Opening and closing of tool clamp capable of being controlled by fixed fork spanner

A technology for fixing forks and tool holders, applied in the direction of tool holders, etc., can solve the problems of weakening of the clamping part of the tool holder, deformation of the clamping part of the tool holder, and reduction in the thickness of the clamping part, so as to reduce processing auxiliary time and quickly disassemble The effect of loading, avoiding deformation or breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

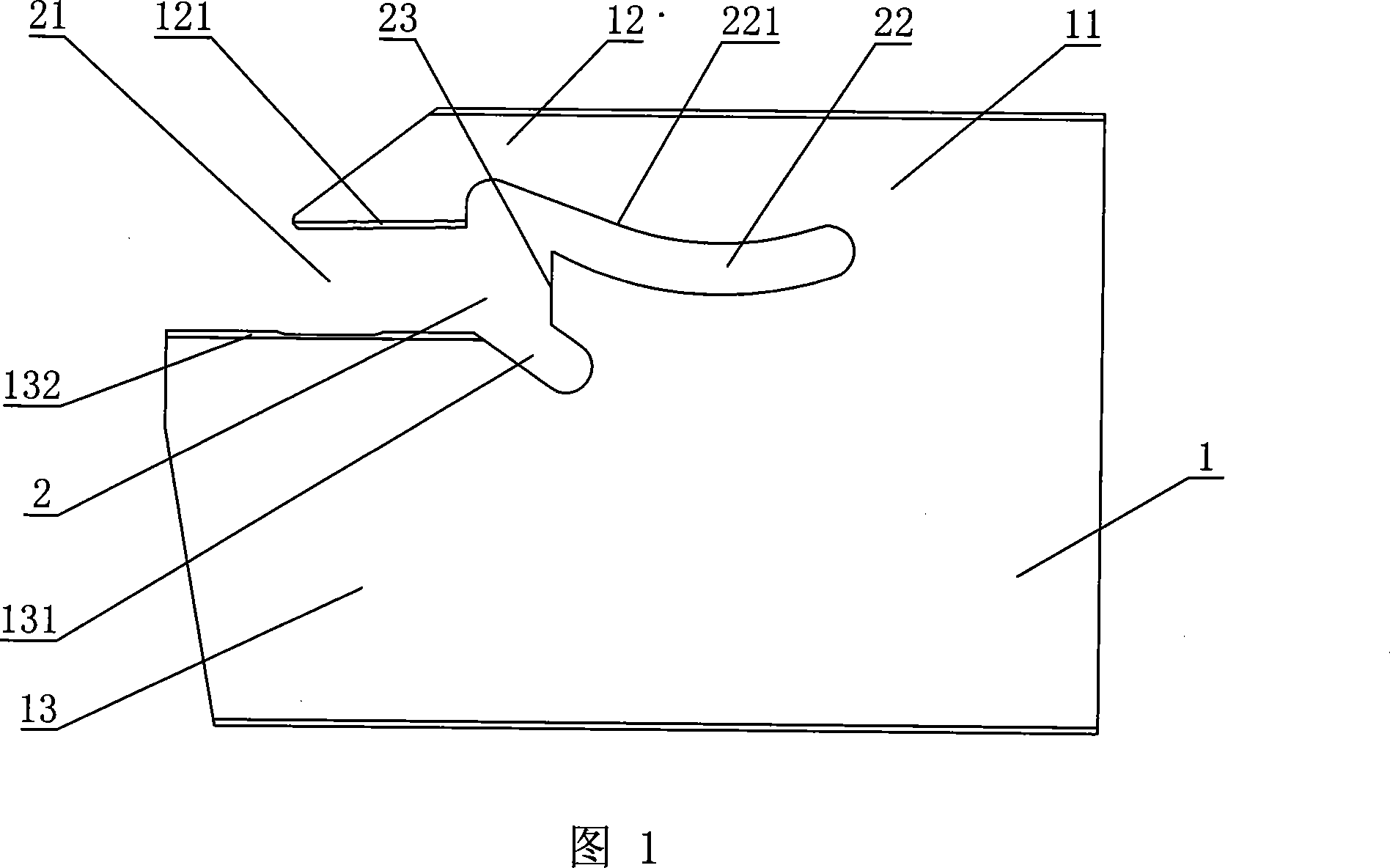

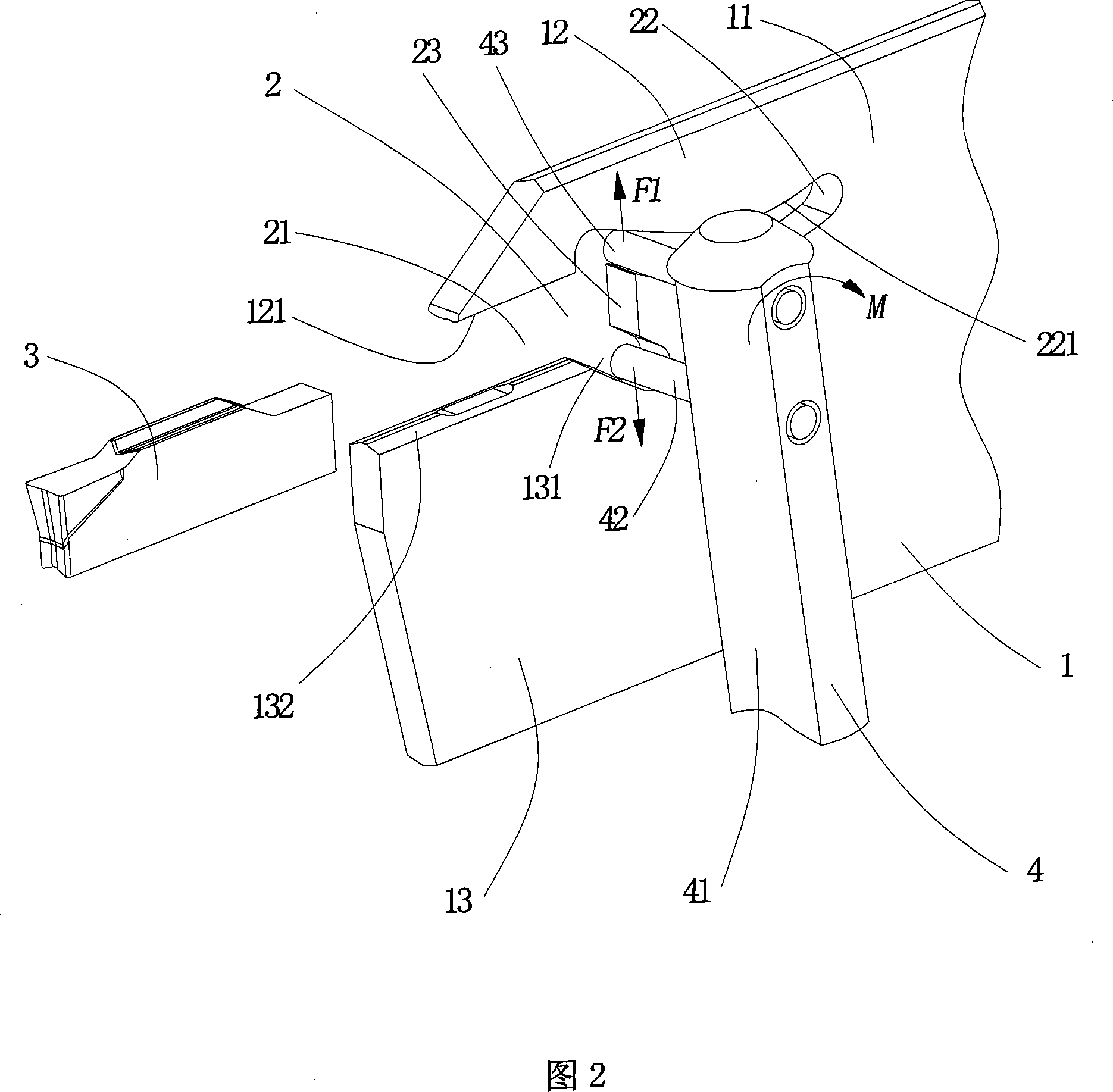

[0026] As shown in Fig. 1 and Fig. 2, a kind of toolholder of the present invention that can be opened and closed by a fixed fork wrench control includes a toolholder body 1, and the toolholder body 1 is divided into a neck 11, an upper clamping part 12 and a lower supporting part 13. The neck 11, the upper clamping part 12 and the lower supporting part 13 form a tank body 2, the tank body 2 is divided into a blade clamping section 21 and an extension section 22 extending to the neck 11, and the lower supporting part 13 is provided with The support groove 131 that can be matched with the support fork 42 of the fixed fork wrench 4, the opening of the support groove 131 is located at the junction of the blade clamping section 21 and the extension section 22, and the upper surface of the extension section 22 can be rotated with the fixed fork wrench 4 The fork 43 keeps in contact with the support surface 221 that drives the upper clamping part 12 to rotate elastically relative to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com