Hydraulic telescopic type positioning pin

A telescopic and positioning pin technology, which is applied in the field of positioning pins, can solve the problems of reducing work efficiency, increasing workload, and high assembly costs, and achieves the effects of reducing auxiliary time for workpiece processing, increasing service life, and smooth and continuous transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

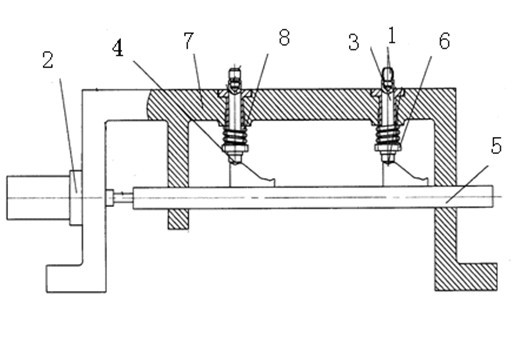

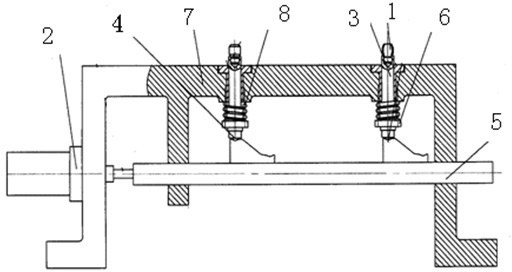

[0012] A hydraulically driven telescopic positioning pin according to the present invention, see figure 1 The telescopic positioning pin includes a pin body 1, a hydraulic cylinder 2, a telescopic rod 3, a flat cam 4, a push rod 5, a roller 6 and a clamp body 7, and the hydraulic cylinder 2, push rod 5 and telescopic rod 3 are installed on the clamp body On 7; the hydraulic cylinder 2 is connected with one end of the push rod 5; the flat cam 4 is fixed on the push rod 5, and the flat cam is disc-shaped, and the number of the flat cams can be set as required, which is two in the present embodiment. A spring 8 is sheathed on the telescopic rod 3 , and a roller 6 cooperating with the flat cam 4 is arranged on the telescopic rod 3 and positioned at the lower end of the spring 8 ;

[0013] When in use, the hydraulic cylinder pushes the telescopic rod and the flat cam to move, so that the flat cam passes through the roller, pushes the push rod to move upwards, and reaches the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com