109202501AGuaranteed machining accuracyReduced clamping man-hoursWork clamping meansPositioning apparatusEngineeringMachine tool

The invention discloses a quick clamping and positioning tool for processing a shutter. The tool comprises a 10-degree tire tooling and an elongated three-claw unit. The 10-degree tire tooling is detachably fixed to a three-claw chuck of a machine tool, and the elongated three-claw unit is fixed to the outer side of the three-claw chuck. Compared with the prior art, the quick clamping and positioning tool has the advantages that (1) the production efficiency is improved, the quick clamping and positioning tool can perform clamping and positioning quickly and conveniently, the clamping work time of the shutter can be significantly reduced, the rigidity of the shutter can be improved after clamping, the cutting amount can be increased during processing, and the processing efficiency can be greatly improved, (2) two sides of the shutter can be processed, sealing surfaces can be processed through turning the shutter, the processing precision is improved, the positioning precision of a position is ensured, the machining assistance time is greatly shortened, and the production efficiency is improved in all directions.

Owner:LANZHOU HIGH PRESSURE VALVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com