Waste rubber crawler belt material recycling production line

A material recycling and waste rubber technology, which is applied in plastic recycling, recycling technology, metal processing, etc., can solve the problems of long process time, high difficulty, rubber residue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

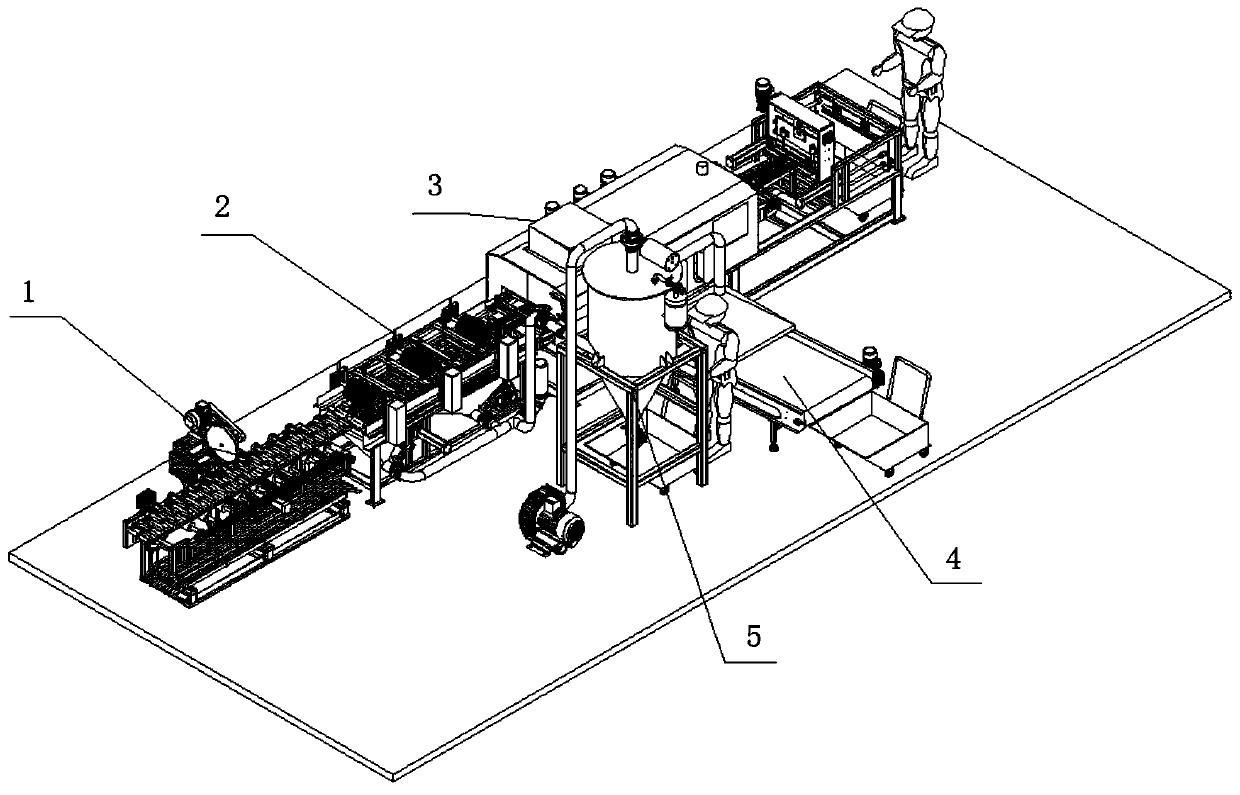

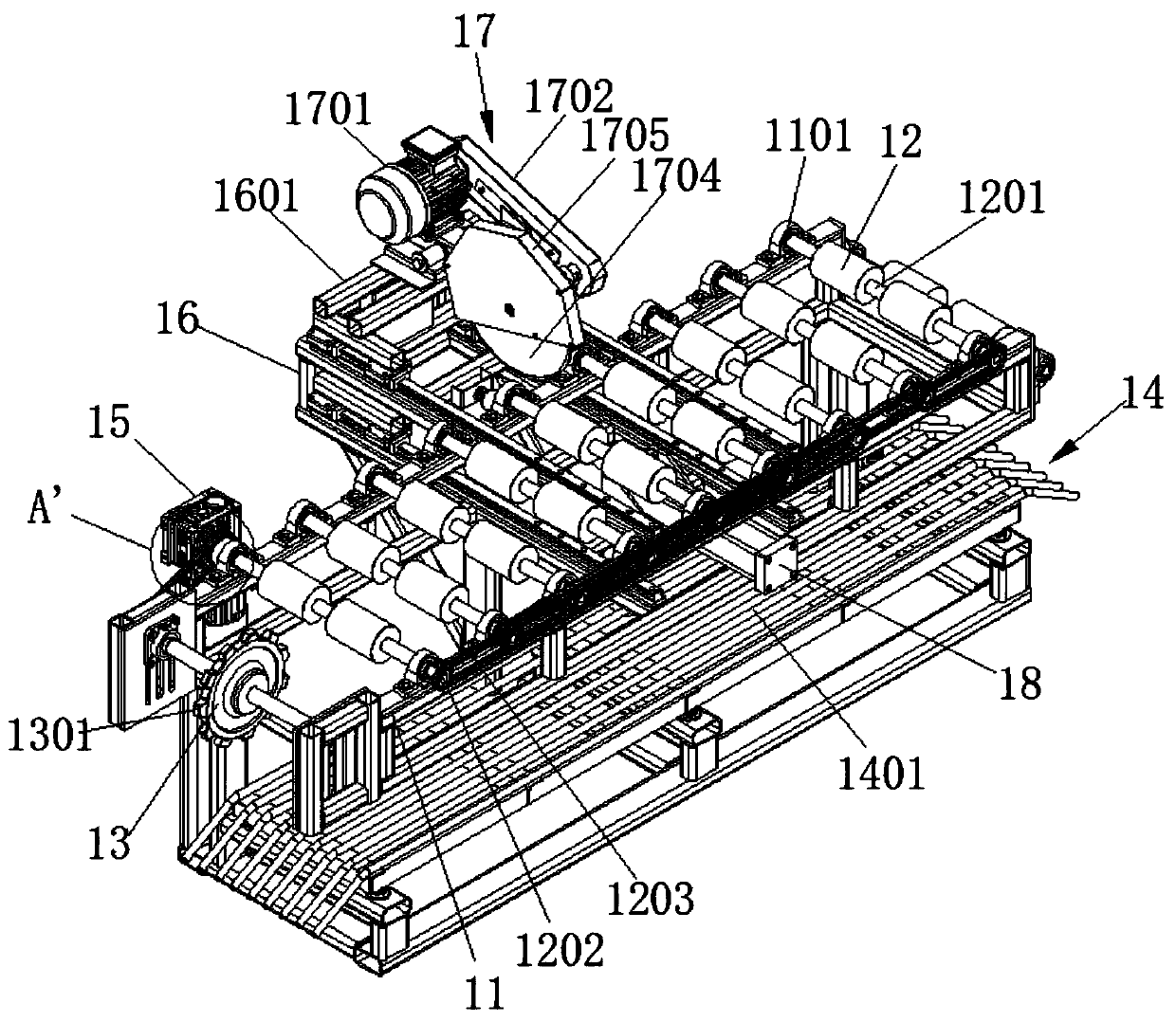

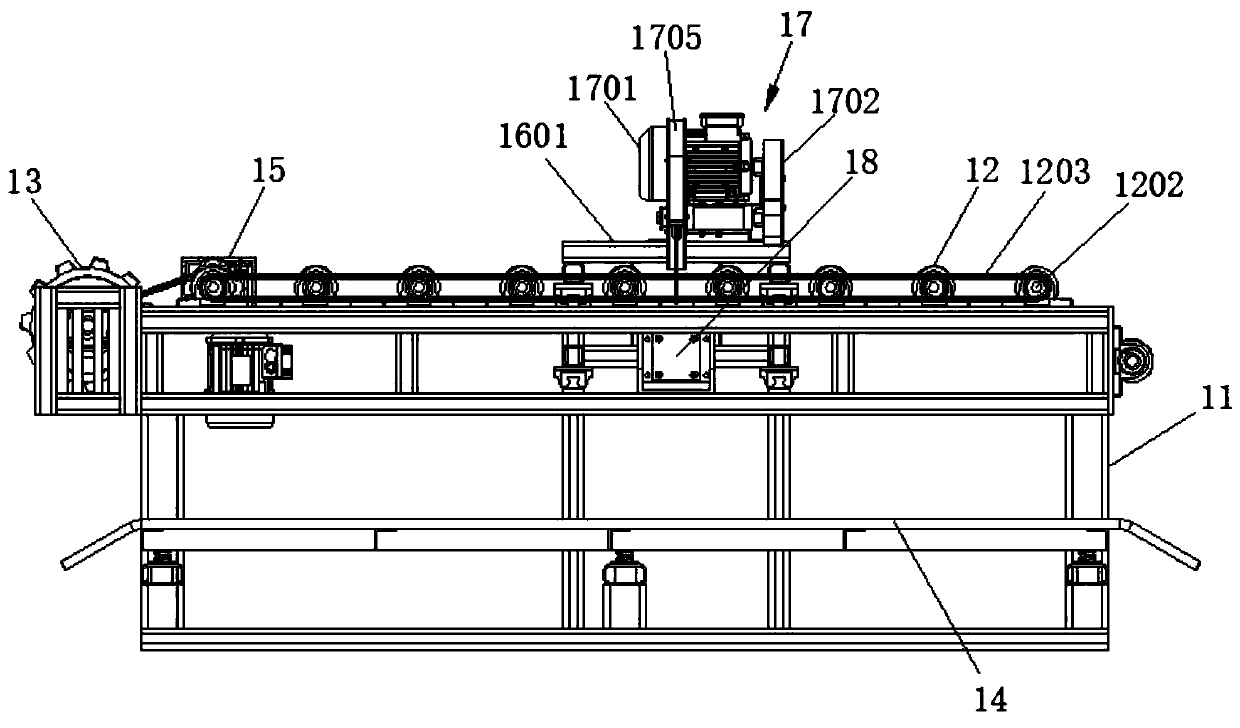

[0115] A waste rubber crawler material recovery production line can be seen in conjunction with the accompanying drawings, which is characterized in that it includes a cutting tool, a surface rough cutting tool, a surface treatment separation device, a recycled material conveying structure, and a vacuum recovery device;

[0116] The splitting and cutting tool is used to split and cut the track;

[0117] The surface rough cutting tool is located on one side of the splitting and cutting tool, and is used for rough cutting the surface rubber of the cut strip track;

[0118] The surface treatment and separation device is located on one side of the surface rough cutting tool, and is used for cutting the remaining surface rubber of the track after rough cutting, separating embedded parts, separating steel wires, and shortening and recycling steel wires;

[0119] The recycled material conveying structure is connected to the bottom of the surface treatment and separation device, and i...

Embodiment 2

[0190] It can be seen from the accompanying drawings that the difference between Embodiment 2 and Embodiment 1 lies in the pressing structure, which includes a fixed piece, a backing plate, a limiting cylinder, a lower pressing rod, a protrusion of the lower pressing rod, a limiting a spring, the abutting plate is arranged on one side of the fixing piece, and is fixedly connected with the fixing piece; the limit cylinder is arranged on the top surface of the fixing piece, is vertically fixedly connected with the abutting plate, and is arranged through; The lower pressing rod is arranged in the limit tube; the lower pressing rod protrusion is arranged on the top of the lower pressing rod, and is fixedly connected with the lower pressing rod; the limiting spring is arranged in the limiting The outer wall of the cylinder, the top end of the limit spring is fixedly connected with the bottom surface of the lower pressure rod bump, and the bottom end of the limit spring is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com