Freshwater aquaculture pond tail water treatment system

A water treatment system and technology of treatment system, applied in biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The water quality of tail water does not meet the discharge standards and other problems, so as to achieve the effect of satisfying the recycling and reuse and reducing the concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1 freshwater pond culture tail water treatment system

[0049] This embodiment combines figure 1 , figure 2 Describe the freshwater pond culture tail water treatment system of the present invention.

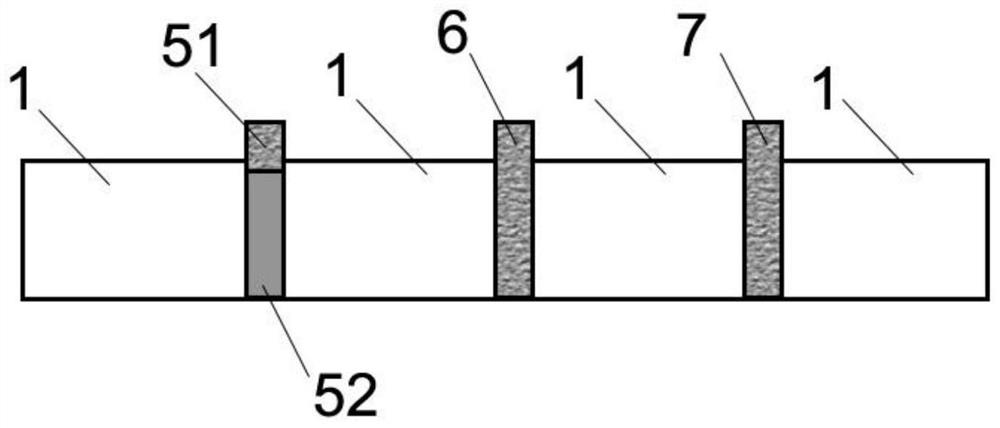

[0050] Such as figure 1As shown, the present embodiment provides a tail water treatment system for freshwater aquaculture ponds, including a primary sedimentation tank 1 receiving the tail water, a nitrification / denitrification tank 2 and an aeration reoxygenation tank 3; the nitrification / denitrification tank 2 consists of The nitrification tank 21 and the denitrification tank 22 are composed, and the nitrification tank 21 is connected with the primary sedimentation tank 1 through the overflow dam 4, wherein, the lower half of the overflow dam 4 is the retaining dam 41, and the upper half is the first filter dam 42 The denitrification tank 22 is connected to the aeration reoxygenation tank 3 through the second filter dam 5 ; the third filter dam 211 is prov...

Embodiment 2

[0056] Embodiment 2 freshwater pond culture tail water treatment system

[0057] This embodiment combines figure 1 , image 3 Describe the freshwater pond culture tail water treatment system of the present invention.

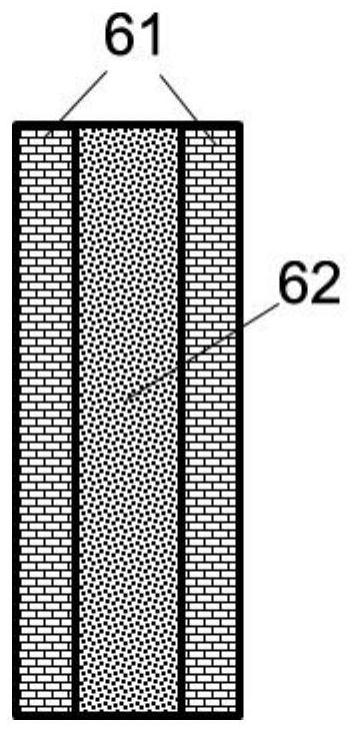

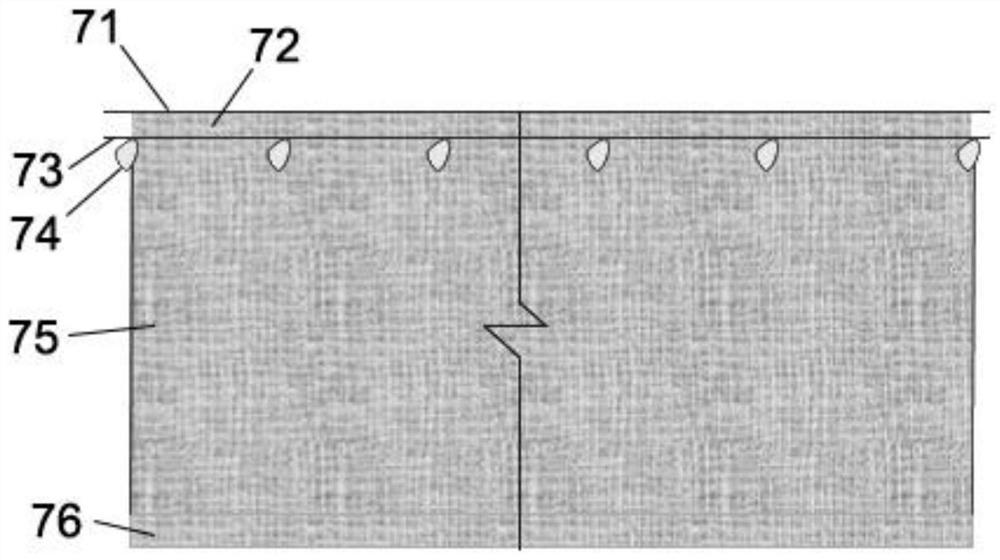

[0058] Each part is set up as embodiment 1, and the difference is that the first filter dam 42, the second filter dam 5, and the third filter dam 211 are composed of multiple channels image 3 The filter composition shown.

[0059] The filter screen comprises an upper key 71, a float 72, a fixed buckle main rope 73, a binding strap 74, an omentum 75 and a ground cage 76 and forms. Among them, the upper line 71 is a polyester rope of about 1cm; the float 72 is a foam strip, and the diameter is configured according to the load; the fixed buckle main rope 73 is also a polyester rope of about 1cm; 40-mesh nylon non-knotted polyester mesh; ground cage 76 is configured according to the impact force of water flow.

Embodiment 3

[0060] Embodiment 3 freshwater pond culture tail water treatment system

[0061] This embodiment combines figure 1 , Figure 4 Describe the freshwater pond culture tail water treatment system of the present invention.

[0062] Each part is set up as embodiment 1, and the difference is that the first filter dam 42, the second filter dam 5, and the third filter dam 211 are composed of multiple channels Figure 4 The filter composition shown.

[0063] The filter screen comprises an upper key 71, a float 72, a fixed buckle main rope 73, a binding strap 74, an omentum 75 and an ecological base 77 and forms. Among them, the upper line 71 is a polyester rope of about 1 cm; the float 72 is a foam strip, and its diameter is configured according to the load; the main rope 73 of the fixed buckle is also a polyester rope of about 1 cm; The membrane 75 is a 40-mesh nylon knot-free polyester net; the length of the ecological base 77 is configured according to the water depth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com