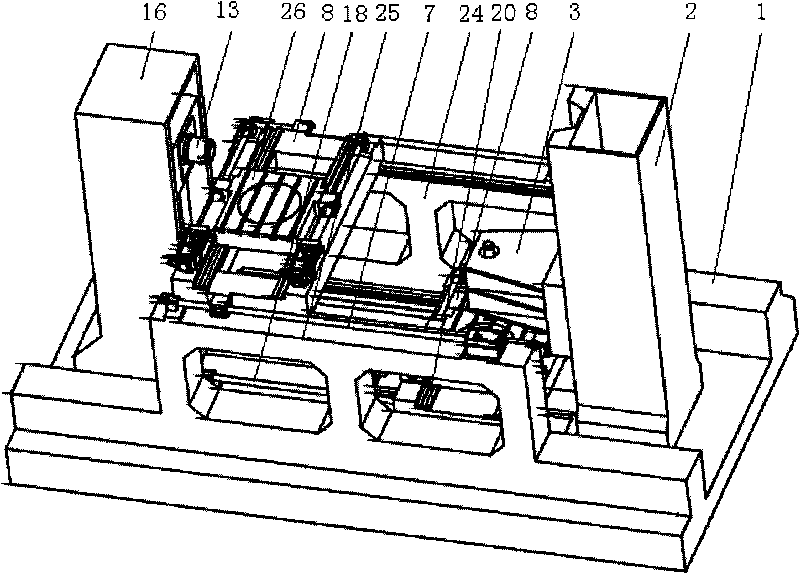

Double-layer vertical and horizontal processing central machine tool

A machining center, vertical and horizontal technology, applied in the field of double-layer vertical and horizontal machining center machine tools, can solve the problems of prolonging the processing time of workpieces, increasing labor intensity of workers, and low production efficiency, so as to reduce processing auxiliary time, novel structure, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

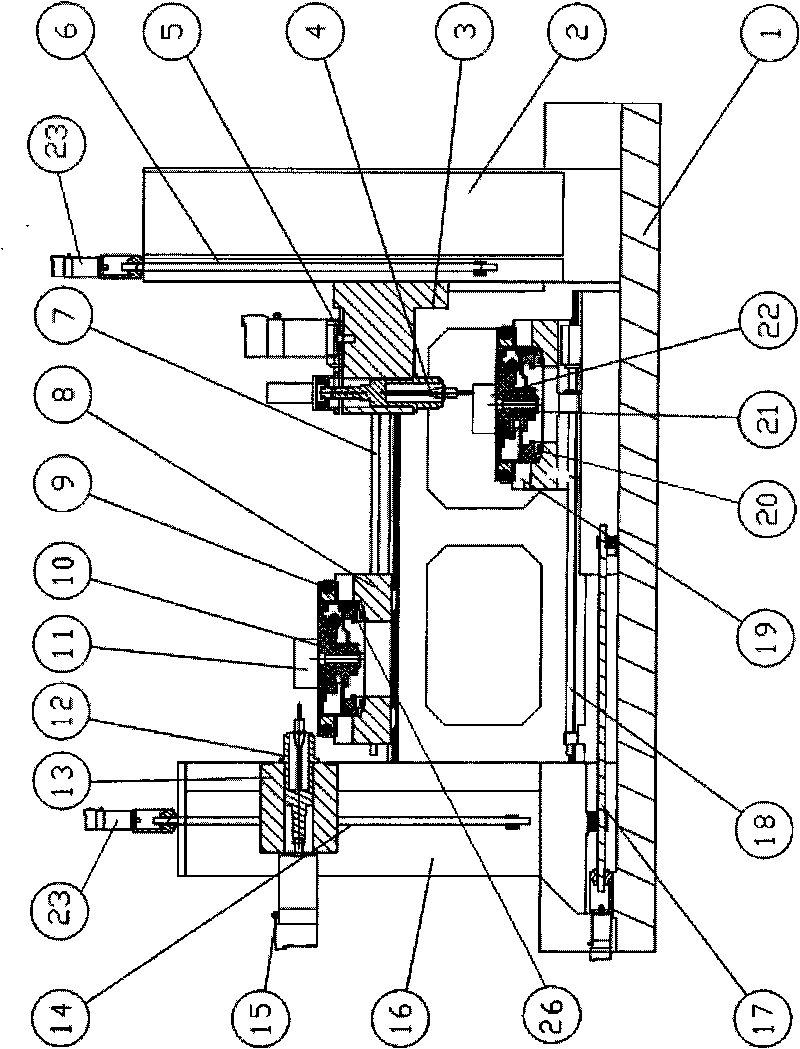

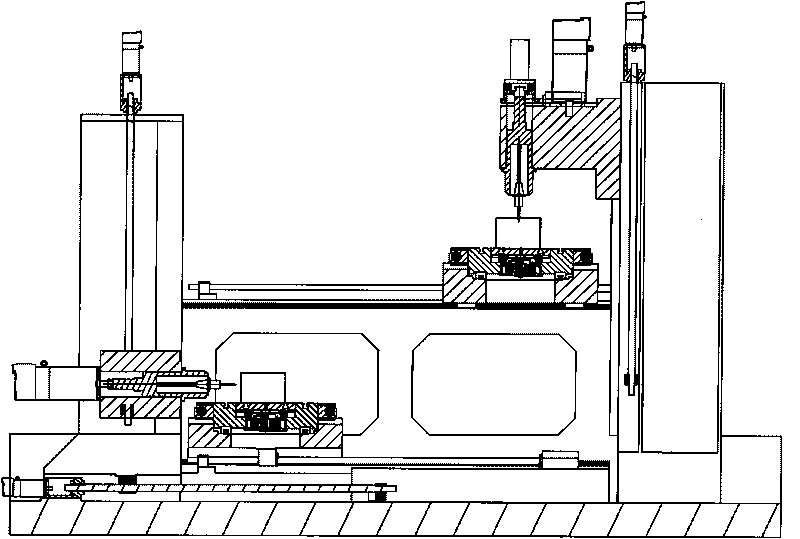

Embodiment 1

[0023] exist figure 2 In the process, the workpiece 11 is clamped on the rotary table 10, and the horizontal spindle box on the movable column 16 is driven by the driving screw 14 to slide up and down along the Y-axis direction, so that it is aligned with the processing surface of the workpiece, and the movable column 16 is driven by the driving screw 17 to slide along the X-axis direction, making it close to the processing surface of the workpiece, using the horizontal milling head 12 to process the workpiece, and the rotary table 10 can be rotated at any angle along the Y-axis to Change the processing surface of the workpiece, and then process it, and simultaneously clamp the workpiece 22 on the rotary table 21 of the lower table device, and the lower table device is driven by the driving screw 18, so that the processed workpiece on the lower table device 22 is facing the vertical milling head 4, the vertical spindle box is driven by the driving screw 6 to slide down the Y-...

Embodiment 2

[0025] exist Figure 4In the process, the workpiece 11 is clamped on the rotary table 10, and the movable column 16 is driven by the driving screw 17 to make the horizontal milling head lean against the workpiece. At the same time, the vertical milling head is driven by the driving screw 6 to make the vertical The vertical milling head is aligned with the upper surface of the workpiece 11, and the horizontal milling head 12 is used to process the peripheral surface of the workpiece 11, while the vertical milling head 4 is used to process the upper surface of the workpiece, so that the vertical milling head and The horizontal milling head processes the workpiece 11 at the same time.

[0026] Due to the adoption of the above structure, the present invention combines the advantages of the vertical machining center machine tool and the horizontal machining center machine tool to realize the simultaneous processing of the same workpiece by the vertical milling head and the horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com