Fast clamping mechanism of machine tool

A clamping mechanism and fast technology, applied in the direction of clamping, metal processing machinery parts, supports, etc., can solve the problems of high labor intensity, low work efficiency, and long moving time of the clamping surface, so as to reduce labor intensity and simple structure , The effect of increasing the clamping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

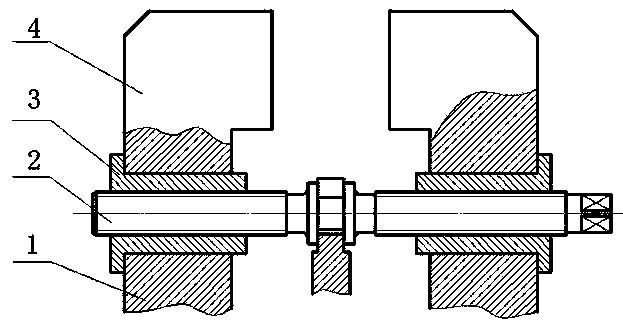

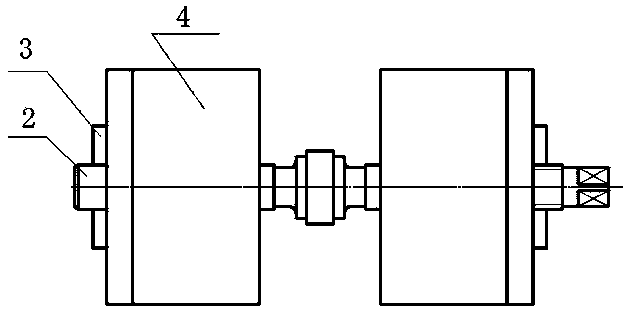

[0019] Such as figure 1 , figure 2 As shown, the fast clamping mechanism of the machine tool includes a slide rail 1, an adjusting screw 2, a moving block 3 and a clamping block 4. The upper end of the slide rail 1 is stuck on the concave edge of the lower end of the moving block 3, and the lower end of the clamping block 4 is pressed On the concave edge of the upper end of the moving block 3 , the adjusting screw 2 is engaged with the moving block 3 . There are two slide rails 1, adjusting screw rods 2, moving blocks 3 and clamping blocks 4; one end of the two adjusting screw rods 2 is connected through a bearing. There is a support bracket at the bottom of the bearing.

[0020] The thread at the left end of the adjusting screw 2 is left-handed, the thread at the right end is right-handed, the thread at the meshing place of the left end of the moving block 3 and the regulating screw 2 is left-handed, and the thread at the meshing place of the right end and the regulating s...

Embodiment 2

[0022] Such as figure 1 , figure 2 As shown, the fast clamping mechanism of the machine tool includes a slide rail 1, an adjusting screw 2, a moving block 3 and a clamping block 4. The upper end of the slide rail 1 is stuck on the concave edge of the lower end of the moving block 3, and the lower end of the clamping block 4 is pressed On the concave edge of the upper end of the moving block 3 , the adjusting screw 2 is engaged with the moving block 3 . There are two slide rails 1, adjusting screw rods 2, moving blocks 3 and clamping blocks 4; one end of the two adjusting screw rods 2 is connected through a bearing.

[0023] The thread at the left end of the adjusting screw 2 is right-handed, the thread at the right end is left-handed, the thread at the meshing place of the left end of the moving block 3 and the regulating screw 2 is right-handed, and the thread at the meshing place of the right end and the regulating screw 2 is left-handed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com