Device for treating alkaliferous waste water through nanofiltration

A technology of alkali wastewater and nanofiltration, which is applied in the direction of osmosis/dialysis water/sewage treatment, etc., can solve the problems of consuming a large amount of sulfuric acid or hydrochloric acid, environmental pollution, waste of resources, etc., and achieves improved service life and service cycle, high economic benefits, good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

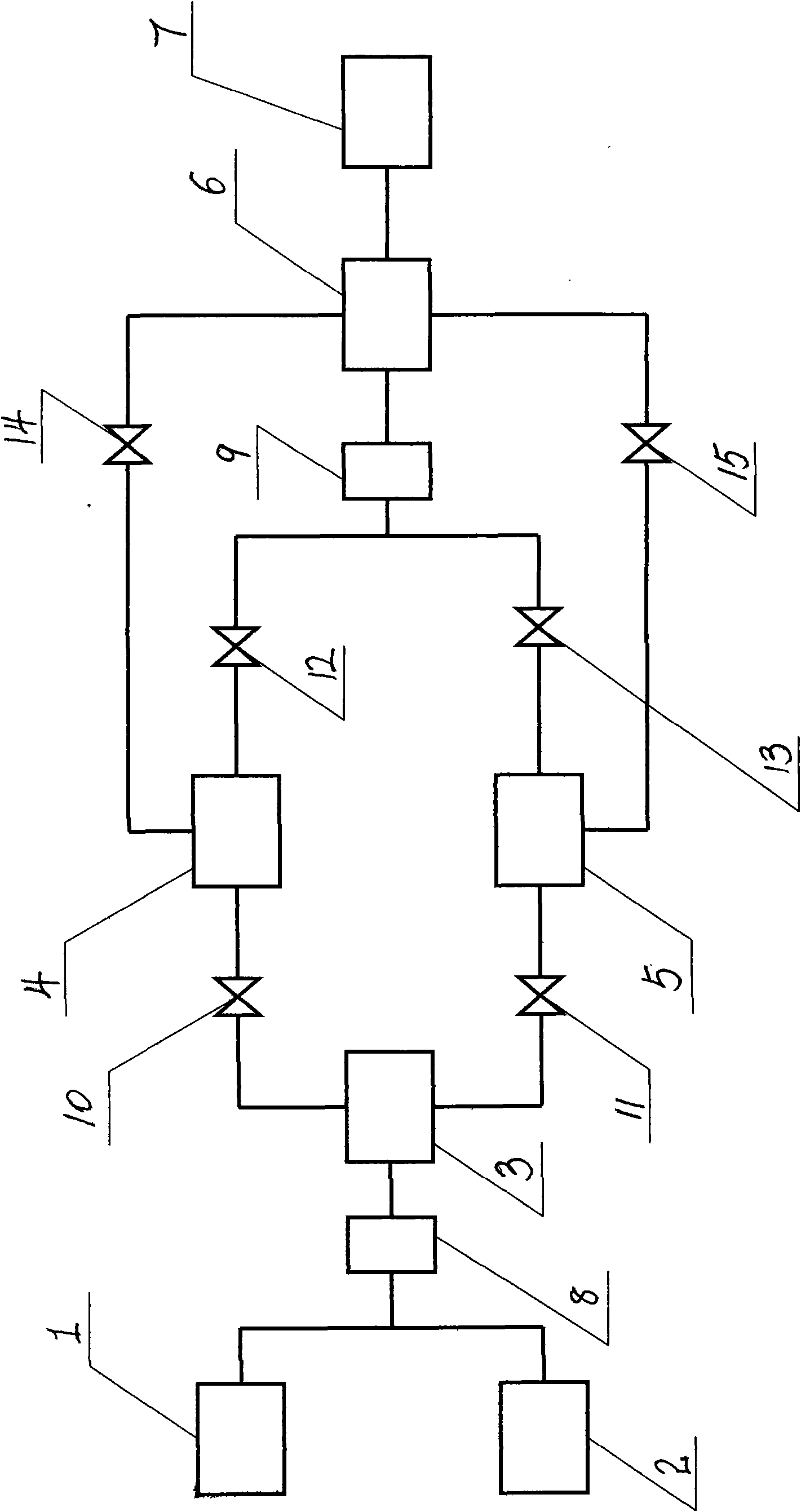

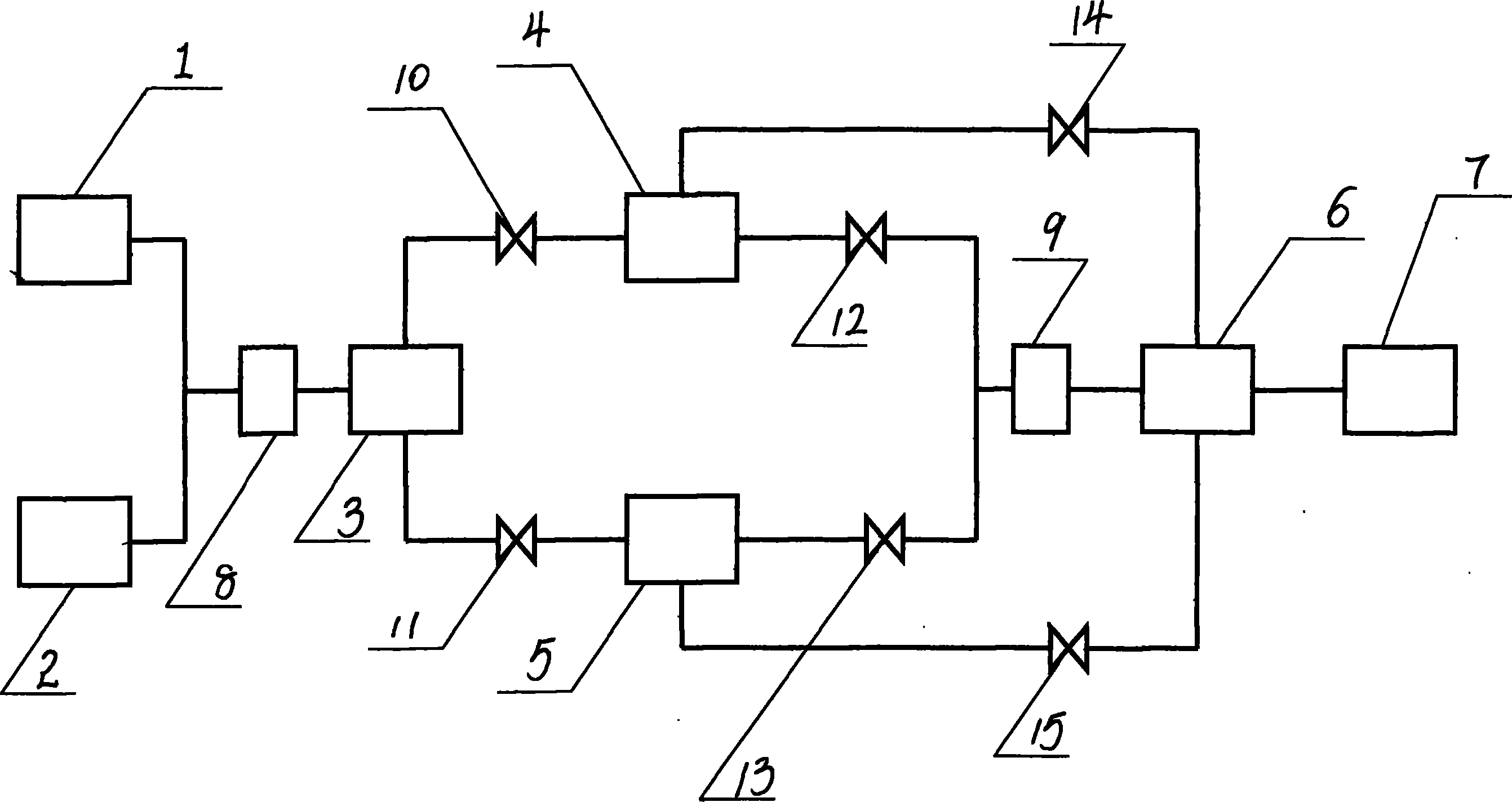

[0015] A kind of technique of the method for treating alkali-containing wastewater by nanofiltration (see figure 1 , figure 2 ), its technological process is, waste water enters reservoir 1,2, links with pretreatment pool 3 with pump 8, and pretreatment pool 3 connects reflux pool 4,5, and sets up between pretreatment pool 3 and reflux pool 4,5 There are valves 10 and 11, and the reflux pools 4 and 5 are respectively connected to the pump 9 through valves 12 and 13, and then connected to the nanofiltration device 6. The outlet of the nanofiltration device 6 is connected to the pure water pool 7, and the concentrated liquid outlet is passed through the valve 14, 15, respectively connected to the return pool 4,5. During normal operation, the storage pool 2 and the return pool 5 are used as backup pools.

[0016] Combined with the actual operation, take the treatment of papermaking wastewater as an example to explain the process flow. First, the alkali-containing waste water ...

Embodiment 2

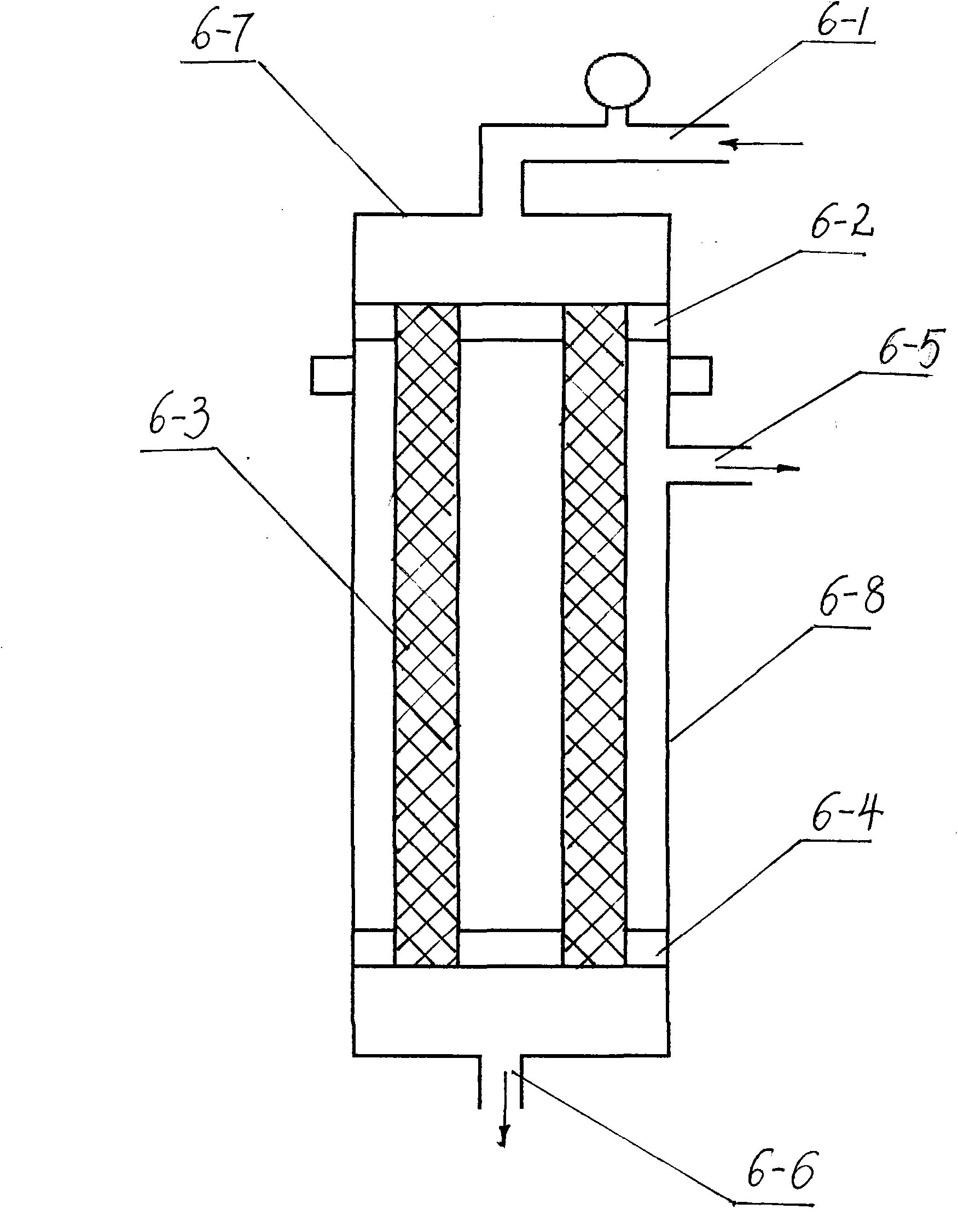

[0018] Combined with the actual operation, take the treatment of papermaking wastewater as an example to explain the process flow. First, the alkali-containing waste water flows into the storage tank 1, and after preliminary filtration in the storage tank 1, large sundries and large particles are removed, and the wastewater in the storage tank 1 is pumped into the pretreatment tank 3 by the pump 8, and the pretreatment tank 3 The alkali-containing wastewater that is further settled in the reflux pool flows into the reflux pool 4. After the reflux pool 4 is filled, the valve 10 of the alkali in the pretreatment pool 3 and the reflux pool 4 is closed, and the pump 9 pumps the waste water in the reflux pool 4. The pressure is 0.9mPa The nanofiltration device 6, waste water enters from the liquid inlet 6-1 of the upper cover 6-7 of the nanofiltration device, and a pressure gauge is arranged on the liquid inlet, after the waste water passes through the water distributor 6-2, it ente...

Embodiment 3

[0020] Combined with the actual operation, take the treatment of papermaking wastewater as an example to explain the process flow. First, the alkali-containing waste water flows into the storage tank 1, and after preliminary filtration in the storage tank 1, large sundries and large particles are removed, and the wastewater in the storage tank 1 is pumped into the pretreatment tank 3 by the pump 8, and the pretreatment tank 3 The alkali-containing wastewater that is further settled in the reflux pool flows into the reflux pool 4. After the reflux pool 4 is filled, the valve 10 of the pretreatment pool 3 and the reflux pool 4 alkali is closed, and the pump 9 pumps the waste water in the reflux pool 4. The pressure is 0.7mPa The nanofiltration device 6, waste water enters from the liquid inlet 6-1 of the upper cover 6-7 of the nanofiltration device, and a pressure gauge is arranged on the liquid inlet, after the waste water passes through the water distributor 6-2, it enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com