Device for processing inclined hole of flat plate of water diversion trench

A processing device and diversion groove technology, applied in the field of machinery, can solve the problems of complex processing technology, high processing cost, and high tool requirements, and achieve the effects of easy guarantee of inclination, low processing cost, and convenient feeding operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

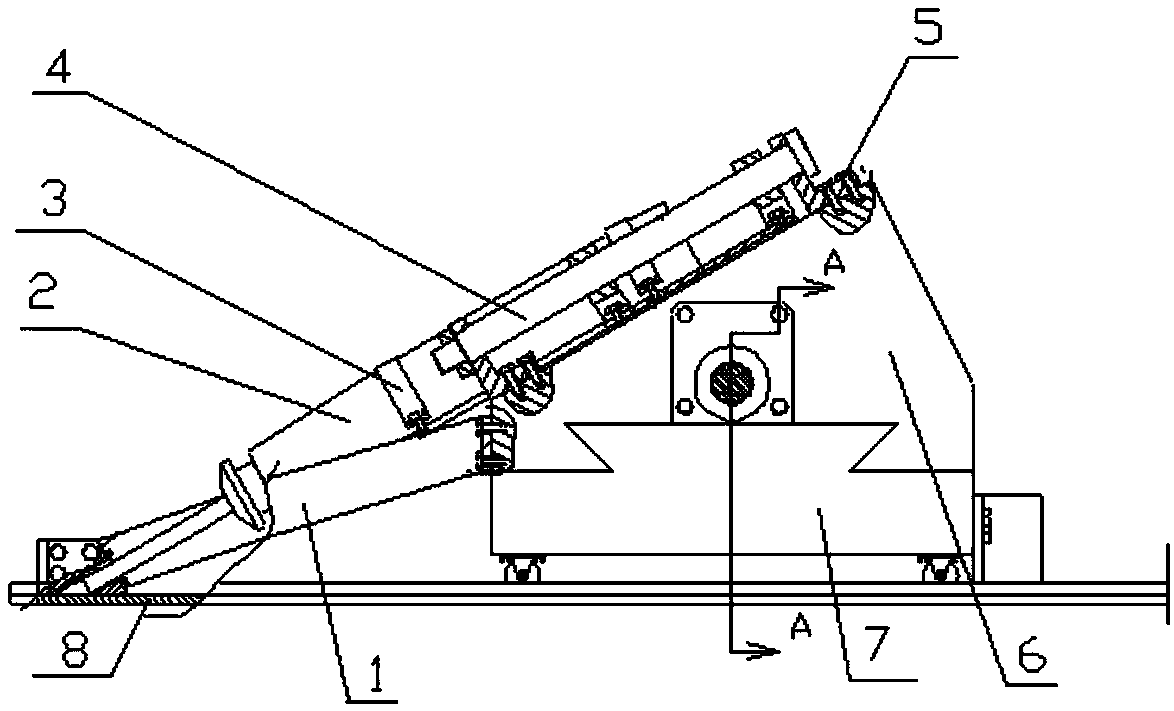

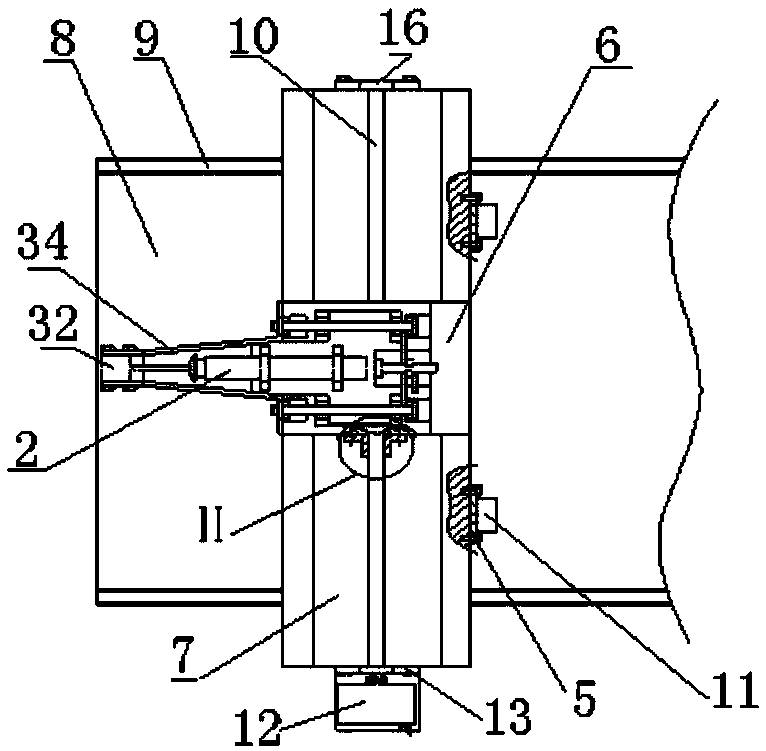

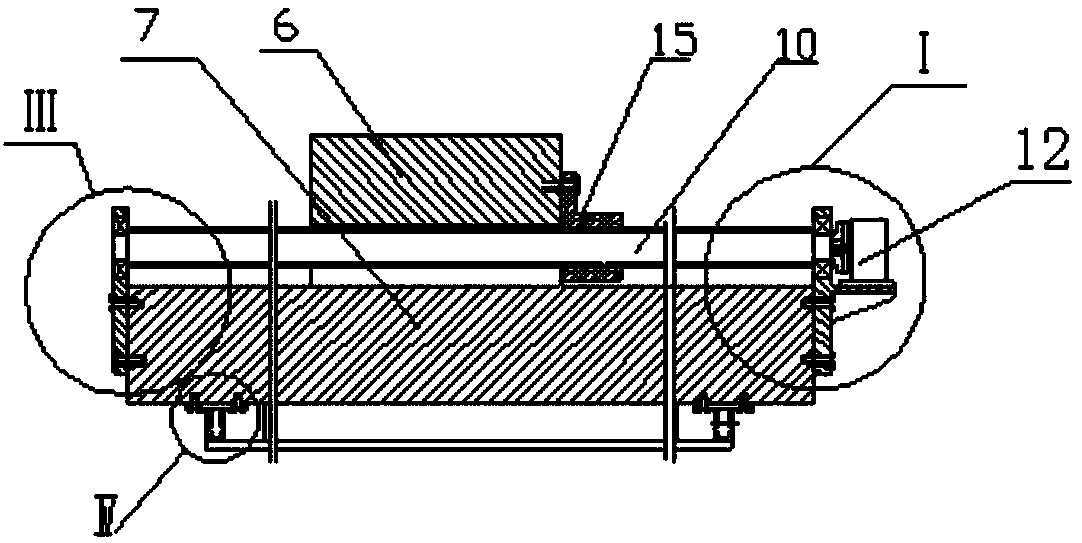

[0026] This embodiment is a processing device for inclined holes in a diversion groove plate, including a drill guide mechanism 1, an electric drill 2, an electric drill feed mechanism 4, a longitudinally moving oblique body 6, a body 7, a guide rail 9, a longitudinally moving screw 10, Two electromagnetic chucks 11, indexing head 12, first bearing seat 13, bearing 14, longitudinally moving screw sleeve 15, second bearing seat 16, moving wheel seat 17, moving wheel 18. Wherein, the body 7 is placed on the guide rail 9 through rollers. One end of the drill guiding mechanism 1 is fixed on the longitudinally moving oblique body 6, and the other end is placed on the surface of the workpiece to be processed. The electric drill feeding mechanism 4 is fixed on the upper surface of the longitudinally moving inclined body; one end of the electric drill 2 is fixed on the described electric drill feeding mechanism, and the other end of the electric drill is equipped with a drill bit. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com