Double-spindle movable gantry ultra-long stroke machining center used for drilling and milling steel rail joint part

A machining center and double-spindle technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as low efficiency, low degree of automation of rails, and inability to clamp at one time, achieving high efficiency and difficult equipment operation The effect of lowering and fast moving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

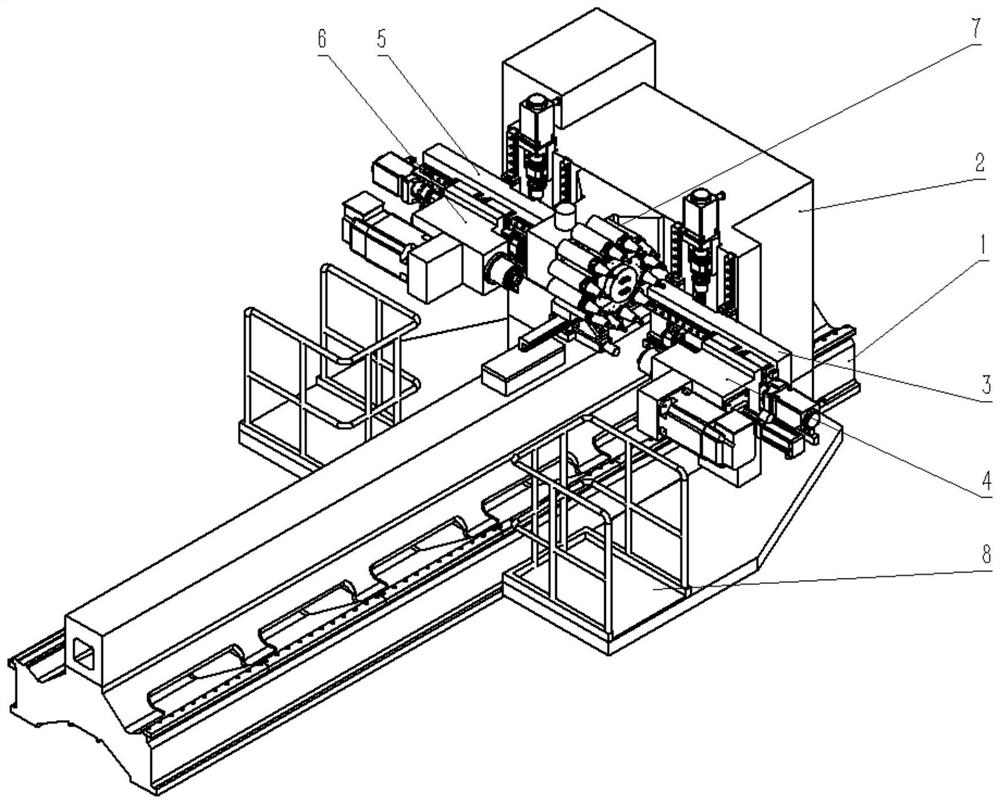

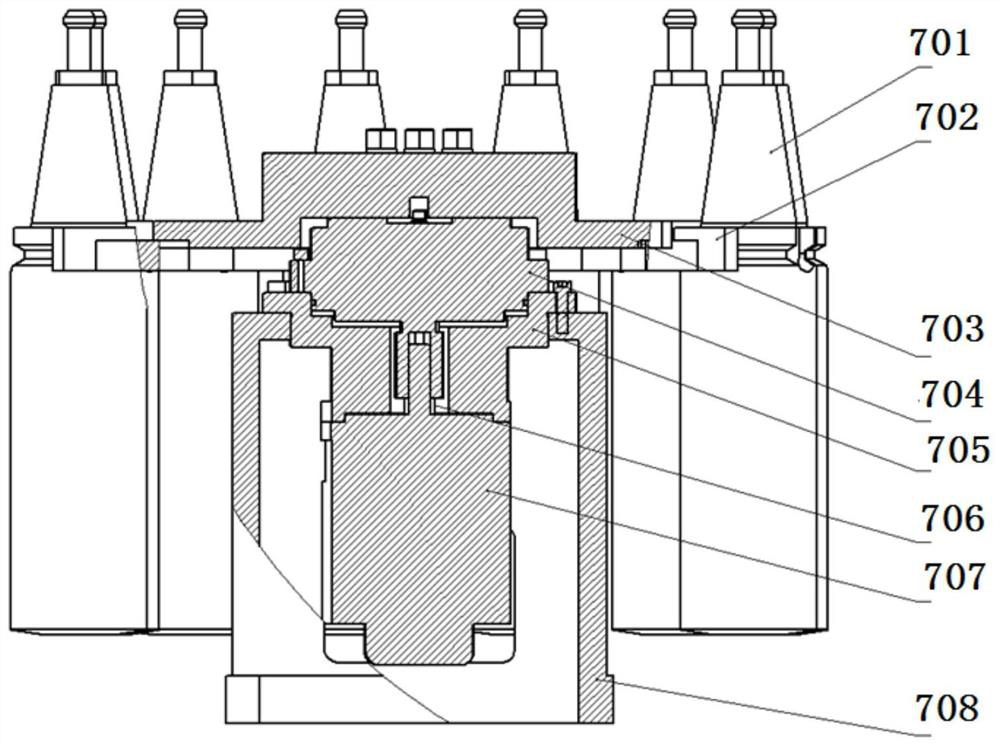

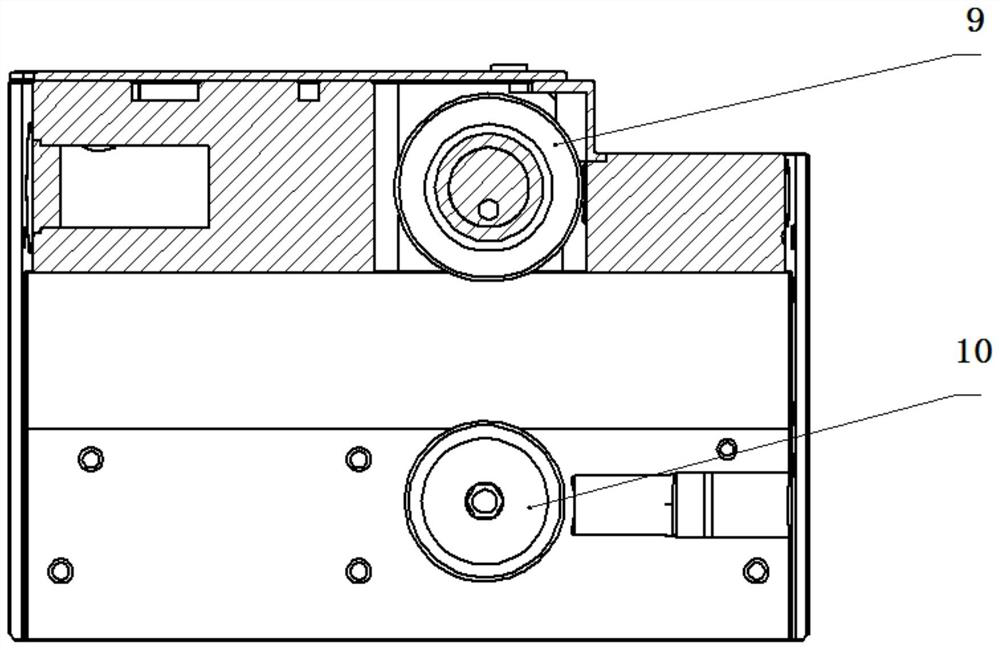

[0030] The invention provides a dual-spindle dynamic gantry super-long-stroke machining center for drilling and milling of rail junctions, which is characterized in that: the dual-spindle dynamic gantry super-long-stroke machining center for drilling and milling of rail junctions includes a bed 1. Gantry frame 2, main processing side slide seat 3, main processing side spindle box 4, auxiliary processing side slide seat 5, auxiliary processing side spindle box 6, fan-shaped servo tool magazine 7, operation table 8;

[0031] Among them: the bed 1 is provided with a gantry frame 2, the main processing side slide seat 3 and the main processing side spindle box 4 are arranged on one side of the bed 1, and the secondary processing side slide seat 5 and the secondary processing side spindle box 6 are arranged on the bed. On the other side of the body 1, the fan-shaped servo tool magazine 7 is set between the main processing side spindle box 4 and the sub-processing side spindle box 6,...

Embodiment 2

[0044] The invention provides a dual-spindle dynamic gantry super-long-stroke machining center for drilling and milling of rail junctions, which is characterized in that: the dual-spindle dynamic gantry super-long-stroke machining center for drilling and milling of rail junctions includes a bed 1. Gantry frame 2, main processing side slide seat 3, main processing side spindle box 4, auxiliary processing side slide seat 5, auxiliary processing side spindle box 6, fan-shaped servo tool magazine 7, operation table 8;

[0045] Among them: the bed 1 is provided with a gantry frame 2, the main processing side slide seat 3 and the main processing side spindle box 4 are arranged on one side of the bed 1, and the secondary processing side slide seat 5 and the secondary processing side spindle box 6 are arranged on the bed. On the other side of the body 1, the fan-shaped servo tool magazine 7 is set between the main processing side spindle box 4 and the sub-processing side spindle box 6,...

Embodiment 3

[0058] The invention provides a dual-spindle dynamic gantry super-long-stroke machining center for drilling and milling of rail junctions, which is characterized in that: the dual-spindle dynamic gantry super-long-stroke machining center for drilling and milling of rail junctions includes a bed 1. Gantry frame 2, main processing side slide seat 3, main processing side spindle box 4, auxiliary processing side slide seat 5, auxiliary processing side spindle box 6, fan-shaped servo tool magazine 7, operation table 8;

[0059] Among them: the bed 1 is provided with a gantry frame 2, the main processing side slide seat 3 and the main processing side spindle box 4 are arranged on one side of the bed 1, and the secondary processing side slide seat 5 and the secondary processing side spindle box 6 are arranged on the bed. On the other side of the body 1, the fan-shaped servo tool magazine 7 is set between the main processing side spindle box 4 and the sub-processing side spindle box 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com