Patents

Literature

63results about How to "Meet the needs of recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

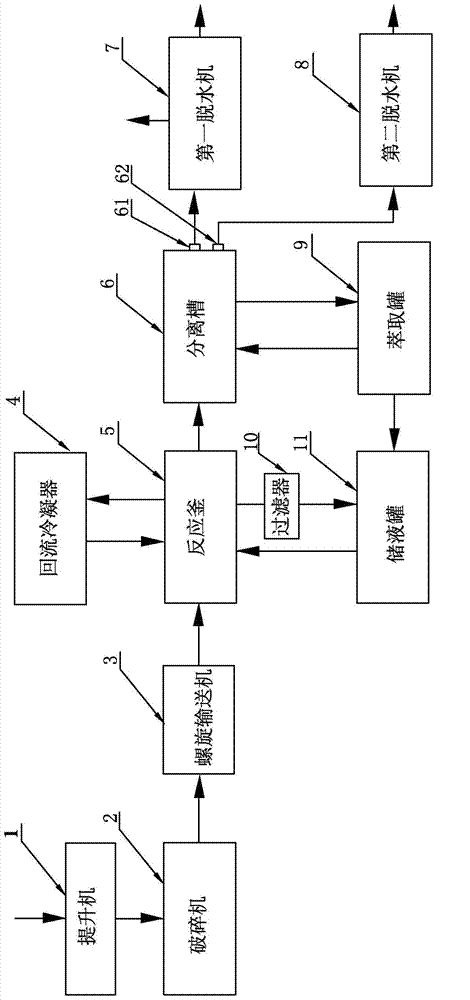

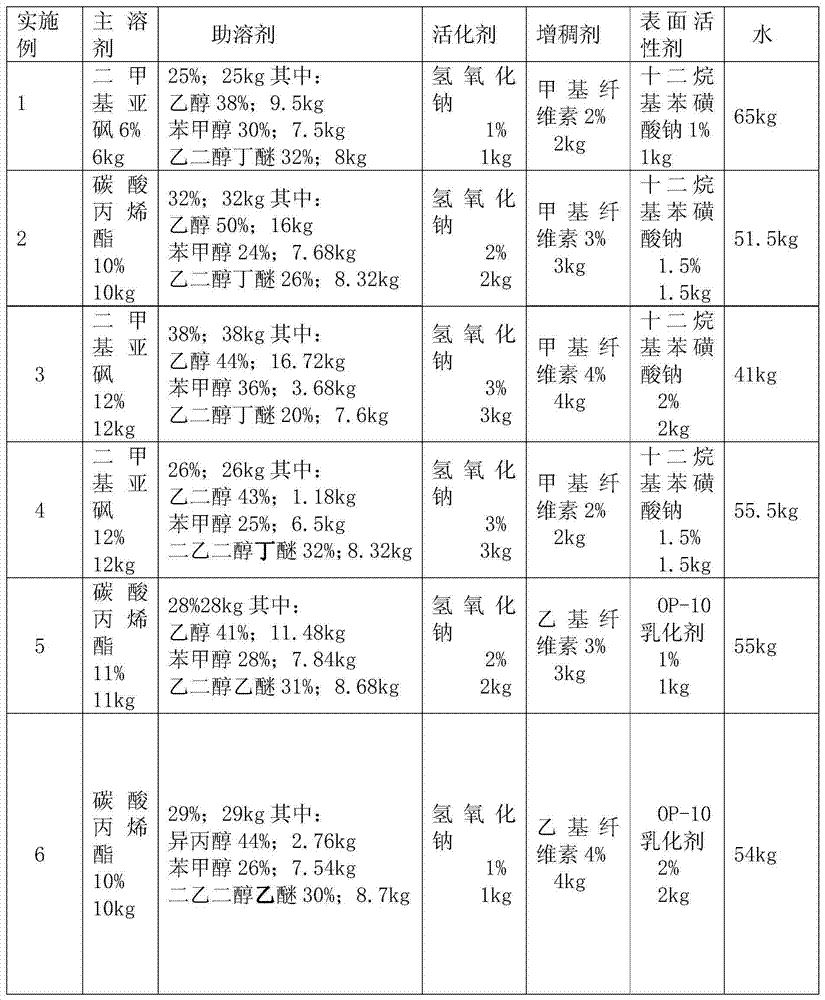

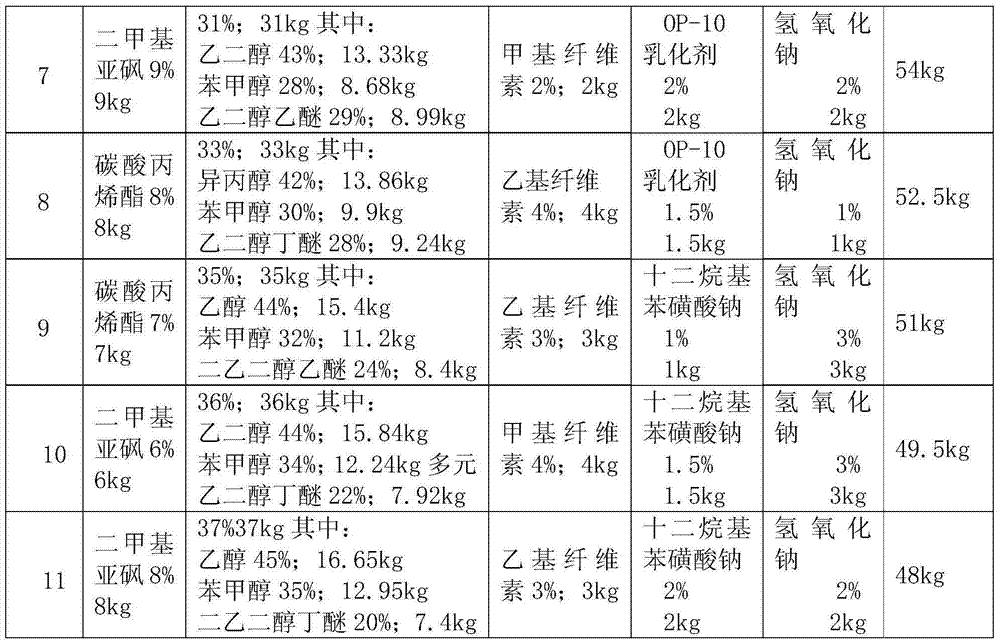

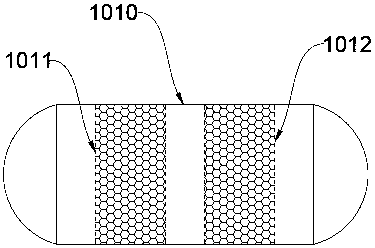

Plastic adhesion layer cleaning agent as well as plastic cleaning process and equipment adopting same

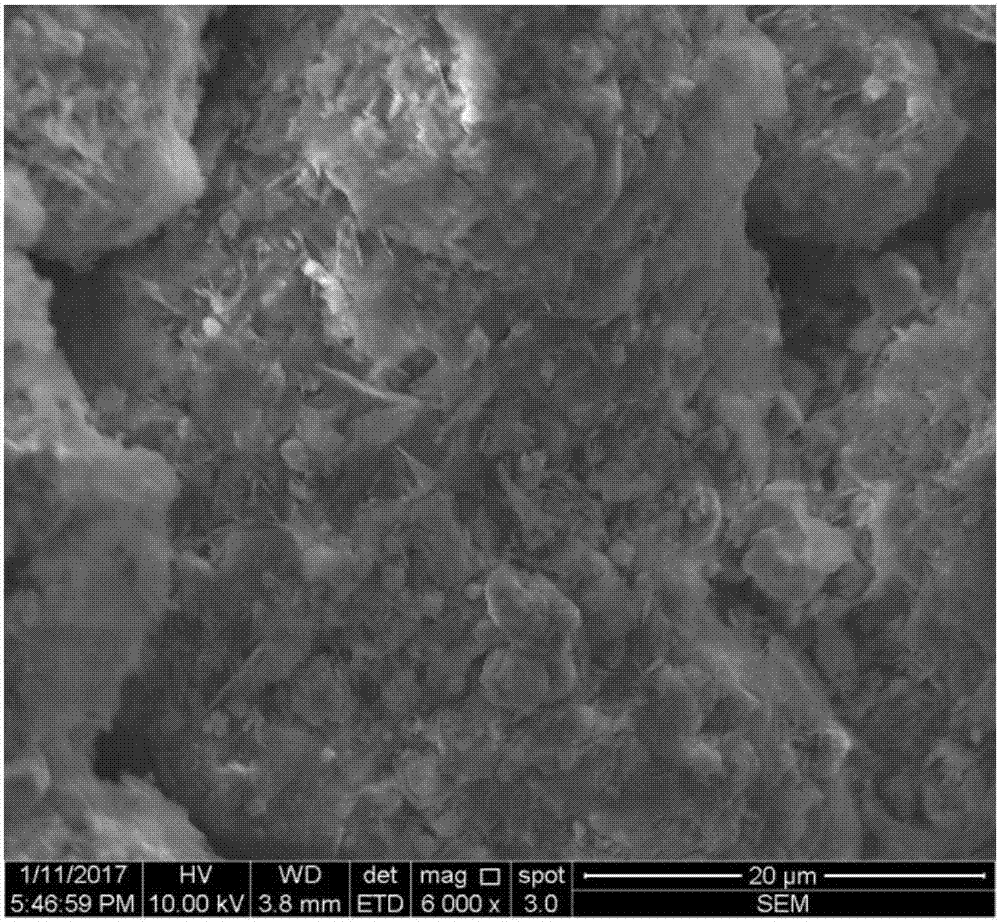

The invention relates to a plastic adhesion layer cleaning agent as well as a plastic cleaning process and equipment adopting the same. The cleaning agent comprises the following components in percentage by mass: 6-12 percent of a master solvent, 25-38 percent of a cosolvent, 1-3 percent of an activating agent, 2-4 percent of a thickener, 1-2 percent of a surfactant and the balance of water, wherein the master solvent is dimethyl sulfoxide or propylene carbonate; the cosolvent comprises the following components in percentage by mass: 38-50 percent of monohydric alcohol or polyhydric alcohol, 24-36 percent of phenylcarbinol and 20-32 percent of polyhydric alcohol ether. The cleaning process comprises the following steps: crushing plastic to form plastic fragments; putting the plastic fragments and the cleaning agent into a reaction kettle according to a mass ratio of 1: 2; heating to 65-75 DEG C in a sealed manner and stirring for 20-40 minutes; leading the cleaning agent out for recycling; separating and dehydrating the plastic fragments and stripped substances of the adhesion layer to obtain a recycled plastic finished-product; and periodically extracting liquid in a separating tank and recovering the cleaning agent. The equipment comprises the reaction kettle, the separating tank, an extracting pot, a liquid storage pot and a reflux condenser.

Owner:天津市生态环境科学研究院

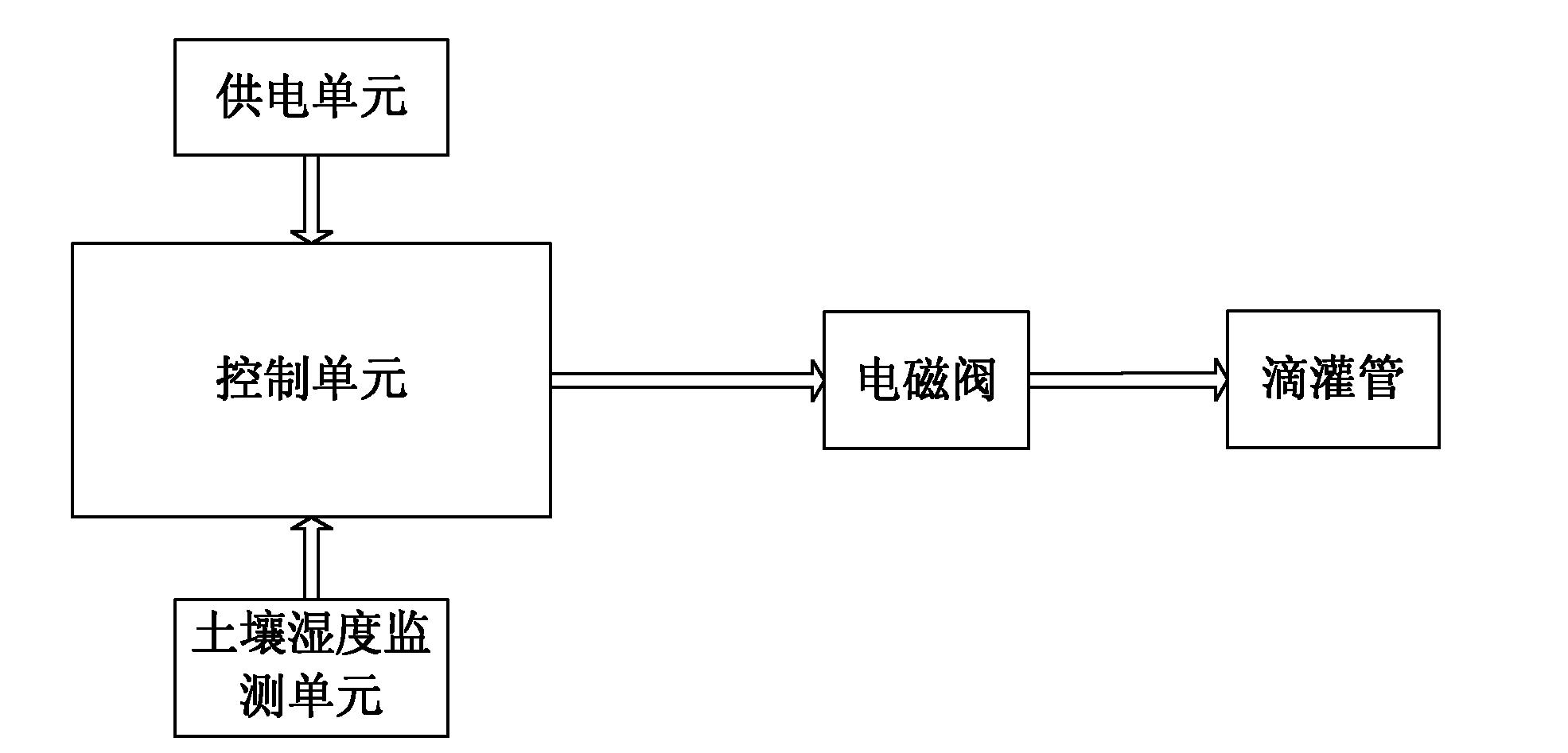

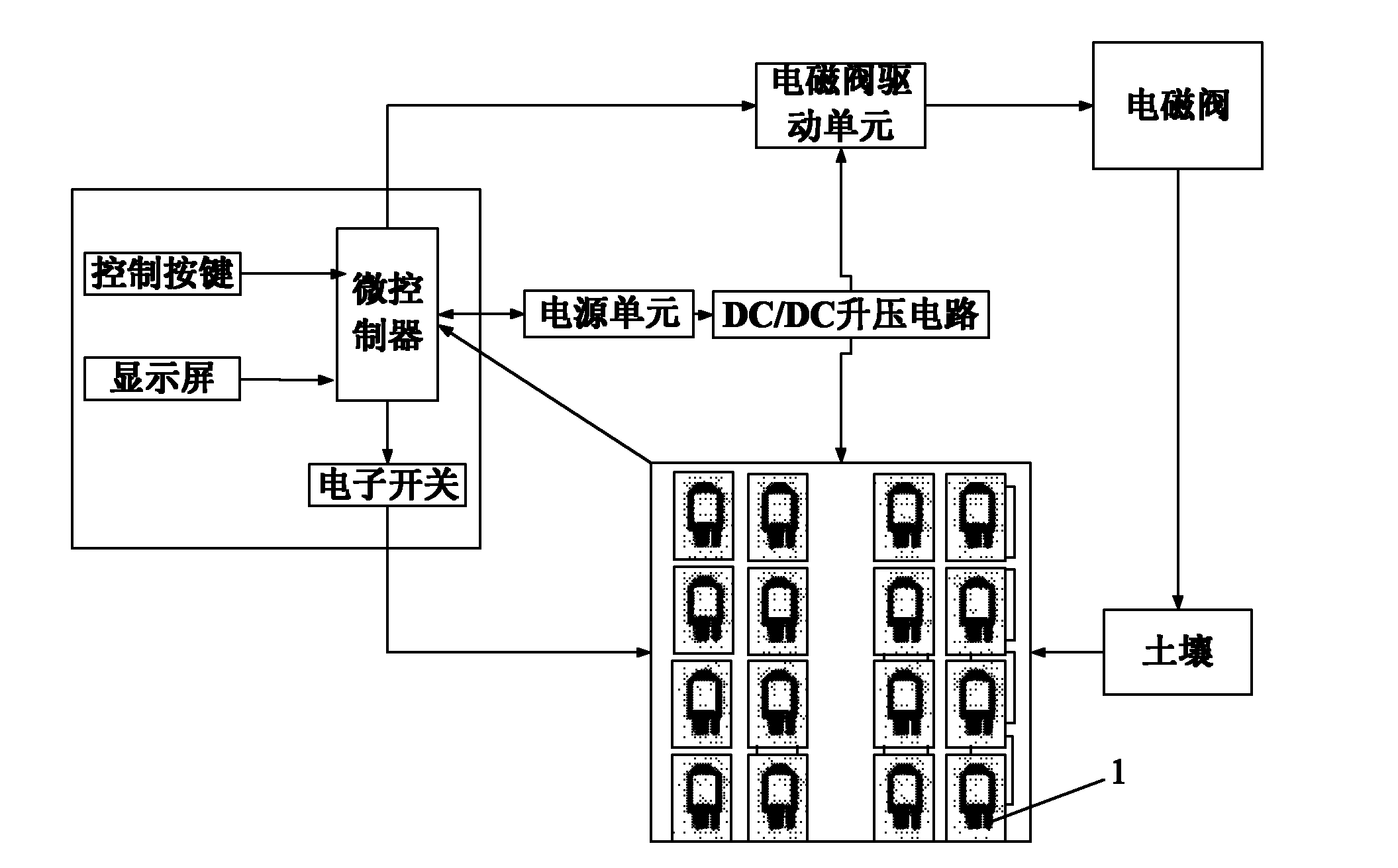

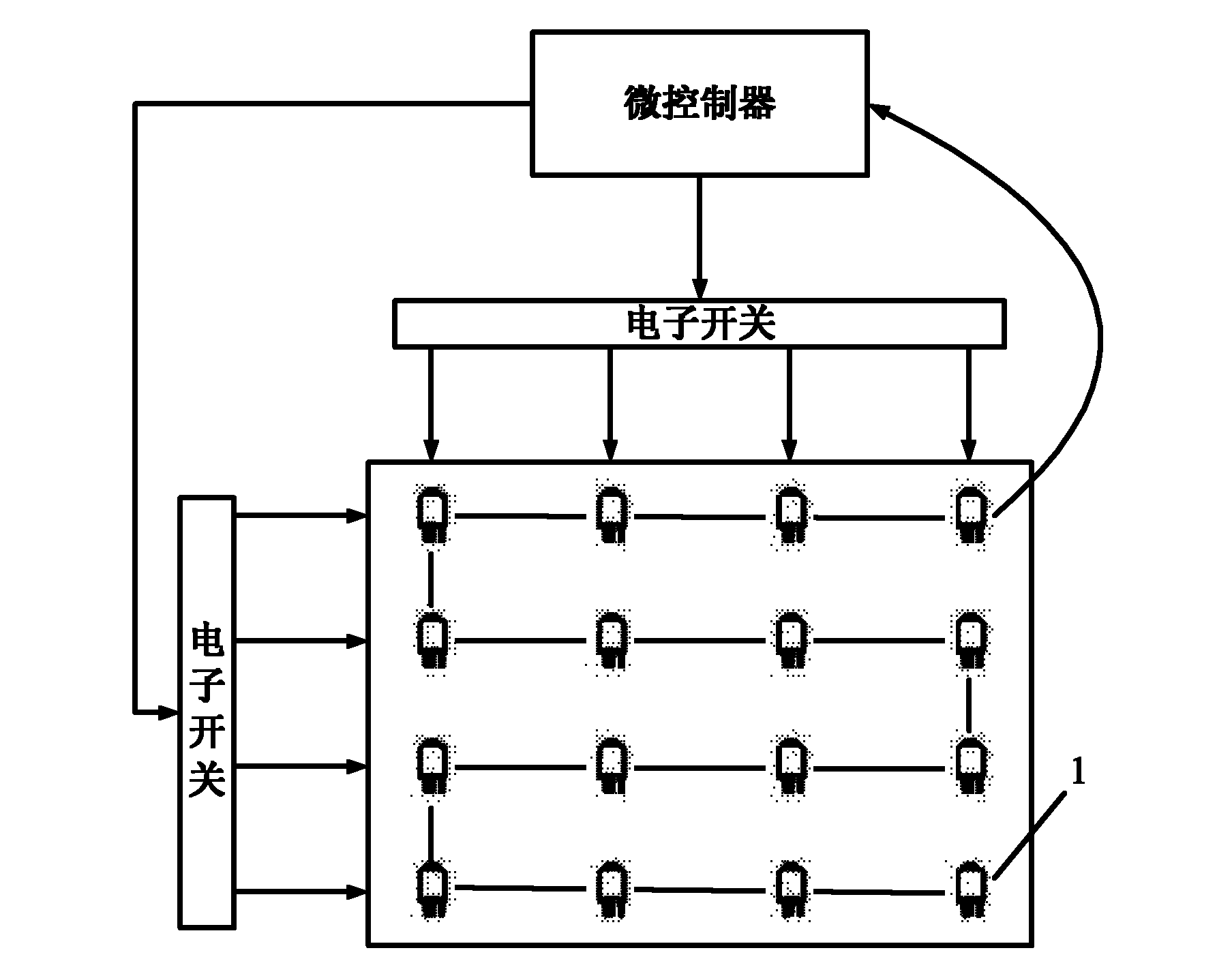

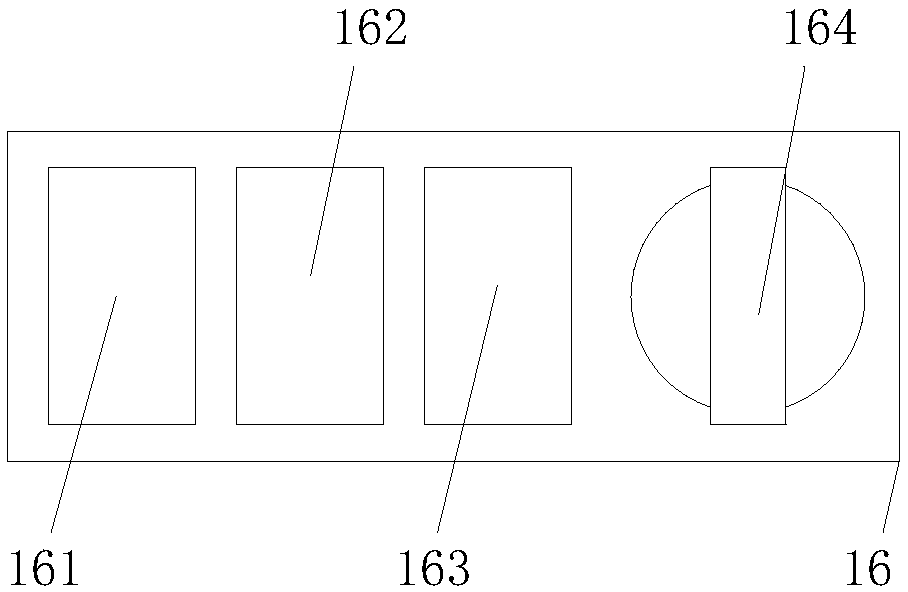

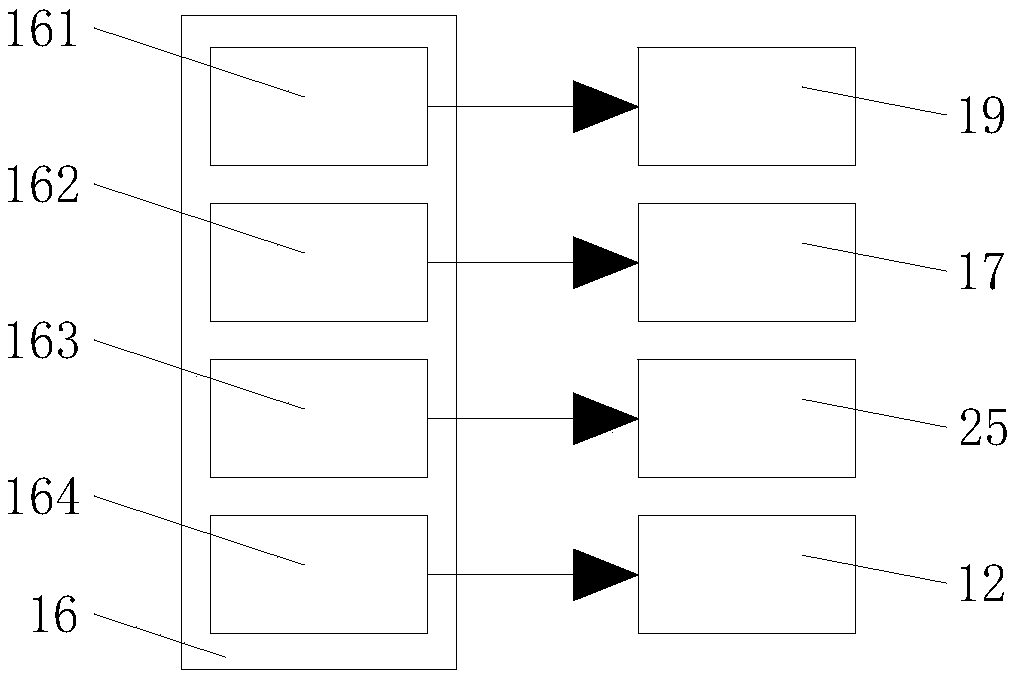

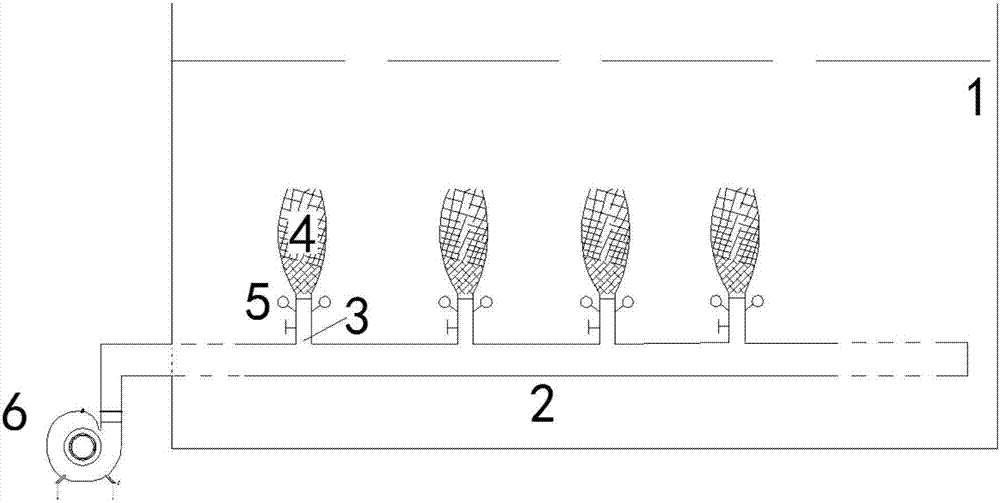

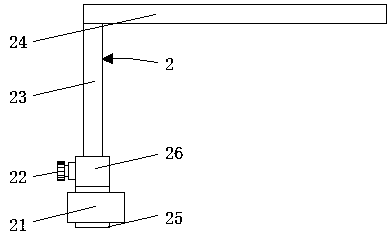

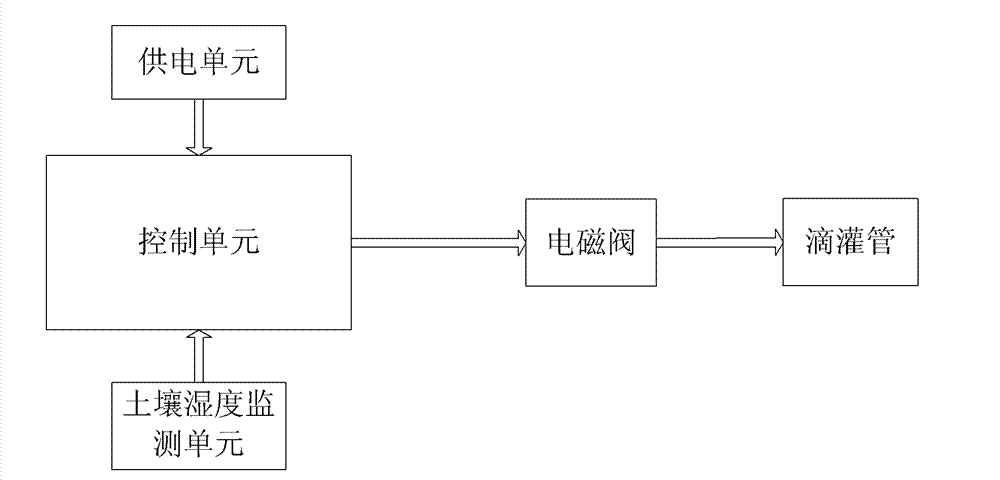

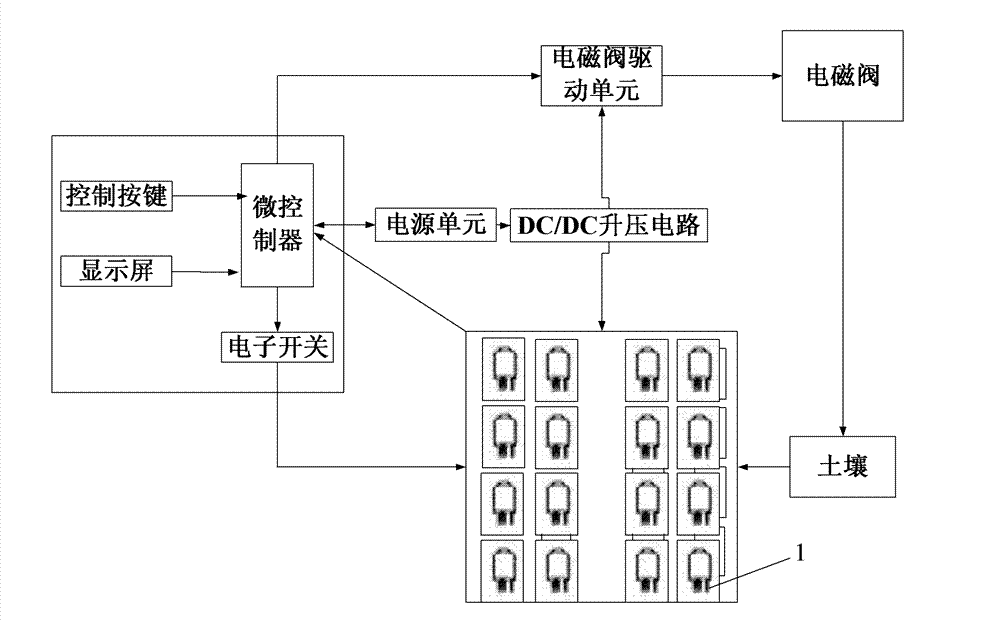

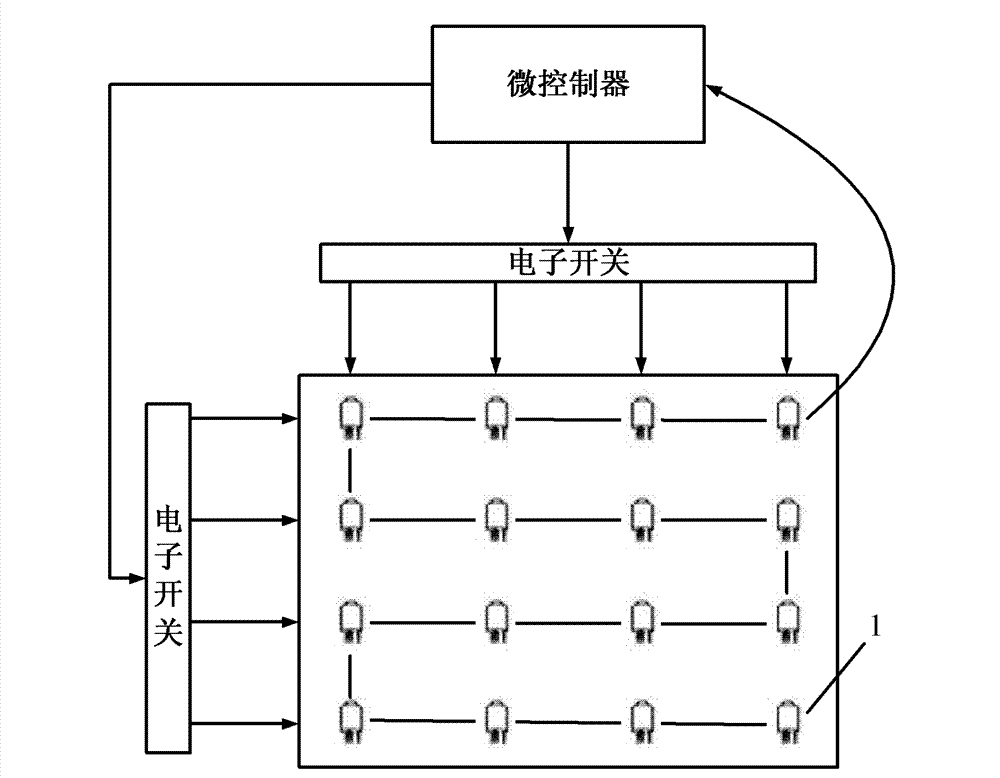

Array-type drip irrigation control device capable of automatic feedback of soil humidity and control method thereof

InactiveCN102204502AReduce energy consumptionEfficiently monitor and assess humidity conditionsSelf-acting watering devicesClimate change adaptationFertilizerSoil humidity

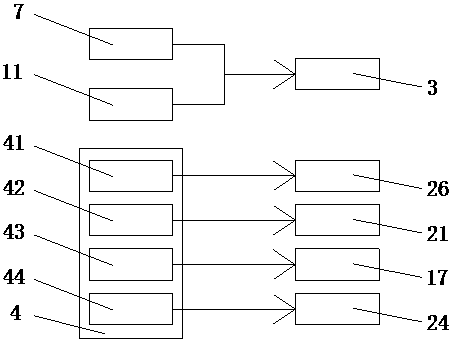

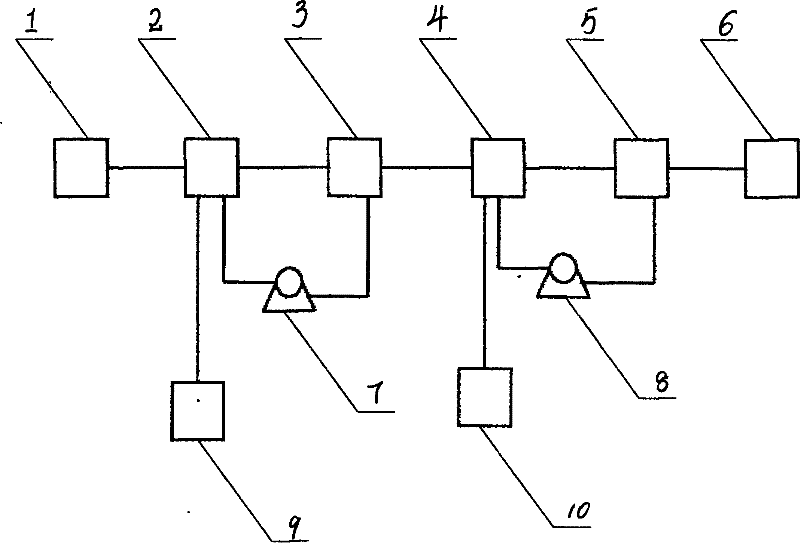

The invention provides an array-type drip irrigation control device capable of automatic feedback of soil humidity. The array-type drip irrigation control device comprises a power supply unit, soil humidity monitoring units, a control unit, a solenoid valve and a drip irrigation pipe, wherein the power supply unit is connected with the soil humidity monitoring units, the control unit and the solenoid valve respectively; and the solenoid valve is connected on the drip irrigation pipe; a plurality of soil humidity monitoring units are arranged and distributed in the soil to be detected in an array manner. The invention also provides a control method of the array-type drip irrigation control device. The array-type drip irrigation control device capable of automatic feedback of soil humidity can be used for effective monitoring and estimation of the soil humidity condition and active drip irrigation of water and fertilizer, effectively improves the working efficiency, and reduces pointless waste of water and fertilizer.

Owner:SOUTH CHINA AGRI UNIV

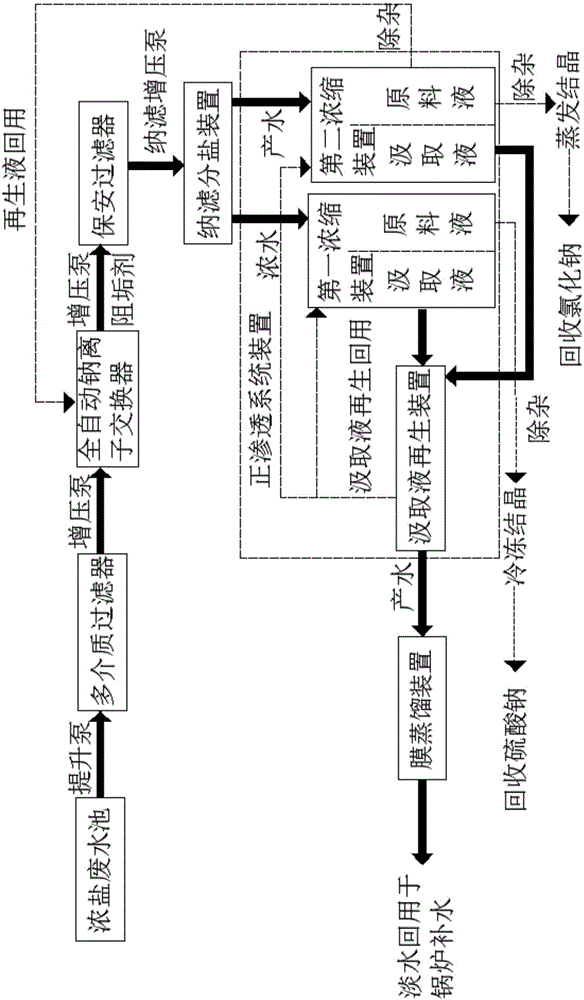

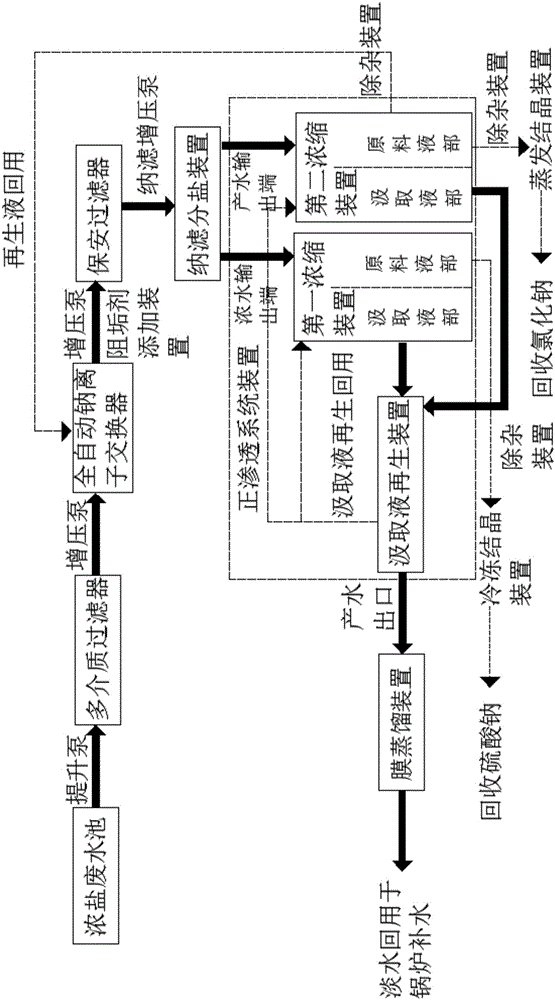

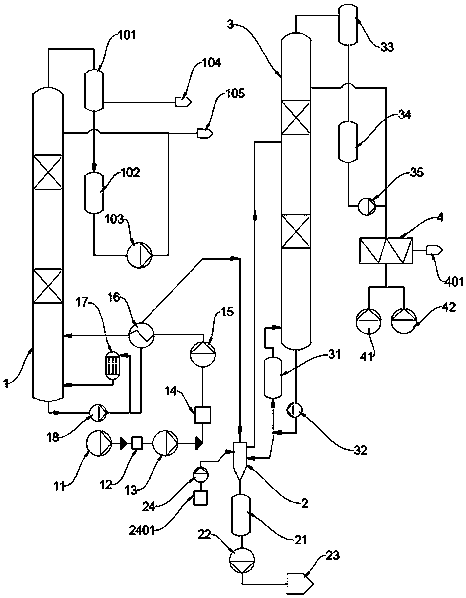

Coal chemical industry concentrated salt wastewater regeneration and recycling treatment method and system for implementing method

ActiveCN106277517AMeeting Recycling NeedsImprove operating conditionsGeneral water supply conservationChemical industryChemical industryIon exchange

The invention relates to a coal chemical industry concentrated salt wastewater regeneration and recycling treatment method which comprises the following steps: concentrated salt wastewater generated by coal chemical industry wastewater treatment enters a full-automatic sodium cation exchanger after flowing through a multimedia filter, and enters a nanofiltration salt separator through a cartridge filter to obtain concentrated water and produced water; the concentrated water and produced water respectively enter a first concentrator and a second concentrator; the diluted drawn solutions in the concentrators respectively enter a drawn solution regenerator, the drawn solution is recycled into the concentrators, the generated fresh water is treated by a membrane distillation device to remove residual ammonia and carbon dioxide, and the effluent water is recycled to the boiler to supplement water circularly; the sodium sulfate concentrated water generated by the first concentrator is subjected to impurity removal and sent to a freezing crystallization system to recycle the sodium sulfate crystal salt; and the sodium chloride concentrated water generated by the second concentrator is subjected to impurity removal, and is partially used as a regeneration solution of the full-automatic sodium cation exchanger and partially subjected to evaporative crystallization to recycle the sodium chloride. The method has the advantages of high recycling rate, investment saving, low energy consumption and simple technical process.

Owner:AEROSPACE ENVIRONMENTAL ENG

Device of recycling tritium from tritiated water and implementation method of same

The invention discloses a device of recycling tritium from tritiated water, which includes, in a successively connected manner through pipelines, a gas circulating pump, a buffer tank filled with an inert carrier gas, a tritiated water storage tank filled with the tritiated water, a first water decomposing bed filled with iron powder, a first adsorption bed filled with a 5A molecular sieve, and a first hydrogen storage bed filled with a zirconium-series hydrogen-storing alloy. The first hydrogen storage bed is also back-connected to the gas circulating pump. The device is compact in structure, is low in cost, is convenient to use, can be used for recycling the tritium from tritiated water continuously without generation of solid waste, and has excellent practical and popularizing values.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

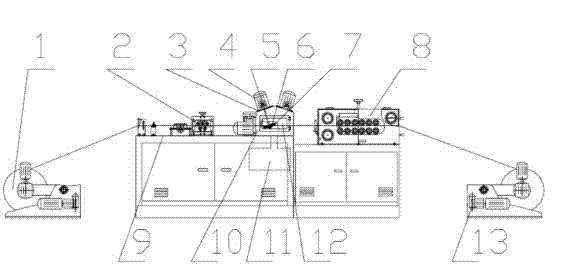

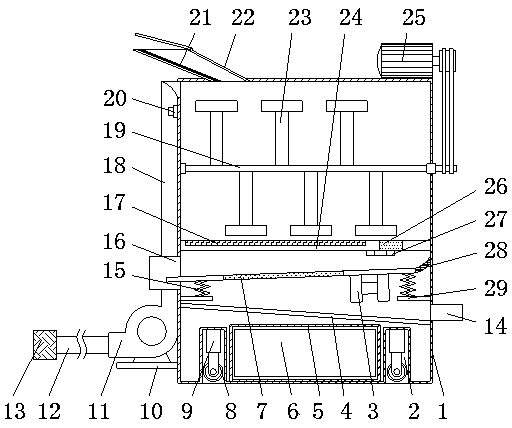

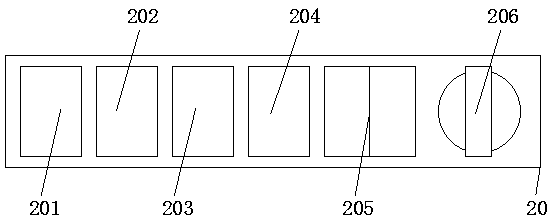

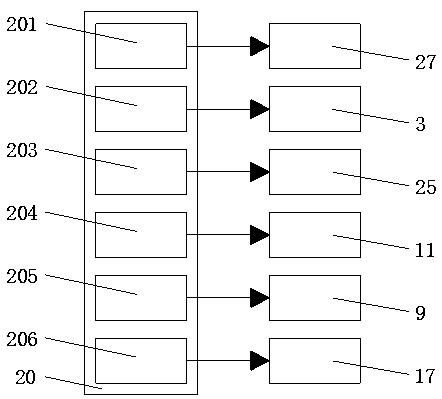

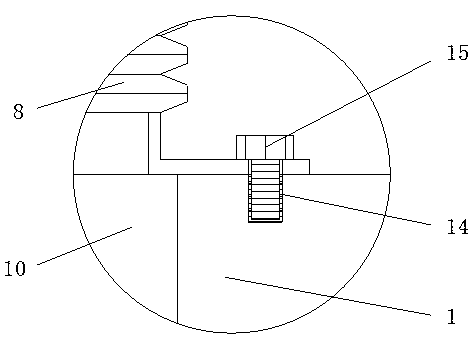

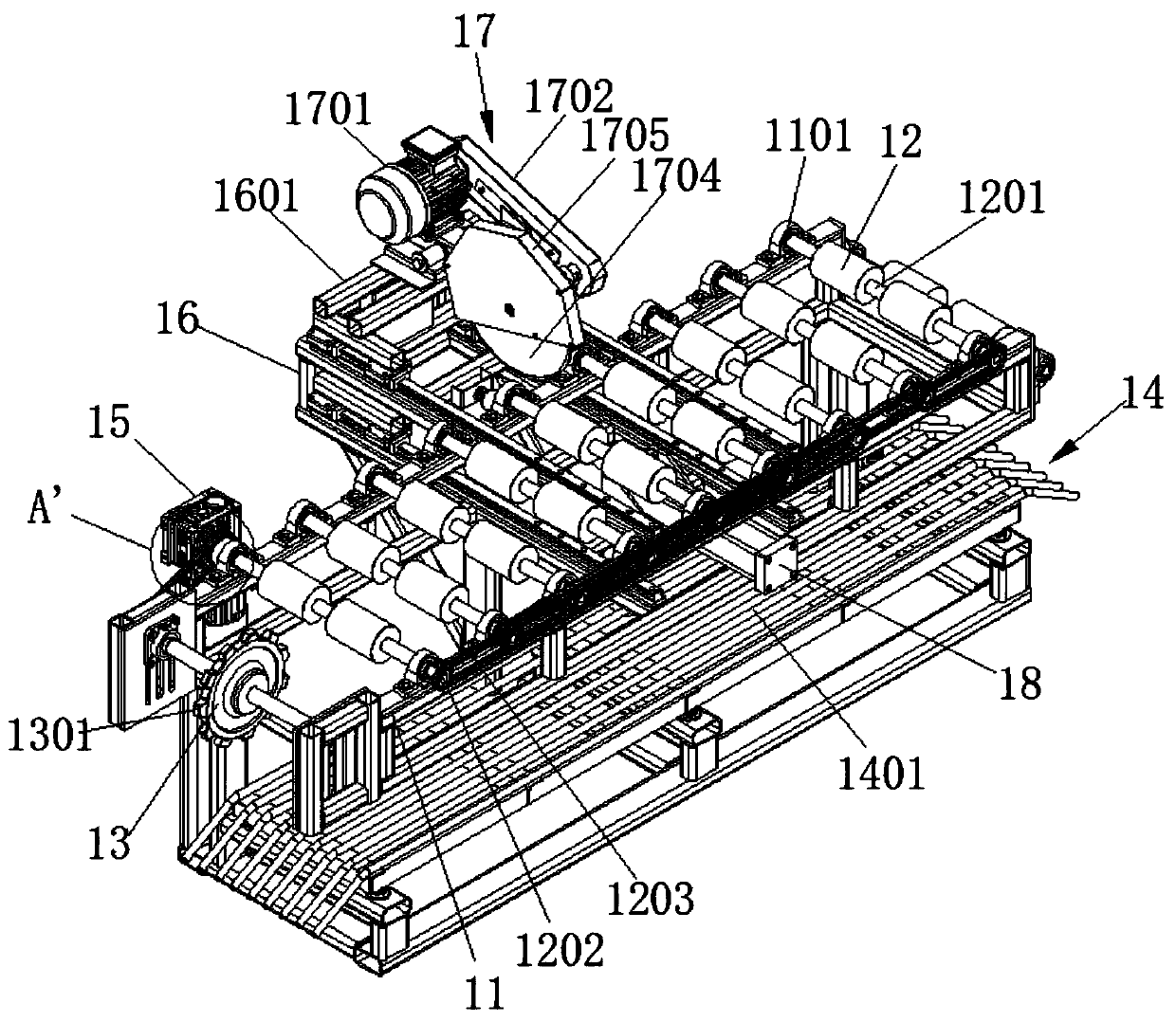

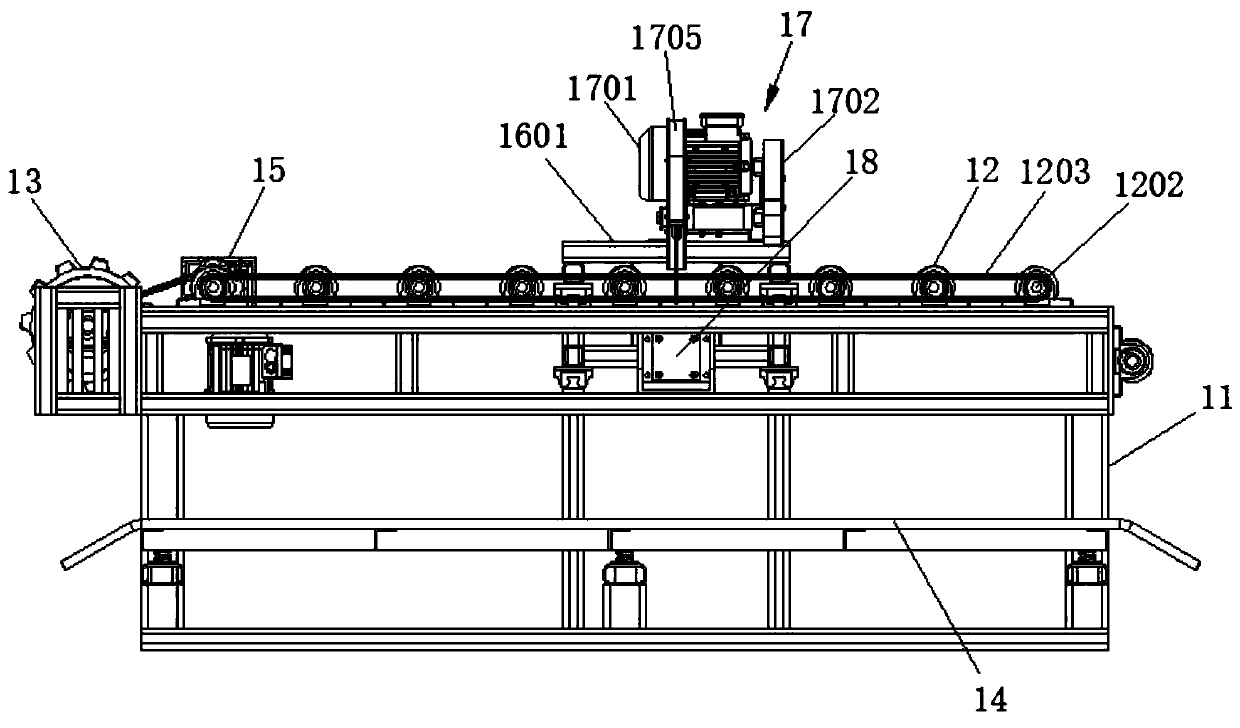

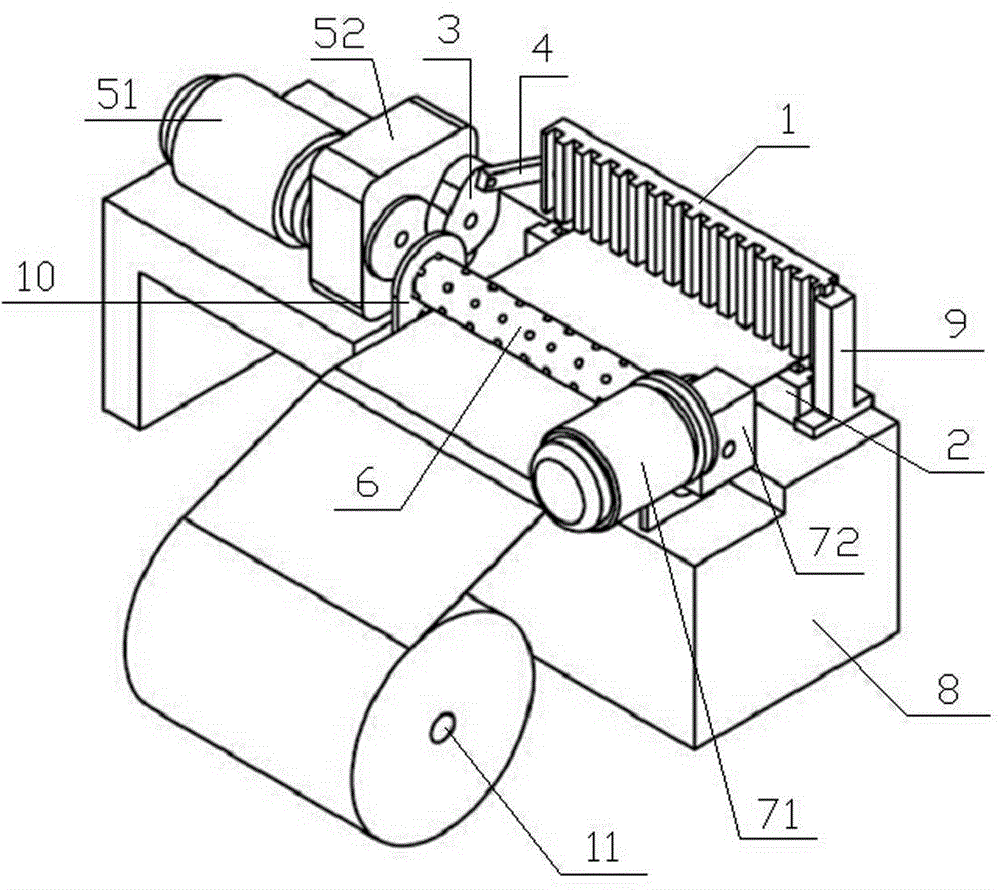

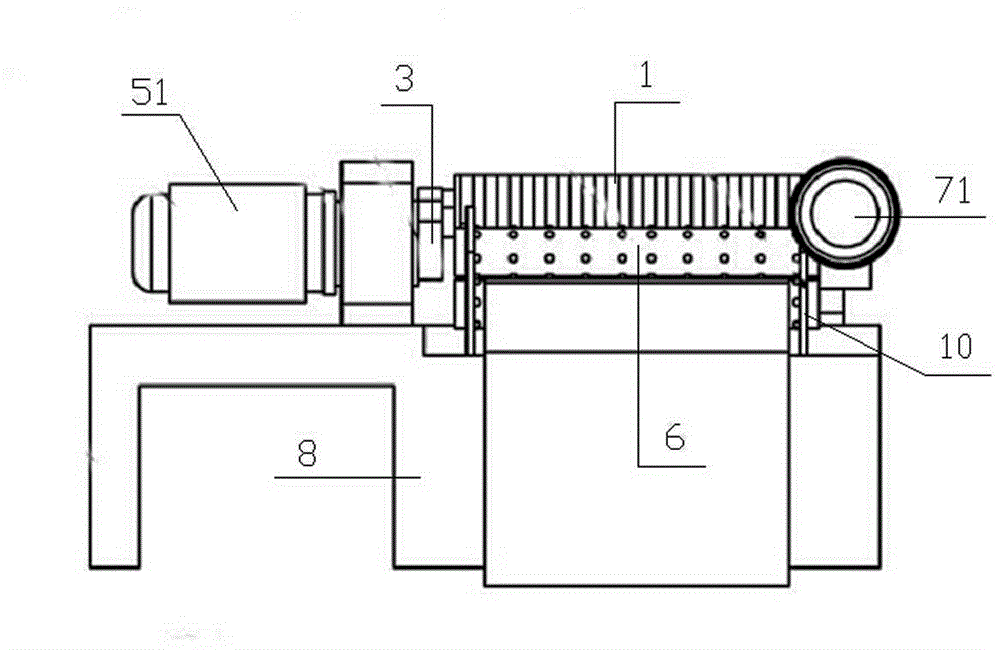

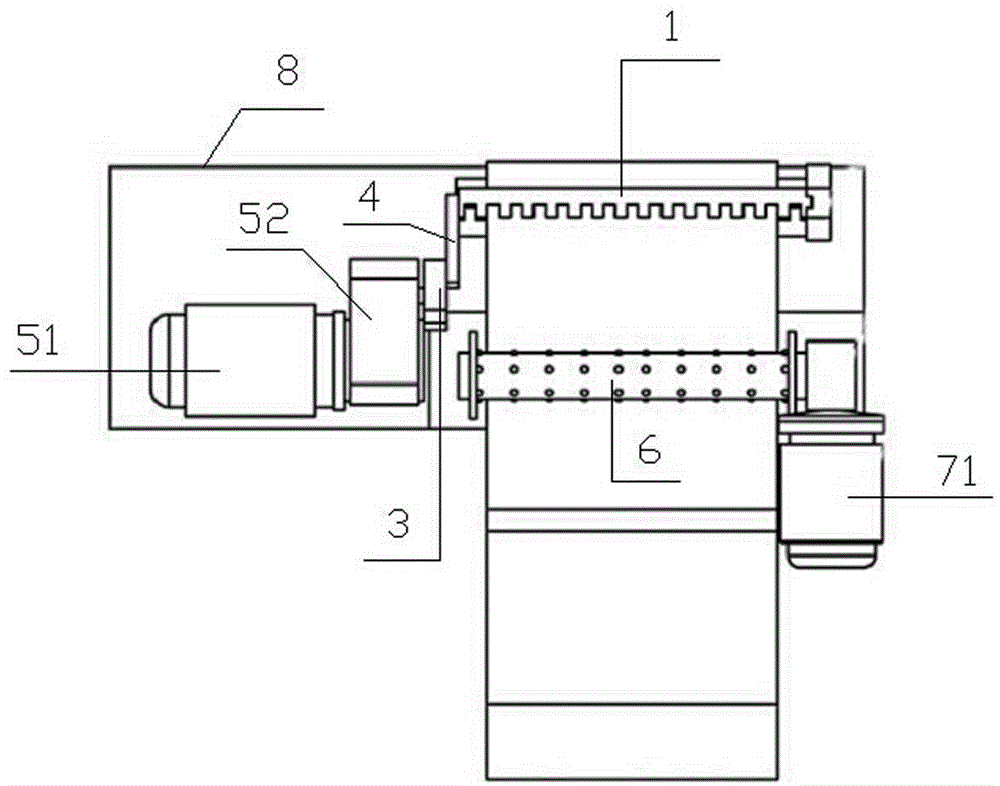

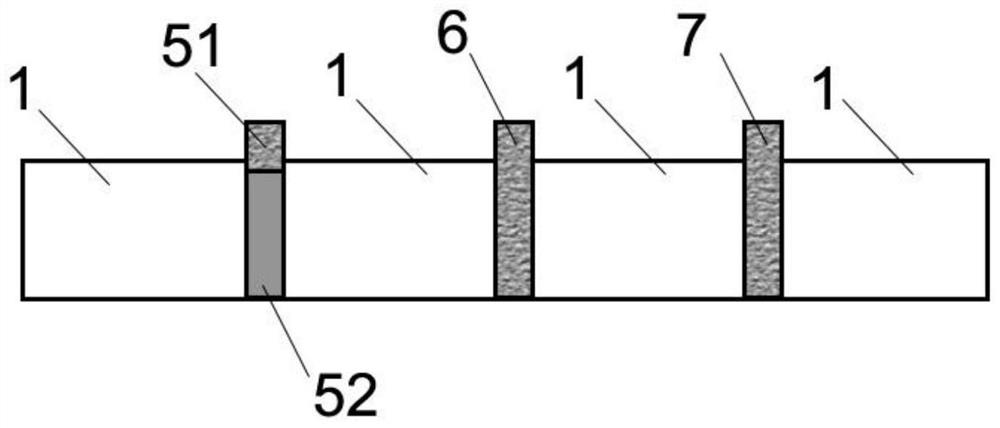

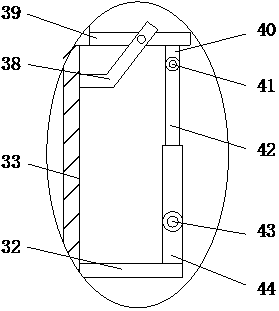

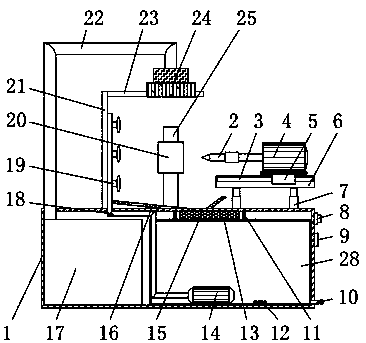

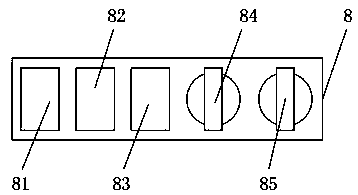

Electromagnetic wire insulating layer separation device and method

ActiveCN103795009ASuitable for separate useSimple structureApparatus for removing/armouring cablesEngineeringEnergy consumption

The invention discloses an electromagnetic wire insulating layer separation device and method. The electromagnetic wire insulating layer separation device comprises a paying-off mechanism, a stripping mechanism, a taking-up mechanism, a straightening device, a traction mechanism, a platform and a dust collection device. The platform is located between the paying-off mechanism and the taking-up mechanism. The straightening device, the stripping mechanism, the dust collection device and the traction mechanism are all arranged on the platform. The stripping mechanism comprises a stripping box, a guide rail, motors, a metal rod, stripping wheels and a transparent baffle. According to the electromagnetic wire insulating layer separation method, an electromagnetic wire is straightened, the guide rail is adjusted so that all the stripping wheels can be attached to the surface of the electromagnetic wire, and the motors rotate to drive the stripping wheels to rotate so that an insulating layer of the electromagnetic wire can be stripped off. The electromagnetic wire insulating layer separation device has the advantages of being simple in structure, reasonable in design, reliable in performance, capable of separating the electromagnetic wire insulating layer through the coordination effect of all components, free of increased power, low in energy consumption, not prone to environment pollution, and capable of meeting the requirement for recycling of metal wires of electromagnetic wires.

Owner:株洲兆源机电科技有限公司

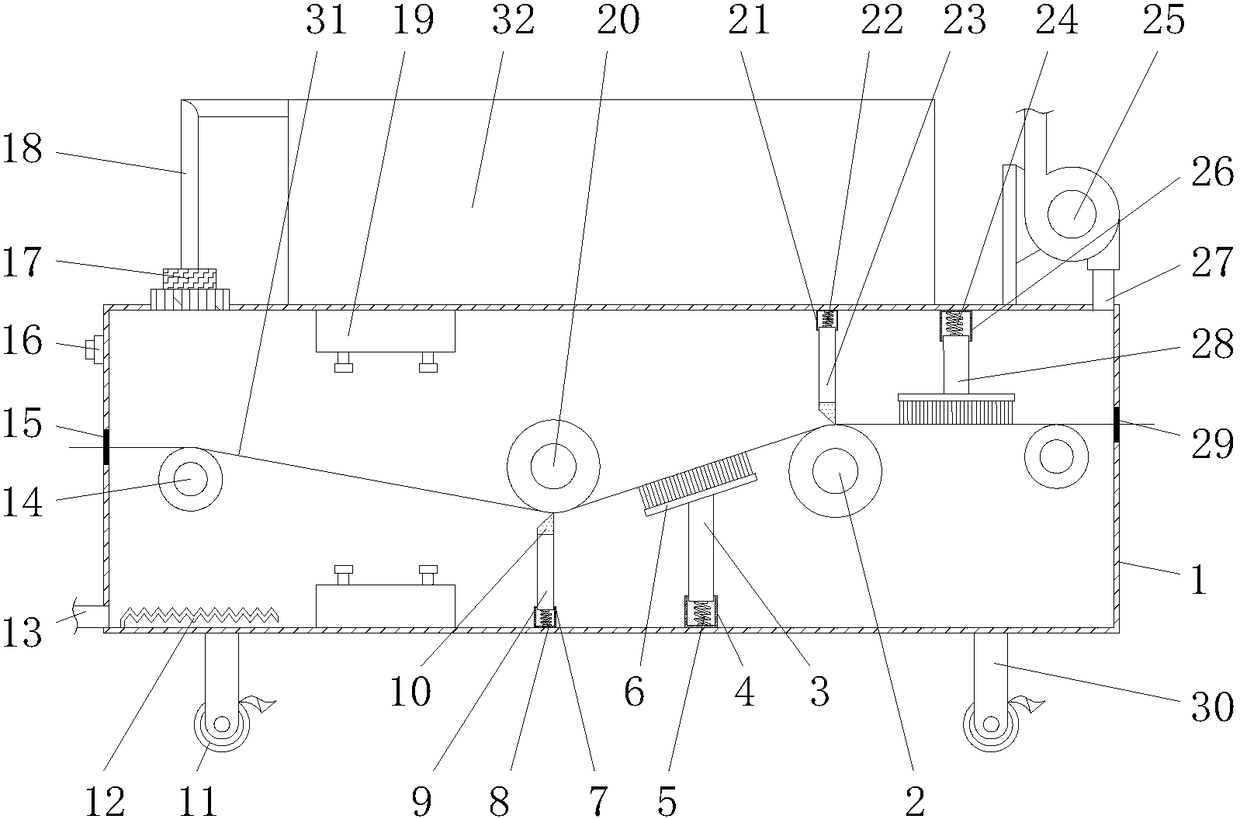

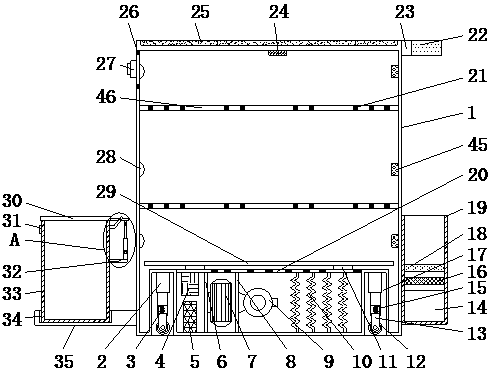

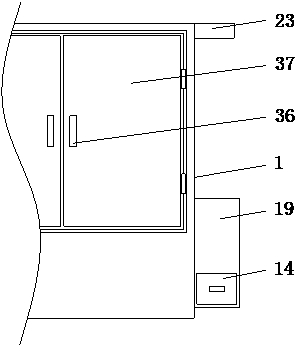

Textile wool removal device

InactiveCN108532196AQuality improvementEfficient Clearance TreatmentTextile shapingEngineeringElectrostatic generator

The invention discloses a textile wool removal device which comprises a shell. Conveying rollers are movably mounted at the left end and the right end of an inner cavity of the shell, a first wool sticking roller is movably mounted in the inner cavity of the shell and positioned at the right end of the left conveying roller, a second wool sticking roller is movably mounted in the inner cavity of the shell and positioned a the left end of the right conveying roller, the second wool sticking roller, the first wool sticking roller and the two conveying rollers are in transmission connection through textile fabrics, electrostatic generators are symmetrically arranged at the left ends of the top and the bottom of the inner cavity of the shell, and a heating wire is fixedly connected at the bottom of the inner cavity of the shell and positioned at the left end of the bottom electrostatic generator. Wool flocculi on the upper surface and the lower surface of a textile fabric can be efficiently removed under actions of the electrostatic generators, the first wool sticking roller, the second wool sticking roller, electrostatic brushes and electrostatic scrapers, the wool removal efficiencyof the device is improved, the quality of the textile fabric is improved, and the device meets enterprise benefits.

Owner:PINGHU YIFANJIA LUGGAGE CO LTD

Stripping liquid regeneration device and process

PendingCN108568131AImprove primary separation efficiencyQuick removalPhotosensitive material processingFractional distillationLiquid wasteFiltration

The invention relates to a stripping liquid regeneration device and process. The device structurally comprises a dewatering rectification tower, a film evaporator and a decolorizing rectification tower arranged sequentially along the flow direction of stripping liquid in a waste stripping liquid purification process, wherein the feeding hole end of the dewatering rectification tower is provided with a waste stripping liquid smelting pool and a primary film filtration pool which are connected in sequence. By adopting the stripping liquid regeneration device and process, the overall regenerationefficiency of the stripping liquid and the final yield of the stripping liquid are increased, and the demand of recycling of the waste stripping liquid of photoresist is met.

Owner:四川久远化工技术有限公司

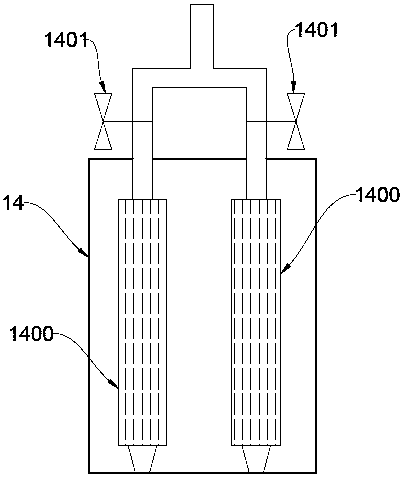

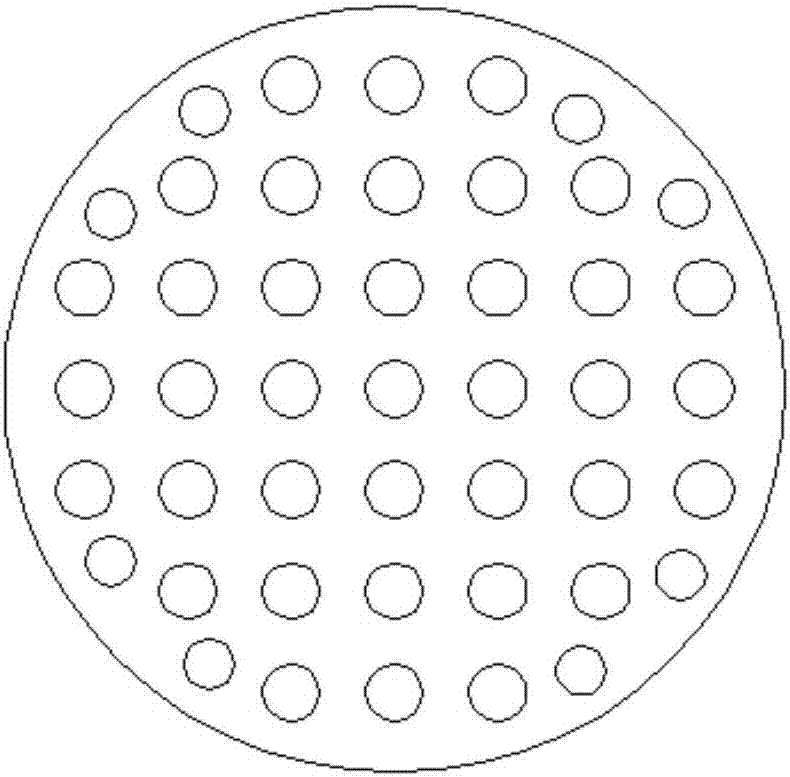

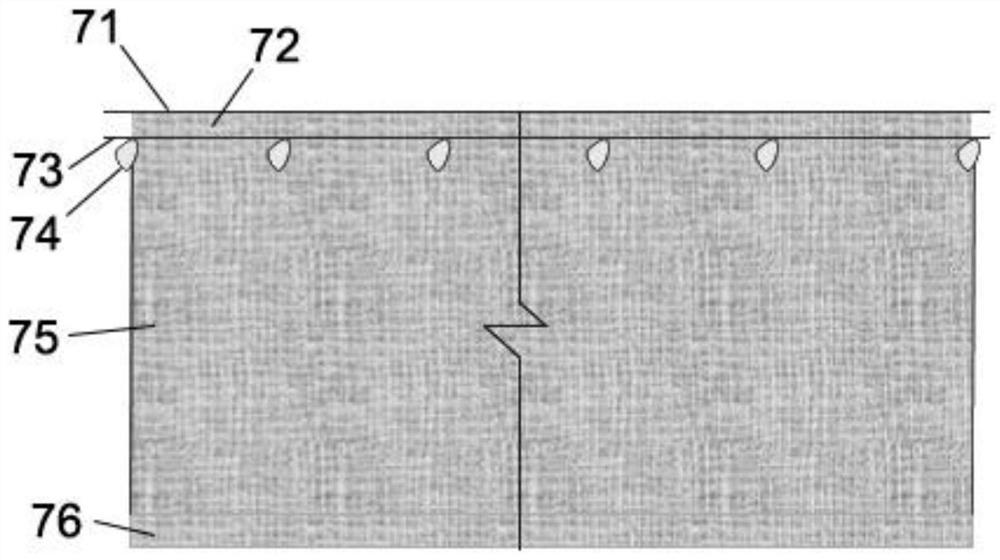

Biological membrane reactor

ActiveCN107055752AIncrease specific gravity and activityShorten the film setting timeTreatment using aerobic processesSustainable biological treatmentSpecific gravityMembrane configuration

The invention belongs to the field of water treatment and particularly relates to a biological membrane reactor. The biological membrane reactor comprises a sewage reaction tank, an aeration pipe and biological membrane filler; the aeration pipe is arranged in the sewage reaction tank and provided with a plurality of air outlet positions, and the biological membrane filler is filled in the sewage reaction tank and connected with the air outlet positions. By connection of the biological membrane filler with the aeration pipe, internal aeration of the biological membrane filler can be realized so as to make the interior of a biological membrane in an aerobic state, activity and proportion of aerobic microorganisms on the biological membrane can be increased beneficially, membrane forming time of sewage microorganisms on the surface of the filler is further shortened, and sewage degradation efficiency is improved. According to experiments, compared with a traditional biological membrane reactor under same conditions, the biological membrane reactor has advantages that membrane forming time is shortened by 17 days, biological membrane thickness is increased by 10.42% after maturity, effluent TN is smaller than 10mg / L, COD is smaller than 50mg / L, and BOD is smaller than 10mg / L.

Owner:GUANGDONG UNIV OF TECH

Production equipment for regenerating building materials from construction waste

PendingCN111760630AAvoid interferenceAffect the screening effectCleaning using toolsMagnetic separationArchitectural engineeringConstruction waste

The invention discloses production equipment for regenerating building materials from construction waste. The equipment comprises a crushing box, a screening box and a lifting chassis; the screening box is fixed at the central position at the top of the crushing box; the lifting chassis is fixed at the central position of one side surface of the crushing box; one side surface of the lifting chassis communicates with an inner cavity of the screening box through a material guiding pipe; a material inlet pipe is installed on one side, away from the lifting chassis, at the top of the screening box; an electromagnetic screening plate is fixedly installed at the central position at the bottom end of the inner cavity of the screening box via a first electric push rod and a supporting stand; discharging channels are arranged on the bottom end surface of the screening box on two sides of the electromagnetic screening plate and communicate with an inner cavity of the crushing box; and the two discharging channels respectively communicate with the tops of a metal discharging cavity and a crushing cavity which are arranged in the crushing box. According to the production equipment for regenerating building materials from construction waste, the situation that metal waste causes interference during waste crushing is effectively avoided, the metal waste can be cleaned without manual operation, and cleaning is more convenient.

Owner:惠州市一帆实业有限公司

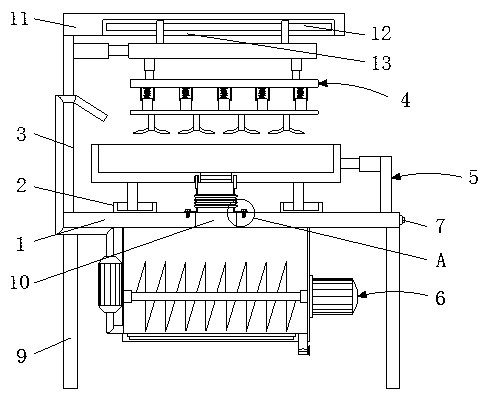

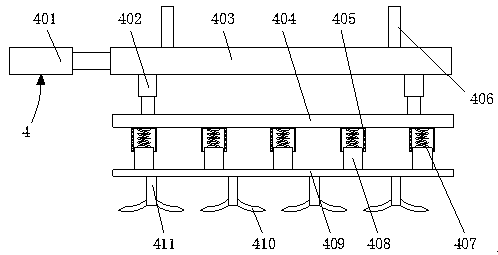

Granulated-feed mixing device for animal husbandry

InactiveCN108525540AAchieve recyclingFulfill mobile needsTransportation and packagingMixer accessoriesEngineeringAnimal husbandry

The invention discloses a granulated-feed mixing device for animal husbandry. The granulated-feed mixing device comprises a shell and is characterized in that a stirring shaft is movably mounted at the upper end of the inner cavity of the shell, stirring blades are fixedly connected to the outer surface of the stirring shaft, a partition is fixedly connected to the middle end of the inner cavity of the shell, a heating plate is embedded into the left end of the top of the partition, and a first discharge outlet is formed in the right end of the inner surface of the partition. The granulated-feed mixing device has the advantages that a vibrating screen are movably connected to the top ends of support plates through springs, and mixed granulated feed can be screened through a vibration motor; a circulating fan is fixedly mounted at the top end of a first support plate, and people's recycling requirements of granulated feed of different particle sizes can be satisfied through an air outlet pipe, an air inlet pipe and a rubber clamp sleeve; meanwhile, granulated feed of various specifications and kinds can be heated through a heating plate, the drying degree of the granulated feed is increased, and the storage time of the mixed granulated feed is prolonged.

Owner:陈苏娟

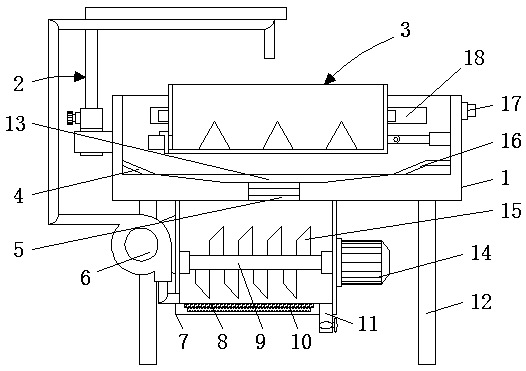

Food flour-coating device capable of recycling coating flour

The invention discloses a food flour-coating device capable of recycling coating flour. The device includes a support seat, the left end of the inner surface of the support seat is provided with a reserved port and the left end of the bottom of the support seat is provided with a coating flour circulation mechanism, the top periphery of the support seat is fixedly connected to second slide seats and the inner surface of each second slide seat is slidably connected to a rocking mechanism, the left end of the top of the support seat is fixedly connected to a first support plate and the top of the first support plate is fixedly connected to a first slide seat, the bottom of the first slide seat is provided with a first slide groove, and the inner cavity of the first slide seat is provided with second slide grooves at front and rear sides of the first slide groove and the inner surface of each second slide groove is slidably connected to a rolling mechanism. According to the invention, theleft end of the bottom of the support seat is provided with the coating flour circulation mechanism, and the circulation mechanism can meet the needs of people for recycling coating flour, avoid waste of the coating flour and save production cost.

Owner:丽水青蓝环保科技有限公司

Food pickling machine capable of performing high-efficiency stirring

InactiveCN107647467AMeeting Mobile NeedsExpand the mixing rangeFood preservationFood shapingEngineering

The invention discloses a food pickling machine capable of performing high-efficiency stirring. The food pickling machine comprises a housing, wherein a first salinity sensor is fixedly mounted at theleft end of the bottom of an inner cavity of the housing; a reserved opening is formed in the middle end of the top of the housing; a supporting plate is fixedly mounted at the right end of the top of the housing; a motor supporting seat is movably connected to the left side of the supporting plate through electric telescopic rods; a motor is fixedly mounted on the left side of the motor supporting seat; a rotating shaft is fixedly connected to an output shaft of the motor; stirring blades are fixedly connected to the external surface of the rotating shaft; a rubber soft plate is movably connected between the rotating shaft and the reserved opening; and a feeding opening is formed in the left end of the top of the housing. According to the food pickling machine disclosed by the invention,the reserved opening is formed in the middle end of the top of the housing; the reserved opening is movably connected with the rotating shaft through the rubber soft plate; through the effect of theelectric telescopic rods, moving requirements for the position of the motor by people can be met; the stirring range of the stirring blades is extended, and the stirring efficiency is improved.

Owner:许昌锦荣食品有限公司

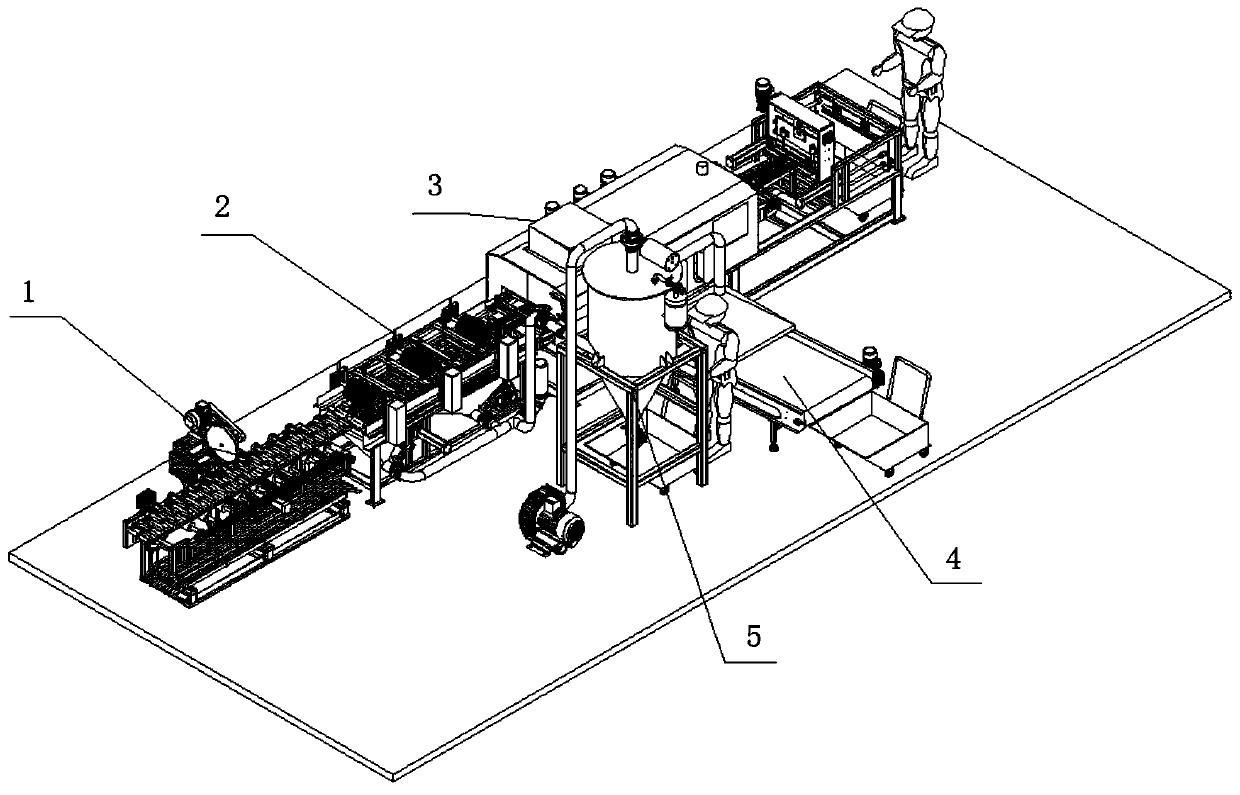

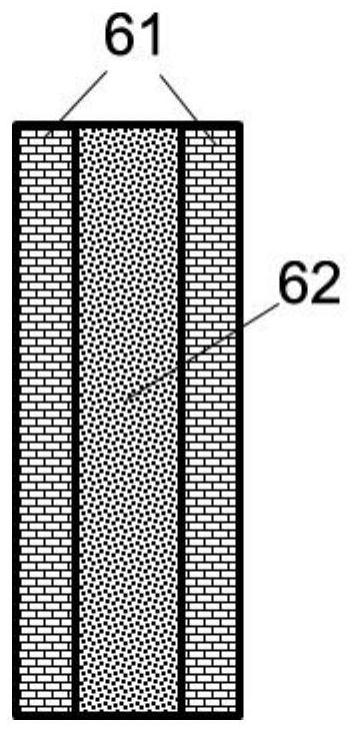

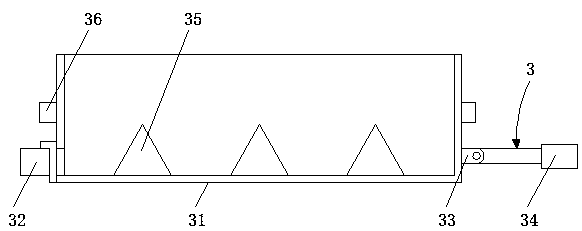

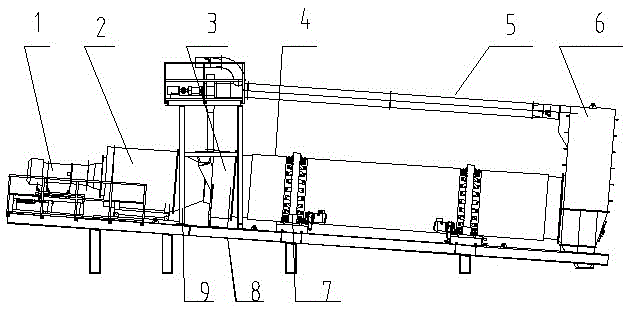

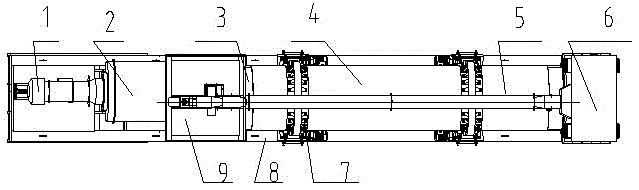

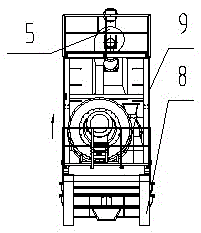

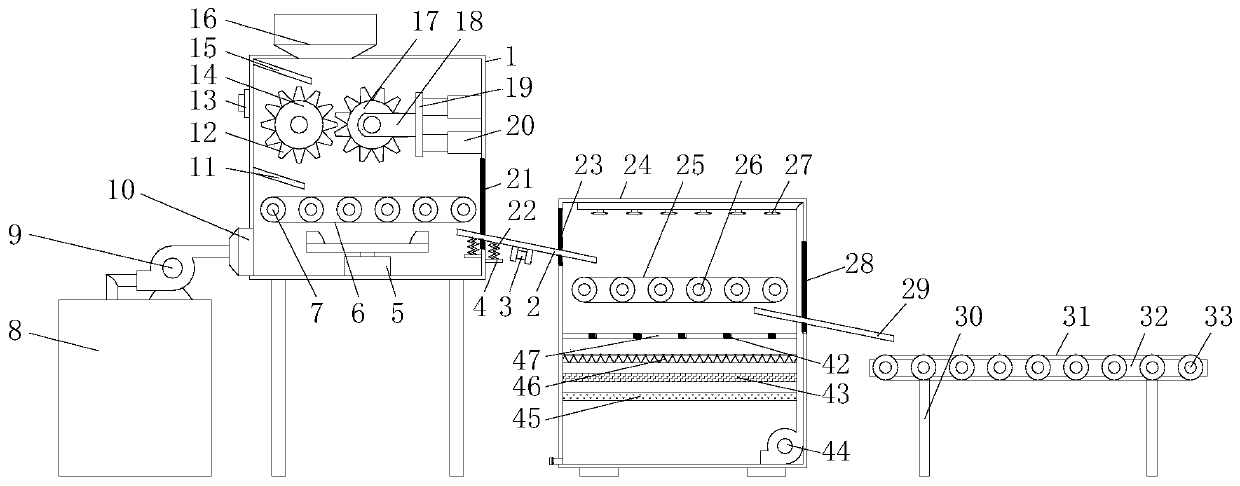

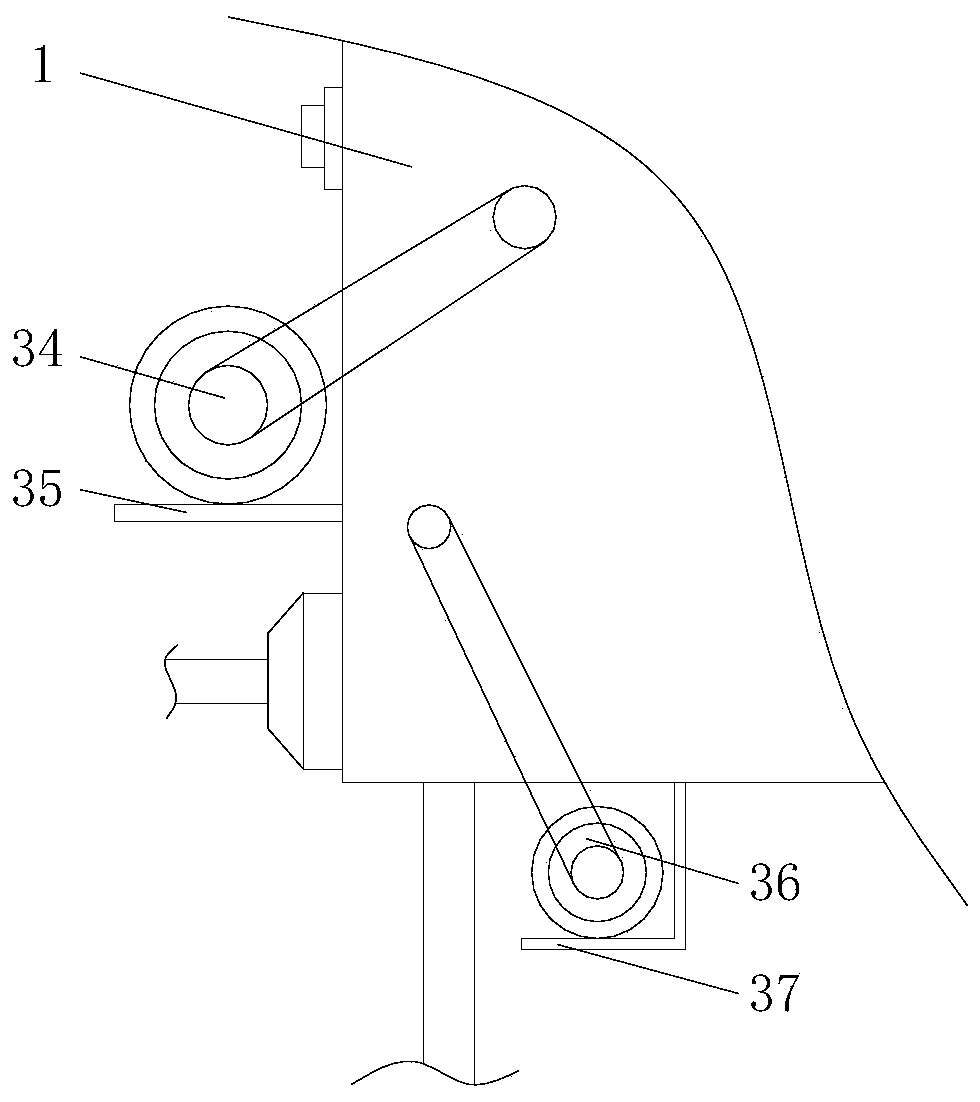

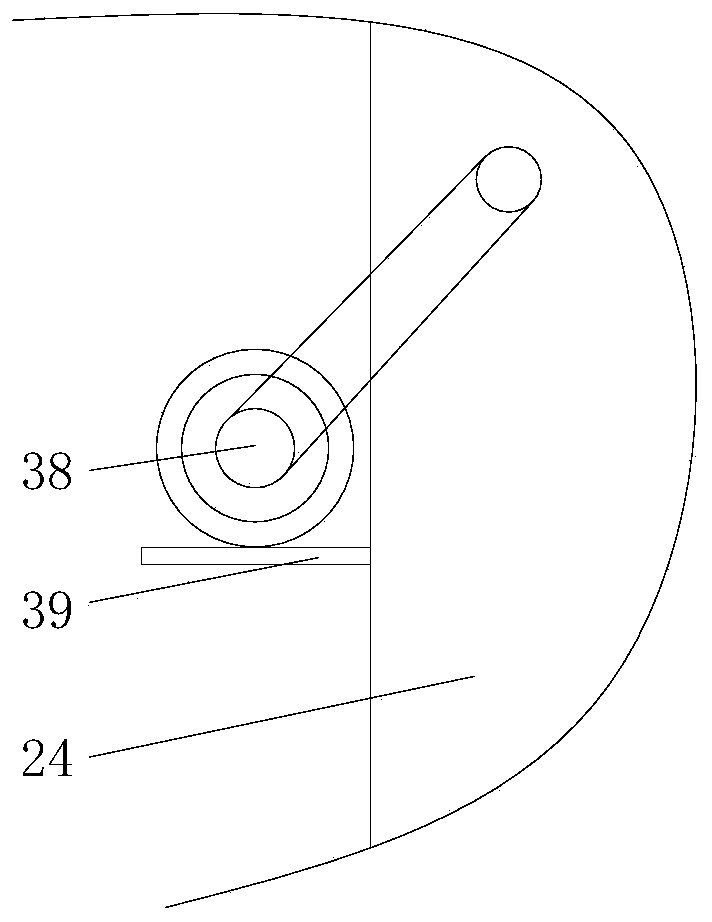

Waste rubber crawler belt material recycling production line

PendingCN110435048AImprove cutting recovery efficiencyNo displacementPlastic recyclingMetal working apparatusProduction lineSurface layer

The invention discloses a waste rubber crawler belt material recycling production line. The waste rubber crawler belt material recycling production line comprises a segmenting and cutting-off tool, asurface rough cutting tool, a surface treatment and separation device, a reclaimed material conveying structure and a vacuum recycling device; the segmenting and cutting-off tool is used for segmenting and cutting off a crawler belt; the surface rough cutting tool is used for carrying out rough cutting treatment on cut-off long-strip-shaped crawler belt surface rubber; the surface treatment and separation device is used for carrying out cutting treatment, embedded part separation, steel wire separation and steel wire shearing short and recycling on the roughly cut crawler belt remaining surface layer rubber; the reclaimed material conveying structure is used for conveying the cut surface rubber and an embedded part; and the vacuum recycling device is used for carrying out vacuum collectionand recycling on rubber particles left by the rough cutting treatment. According to the waste rubber crawler belt material recycling production line, residual rubber scraping, embedded part separation and steel wire shearing short and collection of the waste rubber crawler belt can be realized, the functions of the equipment are various, the classification and collection of all components in thewaste rubber crawler belt are effectively realized, the working synergy of all the mechanisms in the equipment is high, and the working efficiency is high.

Owner:ZHENJIANG SHEN WARD MACHINERY CO LTD

Parallel-cutting crusher

ActiveCN105478202AMeet the needs of recyclingEasy to recycleGrain treatmentsStructural engineeringCrusher

The invention discloses a parallel-cutting crusher, which comprises an upper knife unit, a lower knife unit, a cam, a connecting rod, a knife unit power device, a pressing roller, a pressing roller power device, and a frame. The knife unit power device and the lower knife unit are fixed on the frame; the upper knife unit capable of moving up and down is arranged on the frame through a guide rail; and the upper knife unit matches the lower knife unit in a shearing manner. The knife unit power device drives the cam to rotate; the cam drives the upper knife unit through the connecting rod to perform shearing movement relative to the lower knife unit; and the pressing roller power device is in transmission connection with the pressing roller and drives the pressing roller to rotate. According to the technical scheme, the parallel-cutting crusher is scientific and reasonable in structure, and the problem that a conventional double-shaft crusher cannot meet requirements of recycling sheet materials, such as paper, is overcome. Fine crushing degree of shearing crush can be conveniently regulated through adjusting driving rotational-speeds of the power devices, and different requirements of shearing crush are meet. Shapes of sheared materials are regular, so that the sheared materials are convenient to recycle.

Owner:HUANCHUANG XIAMEN TECH

Freshwater aquaculture pond tail water treatment system

PendingCN111718073AFully purifiedMeet the requirements of recyclingWater contaminantsWaste water treatment from animal husbandryWater treatment systemWater source

The invention discloses a freshwater aquaculture pond tail water treatment system, belonging to the field of freshwater pond aquaculture. The tail water treatment system comprises a primary sedimentation tank 1 for receiving tail water, a nitrification / denitrification tank 2 and an aeration reoxygenation tank 3, wherein the nitrification / denitrification tank 2 is composed of a nitrification tank 21 and a denitrification tank 22, and the nitrification tank 21 is connected with the primary sedimentation tank 1 through an overflow dam 4; the denitrification tank 22 is connected with the aerationreoxygenation tank 3 through a second filter dam 5; and a third filter dam 211 is arranged between the nitrification tank 21 and the denitrification tank 22. With the system, purified water can reacha fishing standard and is even superior to an inflow water source, so cyclic utilization is realized.

Owner:FRESHWATER FISHERIES RES CENT OF CHINESE ACAD OF FISHERY SCI

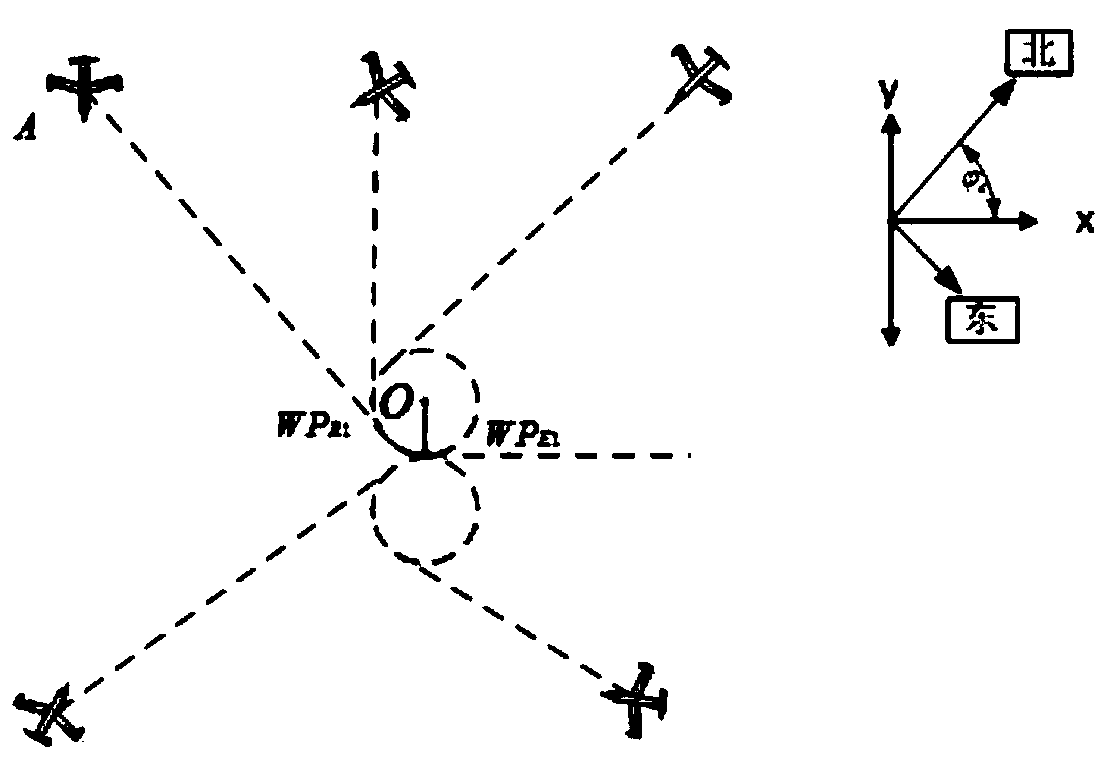

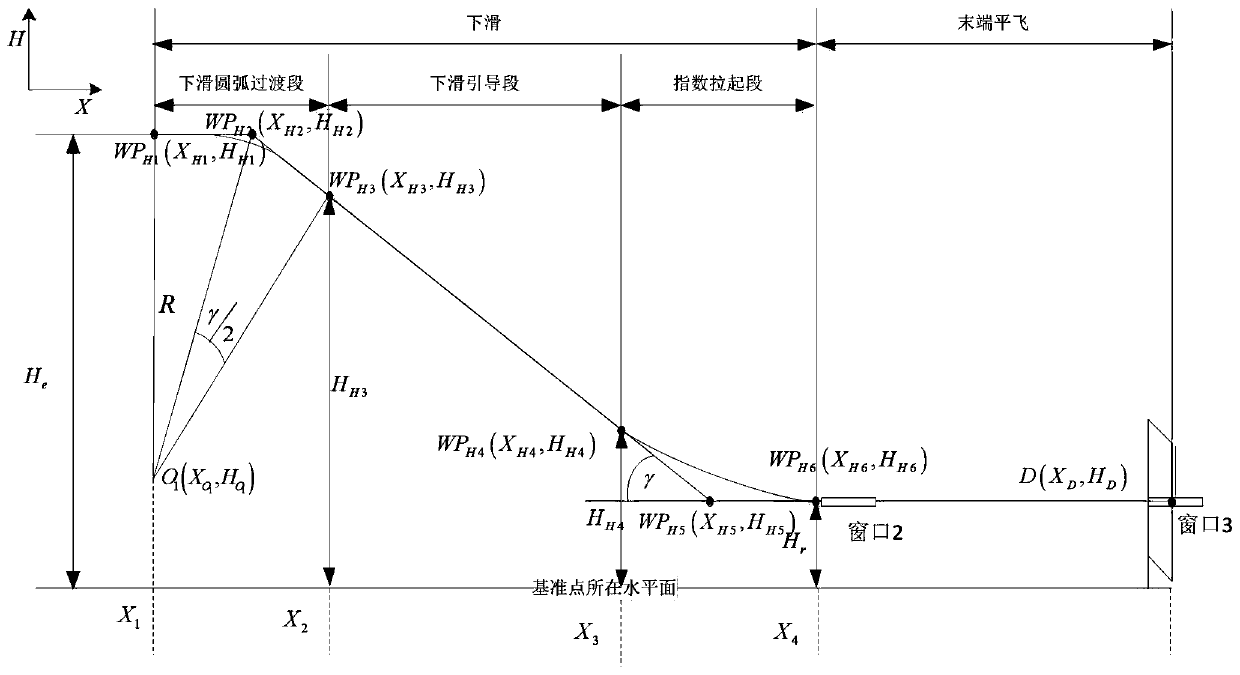

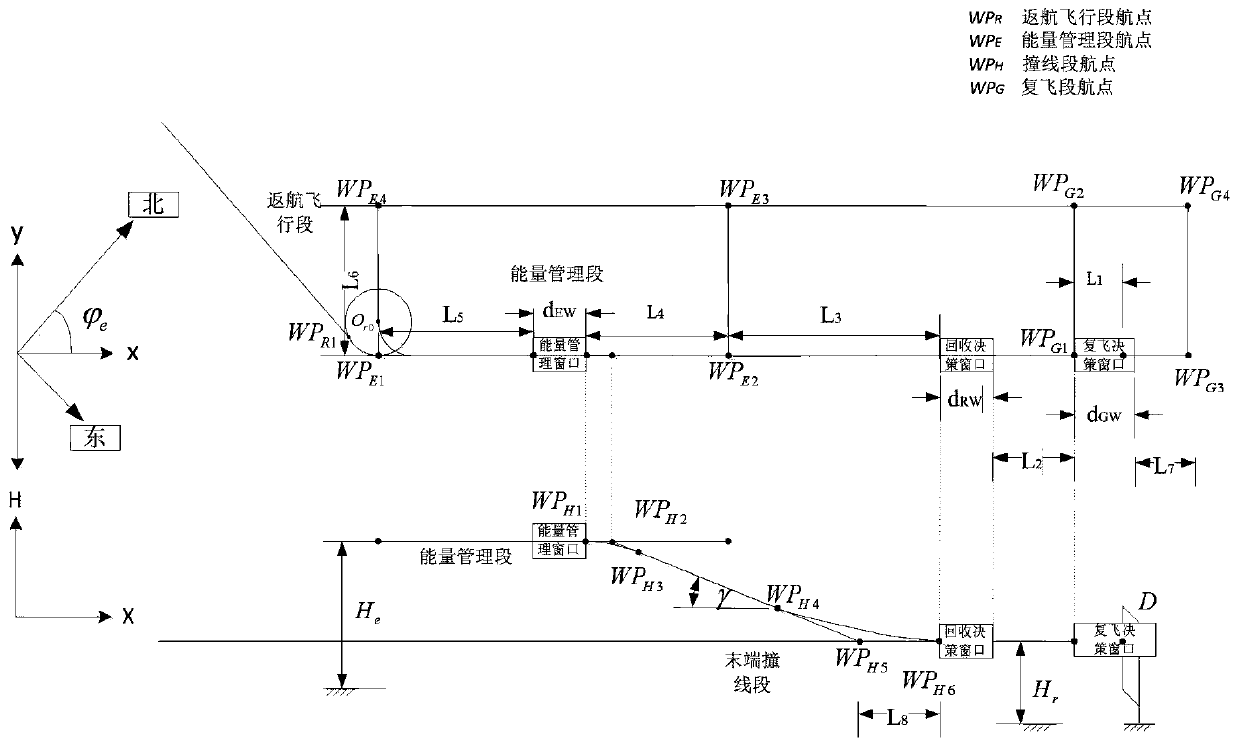

High-fault-tolerance sky hook recovery method based on window decision making

ActiveCN111077903AImprove reliabilityMeet the needs of recyclingPosition/course control in three dimensionsLevel flightUncrewed vehicle

The invention discloses a high-fault-tolerance sky hook recovery method based on window decision making. The method specifically comprises the steps that: an unmanned aerial vehicle flies to enter anenergy management section after flying to an end point of a return flight section; an energy management window arranged in an energy management section judges whether the unmanned aerial vehicle can enter a tail end line collision section or not, and if so, the unmanned aerial vehicle enters the tail end line collision section; otherwise, the unmanned aerial vehicle continuously and circularly flies according to the path of the energy management section until passing through the window; after the unmanned aerial vehicle flies to the end point of a lower sliding section in the tail end line collision section, the unmanned aerial vehicle flies into a recovery decision-making window, the recovery decision-making window judges whether the unmanned aerial vehicle can perform line collision or not, and if so, the unmanned aerial vehicle enters a re-flight decision-making window through a level flight section; otherwise, the unmanned aerial vehicle enters the level flight section and enters the energy management section again through the first re-flight section; the re-flight decision-making window judges whether the unmanned aerial vehicle successfully collides with the line or not, andif so, the engine is shut down; and otherwise, the unmanned aerial vehicle enters the energy management section through a second re-flight section. The method has the advantages of high accuracy and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

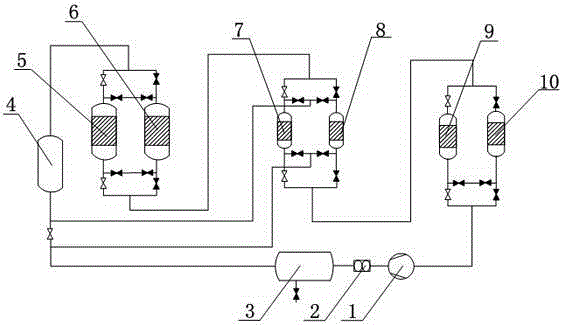

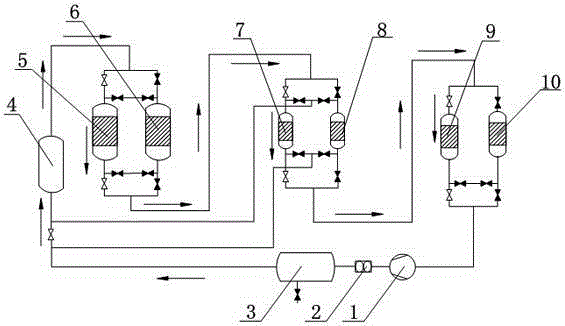

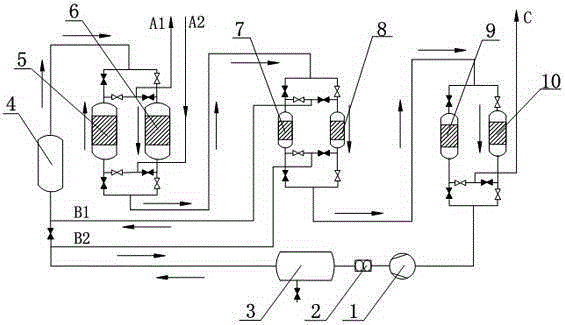

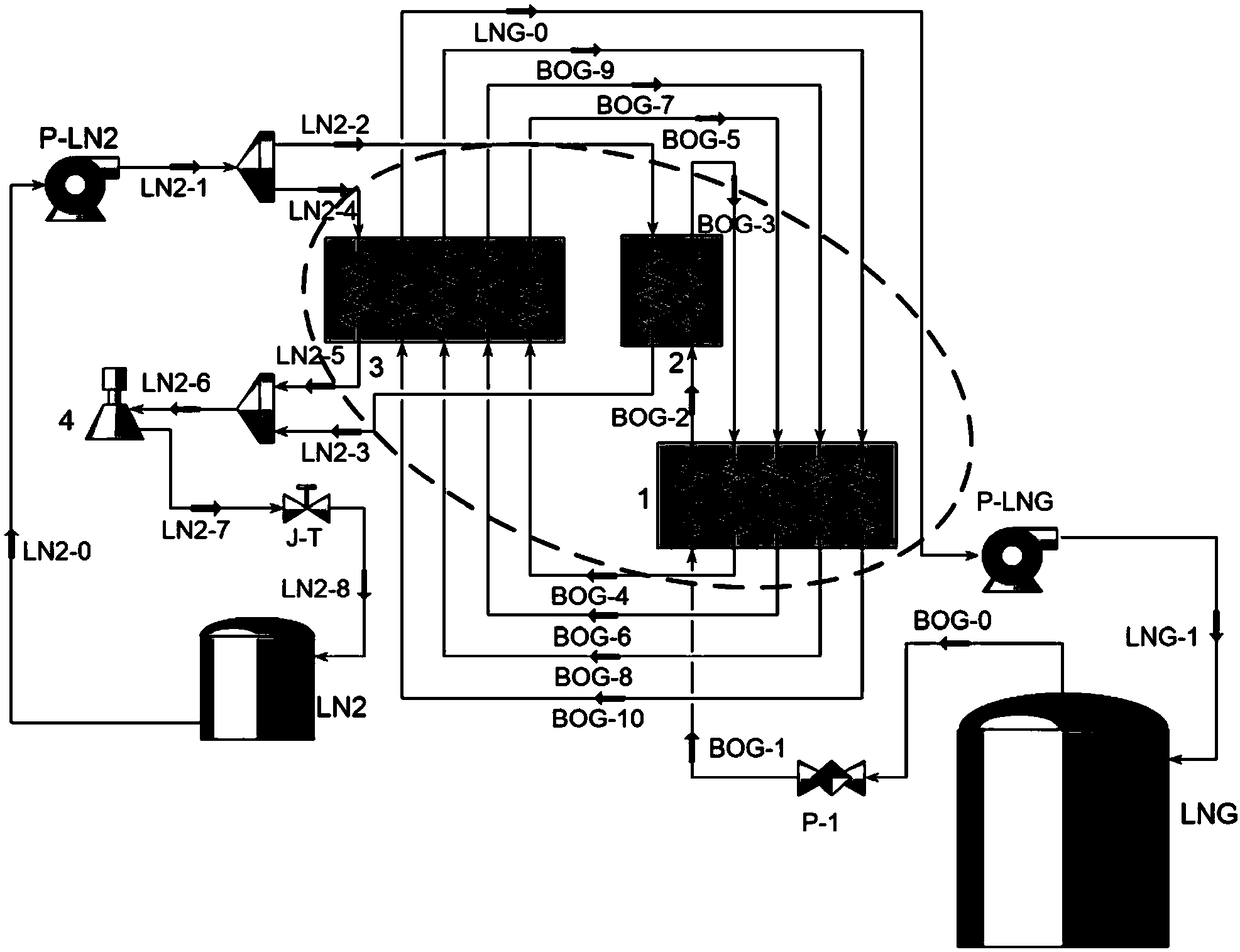

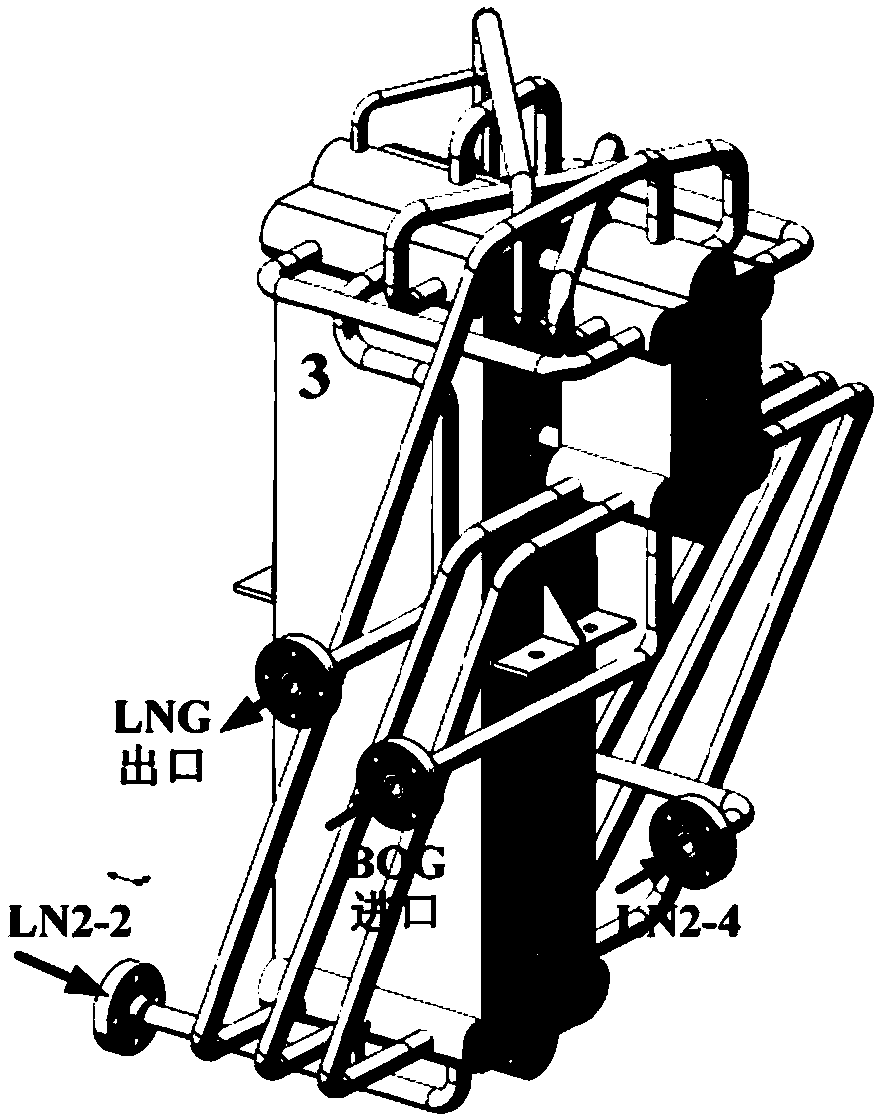

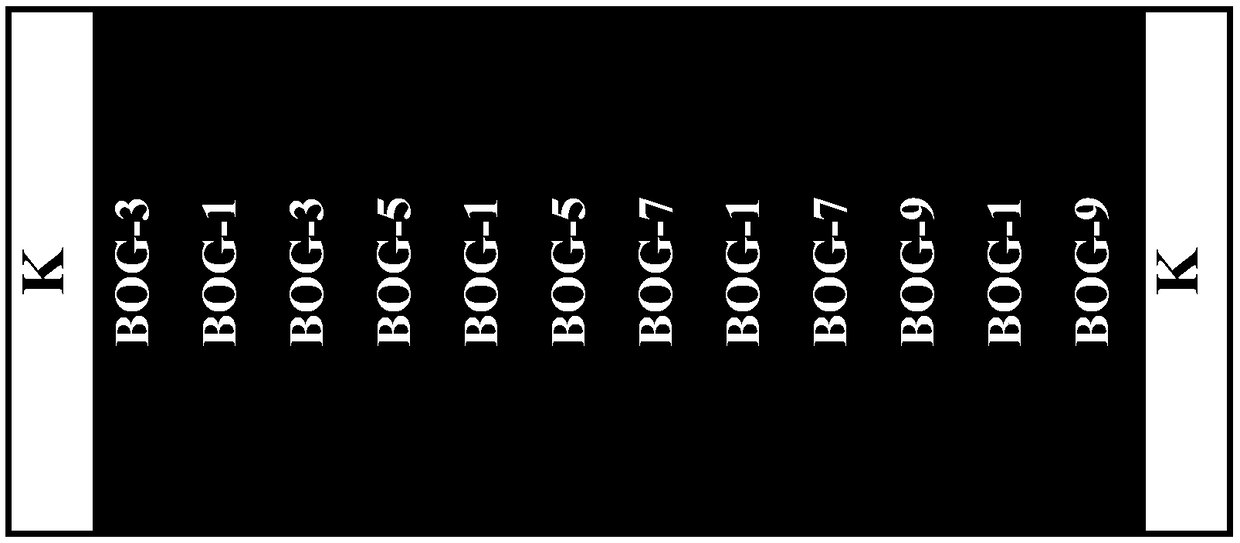

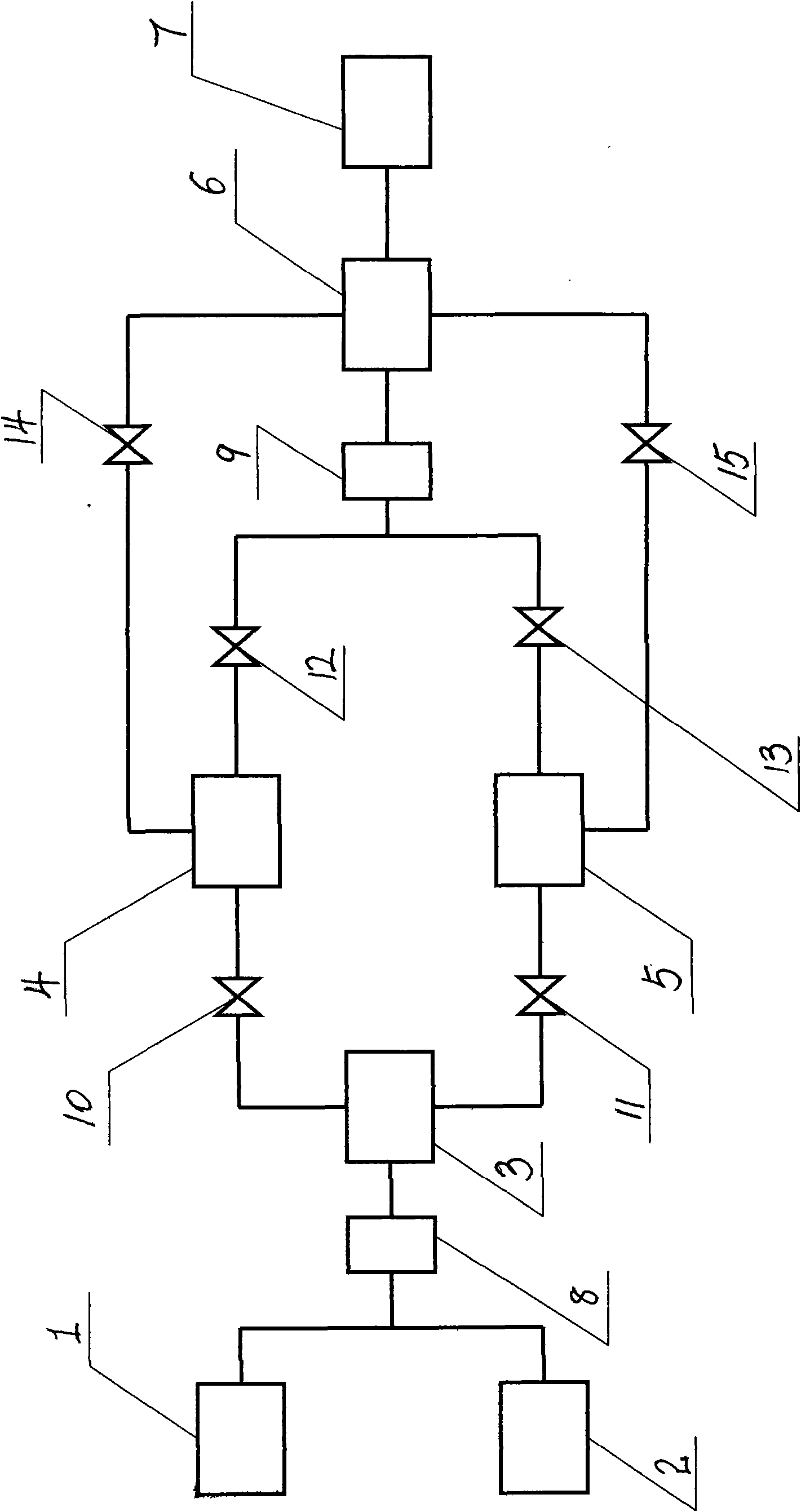

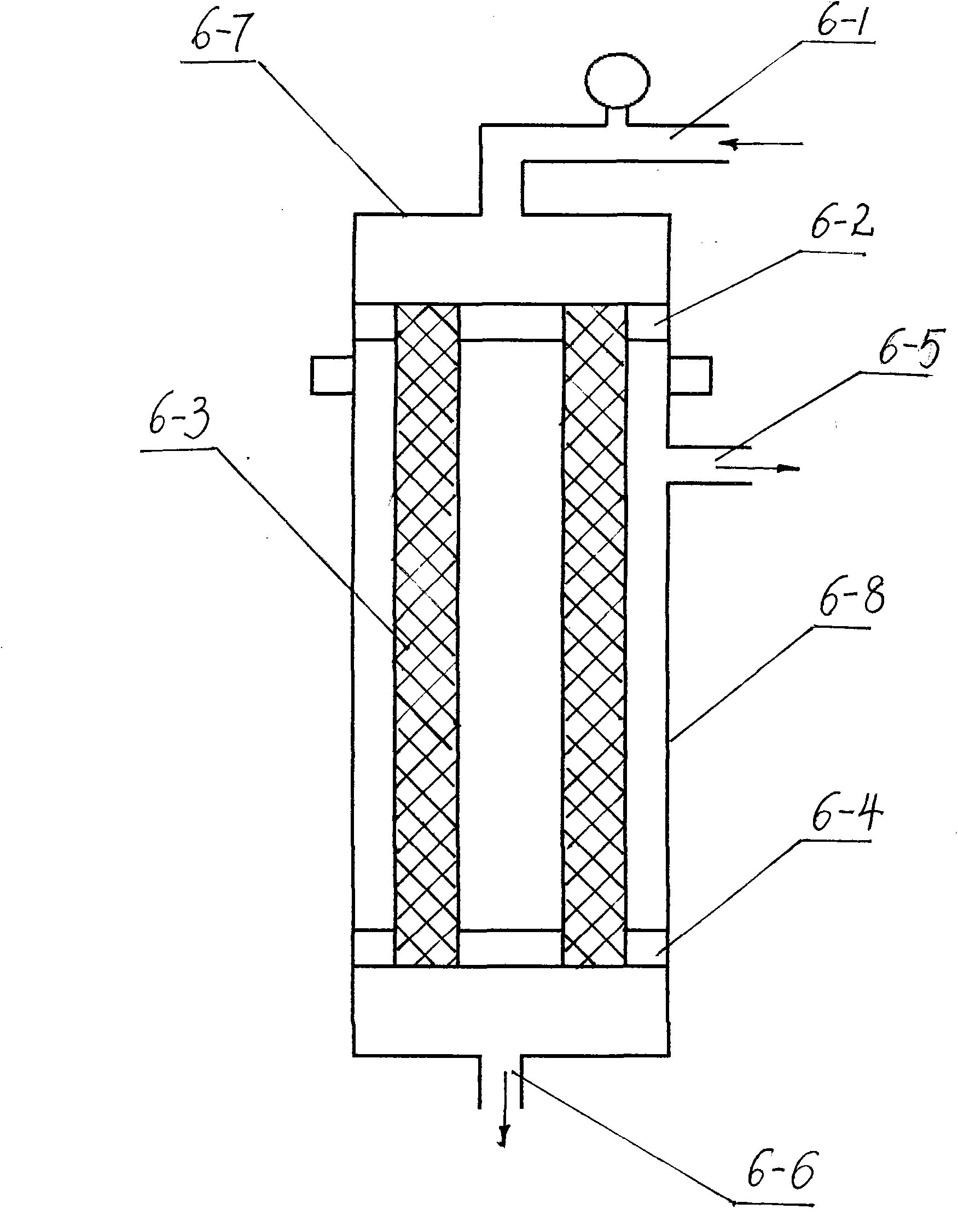

BOG self-circulation re-liquefaction recovery heat exchange system and method for LNG storage tank

ActiveCN109458788APrevent freezingConvenient pre-coolingSolidificationLiquefactionExchange networkDevice form

The invention relates to a BOG self-circulation re-liquefaction recovery heat exchange system and method. The system comprises a BOG liquefaction unit, a circulating heat exchange network and an LN2 regeneration unit, wherein the BOG liquefaction unit and the LN2 regeneration unit are connected for circulating heat exchange and regeneration through the circulating heat exchange network, and the circulating heat exchange network is an integrated composite type circulating heat exchange device formed by a multi-channel pre-cooler, a multi-channel subcooler and a multi-channel condenser in packaged and integrated modes. The system has the characteristics of compact structure, no freezing, efficient liquefaction and the like. According to the system and method, not only BOG can be re-liquefiedand recovered according to the design requirements, the cooling can also be realized through the repeated circulation of LN2, required power devices are few, the liquefaction cycle can be promoted bythe BOG through the pressure of the BOG in the early stage, in addition, an additional refrigerating machine is not needed in the circulation and regeneration processes of the LN2, so that the energyconsumption of the related devices is reduced; and the system and method have the advantages of being simple in the structure, safe, energy-saving, and capable of meeting the requirements of large-flow BOG re-liquefaction recovery.

Owner:DALIAN MARITIME UNIVERSITY

Shoe rack convenient to use

InactiveCN108464641AEasy to movePlay the role of automatic dehumidificationWardrobesRadiationPlasma generatorEngineering

The invention discloses a shoe rack convenient to use. The shoe rack includes a rack body, a third supporting board is fixedly connected to the lower end of an inner cavity of the rack body, and a first supporting board, a second supporting board and heating wires are fixedly connected between the bottom of the third supporting board and the bottom of the inner cavity of the rack body from left toright in sequence; a plasma generator is fixedly installed in the middle of the right side of the first supporting board. Through the functions of the plasma generator and ultraviolet lamp tubes, sterilization and disinfection treatment can be conducted on the internal environment of the rack body; a humidity sensor can test the humidity of the interior of the rack body, and when the internal humidity of the rack body reaches a maximum preset value, the heating wires are electrically connected with a draught fan power source automatically, and an automatic damp removal effect is achieved. Meanwhile, more convenience is provided for people to move the rack body by a first electric retractable rod, the first electric retractable rod is retracted into a first groove by a first retraction control button without movement, and great convenience is provided for people during use.

Owner:平湖市超越时空图文设计有限公司

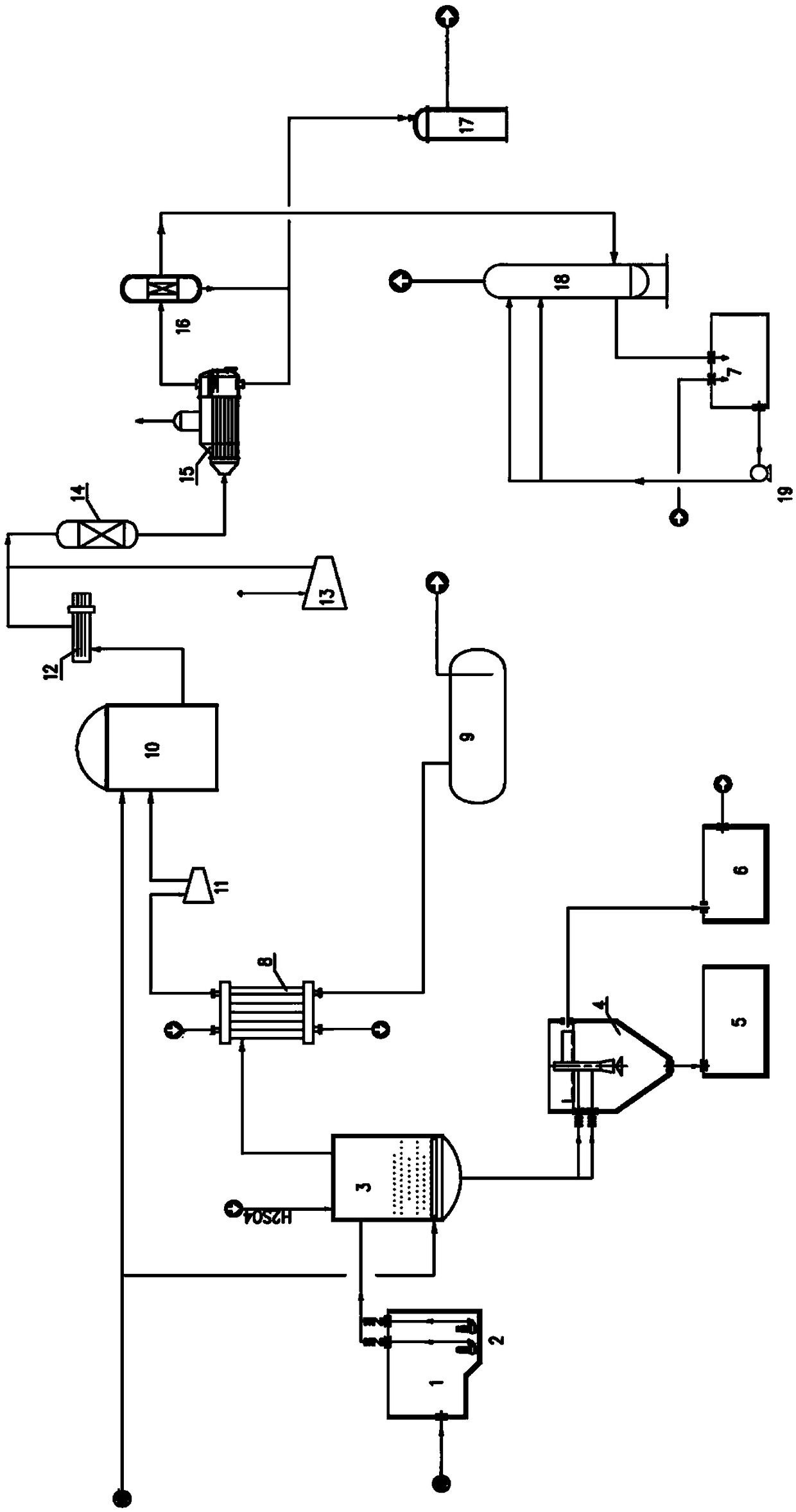

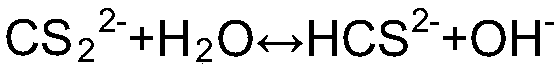

Device and method for sodium thiocarbonate containing sewage treatment and resource recovery

PendingCN108128921AMeet the needs of recyclingAchieve recyclingCarbon disulfideSulfur preparation/purificationSulfurResource recovery

The invention discloses a device and a method for sodium thiocarbonate containing sewage treatment and resource recovery. The device for sewage treatment and resource recovery comprises a sewage collection and reaction unit, a sewage treatment and circulation unit, CS2 recovery unit and a sulfur recovery unit, wherein the sewage collection and reaction unit is respectively connected with the sewage treatment and circulation unit and the CS2 recovery unit; and the CS2 recovery unit is connected with the sulfur recovery unit which is connected with the sewage treatment and circulation unit. Thedevice for sewage treatment and resource recovery provided by the invention can meet the demands of environmental protection, recovers resources, realizes cyclic utilization of the resources, reducesthe cost of production, and meets the needs of an enterprise for management and development.

Owner:JIANGSU HENGXIN ENERGY TECH

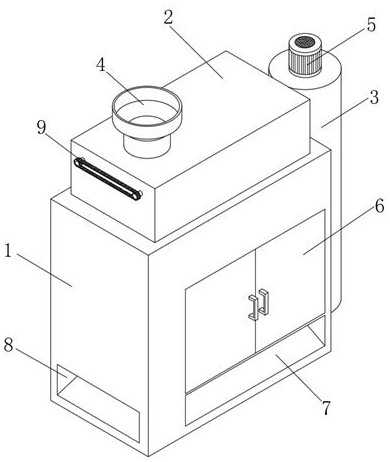

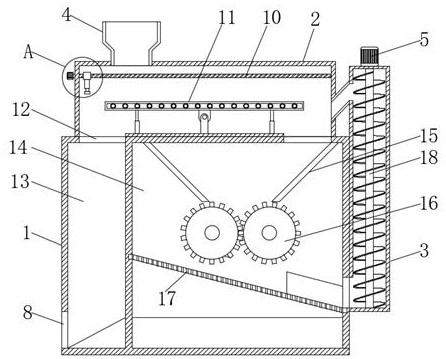

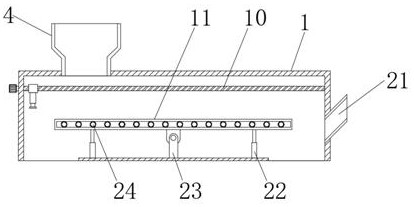

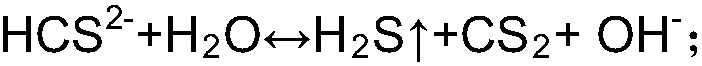

Powder recycling device for powder wrapping device

InactiveCN110236214AMeet heating needsMeet crushing needsFood coatingGrain treatmentsEngineeringEnterprise it

The invention discloses a powder recycling device for a powder wrapping device. The powder recycling device comprises a shell, a steering mechanism and a powder wrapping mechanism, wherein the middle end of the bottom of the shell is fixedly connected with a crushing box, the lower end of the right side of the crushing box is fixedly provided with a motor, an output shaft of the motor is fixedly connected with a crushing shaft, the outer surface of the crushing shaft is fixedly connected with crushing teeth, and the bottom of an inner cavity of the crushing box is embedded with a heating plate; the upper end of the left side of the crushing box is fixedly provided with a fan, the air inlet end and the air outlet end of the fan are both communicated with pipelines, and the tail end of the air inlet end, communicated with the pipeline, of the fan is communicated with the bottom of the left side of the crushing box. According to the powder recycling device, the middle end of the bottom of the shell is fixedly connected with the crushing box, and under the action of the motor, the crushing shaft, the crushing teeth, the heating plate, the fan and the pipelines, the requirement of recycling the powder is met, the recycling rate of powder is effectively improved, and the powder recycling device conforms to the benefits of enterprises themselves.

Owner:陈小燕

Novel waste pitch heating device

ActiveCN105603853AExtended service lifeRaise material temperatureRoads maintainenceCombustorCombustion chamber

The invention provides a novel waste pitch heating device. The novel waste pitch heating device comprises a base and a combustor and is characterized by further comprising a combustion chamber; the combustor, the combustion chamber and a heating assembly are arranged on the base, the combustor and the combustion chamber are fixedly connected in a sealed mode and fixedly connected with the base through a moving assembly, the two ends of the heating assembly are fixedly connected with the base, and the middle of the heating assembly is fixedly connected with the base; the combustion chamber makes contact with the heating assembly in a sealed mode, a hot air circulating assembly is arranged above the heating assembly and fixedly connected with the base, a first inlet of the hot air circulating assembly is connected with a discharging part in a sealed mode, and a third outlet of the hot air circulating assembly is connected with a feeding part in a sealed mode. During use, combustion hot air enters the heating assembly, normal-temperature waste pitch enters a rotating heating drum from the feeding part, is guided to the bottom of the heating drum through a spiral guiding plate and pushed downwards to a V-shaped plate of a scraping conveying section, moves forwards in a fluctuation mode, is heated by the heating drum, and forms a material curtain for full heat exchange, and the waste pitch is discharged from a discharge port when heated to the needed temperature.

Owner:JILIN PROVINCE ROAD CONSTR MASCH CO LTD

Array-type drip irrigation control device capable of automatic feedback of soil humidity and control method thereof

InactiveCN102204502BEfficiently monitor and assess humidity conditionsMonitor and evaluate humidity conditionsSelf-acting watering devicesClimate change adaptationSolenoid valveDrip irrigation

The invention provides an array-type drip irrigation control device capable of automatic feedback of soil humidity. The array-type drip irrigation control device comprises a power supply unit, soil humidity monitoring units, a control unit, a solenoid valve and a drip irrigation pipe, wherein the power supply unit is connected with the soil humidity monitoring units, the control unit and the solenoid valve respectively; and the solenoid valve is connected on the drip irrigation pipe; a plurality of soil humidity monitoring units are arranged and distributed in the soil to be detected in an array manner. The invention also provides a control method of the array-type drip irrigation control device. The array-type drip irrigation control device capable of automatic feedback of soil humidity can be used for effective monitoring and estimation of the soil humidity condition and active drip irrigation of water and fertilizer, effectively improves the working efficiency, and reduces pointless waste of water and fertilizer.

Owner:SOUTH CHINA AGRI UNIV

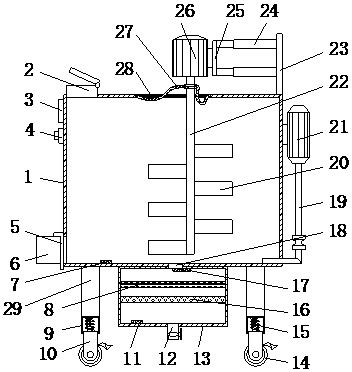

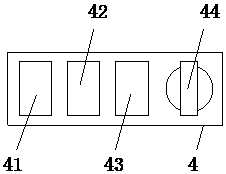

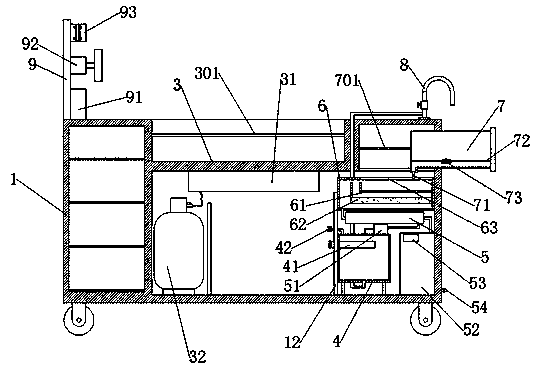

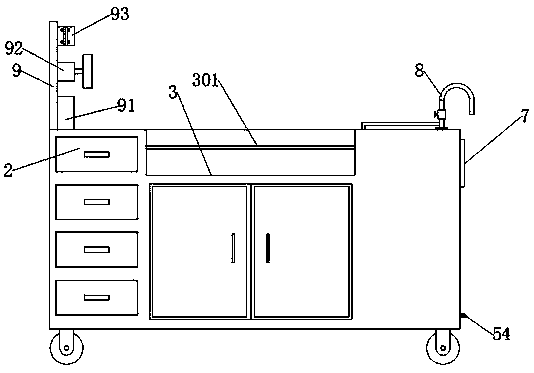

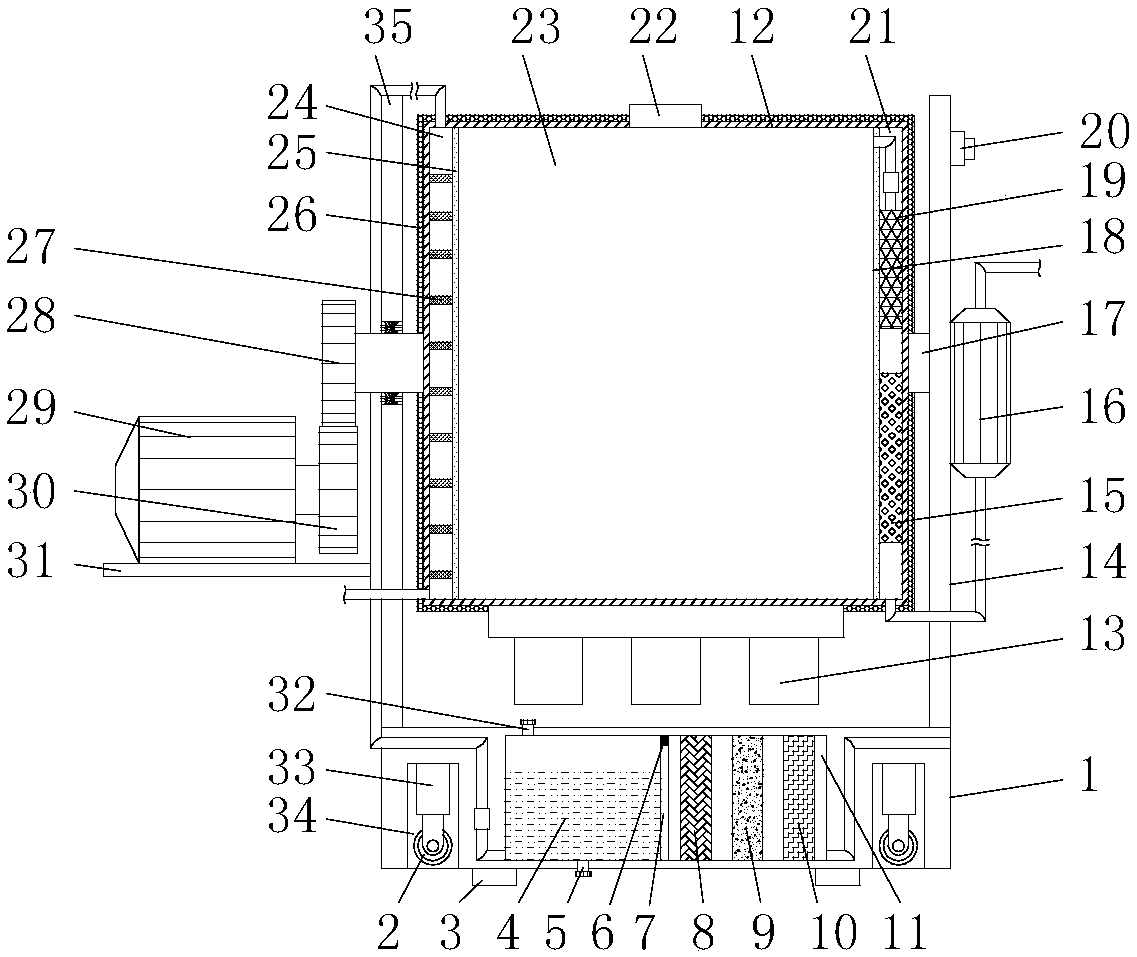

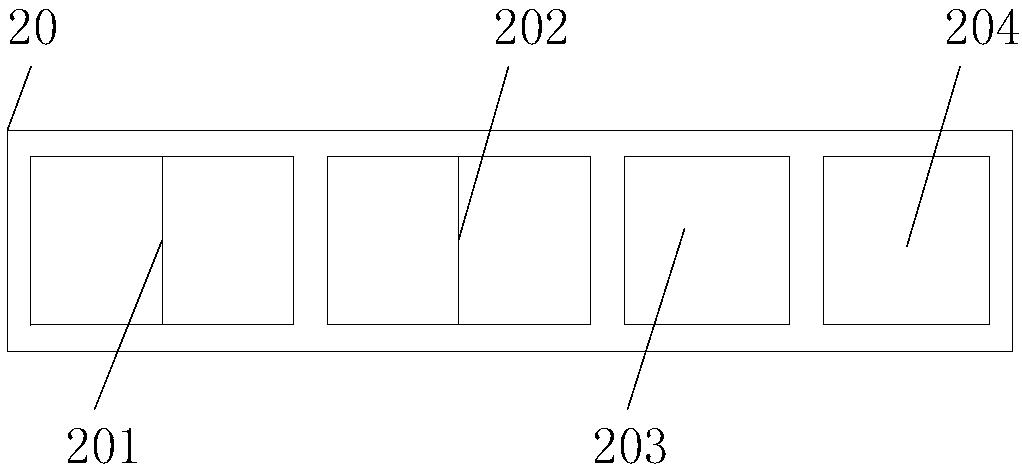

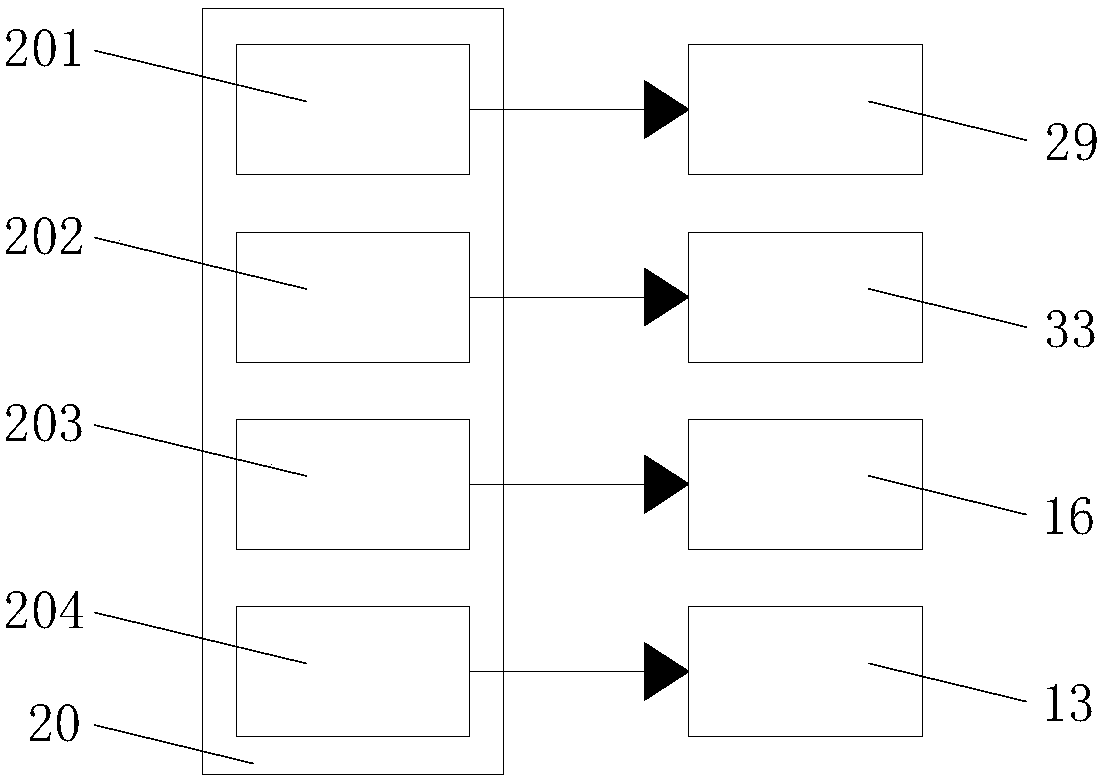

Water-saving type mobile catering cart

InactiveCN108674287AMeeting water needsMeet the needs of recyclingWorkshop/display transportationItem transportation vehiclesWater useWater saving

The invention belongs to the technical field of mobile catering carts and particularly relates to a water-saving type mobile catering cart. The water-saving type mobile catering cart comprises a cartbody and multiple walking truckles arranged at the bottom of the cart body. The left side of the cart body is a storage area, the middle of the cart body is a processing area, and the right side of the cart body is a washing area. A faucet is arranged above the washing area, and a drawer type water collecting pool is arranged on the right side. A filtering basin, a microfilter, a water pump, a water purification tank and a waste water pool are sequentially arranged in the washing area from top to bottom. The drawer type water collecting pool is of a drawer structure with an opening formed in the upper portion. The drawer structure is fixed to the inside of the cart body through sliding rail structures installed on the two sides of the drawer structure, and the opening position is located under a water outlet of the faucet after the drawer structure is pulled out. A drain pipe is arranged at the bottom of the drawer type water collecting pool and extends into the filtering basin. The defects in the prior art are overcome, the use rate of stored water on the mobile catering cart is greatly increased, and the water use requirement of the mobile catering cart is met.

Owner:HEFEI CENTURIES FIVE STAR CATERING EQUIP LIABILITY

Energy conservation and environmental protection type smelting furnace

InactiveCN108507349AMeet the needs of recyclingGuarantee health and hygieneCrucible furnacesWaste heat treatmentGlass fiberSmelting process

The invention discloses an energy conservation and environmental protection type smelting furnace which comprises a supporting base and a furnace body. A filtering purification cavity is formed in themiddle end of an inner cavity of the supporting base, the left end of an inner cavity of the filtering purification cavity is divided by a third separating plate into acid-base neutralization cavities, a through hole is formed in the top end of the inner surface of the third separating plate, a sponge filtering layer, a polypropylene filtering net layer and a KDF filtering layer are fixedly connected to the positions, located on the right side of the third separating plate, of the inner cavity of the filtering purification cavity from left to right in sequence, grooves are formed in the periphery of the bottom of the supporting base, electric stretching rods are fixedly connected to the top ends of inner cavities of the grooves, and walking wheels are movably installed at the bottoms of the electric stretching rods. An inner cavity of the furnace body is divided by a first separating plate and a second separating plate into a first cavity, a smelting cavity and a second cavity; through the effects of a thermal conductive plate, a metal filtering net layer, a glass fiber coalescence filtering element, a circulating draught fan and a pipe, the need of people for circulated use of high temperature waste gas generated in the smelting process can be met, and the smelting efficiency is improved.

Owner:罗金山

Mine stone crushing device

InactiveCN110787868AImprove smoothnessImprove adsorption capacityDirt cleaningMultistage water/sewage treatmentMining engineeringGear wheel

Owner:房文中

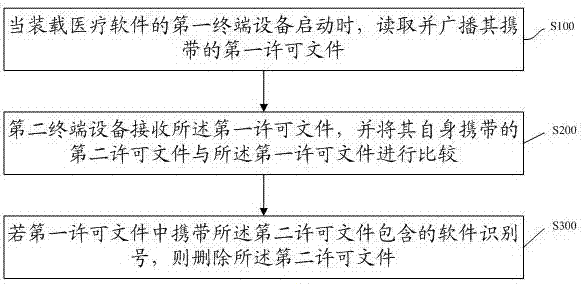

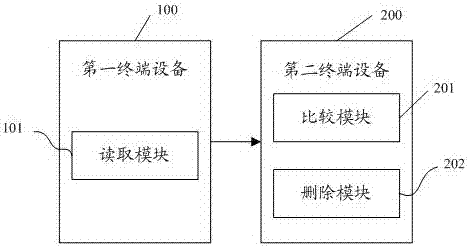

Medical software license file recovery method and system

ActiveCN106971093AMeet the needs of recyclingProgram/content distribution protectionRecovery methodThe Internet

The invention discloses a medical software license file recovery method and system. The method comprises the steps of reading and broadcasting a first license file carried by a first terminal device when the first terminal device loaded with the medical software is started; receiving the first license file by a second terminal device, and comparing a second license file carried by the second terminal device with the first license file; and if the first license file carries a software identification number contained in the second license file, deleting the second license file. The terminal device loaded with the medical software broadcasts the license file carried by the terminal device, so that other terminal devices loaded with the medical software and located in a same local area network can automatically obtain the license file; the obtained license file is compared with the license files of other terminal devices; and the license file is recovered according to a comparison result. Therefore, the old license file can be obtained by using the terminal device without connecting the internet, and the medical software license file recovery demand is met.

Owner:SHENZHEN DELICA MEDICAL EQUIP CO LTD

Bearing pedestal drilling device with fragment collecting function

InactiveCN109420784AImprove collection effectMeeting recycling needsBoring/drilling componentsActivated carbon filtrationEngineering

The invention discloses a bearing pedestal drilling device with a fragment collecting function. The device comprises a supporting base, a dust collection box and a water box are fixedly connected to the bottom of an inner cavity of the supporting base from left to right in sequence, the bottom of an inner cavity of the water box is sequentially and fixedly connected with an atomizer and a pressuresensor from left to right, a mist outlet of the atomizer is movably connected with a nozzle through a first pipeline, the left end of the top of the water tank is fixedly connected with a sleeve, andan inner cavity of the sleeve is fixedly connected with an active carbon filter layer. The right end of the top of the second supporting plate is fixedly provided with a suction ventilator, an air outlet of the suction ventilator is movably connected with the left end of the top of the dust collection box through a second pipeline, in the drilling process, generated fragments can be absorbed, andthe problems that in the machining process of a bearing pedestal, a large amount of fragments are generated, if the fragments are not collected, the environment is polluted, and the body health of aperson is threatened are solved.

Owner:郝力江

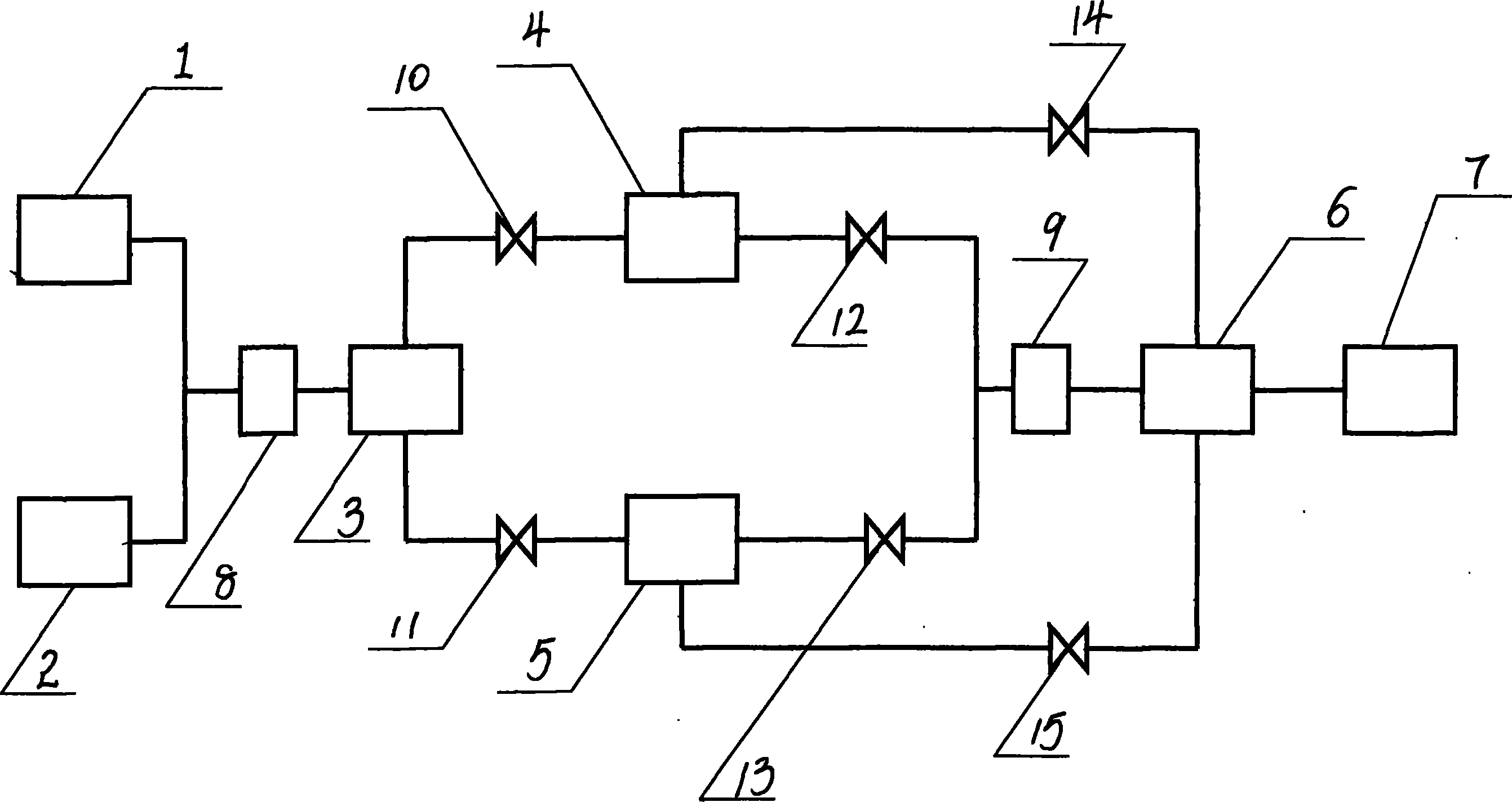

Device for treating alkaliferous waste water through nanofiltration

InactiveCN102689945AEffective concentration and purificationEasy to cleanWater/sewage treatment bu osmosis/dialysisWater storage tankWastewater

The invention discloses a device for treating alkaliferous waste water through nanofiltration and relates to the field of waste water treatment. The device comprises a water storage tank, wherein a pump is connected with a pretreatment pool; the pretreatment pool is connected with a backflow pool; a valve is arranged between the pretreatment pool and the backflow pool; the backflow pool is connected with the pump through the valve and is connected to a nanofiltration device; a drainage port of the nanofiltration device is connected with a pure water tank; concentrated liquid outlets are respectively connected with the backflow pool through the valve; the nanofiltration device is formed in a way that an upper cover with a pressure gauge and a liquid inlet is connected with a nanofiltration tank body through a flange; a water distributor with a water distribution hole is arranged at a lower end of the upper cover; a nanofiltration film is formed on the water distribution hole; the other end of the nanofiltration film is connected to a water collection hole of a water collector at the bottom of the tank body; the water collection hole is connected with an outlet at the bottom end of the tank body; and a water outlet is also arranged on the upper end of the tank body. With the adoption of the device, the environment pollution to alkaliferous waste water in the industrial production is solved, the alkali in the waste water is recovered, and the phenomena that the cost is increased and the resources are wasted because a large amount of sulfuric acid or hydrochloric acid needs to be consumed when alkaliferous waste water is treated by neutralizational process can be avoided.

Owner:吕维学

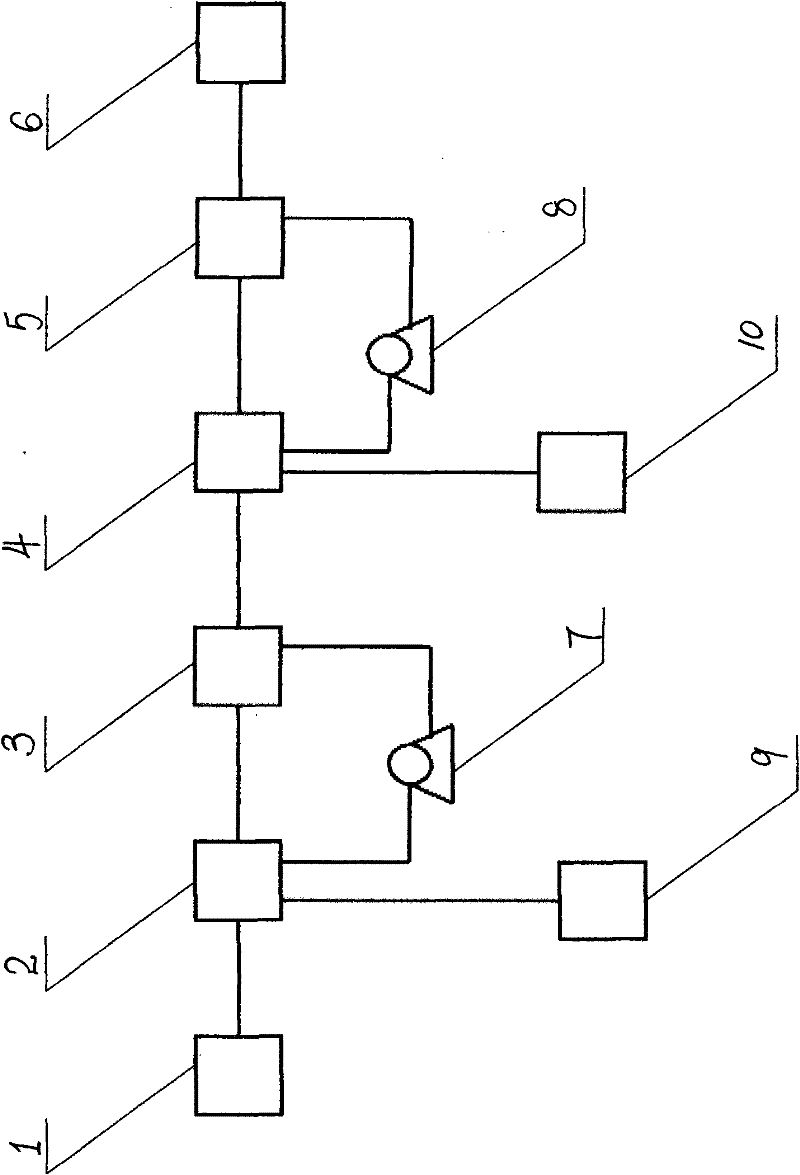

Process for treating maize oil wastewater

InactiveCN102190382AEffective concentration and purificationEasy to cleanWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentSulfate radicalsSecondary stage

The invention discloses a process for treating maize oil wastewater, and belongs to the technical field of wastewater treatment. A pretreatment tank, a primary-stage concentrated liquor tank, a primary-stage ultrafiltration combined membrane, a secondary-stage concentrated liquor tank and a secondary-stage nanofiltration combined membrane are connected in turn through a pipeline; and circulating pumps are arranged between the primary-stage concentrated liquor tank and the primary-stage ultrafiltration combined membrane, and between the secondary-stage concentrated liquor tank and the secondary-stage nanofiltration combined membrane. By utilizing characteristics of the membranes, ammonia nitrogen and sulfate radicals are separated from the maize oil wastewater so as to facilitate recycling.

Owner:吕维学

Method of treating saline industrial wastewater

InactiveCN107804929AImprove dirt holding capacityEfficient removalWater contaminantsTreatment involving filtrationFiberHollow fibre

The invention relates to a method of treating saline industrial wastewater, comprising the steps of (1) pretreating, to be specific, delivering wastewater into a filter tank to remove suspended matters; (2) ultrafiltering, to be specific, delivering the wastewater of step (1) into an external pressure ultrafiltration system to perform ultrafiltering; (3) performing reverse osmosis, to be specific,delivering the wastewater of step (2) to a reverse osmosis system, and removing salt; (4), performing stripping, to be specific, delivering the produced water of reverse osmosis of step (3) into a stripping column, performing stripping, and adjusting pH to meet reuse needs. The method has the advantages that a multistage quartz sand filter tank can be used to effectively remove suspended matterswith blockage rarely occurring; the external pressure ultrafiltration system used herein has good applicability and is available for full-flow filtration; ultrafiltration membranes are of hollow fiber, having good strength, backflushing is more thorough, and the membranes can restore their performance well; BW30XFR-400 / 34i or PROC10 reverse osmosis membrane components can provide high salt removalrate, reaching 98% and above, and the comprehensive recovery rate of wastewater is high, reaching 85% and above.

Owner:NORTHEAST GASOLINEEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com