Clamping device and wiring box using the same

A technology of clamping device and splint, which is applied in the direction of elastic/clamping device, circuit arrangement on the support structure, electrical components, etc., can solve the problems that cannot be put in, the wiring equipment cannot be placed stably, and is easy to shake, etc., to achieve extended use range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

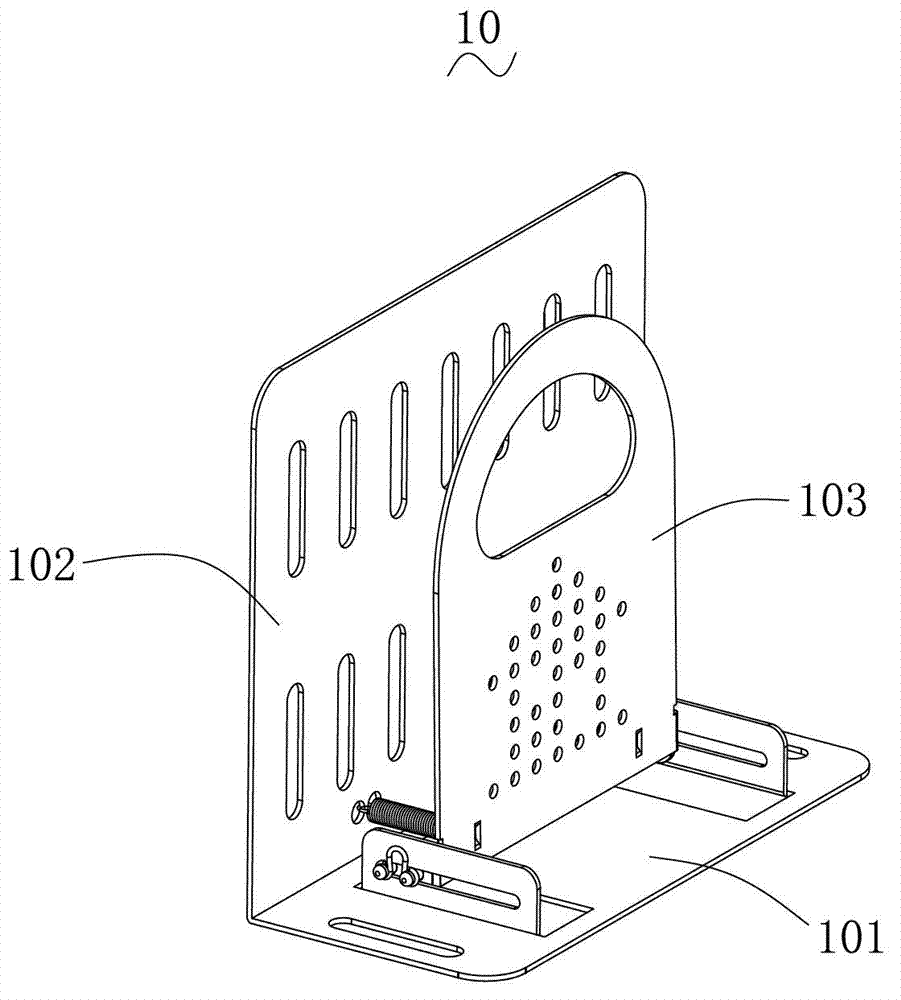

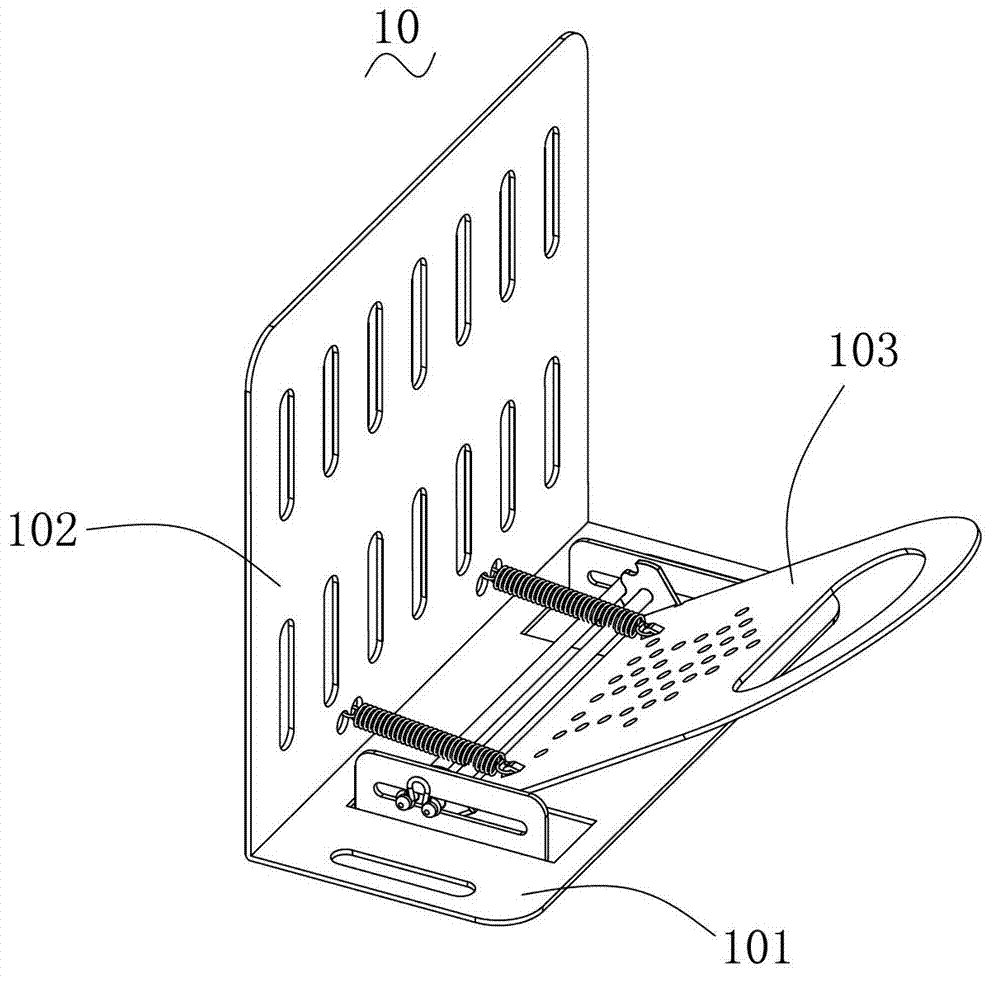

[0030] Such as figure 1 with figure 2 As shown, it is a three-dimensional structure diagram of the clamping device 10 in two different states according to an embodiment of the invention.

[0031] The clamping device 10 includes a base plate 101 , a back plate 102 and a clamping plate 103 , the base plate 101 and the back plate 102 are vertically connected, and the clamping plate 103 is rotatably mounted on the base plate 101 .

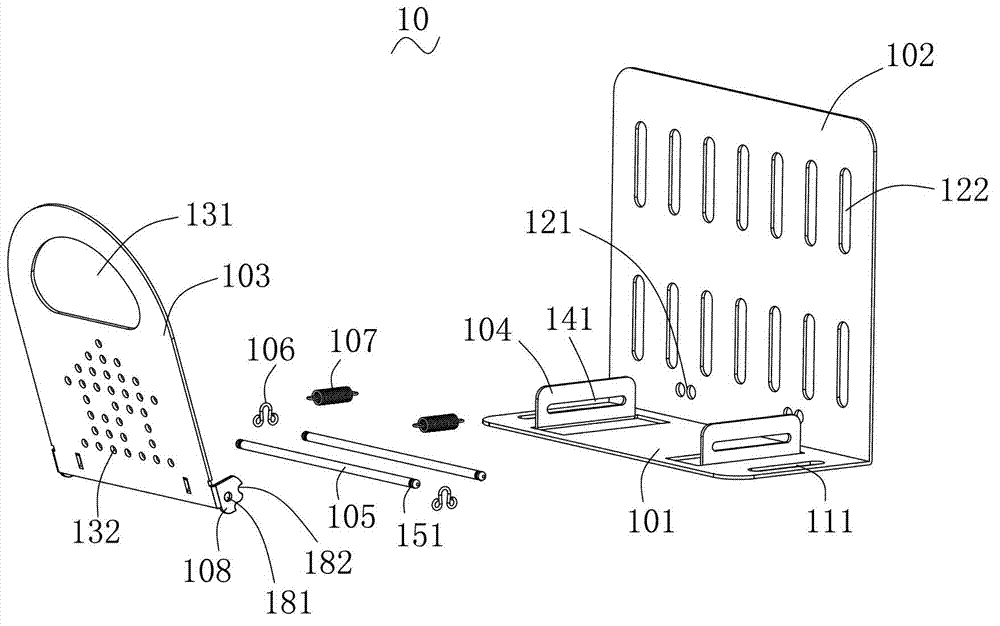

[0032] Please also see image 3 with Figure 4 , which is figure 2 The shown schematic diagrams of the exploded structure of the clamping device 10 from two different viewing angles.

[0033] The clamping device 10 also includes: two baffles 104 , two sliding rods 105 , an elastic member 106 , a spring 107 and a positioning part 108 .

[0034] Two baffles 104 are fixed on the bottom plate 101 in parallel and perpendicular to the back plate 102 . Both baffles 104 are provided with strip-shaped guide grooves 141 perpendicular to the backplane 101...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com