Quick clamping positioning tool for processing shutter

A clamping positioning and tooling technology, used in positioning devices, clamping devices, metal processing equipment, etc., can solve the problems of poor fixing stability, low positioning accuracy, low processing efficiency, etc., to increase the cutting amount and improve production efficiency. , the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

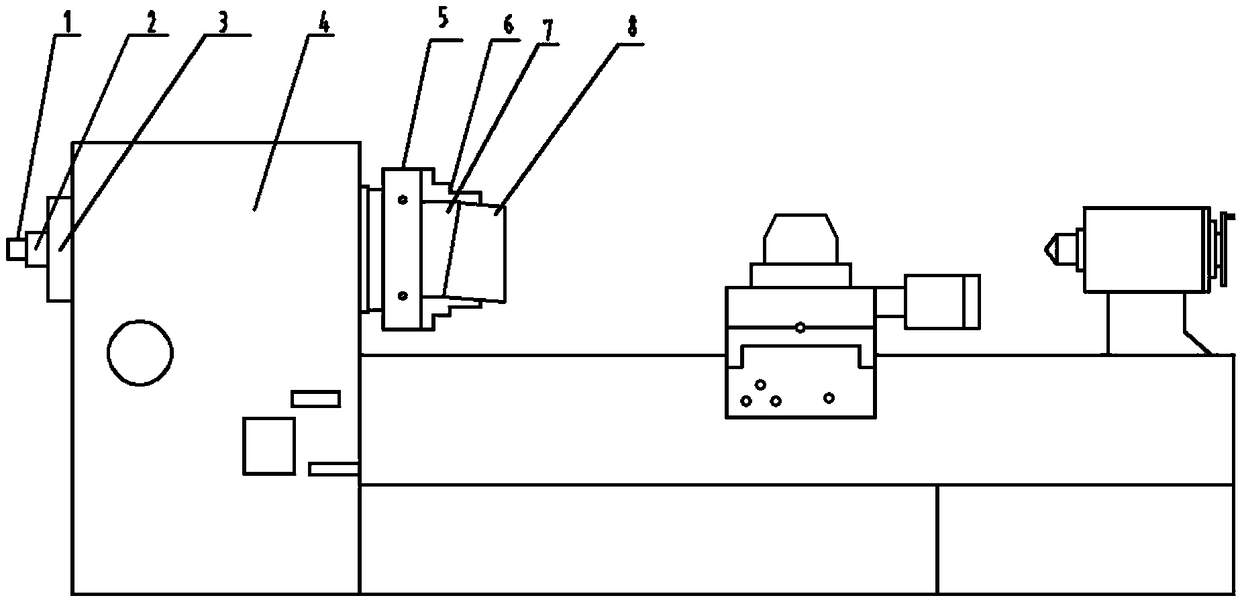

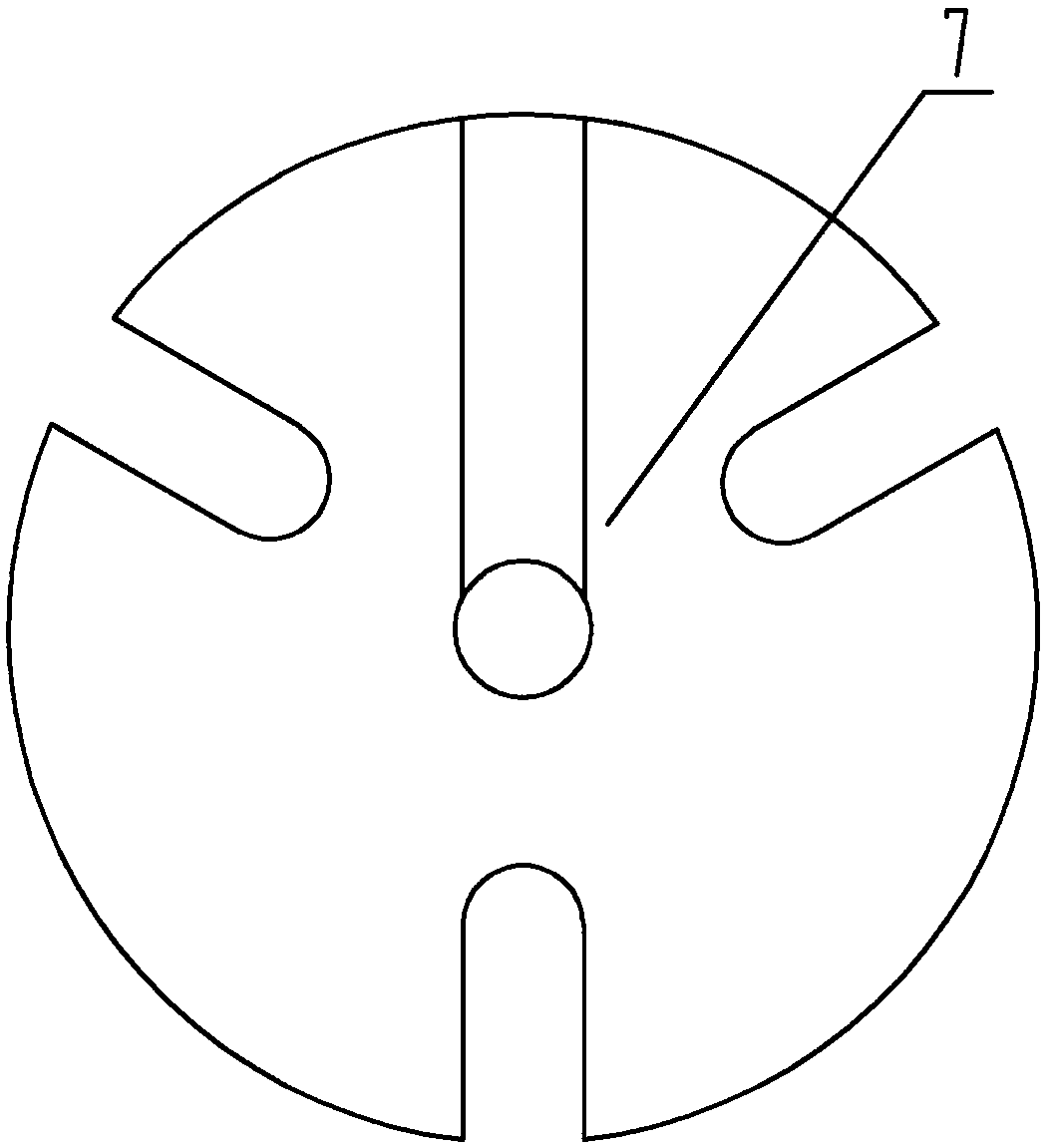

[0019] see Figure 1-2 , a fast clamping and positioning tool for processing gates, including 10° tire tooling 7 and extended three claws 6, the 10° tire tooling 7 is detachably fixed on the three-jaw chuck 5 of the machine tool 4, and the extended three-jaw 6 It is fixed on the outside of the three-jaw chuck 5.

[0020] The machine tool 4 is a horizontal machine tool.

[0021] The 10° tire tooling 7 is fixed by the nut 2 and the stopper 3 after the screw rod 1 penetrates the main shaft hole of the machine tool 4 .

[0022] The gate 8 to be processed is clamped on the extended three claws 6 .

[0023] Specifically: the machine tool 4 is connected with a fixed three-jaw chuck 5, and the lengthened three-jaw 6 is installed on the three-jaw chuck 5, and the three-jaw chuck 5 and the lengthened three-jaw 6 are equipped with a 10° tire tooling 7; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com