Process for treating maize oil wastewater

A treatment process, corn oil technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc., can solve the problems of difficult treatment and large impact of corn oil wastewater, Achieve good treatment effect, improve service life and cycle, and achieve high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

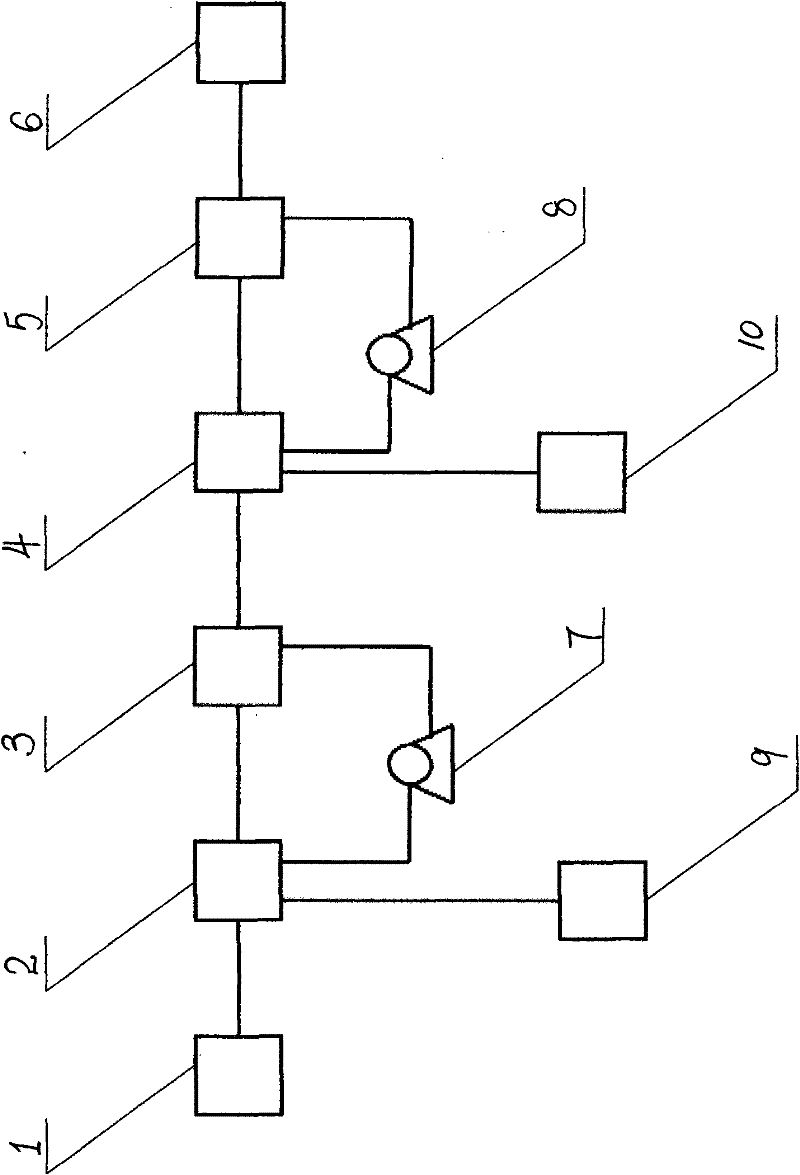

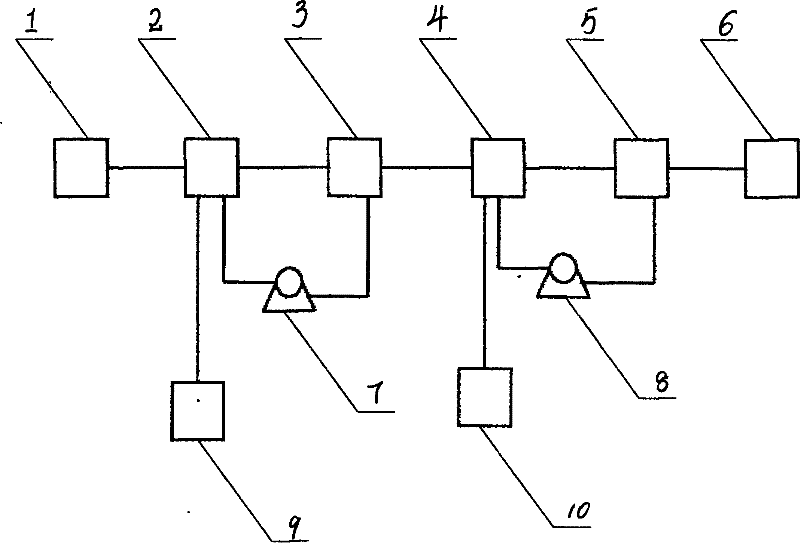

[0016] A treatment process for corn oil wastewater (see figure 1 ), the process is realized by the following devices, including pretreatment tank 1, a concentrated liquid tank 2, a combined ultrafiltration membrane 3, a concentrated liquid tank 4, a combined nanofiltration membrane 5, a clean water tank 6, and an ammonia nitrogen storage tank 9, SO 4 2- Storage tank 10, circulating pumps 7, 8, and pipes for connection.

[0017] First collect the corn oil wastewater and filter it through the pretreatment tank 1. The pretreatment tank 1 uses sand and gravel as the filler to treat the impurities in the wastewater. The wastewater is initially treated. The treated wastewater enters the first concentrated liquid tank 2 for storage. The one-stage ultrafiltration composite membrane 3 composed of 1000D roll-type ultrafiltration membranes adopts a cross-flow method, ultrafiltration treatment to remove ammonia nitrogen, and the wastewater containing ammonia nitrogen is pumped into the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com