Numerical-controlled high-speed drilling and milling device

A drilling and milling, high-speed technology, applied in the field of CNC high-speed drilling and milling devices, can solve the problems that the processing device cannot adapt to the market demand, the feed speed and the tool change speed are slow, etc., to reduce the auxiliary processing time, optimize the structure, and improve the workmanship. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

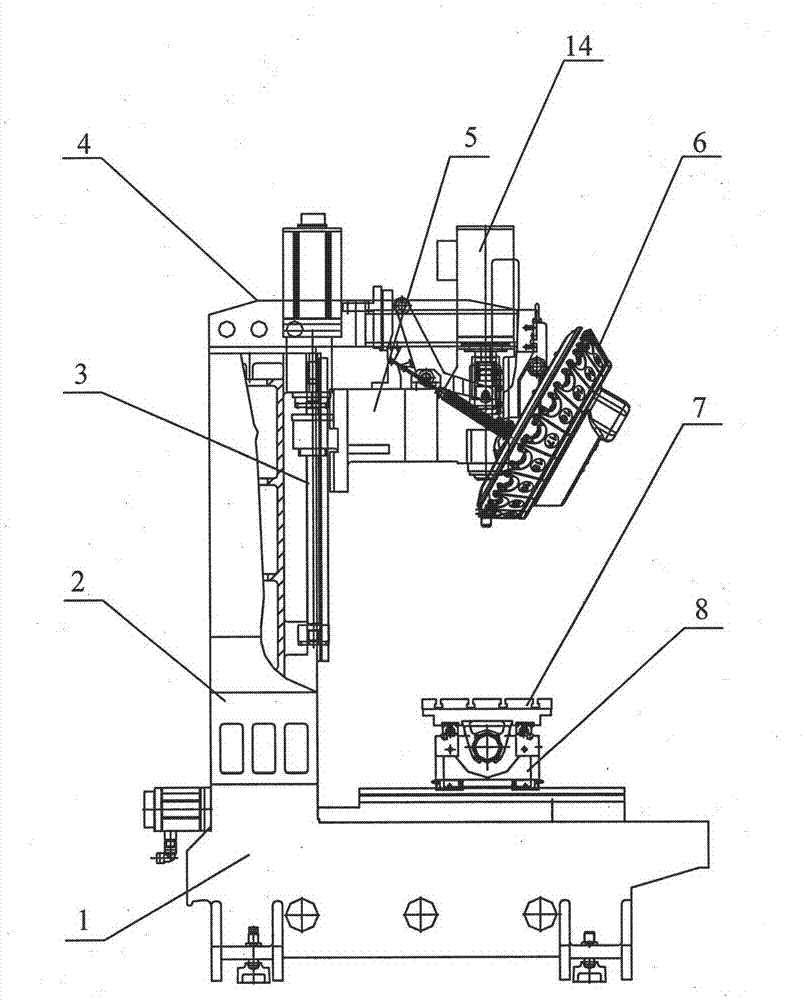

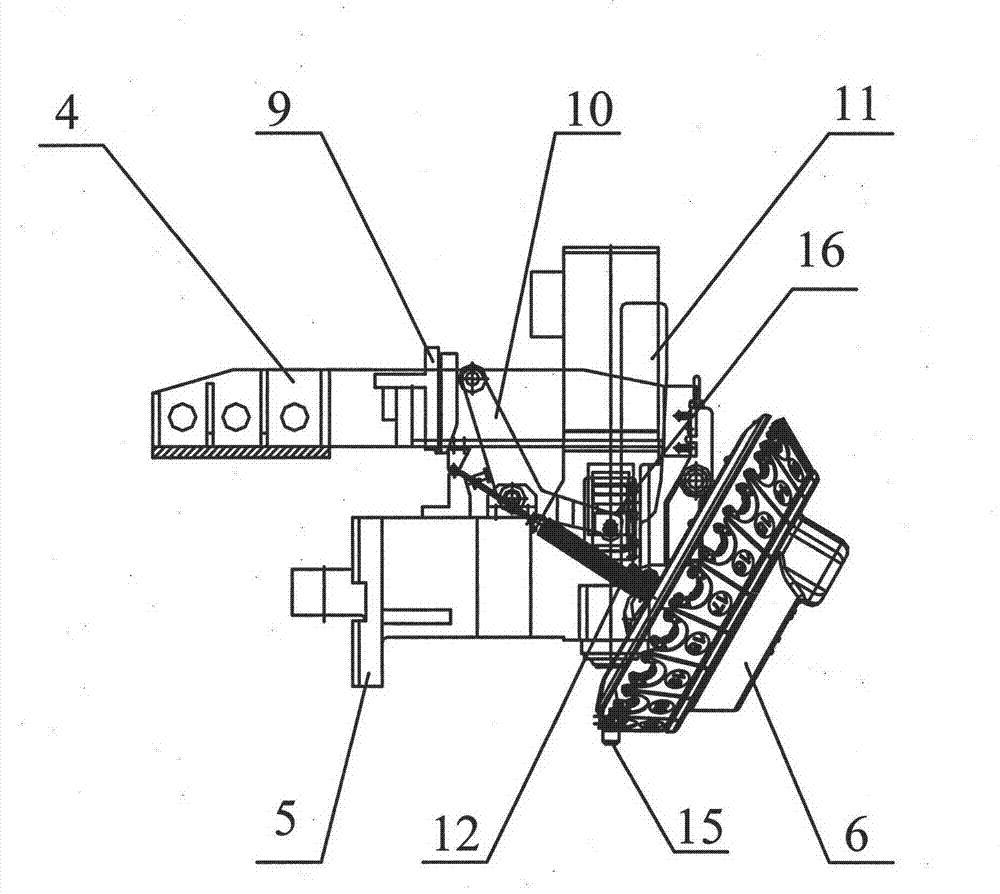

[0013] Such as figure 1 As shown, the CNC high-speed drilling and milling device of the present invention includes a bed 1, a column 2, a ball screw 3, a tool magazine support 4, a spindle box 5, a tool magazine 6, a workbench 7, and a carriage 8, and the column 2 is fixed on the bed 1, the ball screw 3 is located on one side of the column 2, the tool magazine bracket 4 is fixed on the column 2, the spindle box 5 is fixed under the tool magazine bracket 4, the tool magazine 6 is connected with the tool magazine bracket 4, the workbench 7, drag The board 8 is provided on the bed 1 .

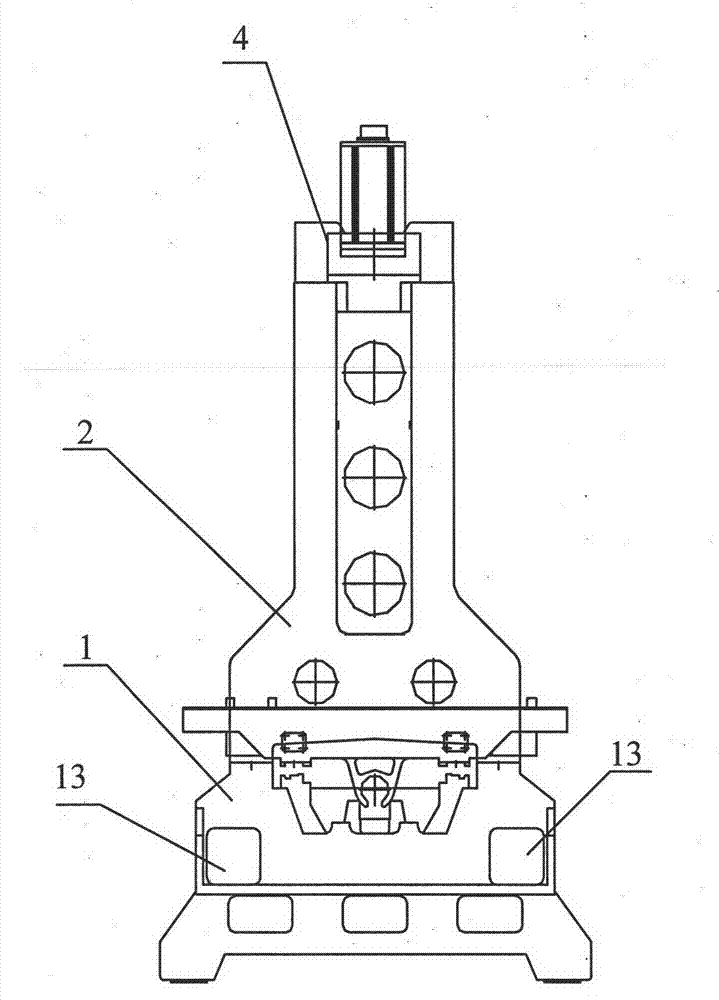

[0014] Among them, bed 1, column 2, headstock 5, workbench 7 and carriage 8 are all integrally cast by HT250 gray cast iron. The shape of column 2 is herringbone (see figure 2 ), which strengthens the strength and stability ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com