BOG self-circulation re-liquefaction recovery heat exchange system and method for LNG storage tank

A technology of circulating heat exchange and heat exchange system, applied in the directions of liquefaction, refrigeration and liquefaction, container filling method, etc., can solve the problem of low liquefaction efficiency, and achieve the effect of ensuring continuous supply, less power units and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

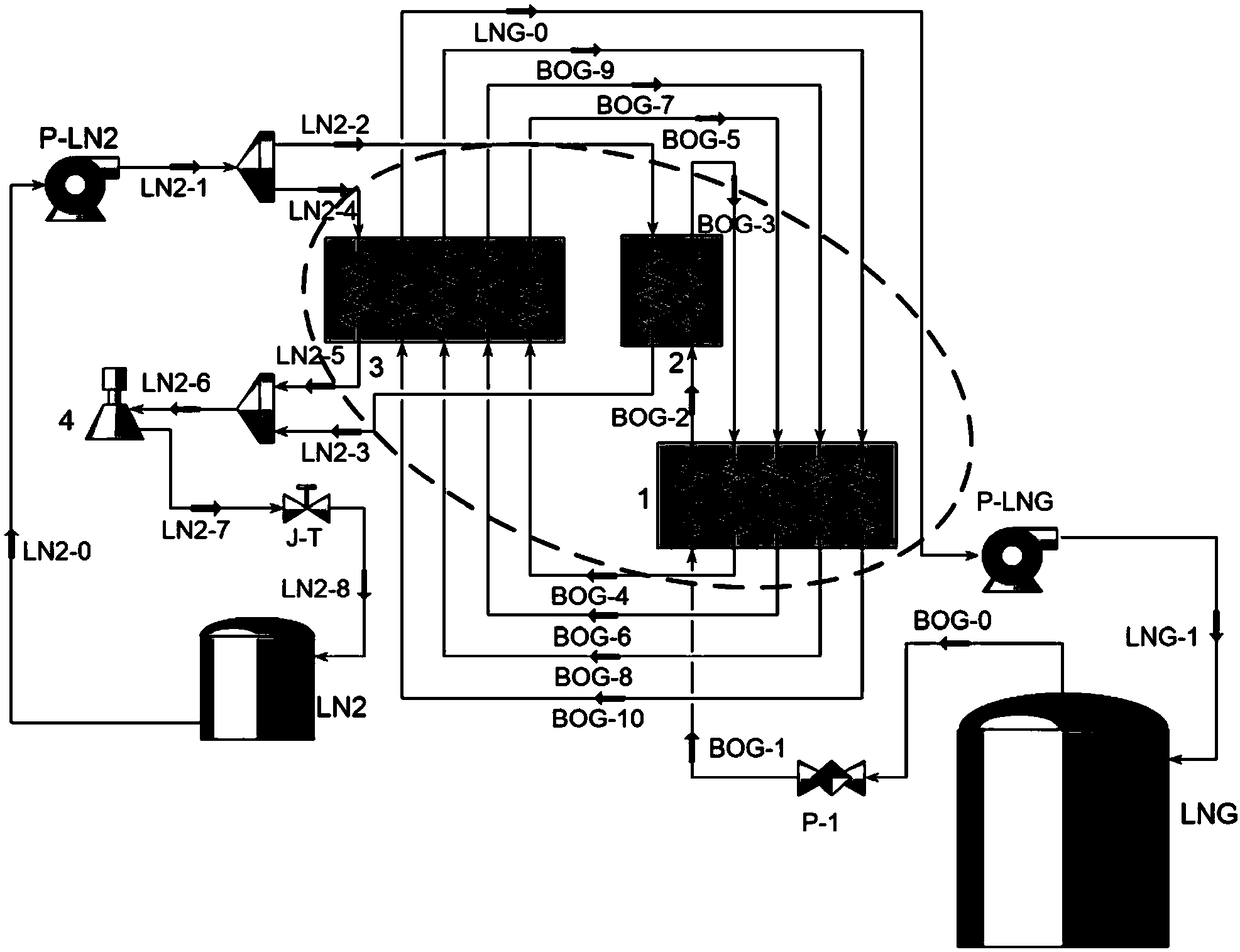

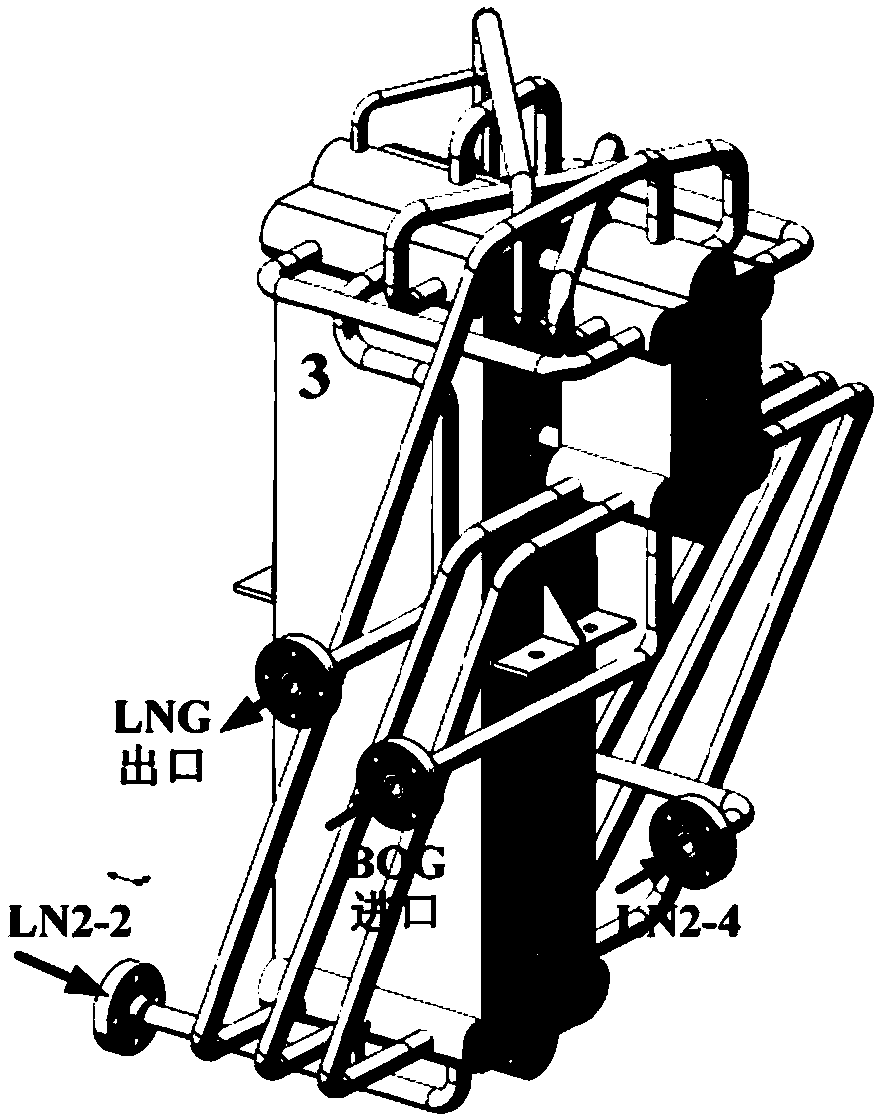

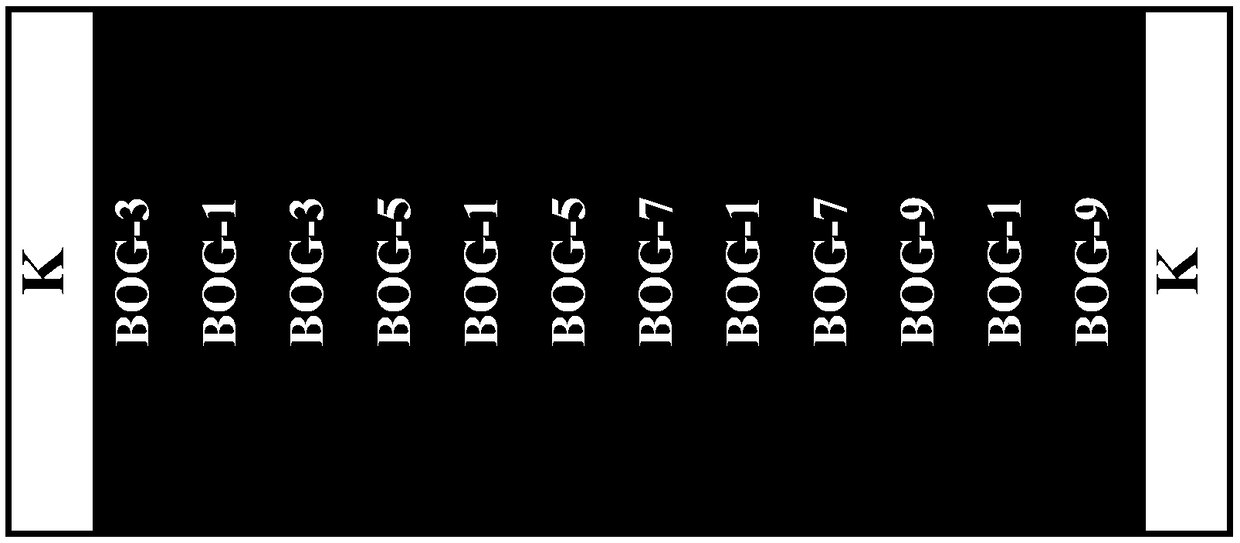

[0057] Such as figure 1 As shown, the LNG storage tank uses BOG self-circulation reliquefaction recovery heat exchange system, including BOG liquefaction unit, circulation heat exchange network and LN2 regeneration unit, BOG liquefaction unit and LN2 regeneration unit are connected to cycle heat exchange and regeneration through the circulation heat exchange network; in:

[0058] The BOG liquefaction circulation unit includes an LNG storage tank LNG, a pressure switch valve P-1 and an LNG return pump P-LNG; the LNG storage tank LNG communicates with the inlet of the circulation heat exchange network through the LNG pressure switch valve P-1, and passes through The LNG return pump P-LNG is connected to the outlet of the circulation heat exchange network; the superheated BOG in the LNG storage tank enters the circulation heat exchange network through the safety pressure switch valve P-1, and the liquefied LNG that has passed through the circulation heat exchange network passes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com