Novel automatic tailstock of lathe

A technology of lathes and tailstocks, applied in the field of new automatic tailstocks, which can solve the problems of special designs that cannot be installed on lathes, long auxiliary time of machine tools, and inability to use long-stroke machine tools, etc., so as to shorten processing auxiliary time and ensure safety and stability. Sexuality, the effect of reducing auxiliary time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

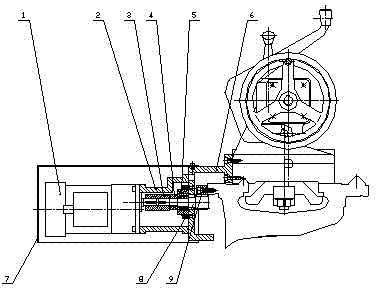

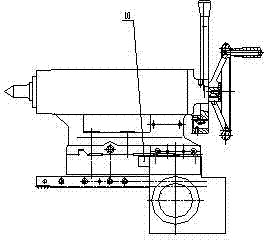

[0014] A new type of automatic tailstock for lathes, such as figure 1 , 2 As shown, it includes: a lathe guide rail, a tailstock is installed on the lathe guide rail, a mobile bracket 6 is fixedly installed on the described tailstock, a rack 9 is installed on the lathe guide rail, and the rack 9 and the gear The shaft 8 meshes, and the gear shaft 8 is mounted on two deep groove ball bearings in the bearing seat 5 of the mobile bracket 6 for radial fixing, and the gear shaft 8 is fixed in the axial position by the lock nut 4, The geared motor 1 is installed on the moving bracket 6 through the motor base 2 , and the geared motor 1 is connected with the gear shaft 8 through the shaft coupling 3 .

[0015] In this embodiment: the front end of the mobile bracket 6 is installed with a position detection switch 10 .

[0016] In this embodiment: a shield ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com