Self-tracking steel plate cutting robot

A cutting robot and robot technology, applied in the direction of welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve the problems of long processing auxiliary time, low precision and efficiency, and poor flexibility in use, so as to reduce processing auxiliary time and improve The effect of improving processing efficiency and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

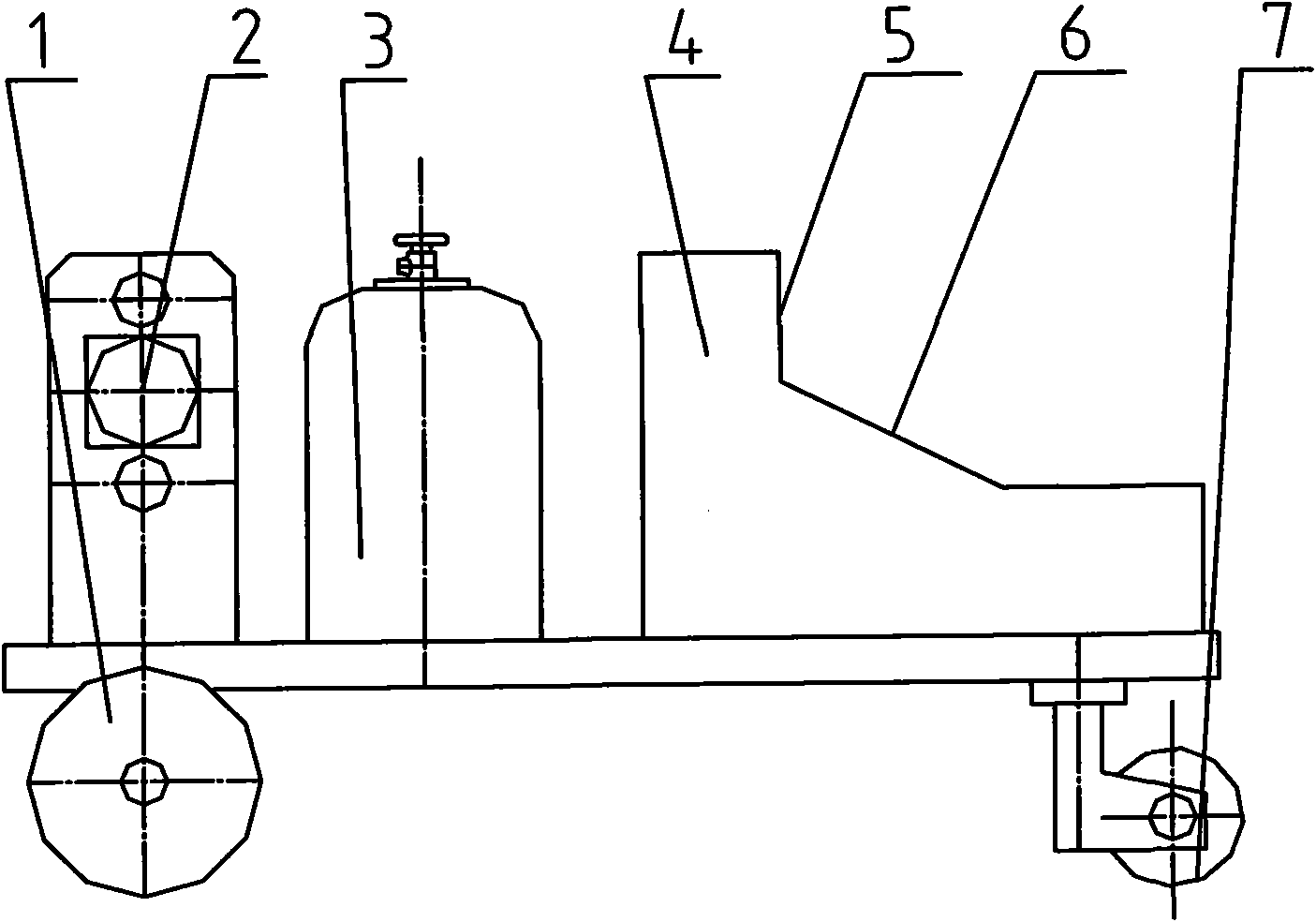

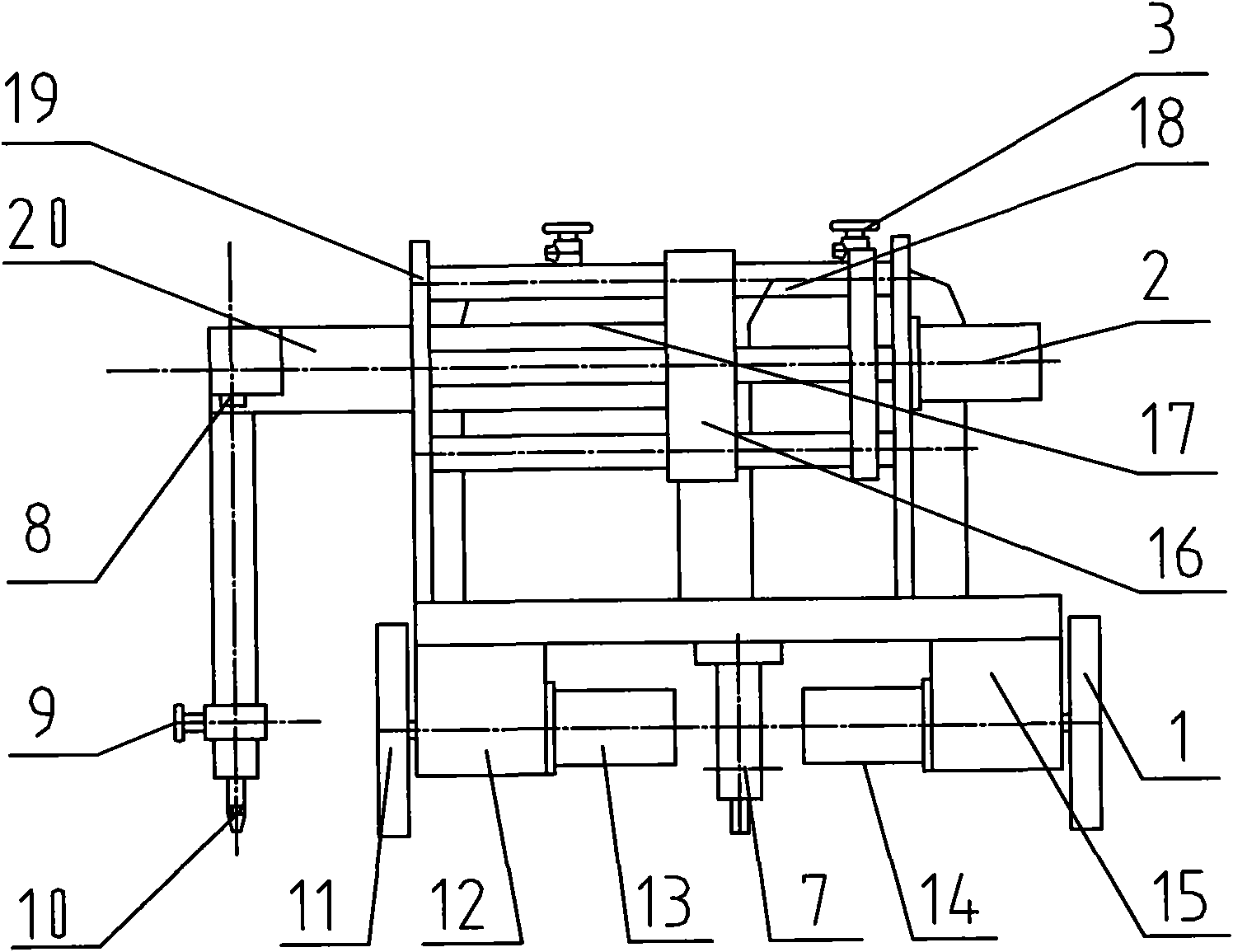

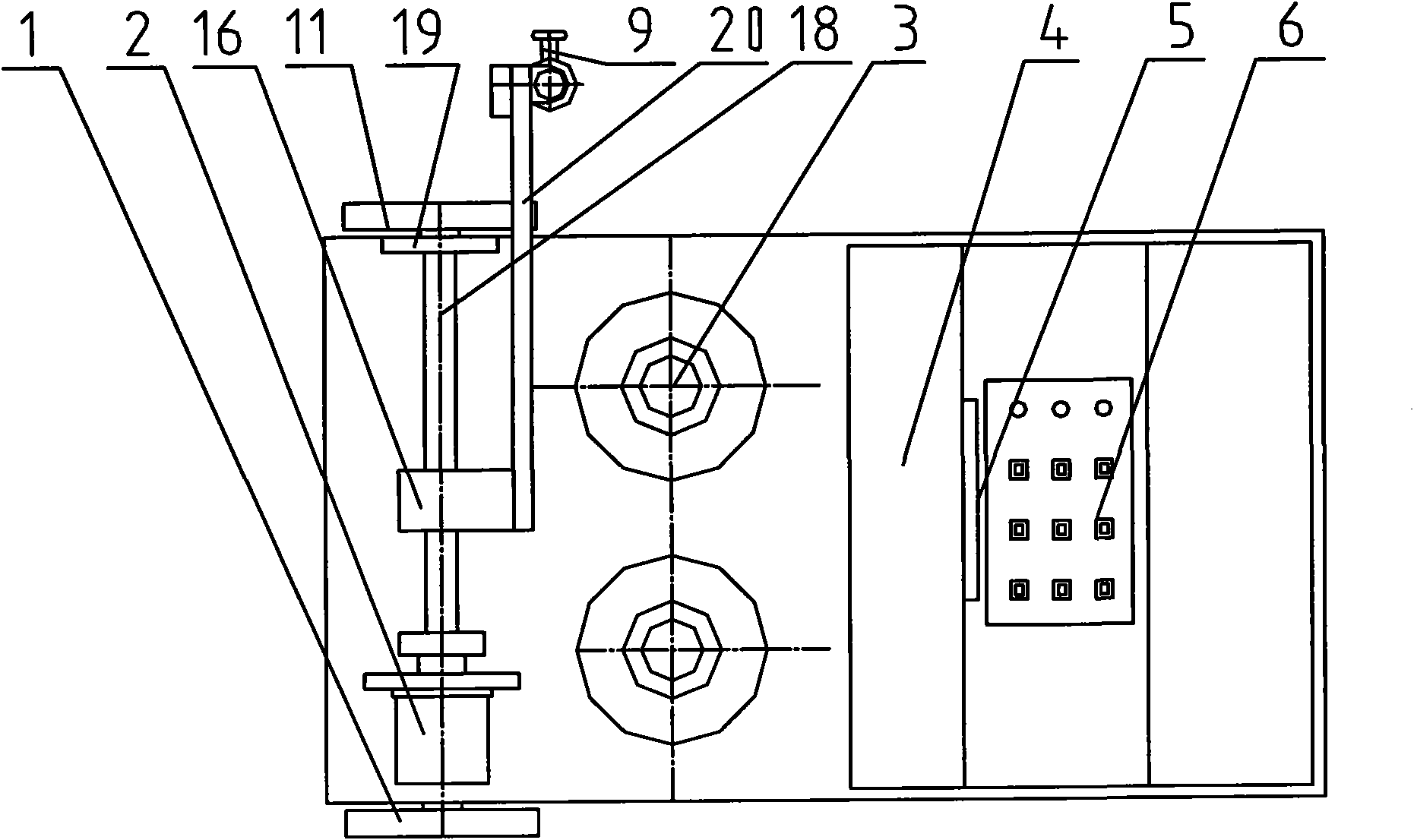

[0013] The flexible cutting mechanism is fixedly connected to one end of the upper part of the mobile car, the flame cutting device is fixedly connected to the middle part of the mobile car, and the robot controller is fixedly connected to the other end of the upper part of the mobile car; the structure of the mobile car is: the left front wheel 1 is connected to the output end of the left reducer 15 , the left stepping motor 14 is connected to the input end of the left reducer, the right front wheel 11 is connected to the output end of the right reducer 12, the right stepping motor 13 is connected to the input end of the right reducer, and the centerline position at the rear of the trolley is connected to the universal rear wheel 7 connection;

[0014] The structure of the flexible cutting mechanism is: the bracket 19 is fixed on the front part of the mobile trolley, the two ends of the two parallel guide rails 18 are fixedly connected with the bracket, the screw 17 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com